Roadmap To Commercial LOHC Integration In Energy Markets

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LOHC Technology Background and Objectives

Liquid Organic Hydrogen Carriers (LOHCs) represent a transformative approach to hydrogen storage and transportation, addressing critical challenges in the global energy transition. The concept of LOHCs emerged in the early 2000s as researchers sought more efficient alternatives to conventional hydrogen storage methods such as compression and liquefaction, which are energy-intensive and present significant safety concerns.

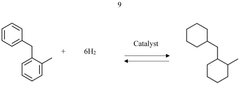

The evolution of LOHC technology has been marked by progressive improvements in carrier molecules, catalysts, and system integration. Early research focused primarily on cycloalkanes like methylcyclohexane, while recent developments have expanded to include heterocyclic compounds such as N-ethylcarbazole and dibenzyl toluene, offering improved energy density and handling characteristics.

The fundamental principle behind LOHCs involves the reversible hydrogenation and dehydrogenation of organic compounds, enabling hydrogen to be chemically bound and released on demand. This approach allows hydrogen to be handled in liquid form at ambient conditions, leveraging existing liquid fuel infrastructure and significantly reducing storage and transportation costs compared to compressed or liquefied hydrogen.

The primary objective of LOHC technology development is to establish a viable hydrogen vector that can facilitate the integration of renewable energy into existing markets while overcoming the spatial and temporal mismatches between production and consumption. This includes enabling long-distance hydrogen transport, seasonal energy storage, and sector coupling between electricity, industry, and mobility applications.

Technical objectives for commercial LOHC implementation include improving energy efficiency in the hydrogenation/dehydrogenation cycle, developing more selective and durable catalysts, optimizing system components for heat management, and reducing overall system costs to competitive levels. Current research aims to achieve hydrogenation efficiencies above 95% and dehydrogenation efficiencies exceeding 85%.

Market integration objectives focus on establishing standardized interfaces with existing energy infrastructure, developing scalable business models, and creating regulatory frameworks that recognize the unique characteristics of LOHC systems. The technology aims to provide a complementary solution to electrification, particularly in hard-to-abate sectors where direct electrification remains challenging.

The roadmap for LOHC commercialization envisions progressive market penetration, beginning with industrial applications and heavy transport, followed by broader integration into energy markets as hydrogen economies mature globally. The ultimate goal is to position LOHCs as a key enabler of a resilient, flexible, and sustainable global energy system that can effectively harness renewable resources across geographic boundaries.

The evolution of LOHC technology has been marked by progressive improvements in carrier molecules, catalysts, and system integration. Early research focused primarily on cycloalkanes like methylcyclohexane, while recent developments have expanded to include heterocyclic compounds such as N-ethylcarbazole and dibenzyl toluene, offering improved energy density and handling characteristics.

The fundamental principle behind LOHCs involves the reversible hydrogenation and dehydrogenation of organic compounds, enabling hydrogen to be chemically bound and released on demand. This approach allows hydrogen to be handled in liquid form at ambient conditions, leveraging existing liquid fuel infrastructure and significantly reducing storage and transportation costs compared to compressed or liquefied hydrogen.

The primary objective of LOHC technology development is to establish a viable hydrogen vector that can facilitate the integration of renewable energy into existing markets while overcoming the spatial and temporal mismatches between production and consumption. This includes enabling long-distance hydrogen transport, seasonal energy storage, and sector coupling between electricity, industry, and mobility applications.

Technical objectives for commercial LOHC implementation include improving energy efficiency in the hydrogenation/dehydrogenation cycle, developing more selective and durable catalysts, optimizing system components for heat management, and reducing overall system costs to competitive levels. Current research aims to achieve hydrogenation efficiencies above 95% and dehydrogenation efficiencies exceeding 85%.

Market integration objectives focus on establishing standardized interfaces with existing energy infrastructure, developing scalable business models, and creating regulatory frameworks that recognize the unique characteristics of LOHC systems. The technology aims to provide a complementary solution to electrification, particularly in hard-to-abate sectors where direct electrification remains challenging.

The roadmap for LOHC commercialization envisions progressive market penetration, beginning with industrial applications and heavy transport, followed by broader integration into energy markets as hydrogen economies mature globally. The ultimate goal is to position LOHCs as a key enabler of a resilient, flexible, and sustainable global energy system that can effectively harness renewable resources across geographic boundaries.

