Process Intensification For LOHC Hydrogen Release Units

AUG 22, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LOHC Hydrogen Release Technology Background and Objectives

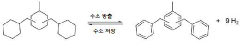

Liquid Organic Hydrogen Carriers (LOHCs) have emerged as a promising technology for hydrogen storage and transportation, addressing key challenges in the hydrogen economy. The concept involves binding hydrogen to organic compounds through hydrogenation reactions, allowing for safe storage at ambient conditions, and releasing hydrogen when needed through dehydrogenation processes. This approach offers significant advantages over conventional hydrogen storage methods such as compression or liquefaction, which require high pressure or cryogenic temperatures.

The evolution of LOHC technology can be traced back to the early 2000s, with significant advancements occurring in the past decade. Initial research focused on identifying suitable carrier molecules with optimal hydrogen storage capacity, favorable thermodynamics, and stability over multiple cycles. Notable carrier systems include dibenzyl toluene (H0-DBT/H18-DBT), N-ethylcarbazole, and methylcyclohexane-toluene pairs, each offering distinct advantages in terms of storage capacity, release conditions, and handling properties.

Process intensification for hydrogen release from LOHCs represents a critical technological frontier in the hydrogen value chain. The primary objective is to develop more efficient, compact, and economically viable dehydrogenation units that can overcome current limitations in reaction kinetics, energy efficiency, and catalyst performance. These advancements are essential for enabling widespread adoption of LOHC technology across various applications, from stationary power generation to mobility solutions.

Current technical goals include reducing the energy penalty associated with hydrogen release, which typically requires temperatures between 150-350°C depending on the carrier system. Researchers aim to develop catalysts that can operate at lower temperatures while maintaining high selectivity and stability. Additionally, there is a focus on improving heat integration strategies to utilize waste heat from other processes, thereby enhancing overall system efficiency.

The miniaturization and modularization of release units represent another key objective, particularly for mobile applications where space constraints are significant. This includes the development of microreactor technologies and novel reactor designs that maximize surface area-to-volume ratios and optimize heat and mass transfer characteristics.

Long-term technological objectives include achieving continuous, on-demand hydrogen release with rapid response times, extending catalyst lifetimes to thousands of cycles, and integrating LOHC release units with fuel cells or other hydrogen utilization technologies in seamless systems. These advancements would position LOHC technology as a cornerstone of the future hydrogen infrastructure, enabling decentralized energy storage and contributing significantly to decarbonization efforts across multiple sectors.

The evolution of LOHC technology can be traced back to the early 2000s, with significant advancements occurring in the past decade. Initial research focused on identifying suitable carrier molecules with optimal hydrogen storage capacity, favorable thermodynamics, and stability over multiple cycles. Notable carrier systems include dibenzyl toluene (H0-DBT/H18-DBT), N-ethylcarbazole, and methylcyclohexane-toluene pairs, each offering distinct advantages in terms of storage capacity, release conditions, and handling properties.

Process intensification for hydrogen release from LOHCs represents a critical technological frontier in the hydrogen value chain. The primary objective is to develop more efficient, compact, and economically viable dehydrogenation units that can overcome current limitations in reaction kinetics, energy efficiency, and catalyst performance. These advancements are essential for enabling widespread adoption of LOHC technology across various applications, from stationary power generation to mobility solutions.

Current technical goals include reducing the energy penalty associated with hydrogen release, which typically requires temperatures between 150-350°C depending on the carrier system. Researchers aim to develop catalysts that can operate at lower temperatures while maintaining high selectivity and stability. Additionally, there is a focus on improving heat integration strategies to utilize waste heat from other processes, thereby enhancing overall system efficiency.

The miniaturization and modularization of release units represent another key objective, particularly for mobile applications where space constraints are significant. This includes the development of microreactor technologies and novel reactor designs that maximize surface area-to-volume ratios and optimize heat and mass transfer characteristics.

Long-term technological objectives include achieving continuous, on-demand hydrogen release with rapid response times, extending catalyst lifetimes to thousands of cycles, and integrating LOHC release units with fuel cells or other hydrogen utilization technologies in seamless systems. These advancements would position LOHC technology as a cornerstone of the future hydrogen infrastructure, enabling decentralized energy storage and contributing significantly to decarbonization efforts across multiple sectors.

