LOHC For Maritime And Heavy-Duty Transportation Applications

LOHC Technology Background and Objectives

Liquid Organic Hydrogen Carriers (LOHC) technology represents a significant advancement in hydrogen storage and transportation systems, emerging as a promising solution to overcome the challenges associated with conventional hydrogen storage methods. The concept of LOHC involves chemically binding hydrogen to organic liquid compounds through hydrogenation reactions, allowing hydrogen to be stored and transported under ambient conditions without the need for cryogenic temperatures or high-pressure vessels.

The evolution of LOHC technology can be traced back to the early 2000s when researchers began exploring alternatives to compressed and liquefied hydrogen storage. The technology has since progressed through various developmental stages, with significant breakthroughs in catalyst efficiency, carrier molecule design, and system integration occurring over the past decade. This progression aligns with the global push towards decarbonization and the increasing recognition of hydrogen as a key element in the future energy landscape.

Maritime and heavy-duty transportation sectors present unique challenges for decarbonization due to their high energy demands, long operational ranges, and limited refueling opportunities. These sectors contribute significantly to global greenhouse gas emissions, with international shipping alone accounting for approximately 2.5% of global CO2 emissions. Traditional battery-electric solutions often fall short in these applications due to weight constraints and energy density limitations.

LOHC technology aims to address these challenges by providing a hydrogen storage medium with high volumetric energy density, safety advantages, and compatibility with existing liquid fuel infrastructure. The primary technical objectives for LOHC implementation in maritime and heavy-duty transportation include achieving high hydrogen storage capacity (>6 wt%), rapid dehydrogenation kinetics at moderate temperatures (<250°C), minimal energy losses during hydrogen release, and long-term stability over multiple hydrogenation-dehydrogenation cycles.

Additionally, the technology seeks to leverage the existing liquid fuel infrastructure with minimal modifications, thereby reducing the capital expenditure required for hydrogen adoption in these sectors. This infrastructure compatibility represents a significant advantage over other hydrogen storage technologies, potentially accelerating the transition to hydrogen-based propulsion systems in maritime vessels and heavy-duty vehicles.

The development of LOHC technology for transportation applications is aligned with broader energy transition goals, including the European Union's target to reduce greenhouse gas emissions by at least 55% by 2030 and achieve climate neutrality by 2050. Similarly, the International Maritime Organization has set ambitious targets to reduce carbon intensity in international shipping by at least 40% by 2030 and pursue efforts towards 70% by 2050, compared to 2008 levels.

Maritime and Heavy-Duty Transport Market Analysis

The maritime and heavy-duty transportation sectors represent significant markets for potential LOHC (Liquid Organic Hydrogen Carriers) adoption, driven by increasing environmental regulations and the need for sustainable energy solutions. The global maritime industry accounts for approximately 3% of global greenhouse gas emissions, with international regulatory bodies like the International Maritime Organization (IMO) setting ambitious targets to reduce emissions by at least 50% by 2050 compared to 2008 levels.

Maritime transportation presents a particularly compelling case for LOHC implementation due to the sector's unique operational requirements. Ocean-going vessels require high energy density fuels for long-distance voyages, making conventional battery-electric solutions impractical. The global commercial fleet consists of over 100,000 vessels, with container ships, bulk carriers, and tankers representing the largest segments by cargo capacity.

Heavy-duty road transportation, including long-haul trucking and specialized industrial vehicles, constitutes another major potential market for LOHC technology. This sector faces similar challenges to maritime transport regarding energy density requirements and operational range. In Europe alone, heavy-duty vehicles are responsible for about 25% of CO2 emissions from road transport despite representing only 5% of vehicles on the road.

Market analysis indicates that early adoption of hydrogen-based solutions, including LOHC, is likely to occur in regions with stringent emissions regulations and supportive policy frameworks. The European Union, Japan, South Korea, and parts of North America are positioned as potential early markets, with combined heavy-duty transportation fleets numbering in the millions of vehicles.