Energy Market Demand Analysis for LOHC Solutions

The global energy market is witnessing a significant shift towards sustainable and efficient energy storage solutions, creating substantial demand for Liquid Organic Hydrogen Carriers (LOHC) technologies. Current market analysis indicates that hydrogen energy storage market is projected to reach $18.2 billion by 2030, with LOHC solutions expected to capture an increasing share due to their superior volumetric energy density and safety advantages compared to compressed or liquefied hydrogen.

Energy security concerns, particularly in regions with volatile fossil fuel supply chains, have accelerated interest in hydrogen as an energy vector. The European Union's REPowerEU plan explicitly targets 10 million tonnes of domestic renewable hydrogen production by 2030, creating a substantial market opportunity for LOHC integration. Similarly, Japan's hydrogen roadmap and South Korea's hydrogen economy initiatives represent significant potential markets for LOHC technologies.

Industrial sectors present the most immediate demand for LOHC solutions. Heavy industries including steel, cement, and chemical manufacturing collectively account for approximately 20% of global CO2 emissions and represent prime candidates for hydrogen-based decarbonization. Market research indicates that industrial hydrogen demand could increase threefold by 2050, with LOHC systems offering advantages for on-site storage and utilization.

The transportation sector represents another substantial market opportunity. Maritime shipping, which contributes roughly 3% of global greenhouse gas emissions, has shown particular interest in LOHC technologies due to their compatibility with existing fuel infrastructure and higher energy density compared to batteries or compressed hydrogen. Major shipping companies have already begun pilot projects incorporating LOHC technologies for long-distance maritime transport.

Grid-scale energy storage represents a growing market segment as renewable energy penetration increases. The intermittent nature of wind and solar generation creates demand for seasonal storage solutions, where LOHC systems offer advantages over batteries in terms of discharge duration and storage capacity. Utility companies in Germany, Australia, and Japan have initiated demonstration projects utilizing LOHC for grid balancing and renewable energy integration.

Regional analysis reveals varying market readiness. Europe leads in policy support and investment, with Germany's €9 billion hydrogen strategy specifically mentioning LOHC as a key technology. The Asia-Pacific region shows strong demand signals, particularly from Japan, South Korea, and increasingly China, driven by industrial decarbonization goals and limited domestic renewable energy resources. North America presents a growing market opportunity, though policy frameworks remain less developed than in Europe.

Energy security concerns, particularly in regions with volatile fossil fuel supply chains, have accelerated interest in hydrogen as an energy vector. The European Union's REPowerEU plan explicitly targets 10 million tonnes of domestic renewable hydrogen production by 2030, creating a substantial market opportunity for LOHC integration. Similarly, Japan's hydrogen roadmap and South Korea's hydrogen economy initiatives represent significant potential markets for LOHC technologies.

Industrial sectors present the most immediate demand for LOHC solutions. Heavy industries including steel, cement, and chemical manufacturing collectively account for approximately 20% of global CO2 emissions and represent prime candidates for hydrogen-based decarbonization. Market research indicates that industrial hydrogen demand could increase threefold by 2050, with LOHC systems offering advantages for on-site storage and utilization.

The transportation sector represents another substantial market opportunity. Maritime shipping, which contributes roughly 3% of global greenhouse gas emissions, has shown particular interest in LOHC technologies due to their compatibility with existing fuel infrastructure and higher energy density compared to batteries or compressed hydrogen. Major shipping companies have already begun pilot projects incorporating LOHC technologies for long-distance maritime transport.

Grid-scale energy storage represents a growing market segment as renewable energy penetration increases. The intermittent nature of wind and solar generation creates demand for seasonal storage solutions, where LOHC systems offer advantages over batteries in terms of discharge duration and storage capacity. Utility companies in Germany, Australia, and Japan have initiated demonstration projects utilizing LOHC for grid balancing and renewable energy integration.

Regional analysis reveals varying market readiness. Europe leads in policy support and investment, with Germany's €9 billion hydrogen strategy specifically mentioning LOHC as a key technology. The Asia-Pacific region shows strong demand signals, particularly from Japan, South Korea, and increasingly China, driven by industrial decarbonization goals and limited domestic renewable energy resources. North America presents a growing market opportunity, though policy frameworks remain less developed than in Europe.