Market Analysis for LOHC Hydrogen Storage Solutions

The global market for Liquid Organic Hydrogen Carrier (LOHC) technology is experiencing significant growth, driven by increasing demand for clean energy solutions and the transition towards hydrogen-based economies. Current market valuations estimate the LOHC sector to reach approximately $3.8 billion by 2030, with a compound annual growth rate of 6.5% from 2023 to 2030. This growth trajectory reflects the expanding recognition of hydrogen as a versatile energy carrier capable of decarbonizing various industrial sectors.

The demand for efficient hydrogen storage solutions is particularly pronounced in regions with ambitious climate targets, including the European Union, Japan, South Korea, and increasingly China. These markets are characterized by substantial government investments in hydrogen infrastructure and supportive policy frameworks that incentivize adoption of innovative storage technologies. The EU Hydrogen Strategy, for instance, aims to install at least 40 GW of renewable hydrogen electrolyzers by 2030, creating significant downstream demand for storage solutions.

LOHC technology addresses several critical market needs that alternative hydrogen storage methods cannot fully satisfy. Unlike compressed or liquefied hydrogen storage, LOHC systems offer higher volumetric energy density, enhanced safety profiles, and compatibility with existing liquid fuel infrastructure. These advantages position LOHC as particularly valuable for medium to long-term storage applications and hydrogen transport over extended distances.

Industry segmentation reveals varying adoption rates across sectors. The transportation sector, especially heavy-duty vehicles and maritime applications, represents a high-growth segment due to the need for high-density energy storage. Industrial applications, particularly in refineries and chemical production, constitute another significant market segment where process heat integration with LOHC dehydrogenation units offers compelling efficiency benefits.

Market barriers include the relatively high capital costs of LOHC systems compared to conventional fossil fuel infrastructure, energy losses during hydrogen loading and release cycles, and competition from alternative storage technologies such as ammonia and metal hydrides. The economic viability of LOHC solutions is heavily influenced by scale economies and process intensification advancements that can reduce operational costs.

Customer requirements are evolving toward more compact, energy-efficient release units with faster response times and lower thermal energy requirements. This trend aligns with the technical focus on process intensification for hydrogen release units, highlighting the market-technology feedback loop driving innovation in this space.

The demand for efficient hydrogen storage solutions is particularly pronounced in regions with ambitious climate targets, including the European Union, Japan, South Korea, and increasingly China. These markets are characterized by substantial government investments in hydrogen infrastructure and supportive policy frameworks that incentivize adoption of innovative storage technologies. The EU Hydrogen Strategy, for instance, aims to install at least 40 GW of renewable hydrogen electrolyzers by 2030, creating significant downstream demand for storage solutions.

LOHC technology addresses several critical market needs that alternative hydrogen storage methods cannot fully satisfy. Unlike compressed or liquefied hydrogen storage, LOHC systems offer higher volumetric energy density, enhanced safety profiles, and compatibility with existing liquid fuel infrastructure. These advantages position LOHC as particularly valuable for medium to long-term storage applications and hydrogen transport over extended distances.

Industry segmentation reveals varying adoption rates across sectors. The transportation sector, especially heavy-duty vehicles and maritime applications, represents a high-growth segment due to the need for high-density energy storage. Industrial applications, particularly in refineries and chemical production, constitute another significant market segment where process heat integration with LOHC dehydrogenation units offers compelling efficiency benefits.

Market barriers include the relatively high capital costs of LOHC systems compared to conventional fossil fuel infrastructure, energy losses during hydrogen loading and release cycles, and competition from alternative storage technologies such as ammonia and metal hydrides. The economic viability of LOHC solutions is heavily influenced by scale economies and process intensification advancements that can reduce operational costs.

Customer requirements are evolving toward more compact, energy-efficient release units with faster response times and lower thermal energy requirements. This trend aligns with the technical focus on process intensification for hydrogen release units, highlighting the market-technology feedback loop driving innovation in this space.

Current Challenges in LOHC Dehydrogenation Processes

Liquid Organic Hydrogen Carriers (LOHCs) represent a promising technology for hydrogen storage and transportation, yet the dehydrogenation process faces significant challenges that impede widespread commercial adoption. The primary obstacle remains the high energy requirement for hydrogen release, with current systems demanding temperatures between 250-320°C and substantial heat input (approximately 60-70 kJ/mol H₂). This energy intensity creates inefficiencies in the overall hydrogen value chain and reduces the net energy available from the stored hydrogen.