Port infrastructure represents a critical nexus between maritime and heavy-duty transport applications, potentially serving as hydrogen distribution hubs. Major port authorities in Rotterdam, Singapore, and Los Angeles have already initiated hydrogen infrastructure projects that could support LOHC deployment.

Economic analysis suggests that while current LOHC implementation costs remain high, economies of scale and technological improvements could drive down costs significantly over the next decade. Total cost of ownership models indicate potential cost parity with conventional fuels by 2030-2035, depending on carbon pricing mechanisms and regulatory incentives.

Market forecasts project that hydrogen-based solutions could capture 5-10% of the maritime fuel market by 2030, with higher penetration in specialized vessel segments like short-sea shipping and ferry operations. For heavy-duty road transport, adoption rates are expected to vary significantly by region, with urban delivery and drayage operations representing early adoption opportunities.

LOHC Development Status and Technical Barriers

LOHC technology has emerged as a promising solution for hydrogen storage and transportation in maritime and heavy-duty applications. Currently, several LOHC systems have reached commercial readiness levels, with the most advanced being methylcyclohexane (MCH)/toluene and dibenzyltoluene (DBT)/perhydro-dibenzyltoluene systems. These carriers demonstrate storage capacities ranging from 5-7 wt% hydrogen, offering significant advantages over compressed or liquefied hydrogen in terms of safety and infrastructure compatibility.

The global development landscape shows varying progress rates. Germany leads European research with significant investments through the Kopernikus P2X project and companies like Hydrogenious LOHC Technologies. Japan has established a commercial-scale LOHC supply chain with Chiyoda Corporation's SPERA Hydrogen system. Meanwhile, South Korea and China are rapidly expanding their research capabilities, with South Korea focusing on integration with existing petrochemical infrastructure.

Despite promising developments, several technical barriers impede widespread LOHC adoption. The energy intensity of dehydrogenation remains a critical challenge, requiring temperatures between 250-320°C and consuming 30-40% of hydrogen's energy content. This thermal requirement presents particular difficulties for maritime applications where waste heat utilization is limited.

Catalyst efficiency and longevity constitute another significant barrier. Current noble metal catalysts (primarily platinum and ruthenium) face degradation issues under maritime conditions, with salt exposure accelerating deactivation. Additionally, the high cost of these catalysts impacts economic viability, especially for large-scale applications.

System integration challenges are particularly pronounced in transportation applications. The additional weight of LOHC systems (carrier medium plus storage tanks) reduces overall energy efficiency, while the space requirements for both hydrogenation and dehydrogenation units present design constraints for vessels and heavy-duty vehicles.

Cycle stability represents another technical hurdle, with current LOHC systems demonstrating degradation after 100-200 cycles in real-world conditions. This degradation manifests as reduced hydrogen capacity and formation of byproducts that can contaminate fuel cells or engines.

Regulatory frameworks and standardization remain underdeveloped, creating uncertainty for technology developers and potential adopters. The lack of clear safety protocols and handling guidelines specific to LOHC systems in maritime environments slows implementation and increases perceived risk among stakeholders.

Addressing these barriers requires coordinated research efforts focused on catalyst development, system integration optimization, and process intensification to improve the overall energy efficiency of LOHC systems for transportation applications.

Current LOHC Solutions for Transportation

01 LOHC synthesis and composition

Liquid Organic Hydrogen Carriers (LOHCs) are compounds specifically designed for hydrogen storage and transport. Various chemical compositions have been developed, including heterocyclic compounds, aromatic hydrocarbons, and nitrogen-containing organic molecules. These carriers can be synthesized through different pathways to optimize their hydrogen storage capacity, stability, and release efficiency. The molecular structure of LOHCs is crucial for determining their hydrogen absorption and desorption properties.- LOHC synthesis and composition: Liquid Organic Hydrogen Carriers (LOHCs) are compounds specifically designed for hydrogen storage and transport. These carriers are synthesized through various chemical processes to create molecules capable of reversibly binding and releasing hydrogen. The composition typically includes aromatic or heterocyclic compounds that can undergo hydrogenation and dehydrogenation cycles. The molecular structure of these carriers is optimized to maximize hydrogen storage capacity while maintaining favorable physical properties such as low volatility and high stability.