LOHC Development Status and Technical Barriers

Liquid Organic Hydrogen Carriers (LOHCs) have emerged as a promising technology for hydrogen storage and transportation, yet their commercial integration faces significant technical barriers. Currently, LOHC systems have reached technology readiness levels (TRL) of 6-7, with demonstration projects operational in several countries including Germany, Japan, and Australia. These systems demonstrate the technical feasibility of hydrogen storage densities reaching 5-7 wt%, surpassing compressed hydrogen storage efficiency in many applications.

Despite this progress, several critical technical challenges impede widespread commercial adoption. The dehydrogenation process remains particularly problematic, requiring temperatures of 250-350°C and significant energy input, with current systems consuming 30-40% of the hydrogen's energy content for release. This energy penalty substantially reduces overall system efficiency and economic viability in commercial applications.

Catalyst development represents another significant barrier. Current catalysts for hydrogenation and dehydrogenation processes, primarily based on precious metals like platinum and ruthenium, face issues of high cost, limited durability, and susceptibility to poisoning. Most catalysts demonstrate degradation after 100-200 cycles, falling short of the 1000+ cycles needed for commercial viability.

The thermal management of LOHC systems presents additional challenges. The exothermic hydrogenation process generates heat that must be efficiently captured and utilized, while the endothermic dehydrogenation requires precise heat input. Current heat integration systems achieve only 50-60% efficiency, significantly below the 80%+ needed for commercial applications.

Material compatibility issues further complicate implementation. Many LOHCs exhibit corrosive properties or degradation products that compromise system integrity over time. Current carrier molecules like dibenzyl toluene and methylcyclohexane show degradation rates of 0.1-0.5% per cycle, necessitating regular replacement and increasing operational costs.

Scale-up challenges persist across the LOHC value chain. Laboratory demonstrations have successfully operated at kilogram scale, but megaton-scale operations required for energy market integration reveal unforeseen complications in fluid dynamics, heat transfer, and process control. Current large-scale demonstrations manage hydrogen throughput of only 100-500 kg/day, whereas commercial viability requires capacities of several tons per day.

Regulatory frameworks and standardization remain underdeveloped for LOHC technologies. The absence of established safety protocols, quality standards, and regulatory guidelines creates uncertainty for potential adopters and investors, further hindering commercial integration into existing energy infrastructure.

Despite this progress, several critical technical challenges impede widespread commercial adoption. The dehydrogenation process remains particularly problematic, requiring temperatures of 250-350°C and significant energy input, with current systems consuming 30-40% of the hydrogen's energy content for release. This energy penalty substantially reduces overall system efficiency and economic viability in commercial applications.

Catalyst development represents another significant barrier. Current catalysts for hydrogenation and dehydrogenation processes, primarily based on precious metals like platinum and ruthenium, face issues of high cost, limited durability, and susceptibility to poisoning. Most catalysts demonstrate degradation after 100-200 cycles, falling short of the 1000+ cycles needed for commercial viability.

The thermal management of LOHC systems presents additional challenges. The exothermic hydrogenation process generates heat that must be efficiently captured and utilized, while the endothermic dehydrogenation requires precise heat input. Current heat integration systems achieve only 50-60% efficiency, significantly below the 80%+ needed for commercial applications.

Material compatibility issues further complicate implementation. Many LOHCs exhibit corrosive properties or degradation products that compromise system integrity over time. Current carrier molecules like dibenzyl toluene and methylcyclohexane show degradation rates of 0.1-0.5% per cycle, necessitating regular replacement and increasing operational costs.

Scale-up challenges persist across the LOHC value chain. Laboratory demonstrations have successfully operated at kilogram scale, but megaton-scale operations required for energy market integration reveal unforeseen complications in fluid dynamics, heat transfer, and process control. Current large-scale demonstrations manage hydrogen throughput of only 100-500 kg/day, whereas commercial viability requires capacities of several tons per day.

Regulatory frameworks and standardization remain underdeveloped for LOHC technologies. The absence of established safety protocols, quality standards, and regulatory guidelines creates uncertainty for potential adopters and investors, further hindering commercial integration into existing energy infrastructure.