Catalyst performance presents another critical challenge. Current catalysts, predominantly based on precious metals like platinum and ruthenium, suffer from limited longevity, susceptibility to poisoning, and high costs. The deactivation mechanisms include coking, sintering, and poisoning by carrier degradation products, necessitating frequent regeneration or replacement and increasing operational expenses.

Heat management within dehydrogenation reactors poses complex engineering challenges. The endothermic nature of the reaction requires efficient heat transfer systems to maintain optimal reaction temperatures. Conventional reactor designs struggle with temperature gradients that lead to uneven reaction rates and incomplete hydrogen release, while also creating thermal stress on materials and catalysts.

Carrier stability during repeated hydrogenation-dehydrogenation cycles remains problematic. Many LOHCs exhibit gradual degradation, forming byproducts that contaminate catalysts and reduce hydrogen storage capacity over time. This degradation necessitates periodic purification or replacement of the carrier medium, adding to system complexity and operational costs.

Scale-up challenges persist as laboratory-proven technologies face difficulties in industrial implementation. Current reactor designs often fail to maintain performance metrics when scaled to commercially viable sizes. Issues include increased pressure drops, heat transfer limitations, and reduced catalyst utilization efficiency at larger scales.

System integration presents multifaceted challenges, particularly in balancing the dehydrogenation unit with downstream applications. The released hydrogen often contains carrier vapor contaminants requiring additional purification steps. Furthermore, the integration of heat recovery systems to improve overall efficiency introduces complexity and additional capital costs.

Control systems for LOHC dehydrogenation units lack sophistication, with current approaches struggling to optimize reaction conditions in response to varying demand patterns and feed compositions. The absence of reliable real-time monitoring techniques for hydrogen release rates and carrier conversion further complicates process control and optimization.

Regulatory and safety concerns add another layer of complexity, as standards for large-scale LOHC handling and dehydrogenation operations remain underdeveloped in many jurisdictions. The thermal hazards associated with high-temperature operations and the potential for carrier leakage require robust safety systems that add to system complexity and cost.

Catalyst performance presents another critical challenge. Current catalysts, predominantly based on precious metals like platinum and ruthenium, suffer from limited longevity, susceptibility to poisoning, and high costs. The deactivation mechanisms include coking, sintering, and poisoning by carrier degradation products, necessitating frequent regeneration or replacement and increasing operational expenses.

Heat management within dehydrogenation reactors poses complex engineering challenges. The endothermic nature of the reaction requires efficient heat transfer systems to maintain optimal reaction temperatures. Conventional reactor designs struggle with temperature gradients that lead to uneven reaction rates and incomplete hydrogen release, while also creating thermal stress on materials and catalysts.

Carrier stability during repeated hydrogenation-dehydrogenation cycles remains problematic. Many LOHCs exhibit gradual degradation, forming byproducts that contaminate catalysts and reduce hydrogen storage capacity over time. This degradation necessitates periodic purification or replacement of the carrier medium, adding to system complexity and operational costs.

Scale-up challenges persist as laboratory-proven technologies face difficulties in industrial implementation. Current reactor designs often fail to maintain performance metrics when scaled to commercially viable sizes. Issues include increased pressure drops, heat transfer limitations, and reduced catalyst utilization efficiency at larger scales.

System integration presents multifaceted challenges, particularly in balancing the dehydrogenation unit with downstream applications. The released hydrogen often contains carrier vapor contaminants requiring additional purification steps. Furthermore, the integration of heat recovery systems to improve overall efficiency introduces complexity and additional capital costs.

Control systems for LOHC dehydrogenation units lack sophistication, with current approaches struggling to optimize reaction conditions in response to varying demand patterns and feed compositions. The absence of reliable real-time monitoring techniques for hydrogen release rates and carrier conversion further complicates process control and optimization.

Regulatory and safety concerns add another layer of complexity, as standards for large-scale LOHC handling and dehydrogenation operations remain underdeveloped in many jurisdictions. The thermal hazards associated with high-temperature operations and the potential for carrier leakage require robust safety systems that add to system complexity and cost.

