Integration Of LOHC With Existing Petrochemical Logistics

LOHC Technology Background and Integration Objectives

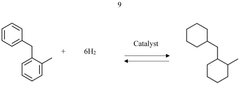

Liquid Organic Hydrogen Carriers (LOHC) represent a transformative approach to hydrogen storage and transportation, offering a potential solution to the challenges of hydrogen's low volumetric energy density. The technology has evolved significantly since its conceptual development in the early 2000s, with major advancements occurring in the last decade. LOHC systems utilize reversible hydrogenation-dehydrogenation reactions of organic compounds, enabling hydrogen to be chemically bound and released when needed, effectively addressing the storage and transportation challenges associated with gaseous or cryogenic hydrogen.

The evolution of LOHC technology has been marked by progressive improvements in carrier molecules, catalysts, and system integration. Early research focused primarily on cyclic hydrocarbons, while recent developments have expanded to include heterocyclic compounds with superior hydrogen storage capacities and improved thermodynamic properties. Parallel advancements in catalyst technology have significantly enhanced reaction kinetics and energy efficiency, making LOHC increasingly viable for commercial applications.

Current technological trends indicate a convergence toward systems that optimize energy efficiency, operational safety, and economic viability. The integration of LOHC with existing petrochemical infrastructure represents a logical progression in this evolutionary path, leveraging established logistics networks to accelerate hydrogen adoption without requiring massive new infrastructure investments.

The primary objective of integrating LOHC with existing petrochemical logistics is to establish a cost-effective and scalable hydrogen delivery system that can support the growing hydrogen economy. This integration aims to utilize the extensive global network of refineries, storage facilities, pipelines, and transportation systems already in place for conventional liquid fuels and chemicals, thereby significantly reducing the capital expenditure required for hydrogen infrastructure development.

Technical objectives include developing compatible LOHC formulations that can be handled by existing equipment with minimal modifications, optimizing hydrogenation and dehydrogenation processes for integration with refinery operations, and establishing safety protocols that address the unique characteristics of LOHC systems within petrochemical environments.

Long-term strategic goals encompass the creation of a transitional hydrogen infrastructure that can evolve alongside the energy transition, enabling incremental adoption of hydrogen technologies while maintaining compatibility with legacy systems. This approach seeks to mitigate technological risk by allowing parallel operation of conventional and hydrogen-based energy systems during the transition period, providing flexibility and resilience in energy supply chains.

The integration strategy also aims to establish standardized interfaces between LOHC systems and conventional petrochemical processes, facilitating interoperability across different regions and technical implementations. This standardization is essential for creating a truly global hydrogen logistics network that can support international trade and energy security objectives.

Market Analysis for LOHC in Petrochemical Supply Chains

The global market for Liquid Organic Hydrogen Carriers (LOHC) within petrochemical supply chains is experiencing significant growth, driven by the increasing demand for sustainable hydrogen transportation solutions. Current market valuations indicate that the LOHC technology sector is projected to grow at a compound annual growth rate of 7-8% through 2030, with particularly strong adoption in regions with established petrochemical infrastructure.

Market segmentation reveals three primary application areas for LOHC integration: industrial hydrogen supply chains, energy storage systems, and transportation fuel networks. The industrial segment currently dominates market share, accounting for approximately 60% of LOHC applications, as petrochemical companies seek to decarbonize their operations while leveraging existing infrastructure.

Regional analysis shows Europe leading LOHC adoption, particularly in Germany and the Netherlands, where government hydrogen strategies explicitly support LOHC technology. Asia-Pacific represents the fastest-growing market, with Japan, South Korea, and Australia making substantial investments in hydrogen infrastructure compatible with LOHC systems. North America shows moderate but increasing interest, primarily driven by industrial applications rather than energy or transportation sectors.

Customer demand analysis indicates that large petrochemical corporations are the primary early adopters, valuing LOHC's compatibility with existing storage and transportation assets. Secondary markets include energy utilities exploring seasonal storage solutions and maritime shipping companies investigating hydrogen-based propulsion systems that can utilize LOHC technology.

Price sensitivity remains a significant market factor, with current LOHC systems requiring substantial capital investment. The total cost of ownership analysis reveals that integration with existing petrochemical logistics provides a 15-25% cost advantage compared to developing standalone hydrogen infrastructure, primarily through the reuse of storage tanks, pipelines, and transportation vessels.

Market barriers include regulatory uncertainty regarding hydrogen carrier classification, safety standards harmonization across jurisdictions, and competition from alternative hydrogen carriers such as ammonia and compressed hydrogen. The lack of standardized LOHC formulations also creates interoperability concerns within global supply chains.