- Hydrogen loading and unloading systems: Systems for efficient hydrogen loading (hydrogenation) and unloading (dehydrogenation) are critical components of LOHC technology. These systems typically include catalysts, reactors, heat exchangers, and control mechanisms designed to optimize the hydrogen transfer process. The loading process binds hydrogen to the carrier molecule under specific pressure and temperature conditions, while unloading releases hydrogen for use in fuel cells or other applications. Advanced systems incorporate energy recovery mechanisms to improve overall efficiency and reduce operational costs.

- Catalytic technologies for LOHC systems: Catalysts play a crucial role in LOHC systems by facilitating both hydrogenation and dehydrogenation reactions at lower temperatures and pressures. These catalysts are typically based on noble metals such as platinum, palladium, or ruthenium, though research is advancing toward more cost-effective alternatives using non-precious metals. Catalyst design focuses on maximizing activity, selectivity, and durability while minimizing degradation over multiple hydrogen loading and unloading cycles. Novel support materials and nanostructured catalysts are being developed to enhance performance and reduce catalyst loading.

- LOHC transportation and storage infrastructure: Infrastructure for LOHC transportation and storage leverages existing liquid fuel logistics networks, providing significant advantages over compressed or liquefied hydrogen. These systems include specialized containers, pumping equipment, and safety mechanisms designed for handling hydrogen-loaded carriers. The infrastructure accommodates the physical properties of various LOHC compounds, which typically remain liquid at ambient conditions. Advanced monitoring systems track carrier degradation and hydrogen content throughout the supply chain, ensuring reliable delivery and minimizing losses during transport and storage.

- Integration of LOHC in renewable energy systems: LOHC technology serves as an energy storage solution in renewable energy systems, addressing intermittency issues associated with solar and wind power. By converting excess renewable electricity to hydrogen and storing it in liquid carriers, energy can be transported and utilized when and where needed. These integrated systems include electrolyzers for hydrogen production, LOHC loading units, storage facilities, and dehydrogenation units coupled with fuel cells or turbines for electricity generation. The integration enables sector coupling between electricity, transportation, and industrial applications, supporting decarbonization efforts across multiple domains.

02 Hydrogen loading and unloading systems

Systems for efficient hydrogen loading (hydrogenation) and unloading (dehydrogenation) are essential components of LOHC technology. These systems typically involve catalytic processes that facilitate the binding of hydrogen to the carrier molecule during storage and its controlled release when needed. Advanced catalysts, including noble metals and transition metal complexes, are employed to enhance reaction rates and reduce energy requirements. The design of these systems focuses on optimizing operating conditions such as temperature, pressure, and reaction time to maximize hydrogen transfer efficiency.Expand Specific Solutions03 LOHC storage and transportation infrastructure

Infrastructure for storing and transporting hydrogen using LOHC technology includes specialized containers, pipeline systems, and handling equipment. These systems are designed to maintain the stability of the carrier while ensuring safety during storage and transport. The infrastructure accommodates the physical properties of LOHCs, which typically exist as liquids at ambient conditions, making them compatible with existing fuel logistics networks. This enables hydrogen to be stored and transported more efficiently compared to compressed or liquefied hydrogen methods.Expand Specific Solutions04 LOHC integration with renewable energy systems

LOHCs can be integrated with renewable energy systems to store excess energy in the form of hydrogen. This integration involves coupling electrolyzers powered by renewable sources with LOHC hydrogenation systems. The stored hydrogen can later be released and converted back to electricity using fuel cells or combustion systems when renewable energy production is insufficient. This approach provides a solution for the intermittency challenges of renewable energy sources like solar and wind, enabling long-term energy storage and grid stabilization.Expand Specific Solutions05 LOHC recycling and environmental considerations