Current Process Intensification Approaches for LOHC Units

01 Catalytic dehydrogenation systems for LOHC

Catalytic systems play a crucial role in the dehydrogenation of Liquid Organic Hydrogen Carriers (LOHC). These systems typically employ noble metal catalysts such as platinum, palladium, or ruthenium supported on various substrates to facilitate hydrogen release. Process intensification in these systems focuses on optimizing catalyst composition, increasing active surface area, and enhancing stability to improve hydrogen release rates while reducing energy requirements and catalyst degradation.- Catalytic dehydrogenation systems for LOHC: Catalytic systems play a crucial role in the dehydrogenation of Liquid Organic Hydrogen Carriers (LOHC). These systems typically employ noble metal catalysts such as platinum, palladium, or ruthenium supported on various substrates to facilitate hydrogen release. Process intensification in this area focuses on developing catalysts with higher activity, improved selectivity, and enhanced stability under reaction conditions, allowing for more efficient hydrogen release at lower temperatures and pressures.

- Reactor design optimization for hydrogen release: Advanced reactor designs are essential for process intensification in LOHC hydrogen release units. Innovations include microreactor technology, structured reactors with enhanced heat and mass transfer characteristics, and membrane reactors that allow for simultaneous reaction and separation. These designs aim to overcome thermodynamic limitations, improve reaction kinetics, and enhance overall system efficiency by optimizing parameters such as residence time, temperature distribution, and catalyst contact.

- Heat management and energy integration techniques: Effective heat management is critical for LOHC dehydrogenation processes due to their endothermic nature. Process intensification approaches include advanced heat exchanger designs, thermal energy storage systems, and heat recovery networks. By integrating waste heat from other processes, implementing phase-change materials for thermal buffering, and utilizing novel heating methods such as induction or microwave heating, the energy efficiency of hydrogen release units can be significantly improved.

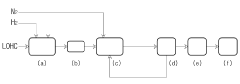

- Continuous flow and process automation systems: Continuous flow processing represents a significant advancement over batch operations for LOHC hydrogen release. These systems incorporate real-time monitoring and control strategies, automated feed adjustment based on demand fluctuations, and integrated purification steps. Process intensification in this area focuses on developing robust control algorithms, implementing advanced sensors for process parameters, and creating modular designs that can be scaled according to hydrogen demand requirements.

- Novel LOHC materials and formulations: The development of advanced LOHC materials with improved hydrogen storage capacity and release kinetics is fundamental to process intensification. Research focuses on synthesizing carriers with lower dehydrogenation temperatures, faster reaction rates, and enhanced cycling stability. Innovations include heterocyclic compounds with optimized molecular structures, composite materials that combine storage and catalytic functions, and additives that promote hydrogen release while preventing carrier degradation over multiple cycles.

02 Reactor design innovations for hydrogen release

Advanced reactor designs for LOHC dehydrogenation focus on maximizing heat transfer efficiency and reaction surface area. Innovations include microreactor technology, structured reactors with enhanced surface-to-volume ratios, membrane reactors that allow for simultaneous reaction and separation, and fluidized bed systems. These designs aim to overcome thermodynamic limitations, reduce energy consumption, and increase hydrogen production rates while maintaining process stability and control.Expand Specific Solutions03 Heat management and energy integration techniques

Effective heat management is critical for LOHC dehydrogenation processes due to their endothermic nature. Process intensification approaches include heat recovery systems, thermal energy storage, direct coupling with exothermic processes, and utilization of renewable heat sources. Advanced heat exchanger designs, such as plate heat exchangers and compact recuperators, enable efficient thermal energy transfer while minimizing system footprint and maximizing overall energy efficiency.Expand Specific Solutions04 Process control and system integration strategies

Sophisticated process control strategies enhance the performance of LOHC hydrogen release units through real-time monitoring and adjustment of operating parameters. These approaches incorporate advanced sensors, predictive modeling, and artificial intelligence to optimize reaction conditions. System integration strategies focus on coupling hydrogen release units with downstream applications, such as fuel cells or industrial processes, and developing modular designs that can be scaled according to hydrogen demand while maintaining efficiency across varying load profiles.Expand Specific Solutions05 Novel LOHC materials and formulations

Development of improved LOHC materials focuses on compounds with higher hydrogen storage capacity, lower dehydrogenation temperatures, and enhanced stability over multiple cycles. Research includes heterocyclic compounds, aromatic systems, and nitrogen-containing carriers with optimized thermodynamic properties. Additives and formulations are being developed to reduce catalyst poisoning, prevent carrier degradation, and improve flow characteristics, thereby enhancing the overall efficiency and lifetime of hydrogen release systems.Expand Specific Solutions