Current LOHC Commercial Integration Approaches

01 LOHC storage and transportation systems

Liquid Organic Hydrogen Carriers (LOHC) provide an efficient method for hydrogen storage and transportation in commercial settings. These systems involve specialized containers, vessels, and infrastructure designed to safely store hydrogen in its bound form within organic carriers. The technology enables hydrogen to be transported using existing fuel logistics networks, making it more commercially viable for widespread adoption. These systems typically include loading/unloading stations and can be integrated with existing industrial infrastructure.- LOHC storage and transportation systems: Liquid Organic Hydrogen Carriers (LOHC) provide an efficient method for hydrogen storage and transportation in commercial settings. These systems involve specialized containers, vessels, and infrastructure designed to safely store hydrogen in its bound form within organic carriers. The technology enables hydrogen to be transported using existing fuel infrastructure with minimal modifications, making it commercially viable for long-distance transport and distribution networks.

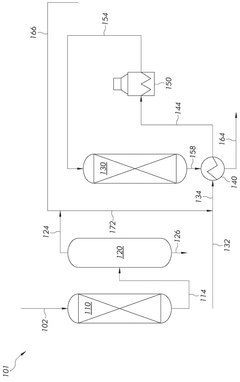

- LOHC dehydrogenation and hydrogenation processes: Commercial integration of LOHC technology relies on efficient dehydrogenation and hydrogenation processes. These catalytic reactions allow for the loading (hydrogenation) and unloading (dehydrogenation) of hydrogen from the carrier molecules. Advanced catalysts and reactor designs have been developed to optimize these processes for commercial-scale operations, improving energy efficiency and reaction rates while maintaining the stability of the carrier molecules through multiple cycles.

- Integration with renewable energy systems: LOHC systems can be integrated with renewable energy sources to create sustainable hydrogen value chains. This integration allows for the conversion of excess renewable electricity into hydrogen through electrolysis, which is then stored in LOHC for later use. Commercial implementations include grid-scale energy storage solutions, power-to-gas facilities, and hybrid energy systems that combine solar, wind, or hydroelectric power with LOHC technology to provide stable energy supply despite the intermittent nature of renewables.

- LOHC applications in transportation and mobility: Commercial applications of LOHC technology in the transportation sector include hydrogen refueling stations, maritime shipping, and heavy-duty vehicles. LOHC systems offer advantages over compressed or liquefied hydrogen for mobility applications due to their higher energy density, safer handling characteristics, and compatibility with existing fuel infrastructure. These systems enable hydrogen to be used as a clean fuel for various transportation modes while addressing range anxiety and refueling challenges.

- Economic and business models for LOHC commercialization: Successful commercial integration of LOHC technology depends on viable economic and business models. These include hydrogen-as-a-service offerings, leasing arrangements for LOHC materials, and integrated supply chain solutions. Cost optimization strategies focus on reducing catalyst costs, improving energy efficiency of dehydrogenation processes, and extending the lifecycle of carrier molecules. Various business models have emerged to address market barriers and create value propositions for different stakeholders in the hydrogen economy.

02 LOHC dehydrogenation and hydrogenation processes

Commercial integration of LOHC technology relies heavily on efficient dehydrogenation and hydrogenation processes. These chemical reactions involve catalysts and specific reaction conditions to either bind hydrogen to the carrier molecule or release it for use. Innovations in catalyst technology have improved reaction efficiency, reduced energy requirements, and enhanced the commercial viability of LOHC systems. These processes are critical for the practical implementation of hydrogen as an energy carrier in various industrial applications.Expand Specific Solutions03 Integration with renewable energy systems

LOHC technology can be integrated with renewable energy systems to create sustainable hydrogen production and utilization pathways. This integration allows for the storage of excess renewable energy as hydrogen, which can later be released when needed. Commercial applications include grid balancing, seasonal energy storage, and providing clean fuel for various industrial processes. The integration helps address intermittency issues associated with renewable energy sources and contributes to decarbonization efforts across multiple sectors.Expand Specific Solutions04 LOHC applications in transportation and mobility

LOHC systems offer practical solutions for hydrogen use in transportation and mobility sectors. The technology enables hydrogen to be safely stored and transported for use in fuel cell vehicles, maritime applications, and aviation. Commercial integration in this sector involves developing refueling infrastructure, onboard storage systems, and efficient hydrogen release mechanisms. These applications help reduce emissions in transportation while leveraging existing fuel distribution networks and infrastructure.Expand Specific Solutions05 Economic and regulatory frameworks for LOHC commercialization