The recyclability of LOHCs is a critical aspect of their sustainability as hydrogen carriers. After hydrogen release, the dehydrogenated carrier can be rehydrogenated and reused multiple times, creating a closed-loop system. Research focuses on improving the cycle stability of carriers and reducing degradation over multiple hydrogenation-dehydrogenation cycles. Environmental considerations include minimizing toxicity, reducing energy requirements for hydrogen release, and ensuring that the overall life cycle of LOHC systems results in lower greenhouse gas emissions compared to conventional energy storage and transport methods.Expand Specific Solutions

Key Industry Players in LOHC Development

The LOHC technology for maritime and heavy-duty transportation is in an early growth phase, with market size expanding as decarbonization efforts intensify globally. The competitive landscape features established energy giants (Saudi Aramco, Sinopec) investing alongside specialized innovators like Hydrogenious LOHC Technologies, which pioneered commercial applications. Academic-industry partnerships are driving technological advancement, with Friedrich-Alexander University Erlangen-Nürnberg and Chinese institutions (Dalian Institute of Chemical Physics, Xi'an Jiaotong University) making significant research contributions. While LOHC technology shows promise for safe hydrogen storage and transport, technical challenges in carrier efficiency and system integration remain, indicating medium maturity with substantial room for optimization before widespread commercial deployment in transportation applications.

Saudi Arabian Oil Co.

China Petroleum & Chemical Corp.

Critical LOHC Patents and Technical Literature

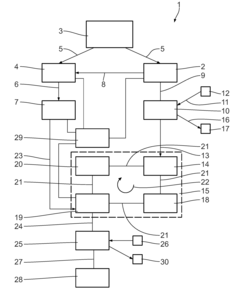

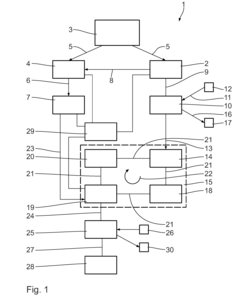

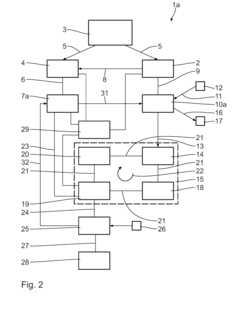

- A system comprising a hydrogen production unit, a hydrogen storage device, a heat generation unit, and a heat storage unit, where hydrogen is stored chemically bound with a carrier medium, allowing for efficient storage and release of energy using heat from the heat storage unit during energy-rich and energy-poor periods.

Environmental Impact Assessment

The environmental impact assessment of LOHC (Liquid Organic Hydrogen Carriers) technology for maritime and heavy-duty transportation applications reveals both significant advantages and potential concerns that warrant careful consideration in deployment strategies.

LOHC systems offer substantial environmental benefits compared to conventional fossil fuel solutions. Most notably, when hydrogen carried by LOHCs is used in fuel cells, the only emission is water vapor, eliminating harmful pollutants like nitrogen oxides (NOx), sulfur oxides (SOx), and particulate matter that plague traditional combustion engines. This characteristic is particularly valuable in maritime applications, where emissions in sensitive coastal ecosystems and ports can have outsized environmental impacts.

The carbon footprint of LOHC technology depends critically on the hydrogen production method. When green hydrogen (produced via electrolysis powered by renewable energy) is used, the well-to-wheel emissions can be near-zero. Analysis indicates potential greenhouse gas emission reductions of 60-95% compared to conventional diesel in heavy-duty transportation applications, depending on the renewable energy mix utilized for hydrogen production.