Key Industry Players in LOHC Hydrogen Systems

Process intensification for LOHC hydrogen release units is currently in an early growth phase, with the market expanding rapidly due to increasing hydrogen economy demands. The global market size is projected to reach significant scale by 2030 as hydrogen infrastructure develops. Technologically, the field shows varying maturity levels across players. Hydrogenious LOHC Technologies leads as a pioneer with commercial-ready solutions, while major energy corporations like Sinopec, PetroChina, and Ecopetrol are investing heavily in R&D. Academic institutions including KAIST, Dalian Institute of Chemical Physics, and Karlsruhe Institute of Technology are advancing fundamental research. The competitive landscape features collaboration between specialized technology providers and large energy companies, with increasing interest from automotive players like BMW and Bosch seeking to integrate LOHC technology into hydrogen mobility applications.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed comprehensive process intensification technologies for LOHC hydrogen release units integrated with their existing refinery and petrochemical infrastructure. Their approach focuses on large-scale implementation with emphasis on heat integration and catalyst optimization. Sinopec employs multi-tubular fixed-bed reactor designs with enhanced heat transfer characteristics, operating at moderate temperatures (280-320°C) and pressures (1-5 bar). Their catalyst systems utilize proprietary formulations based on transition metals (primarily Ni and Co) supported on specialized carriers that balance activity and stability while minimizing costs. The company has implemented advanced heat recovery systems that capture approximately 45% of process heat for reuse within integrated facilities, significantly improving overall energy efficiency. Their technology achieves hydrogen release rates of approximately 350-400 Nl H₂/h/kg catalyst while maintaining carrier stability over extended operational periods (>800 cycles). Recent developments include pilot demonstrations of intensified reactors with structured internals that improve mass transfer and reduce pressure drop by approximately 30% compared to conventional designs.

Strengths: Extensive integration capabilities with existing petrochemical infrastructure; significant scale-up experience; cost-effective catalyst formulations with reduced precious metal content. Weaknesses: Technology primarily optimized for large-scale centralized applications; relatively lower hydrogen release rates compared to some specialized competitors.

Hydrogenious LOHC Technologies GmbH

Technical Solution: Hydrogenious has developed a proprietary LOHC system based on dibenzyltoluene (DBT) as the carrier medium, which remains in liquid state throughout the entire process cycle. Their process intensification approach focuses on structured reactor designs with enhanced heat transfer capabilities. The company employs a modular reactor concept with integrated heat management systems that optimize the endothermic dehydrogenation process. Their technology utilizes precious metal catalysts (primarily platinum-based) supported on specialized substrates that maximize surface area while minimizing pressure drop. The system operates at moderate temperatures (280-320°C) and pressures (1-5 bar), achieving hydrogen release rates of up to 500 Nl H₂/h/kg catalyst. Their latest generation systems incorporate microstructured heat exchangers that improve thermal efficiency by approximately 30% compared to conventional designs, significantly reducing energy requirements for the dehydrogenation process.

Strengths: Industry-leading LOHC technology with commercial-scale implementations; highly stable carrier medium with over 1000 demonstrated loading/unloading cycles; modular design allows for scalable deployment. Weaknesses: Relatively high catalyst costs due to precious metal content; energy intensity of dehydrogenation process still presents efficiency challenges.

Critical Patents and Catalytic Technologies for Hydrogen Release

Process for Storing and Releasing Hydrogen Using Liquid Organic Hydrogen Carriers

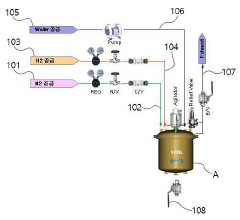

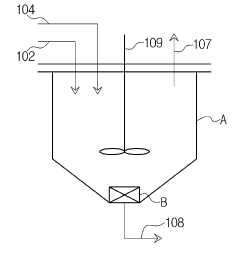

PatentActiveKR1020210126491A

Innovation

- A process utilizing a powder-form catalyst in combination with flange-type filters in hydrogenation and dehydrogenation reactors, allowing for efficient hydrogen storage and release by maximizing contact between the catalyst and LOHC, while maintaining the catalyst within the reactor to prevent exposure and deterioration, and incorporating a condenser and adsorption tower for high-purity hydrogen recovery.

System and method for storing and releasing energy

PatentActiveUS20160301093A1

Innovation

- A system comprising a hydrogen production unit, a hydrogen storage device, a heat generation unit, and a heat storage unit, where hydrogen is stored chemically bound with a carrier medium, allowing for efficient storage and release of energy using heat from the heat storage unit during energy-rich and energy-poor periods.