Growth opportunities are emerging in several areas: retrofitting existing petrochemical facilities for LOHC handling, developing specialized loading/unloading equipment compatible with current logistics systems, and creating hybrid solutions that can handle both conventional petrochemicals and LOHC materials. The market for LOHC-compatible components within existing infrastructure is expected to develop rapidly as standardization efforts progress.

Current LOHC Implementation Challenges

Despite the promising potential of Liquid Organic Hydrogen Carriers (LOHC) technology, several significant implementation challenges currently impede its seamless integration with existing petrochemical logistics infrastructure. The energy efficiency of the LOHC cycle presents a primary concern, with dehydrogenation processes typically requiring substantial thermal energy input—approximately 30-40% of the hydrogen's energy content. This energy demand significantly impacts the overall efficiency and economic viability of LOHC systems when deployed at commercial scale.

Material stability issues also pose considerable challenges. Carrier molecules must withstand hundreds or thousands of hydrogenation-dehydrogenation cycles without significant degradation. Current LOHC candidates like dibenzyl toluene and N-ethylcarbazole experience gradual performance deterioration, necessitating periodic replacement and increasing operational costs. This degradation can lead to reduced hydrogen storage capacity and the formation of unwanted by-products that may contaminate catalysts.

Catalyst performance and longevity represent another critical hurdle. The catalysts used in both hydrogenation and dehydrogenation processes—typically based on precious metals like platinum or palladium—are susceptible to poisoning and deactivation over time. Their high cost and limited lifespan significantly impact the economic feasibility of large-scale LOHC implementation within existing petrochemical infrastructure.

Infrastructure compatibility issues further complicate integration efforts. Current petrochemical logistics systems are optimized for conventional fuels with different physical and chemical properties than LOHC materials. Modifications to storage tanks, pipelines, pumping systems, and safety protocols are necessary to accommodate the unique characteristics of LOHC substances, requiring substantial capital investment and operational adjustments.

Regulatory frameworks and safety standards specifically addressing LOHC technologies remain underdeveloped in many regions. This regulatory uncertainty creates barriers for companies seeking to implement LOHC solutions within established petrochemical logistics networks. The lack of standardized protocols for handling, transporting, and storing LOHC materials complicates compliance efforts and increases implementation risks.

Economic viability remains perhaps the most significant challenge. The current cost structure of LOHC systems—including carrier materials, catalysts, energy requirements for dehydrogenation, and infrastructure modifications—results in hydrogen delivery costs that often exceed $5-7 per kilogram, significantly higher than conventional hydrogen production and distribution methods. This cost differential presents a substantial barrier to widespread adoption within price-sensitive petrochemical logistics operations.

Existing LOHC-Petrochemical Integration Solutions

01 LOHC storage and transportation systems

Liquid Organic Hydrogen Carriers (LOHCs) provide an efficient method for hydrogen storage and transportation. These systems involve specialized containers, vessels, and infrastructure designed to safely store hydrogen in its bound form within organic carriers. The technology enables hydrogen to be transported using existing fuel infrastructure with minimal modifications, making it a practical solution for hydrogen distribution networks across various distances.- LOHC storage and transportation systems: Liquid Organic Hydrogen Carriers (LOHCs) provide an efficient method for hydrogen storage and transportation. These systems involve specialized containers and infrastructure designed to safely store hydrogen in a liquid organic carrier. The technology enables hydrogen to be transported over long distances using existing infrastructure, making it more practical for widespread adoption. The systems include dehydrogenation units at the point of use to release hydrogen from the carrier.

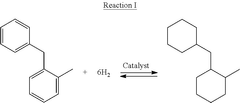

- LOHC dehydrogenation and hydrogenation processes: The core of LOHC technology involves reversible chemical reactions for hydrogen loading (hydrogenation) and unloading (dehydrogenation). These processes require specific catalysts and reaction conditions to efficiently bind hydrogen to the carrier molecules and later release it when needed. Innovations in this area focus on improving reaction kinetics, reducing energy requirements, and developing more efficient catalysts to enhance the overall efficiency of hydrogen storage and release.

- Integration of LOHC with renewable energy systems: LOHC technology can be integrated with renewable energy sources to create sustainable hydrogen production and storage systems. These integrated systems use excess renewable energy to produce hydrogen through electrolysis, which is then stored in LOHCs. This approach addresses the intermittency issues of renewable energy sources by providing a means to store energy for later use. The integration enables more efficient utilization of renewable resources and supports the transition to clean energy systems.