Successful commercial integration of LOHC technology depends on supportive economic and regulatory frameworks. This includes standards for safety, quality, and interoperability, as well as financial incentives and carbon pricing mechanisms. Commercial deployment requires consideration of the entire value chain, from production to end-use, and often involves international cooperation for cross-border hydrogen trade. These frameworks help create market certainty and drive investment in LOHC infrastructure and technology development.Expand Specific Solutions

Key Industry Players in LOHC Development

The LOHC (Liquid Organic Hydrogen Carrier) integration market is currently in its early commercialization phase, transitioning from research to practical applications. The global market is projected to grow significantly as hydrogen becomes central to clean energy strategies, though exact market size remains limited by early adoption. Technologically, academic institutions like North China Electric Power University and Xi'an Jiaotong University are advancing fundamental research, while commercial players demonstrate varying maturity levels. Hydrogenious LOHC Technologies has emerged as a market leader with operational systems, while major energy corporations like State Grid Corp. of China and Hitachi are investing in pilot projects. Research collaborations between universities and energy companies are accelerating technological readiness, though widespread commercial deployment remains 3-5 years away.

Claire Technologies Corp.

Technical Solution: Claire Technologies has developed a novel LOHC system based on proprietary heterocyclic compounds that achieve hydrogen storage densities of up to 7 wt%, exceeding many conventional LOHC carriers. Their technology employs a dual-catalyst approach that enables both hydrogenation and dehydrogenation processes to occur at lower temperatures and pressures than competing systems. The company's commercial roadmap focuses on modular, scalable units ranging from 25 kg/day to 1 ton/day of hydrogen handling capacity, targeting distributed energy storage applications. Claire's system integrates thermal management solutions that recover and repurpose waste heat from industrial processes to drive the dehydrogenation reaction, significantly improving overall system efficiency. Their technology has been demonstrated in pilot projects with several energy companies, showing stable performance over 500+ hydrogenation/dehydrogenation cycles without significant carrier degradation. The company plans commercial deployment beginning with industrial hydrogen users in 2024, followed by grid-scale energy storage applications by 2026.

Strengths: Higher hydrogen storage density than many competing LOHC systems; improved energy efficiency through innovative heat integration; modular design enabling flexible deployment scales; demonstrated long-term cycling stability. Weaknesses: Proprietary carrier compounds may have higher production costs than commodity chemicals used in other LOHC systems; limited large-scale demonstration history; requires specialized handling procedures for the carrier material.

Hydrogenious Lohc Technologies GmbH

Technical Solution: Hydrogenious LOHC Technologies has developed a proprietary Liquid Organic Hydrogen Carrier (LOHC) system based on benzyltoluene as the carrier medium. Their technology enables hydrogen to be chemically bound to the liquid carrier at 25 bar pressure and moderate temperatures (150-200°C), storing hydrogen at high density without requiring cryogenic or high-pressure conditions. The company's StorageBOX and ReleaseBOX systems handle the hydrogenation and dehydrogenation processes respectively, with capacities ranging from 5 to 1,000+ kg of hydrogen per day. Their commercial roadmap includes scaling up from current pilot projects to industrial-scale applications by 2025, with plans for integration into existing fuel infrastructure networks. The technology has been demonstrated in several European projects including HySTOC and TransHyDE, showing the feasibility of LOHC in real-world energy market applications.

Strengths: Uses existing liquid fuel infrastructure; operates at ambient conditions; offers high volumetric energy density; provides inherent safety advantages due to non-explosive nature of the carrier. Weaknesses: Energy-intensive dehydrogenation process requiring significant heat input; catalyst degradation over multiple cycles; higher system complexity compared to compressed hydrogen solutions.

Critical Patents and Innovations in LOHC Technology

Methods for processing liquid organic hydrogen carriers

PatentWO2025111255A1

Innovation

- The use of liquid organic hydrogen carriers (LOHCs) that can store and transport hydrogen through chemical processes, integrated with naphtha hydrotreating in a refinery, where the additional hydrogen portion is first used to charge LOHCs upstream of its use in hydrotreating naphtha, allowing for synergistic effects and efficient hydrogen management.