However, several environmental challenges must be addressed. The energy efficiency of the LOHC cycle—including hydrogenation, transportation, storage, and dehydrogenation—currently results in energy losses of 35-45%. This inefficiency translates to higher overall energy consumption compared to direct hydrogen use or battery-electric solutions in some applications.

The production and lifecycle management of carrier molecules present additional environmental considerations. Most LOHCs, such as dibenzyl toluene (DBT) and methylcyclohexane (MCH), are derived from fossil resources. Life cycle assessments indicate that carrier production contributes 5-15% of the total environmental impact. Potential leakage or spills of carrier molecules in maritime environments could have toxicological implications, though most modern LOHCs demonstrate relatively low ecotoxicity compared to conventional marine fuels.

Water consumption represents another environmental factor, particularly for the electrolysis process in hydrogen production. Estimates suggest that producing 1 kg of hydrogen via electrolysis requires 9-10 liters of purified water, creating potential resource competition in water-scarce regions.

Land use impacts vary significantly based on the renewable energy source powering hydrogen production. Wind and solar installations for dedicated hydrogen production can require substantial land area, though offshore wind applications may mitigate this concern for maritime LOHC applications.

Comprehensive environmental impact mitigation strategies should include closed-loop carrier recycling systems, optimization of dehydrogenation energy efficiency, and prioritization of renewable energy sources for the entire LOHC value chain. With these measures, LOHC technology presents a promising pathway toward decarbonizing challenging transportation sectors.

Regulatory Framework for LOHC Implementation

The regulatory landscape for LOHC implementation in maritime and heavy-duty transportation applications is complex and evolving rapidly as governments worldwide seek to reduce carbon emissions. Currently, the International Maritime Organization (IMO) has established the Initial GHG Strategy, aiming to reduce total annual GHG emissions from international shipping by at least 50% by 2050 compared to 2008 levels. This creates a significant regulatory push for alternative fuels like LOHC-based hydrogen systems.

In the European Union, the FuelEU Maritime initiative specifically targets the maritime sector's greenhouse gas intensity reduction, with progressive targets from 2025 to 2050. The initiative creates a market-based mechanism that could potentially favor LOHC technology adoption. Additionally, the EU's Alternative Fuels Infrastructure Regulation (AFIR) mandates the development of hydrogen refueling infrastructure along major transport corridors, which will be crucial for LOHC deployment in heavy-duty transportation.

For heavy-duty vehicles, regulations such as the EU's CO2 emission standards for heavy-duty vehicles set increasingly stringent targets, with a 30% reduction required by 2030 compared to 2019 levels. Similar regulations are being implemented in North America, with California's Advanced Clean Trucks regulation requiring increasing sales of zero-emission trucks starting from 2024.

Safety regulations present both challenges and opportunities for LOHC implementation. The International Code for Ships Using Gases or Other Low-flashpoint Fuels (IGF Code) currently does not specifically address LOHC systems, creating regulatory uncertainty. However, classification societies like DNV GL and Lloyd's Register are developing guidelines for hydrogen carriers that will likely incorporate LOHC technologies.

Customs and trade regulations also impact LOHC adoption, particularly for international shipping. The World Customs Organization's Harmonized System does not yet have specific codes for hydrogen carriers, potentially complicating international trade of LOHC materials. Additionally, the Basel Convention on hazardous waste may apply to spent LOHC materials, requiring careful consideration of reverse logistics.

Tax incentives and subsidies vary significantly by region but are increasingly favorable for hydrogen technologies. The EU's Innovation Fund, Japan's Green Innovation Fund, and various national hydrogen strategies provide financial support for LOHC demonstration projects. In the United States, the Inflation Reduction Act offers production tax credits for clean hydrogen that could benefit LOHC applications in transportation.

Standardization efforts are underway through organizations like ISO and IEC to develop technical standards for hydrogen carriers, which will be essential for widespread LOHC adoption. These standards will address safety requirements, performance metrics, and interoperability considerations for LOHC systems across different transportation modes.