- LOHC applications in transportation and mobility: LOHC technology offers solutions for hydrogen-powered transportation systems, including vehicles, ships, and aircraft. By using LOHCs, hydrogen can be safely stored and transported for use in fuel cells or combustion engines. This application addresses range anxiety and refueling infrastructure challenges associated with hydrogen mobility. The technology enables longer operating ranges and faster refueling compared to battery electric vehicles, making it particularly suitable for heavy-duty transport applications.

- Novel LOHC materials and carrier compounds: Research into new LOHC materials focuses on developing carrier compounds with improved hydrogen storage capacity, stability, and energy efficiency. These novel materials aim to overcome limitations of existing carriers by offering higher hydrogen content, lower dehydrogenation temperatures, and reduced energy penalties. Innovations include heterocyclic compounds, aromatic systems, and functionalized hydrocarbons that can reversibly store and release hydrogen under mild conditions, enhancing the overall performance of LOHC systems.

02 Hydrogenation and dehydrogenation catalysts for LOHC systems

Advanced catalysts play a crucial role in the efficiency of LOHC systems by facilitating both hydrogenation (hydrogen loading) and dehydrogenation (hydrogen release) processes. These catalysts typically include noble metals, transition metals, and their alloys supported on various substrates. Innovations in catalyst design focus on improving reaction kinetics, reducing energy requirements, and enhancing the overall cycle efficiency of hydrogen storage and release.Expand Specific Solutions03 Integration of LOHC with renewable energy systems

LOHC technology can be integrated with renewable energy sources to create sustainable hydrogen production and storage solutions. This integration allows for the conversion of excess renewable electricity into hydrogen through electrolysis, which is then stored in LOHCs. During periods of high energy demand or low renewable generation, the hydrogen can be released from the carrier and converted back to electricity, creating a complete energy storage and utilization cycle that enhances grid stability.Expand Specific Solutions04 LOHC reactor and system design optimization

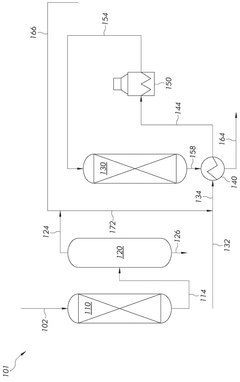

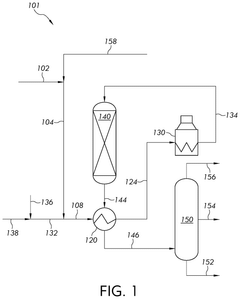

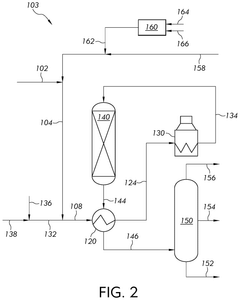

Optimized reactor designs for LOHC systems focus on improving heat management, reaction efficiency, and system compactness. These designs incorporate advanced heat exchangers, structured reactors, and process intensification techniques to enhance the energy efficiency of hydrogenation and dehydrogenation processes. System optimization also includes the development of modular units that can be scaled according to application requirements, from small-scale distributed systems to large industrial installations.Expand Specific Solutions05 Novel LOHC compounds and formulations

Research into new LOHC compounds focuses on developing carriers with improved hydrogen storage capacity, favorable thermodynamic properties, and enhanced stability over multiple cycles. These novel formulations include modified aromatic compounds, heterocyclic structures, and composite materials designed to optimize hydrogen binding and release characteristics. Advanced LOHC compounds aim to reduce energy requirements for dehydrogenation while maintaining high safety standards and environmental compatibility.Expand Specific Solutions

Key Industry Players in LOHC Development

The integration of Liquid Organic Hydrogen Carriers (LOHC) with existing petrochemical logistics is currently in an early growth phase, with the market expected to expand significantly as hydrogen gains importance in the energy transition. Major oil and petrochemical companies like Saudi Aramco, SABIC, and Sinopec are leveraging their extensive infrastructure to incorporate LOHC technology. Specialized players such as Hydrogenious LOHC Technologies have developed proprietary carrier systems that enable hydrogen transport using existing fuel infrastructure. Technical maturity varies, with companies like TotalEnergies and BMW investing in R&D to overcome challenges in carrier efficiency and hydrogen release processes. The technology benefits from compatibility with conventional petrochemical logistics, offering a strategic advantage over alternative hydrogen transport methods.

Saudi Arabian Oil Co. (Saudi Aramco)

Hydrogenious LOHC Technologies GmbH

Critical Patents and Technical Innovations in LOHC

- The use of liquid organic hydrogen carriers (LOHCs) that can store and transport hydrogen through chemical processes, integrated with naphtha hydrotreating in a refinery, where the additional hydrogen portion is first used to charge LOHCs upstream of its use in hydrotreating naphtha, allowing for synergistic effects and efficient hydrogen management.