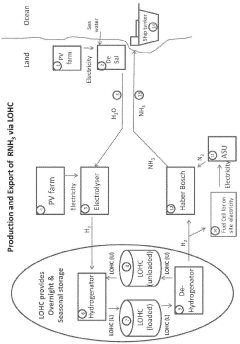

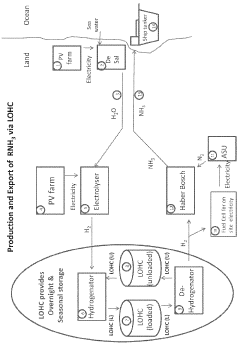

Facilitating renewable ammonia production and export via LOHC

PatentInactiveAU2015100655A4

Innovation

- A Liquid Organic Hydrogen Carrier (LOHC) storage system is used to store intermittent renewable hydrogen, converting it into a steady stream for ammonia production, utilizing hydrogenation and dehydrogenation units to maintain hydrogen in a liquid state at ambient conditions, enabling efficient storage and release for Haber Bosch processes, and powering nitrogen generation and other plant components.

Regulatory Framework for LOHC Implementation

The regulatory landscape for Liquid Organic Hydrogen Carriers (LOHC) remains in nascent stages across most global markets, presenting both challenges and opportunities for commercial integration. Current regulatory frameworks primarily address hydrogen as a broader category, with limited specific provisions for LOHC technologies. This regulatory gap necessitates urgent attention as LOHC systems approach commercial readiness.

Safety standards represent the most developed regulatory area, with organizations like ISO and CEN working on hydrogen handling protocols that can be adapted for LOHC applications. These standards address critical aspects including storage parameters, transportation requirements, and handling procedures. However, significant gaps exist regarding the specific chemical properties and operational characteristics unique to various LOHC compounds.

Cross-border transportation regulations present particular complexity for LOHC implementation. While conventional fuel transport regulations provide some foundation, the novel characteristics of hydrogen-loaded carriers require specialized classification and handling protocols. The International Maritime Organization has begun developing guidelines for hydrogen transport that may eventually incorporate LOHC-specific provisions.

Permitting processes for LOHC infrastructure currently follow general industrial chemical facility frameworks, creating inefficiencies and potential barriers to rapid deployment. Several jurisdictions, notably Germany and Japan, have initiated LOHC-specific permitting pathways that could serve as models for broader regulatory harmonization.

Tax incentives and subsidies remain inconsistent across markets, with hydrogen production incentives not always explicitly extending to LOHC technologies. Progressive policy frameworks in the EU, through initiatives like the European Hydrogen Strategy, are beginning to recognize storage and transport solutions as essential components of the hydrogen value chain, potentially opening pathways for LOHC-specific support mechanisms.

Certification systems for hydrogen "color" classification (green, blue, etc.) must evolve to properly account for the energy requirements and carbon footprint of LOHC loading/unloading processes. This represents a critical regulatory development needed to ensure LOHC systems can participate effectively in emerging clean hydrogen markets and carbon accounting frameworks.

Successful commercial integration will require coordinated regulatory development across multiple jurisdictions, with particular focus on establishing international standards for LOHC compounds, harmonizing transport regulations, and creating certification frameworks that properly account for the unique characteristics of these hydrogen carrier systems.

Safety standards represent the most developed regulatory area, with organizations like ISO and CEN working on hydrogen handling protocols that can be adapted for LOHC applications. These standards address critical aspects including storage parameters, transportation requirements, and handling procedures. However, significant gaps exist regarding the specific chemical properties and operational characteristics unique to various LOHC compounds.

Cross-border transportation regulations present particular complexity for LOHC implementation. While conventional fuel transport regulations provide some foundation, the novel characteristics of hydrogen-loaded carriers require specialized classification and handling protocols. The International Maritime Organization has begun developing guidelines for hydrogen transport that may eventually incorporate LOHC-specific provisions.

Permitting processes for LOHC infrastructure currently follow general industrial chemical facility frameworks, creating inefficiencies and potential barriers to rapid deployment. Several jurisdictions, notably Germany and Japan, have initiated LOHC-specific permitting pathways that could serve as models for broader regulatory harmonization.

Tax incentives and subsidies remain inconsistent across markets, with hydrogen production incentives not always explicitly extending to LOHC technologies. Progressive policy frameworks in the EU, through initiatives like the European Hydrogen Strategy, are beginning to recognize storage and transport solutions as essential components of the hydrogen value chain, potentially opening pathways for LOHC-specific support mechanisms.