Energy Integration Strategies for LOHC Systems

Energy integration represents a critical aspect of process intensification for LOHC hydrogen release units. The dehydrogenation of Liquid Organic Hydrogen Carriers (LOHCs) is an endothermic process requiring substantial thermal energy input, typically operating at temperatures between 250-350°C. Effective energy management strategies can significantly improve the overall system efficiency and economic viability of LOHC-based hydrogen storage and release systems.

Heat integration within LOHC systems can be achieved through several approaches. The primary strategy involves utilizing waste heat from external processes or from the hydrogen utilization unit itself. For instance, in combined heat and power (CHP) applications, waste heat from fuel cells or combustion processes can be redirected to supply the dehydrogenation energy requirements. This symbiotic relationship reduces the need for additional energy inputs and improves overall system efficiency by 15-30% according to recent studies.

Pinch analysis techniques have proven particularly valuable for optimizing heat exchanger networks in LOHC systems. By identifying the minimum energy requirements and maximum heat recovery potential, engineers can design more efficient thermal integration schemes. Advanced heat exchanger designs, including compact plate heat exchangers and microchannel reactors, further enhance heat transfer efficiency while reducing equipment footprint—a key consideration for mobile or space-constrained applications.

Another promising approach involves thermal energy storage integration, allowing for temporal decoupling of heat generation and consumption. Phase change materials (PCMs) with melting points aligned with LOHC dehydrogenation temperatures can store excess heat during periods of low hydrogen demand and release it when needed, thereby smoothing out energy consumption profiles and potentially enabling integration with intermittent renewable energy sources.

Catalytic combustion of a portion of the released hydrogen represents another energy integration strategy, providing the necessary heat for continued dehydrogenation. While this approach reduces net hydrogen yield, it eliminates the need for external heat sources, making it suitable for autonomous operation in remote locations. Advanced catalytic combustion systems can achieve combustion efficiencies exceeding 99%, minimizing hydrogen losses while maintaining precise temperature control.

Process intensification through reactor design also contributes significantly to energy integration. Structured reactors incorporating heat exchange functionality, such as plate reactors or membrane reactors, allow for simultaneous reaction and heat transfer, reducing thermal gradients and improving energy utilization. Recent developments in 3D-printed reactors have demonstrated potential for optimized flow patterns and enhanced heat transfer characteristics, potentially reducing energy requirements by up to 25% compared to conventional reactor designs.

Heat integration within LOHC systems can be achieved through several approaches. The primary strategy involves utilizing waste heat from external processes or from the hydrogen utilization unit itself. For instance, in combined heat and power (CHP) applications, waste heat from fuel cells or combustion processes can be redirected to supply the dehydrogenation energy requirements. This symbiotic relationship reduces the need for additional energy inputs and improves overall system efficiency by 15-30% according to recent studies.

Pinch analysis techniques have proven particularly valuable for optimizing heat exchanger networks in LOHC systems. By identifying the minimum energy requirements and maximum heat recovery potential, engineers can design more efficient thermal integration schemes. Advanced heat exchanger designs, including compact plate heat exchangers and microchannel reactors, further enhance heat transfer efficiency while reducing equipment footprint—a key consideration for mobile or space-constrained applications.

Another promising approach involves thermal energy storage integration, allowing for temporal decoupling of heat generation and consumption. Phase change materials (PCMs) with melting points aligned with LOHC dehydrogenation temperatures can store excess heat during periods of low hydrogen demand and release it when needed, thereby smoothing out energy consumption profiles and potentially enabling integration with intermittent renewable energy sources.

Catalytic combustion of a portion of the released hydrogen represents another energy integration strategy, providing the necessary heat for continued dehydrogenation. While this approach reduces net hydrogen yield, it eliminates the need for external heat sources, making it suitable for autonomous operation in remote locations. Advanced catalytic combustion systems can achieve combustion efficiencies exceeding 99%, minimizing hydrogen losses while maintaining precise temperature control.

Process intensification through reactor design also contributes significantly to energy integration. Structured reactors incorporating heat exchange functionality, such as plate reactors or membrane reactors, allow for simultaneous reaction and heat transfer, reducing thermal gradients and improving energy utilization. Recent developments in 3D-printed reactors have demonstrated potential for optimized flow patterns and enhanced heat transfer characteristics, potentially reducing energy requirements by up to 25% compared to conventional reactor designs.