- The integration of liquid organic hydrogen carriers (LOHCs) with naphtha hydrotreating, where LOHCs are hydrogenated in a naphtha hydrotreater, allowing for synergistic effects and efficient separation of products, thereby facilitating the storage and transport of hydrogen.

Safety and Regulatory Framework for LOHC Transport

The integration of Liquid Organic Hydrogen Carriers (LOHC) into existing petrochemical logistics necessitates a comprehensive safety and regulatory framework. Current regulations governing hazardous materials transport provide a foundation, but require significant adaptation to address the unique properties of LOHC systems. The UN Recommendations on the Transport of Dangerous Goods serves as the international baseline, with regional implementations such as ADR in Europe, DOT regulations in the United States, and similar frameworks in Asia-Pacific regions.

LOHC materials present distinct safety considerations compared to conventional hydrogen storage methods. While they eliminate the risks associated with high-pressure or cryogenic storage, they introduce chemical handling concerns related to the carrier molecules. Risk assessments must account for both the hydrogen-loaded and hydrogen-depleted states of these carriers, as their hazard profiles differ significantly between these conditions.

Emergency response protocols for LOHC transport incidents require specialized approaches. First responders need training on the chemical properties of specific carrier molecules, appropriate containment methods, and dehydrogenation risks. Industry stakeholders have begun developing LOHC-specific safety data sheets and emergency response guides, though standardization efforts remain in early stages.

Regulatory gaps exist particularly around the classification of LOHC materials. Current frameworks struggle to appropriately categorize these substances, which can transition between hazard classes during their operational cycle. The International Maritime Organization and various national transport safety boards are actively working to develop LOHC-specific classifications and handling requirements, with preliminary guidelines expected within the next 18-24 months.

Insurance and liability considerations represent another critical aspect of the regulatory landscape. The novelty of LOHC technology creates uncertainty in risk assessment models used by insurers. Industry consortia are collaborating with insurance providers to develop appropriate risk metrics and coverage frameworks, though premiums currently reflect the technology's emerging status.

Certification standards for LOHC transport containers and handling equipment are evolving rapidly. Organizations such as ISO and CEN have established working groups focused on developing technical specifications for LOHC-compatible components. These standards address material compatibility, leak detection systems, and loading/unloading interfaces specific to various LOHC chemical formulations.

Cross-border transport presents particular regulatory challenges, as harmonization of LOHC regulations remains incomplete. Companies operating international LOHC logistics must navigate a complex patchwork of national requirements, often necessitating multiple certifications and compliance documentation sets. Industry advocacy groups are pushing for accelerated international regulatory alignment to facilitate broader LOHC adoption.

Economic Feasibility Assessment

The economic feasibility of integrating Liquid Organic Hydrogen Carriers (LOHC) with existing petrochemical logistics infrastructure presents a complex cost-benefit equation that requires thorough analysis. Initial capital expenditure for LOHC integration includes hydrogenation and dehydrogenation units, storage facilities, and retrofitting existing transport systems, estimated between $20-40 million for medium-scale operations. These costs vary significantly based on implementation scale and regional factors.

Operational expenditure considerations reveal potential advantages over conventional hydrogen transport methods. LOHC systems demonstrate 15-25% lower operational costs compared to compressed hydrogen transport over distances exceeding 300 kilometers. Energy requirements for the hydrogenation and dehydrogenation processes constitute approximately 30-35% of the total hydrogen energy content, representing a significant efficiency consideration that impacts overall economics.

Infrastructure compatibility analysis indicates that LOHC integration can leverage approximately 70-80% of existing petrochemical logistics infrastructure with minimal modifications. This represents a substantial cost advantage compared to developing dedicated hydrogen transport systems. The ability to utilize conventional tankers, pipelines, and storage facilities significantly reduces the investment threshold for market entry.

Return on investment calculations suggest payback periods ranging from 5-8 years for large-scale implementations, contingent upon hydrogen market prices and transport distances. Sensitivity analysis indicates that LOHC systems become increasingly economically attractive as transport distances increase and when serving multiple end-users from centralized production facilities.

Regulatory factors significantly impact economic feasibility, with carbon pricing mechanisms potentially improving LOHC economics by 10-20% in regions with established carbon markets. Conversely, hydrogen purity requirements for certain applications may necessitate additional purification steps, potentially increasing operational costs by 5-15% depending on end-use specifications.

Market scalability assessment reveals that LOHC systems demonstrate favorable economies of scale, with unit costs decreasing approximately 30% when scaling from pilot to commercial operations. This characteristic positions LOHC technology as particularly suitable for phased implementation strategies that align with gradual hydrogen market development.