Certification systems for hydrogen "color" classification (green, blue, etc.) must evolve to properly account for the energy requirements and carbon footprint of LOHC loading/unloading processes. This represents a critical regulatory development needed to ensure LOHC systems can participate effectively in emerging clean hydrogen markets and carbon accounting frameworks.

Successful commercial integration will require coordinated regulatory development across multiple jurisdictions, with particular focus on establishing international standards for LOHC compounds, harmonizing transport regulations, and creating certification frameworks that properly account for the unique characteristics of these hydrogen carrier systems.

Economic Viability and Cost Analysis

The economic viability of Liquid Organic Hydrogen Carriers (LOHC) integration into energy markets hinges on several critical cost factors. Current LOHC systems face significant economic challenges with estimated levelized costs ranging from $4-7 per kilogram of hydrogen, substantially higher than conventional fossil fuel alternatives. This cost differential represents a major barrier to widespread commercial adoption despite the technical advantages of LOHC technology.

Production costs constitute approximately 40-50% of the total LOHC system economics, encompassing catalyst expenses, carrier molecule synthesis, and manufacturing infrastructure. The hydrogenation and dehydrogenation processes require precious metal catalysts that significantly impact overall system costs. Recent innovations in catalyst design have demonstrated potential cost reductions of 15-20%, though further improvements remain necessary for commercial viability.

Transportation and storage economics represent a comparative advantage for LOHC systems. Unlike compressed or liquefied hydrogen, LOHC technology leverages existing liquid fuel infrastructure, potentially reducing distribution costs by 30-40% compared to alternative hydrogen carriers. This infrastructure compatibility provides a pathway to gradual market integration without requiring massive capital investments in specialized distribution networks.

Lifecycle economic analysis reveals that carrier molecule durability significantly impacts long-term costs. Current LOHC molecules demonstrate degradation rates of 0.1-0.5% per cycle, necessitating periodic replenishment. Extending carrier lifecycle from the current average of 100-200 cycles to 500+ cycles could reduce operational costs by up to 25%, representing a critical path toward economic competitiveness.

Scale economies present another crucial factor for LOHC commercialization. Economic modeling indicates that LOHC systems require production scales exceeding 50 tons of hydrogen per day to achieve cost parity with conventional energy carriers. This threshold highlights the importance of strategic deployment in high-volume applications such as industrial clusters or transportation hubs where sufficient demand density exists.

Market incentives and carbon pricing mechanisms will likely play a decisive role in LOHC economic viability during early commercialization phases. Analysis suggests that carbon prices exceeding $75-100 per ton would create sufficient economic incentives to bridge the current cost gap between LOHC systems and fossil alternatives, particularly in regions with aggressive decarbonization targets and supportive policy frameworks.

Production costs constitute approximately 40-50% of the total LOHC system economics, encompassing catalyst expenses, carrier molecule synthesis, and manufacturing infrastructure. The hydrogenation and dehydrogenation processes require precious metal catalysts that significantly impact overall system costs. Recent innovations in catalyst design have demonstrated potential cost reductions of 15-20%, though further improvements remain necessary for commercial viability.

Transportation and storage economics represent a comparative advantage for LOHC systems. Unlike compressed or liquefied hydrogen, LOHC technology leverages existing liquid fuel infrastructure, potentially reducing distribution costs by 30-40% compared to alternative hydrogen carriers. This infrastructure compatibility provides a pathway to gradual market integration without requiring massive capital investments in specialized distribution networks.

Lifecycle economic analysis reveals that carrier molecule durability significantly impacts long-term costs. Current LOHC molecules demonstrate degradation rates of 0.1-0.5% per cycle, necessitating periodic replenishment. Extending carrier lifecycle from the current average of 100-200 cycles to 500+ cycles could reduce operational costs by up to 25%, representing a critical path toward economic competitiveness.

Scale economies present another crucial factor for LOHC commercialization. Economic modeling indicates that LOHC systems require production scales exceeding 50 tons of hydrogen per day to achieve cost parity with conventional energy carriers. This threshold highlights the importance of strategic deployment in high-volume applications such as industrial clusters or transportation hubs where sufficient demand density exists.

Market incentives and carbon pricing mechanisms will likely play a decisive role in LOHC economic viability during early commercialization phases. Analysis suggests that carbon prices exceeding $75-100 per ton would create sufficient economic incentives to bridge the current cost gap between LOHC systems and fossil alternatives, particularly in regions with aggressive decarbonization targets and supportive policy frameworks.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!