Environmental Impact Assessment of LOHC Technologies

Liquid Organic Hydrogen Carriers (LOHC) technologies represent a promising approach for hydrogen storage and transportation, yet their environmental implications require thorough assessment. The environmental footprint of LOHC hydrogen release units encompasses multiple dimensions that must be systematically evaluated. When examining the life cycle assessment (LCA) of these systems, carbon emissions emerge as a critical factor. Conventional hydrogen release processes often operate at high temperatures (250-300°C), resulting in significant energy consumption and associated greenhouse gas emissions. However, process intensification techniques can substantially reduce these environmental impacts through improved heat integration and catalyst efficiency.

Water consumption represents another vital environmental consideration for LOHC technologies. The dehydrogenation process typically requires cooling systems that may consume substantial water resources, particularly in conventional reactor designs. Process intensification approaches such as microreactor technology and advanced heat exchanger designs can reduce water requirements by 30-45% compared to traditional systems, offering significant environmental benefits in water-stressed regions.

Land use impacts of LOHC hydrogen release units are generally favorable compared to alternative hydrogen storage methods. The high volumetric energy density of LOHCs (approximately 57 kg H₂/m³) enables compact system designs with minimal spatial footprint. Process intensification further enhances this advantage by reducing equipment size through intensified heat and mass transfer, resulting in release units that require 40-60% less physical space than conventional hydrogen storage alternatives.

Air quality considerations extend beyond carbon emissions to include potential volatile organic compound (VOC) releases during the dehydrogenation process. Traditional LOHC systems may experience minimal carrier losses (0.01-0.1% per cycle) that contribute to local air pollution. Advanced process intensification techniques incorporating improved sealing technologies and optimized operating conditions can reduce these emissions by an order of magnitude, minimizing local air quality impacts.

Resource efficiency represents a fundamental environmental benefit of LOHC technologies. The carrier molecules can theoretically undergo thousands of hydrogenation-dehydrogenation cycles without significant degradation. Process intensification measures that optimize operating conditions and catalyst performance can extend carrier lifetime by 20-30%, reducing the environmental burden associated with carrier production and disposal. Additionally, the integration of waste heat recovery systems can improve overall energy efficiency by 15-25%, further enhancing the environmental profile of these systems.

Noise pollution and safety considerations also factor into the environmental assessment of LOHC technologies. Process intensification approaches that reduce system complexity and operating pressures generally improve safety profiles while minimizing noise generation, creating more environmentally compatible installations for urban or sensitive environments.

Water consumption represents another vital environmental consideration for LOHC technologies. The dehydrogenation process typically requires cooling systems that may consume substantial water resources, particularly in conventional reactor designs. Process intensification approaches such as microreactor technology and advanced heat exchanger designs can reduce water requirements by 30-45% compared to traditional systems, offering significant environmental benefits in water-stressed regions.

Land use impacts of LOHC hydrogen release units are generally favorable compared to alternative hydrogen storage methods. The high volumetric energy density of LOHCs (approximately 57 kg H₂/m³) enables compact system designs with minimal spatial footprint. Process intensification further enhances this advantage by reducing equipment size through intensified heat and mass transfer, resulting in release units that require 40-60% less physical space than conventional hydrogen storage alternatives.

Air quality considerations extend beyond carbon emissions to include potential volatile organic compound (VOC) releases during the dehydrogenation process. Traditional LOHC systems may experience minimal carrier losses (0.01-0.1% per cycle) that contribute to local air pollution. Advanced process intensification techniques incorporating improved sealing technologies and optimized operating conditions can reduce these emissions by an order of magnitude, minimizing local air quality impacts.

Resource efficiency represents a fundamental environmental benefit of LOHC technologies. The carrier molecules can theoretically undergo thousands of hydrogenation-dehydrogenation cycles without significant degradation. Process intensification measures that optimize operating conditions and catalyst performance can extend carrier lifetime by 20-30%, reducing the environmental burden associated with carrier production and disposal. Additionally, the integration of waste heat recovery systems can improve overall energy efficiency by 15-25%, further enhancing the environmental profile of these systems.

Noise pollution and safety considerations also factor into the environmental assessment of LOHC technologies. Process intensification approaches that reduce system complexity and operating pressures generally improve safety profiles while minimizing noise generation, creating more environmentally compatible installations for urban or sensitive environments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!