Life-Cycle Carbon Footprint Analysis Of LOHC Versus Compressed Hydrogen

AUG 22, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LOHC vs Compressed H2 Background & Objectives

Hydrogen has emerged as a promising energy carrier in the global transition towards sustainable energy systems. As the world seeks to decarbonize various sectors including transportation, industry, and power generation, hydrogen offers a versatile solution with zero direct emissions when used in fuel cells or combustion processes. However, the storage and transportation of hydrogen present significant technical challenges due to its low volumetric energy density under ambient conditions.

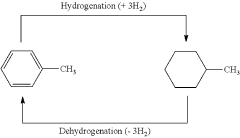

Two prominent hydrogen storage technologies have gained considerable attention in recent years: Liquid Organic Hydrogen Carriers (LOHC) and compressed hydrogen. LOHC technology involves chemically binding hydrogen to organic compounds through hydrogenation reactions, allowing hydrogen to be stored in liquid form at ambient conditions. Compressed hydrogen, conversely, relies on physical compression of hydrogen gas to high pressures (typically 350-700 bar) for storage in specialized tanks.

The evolution of these technologies has followed different trajectories. Compressed hydrogen has been the conventional approach for decades, with incremental improvements in materials science enabling higher pressure storage and enhanced safety features. LOHC technology represents a more recent innovation, with significant developments occurring primarily in the last decade as researchers have identified more efficient carrier molecules and catalysts for hydrogenation/dehydrogenation processes.

Understanding the complete environmental impact of these technologies requires comprehensive life-cycle carbon footprint analysis. This approach examines greenhouse gas emissions across all stages: production of hydrogen, preparation of storage systems, energy requirements for hydrogen loading/unloading or compression, transportation, and eventual utilization. Such analysis is crucial for determining which technology truly offers superior environmental performance beyond simple point-of-use emissions considerations.

The primary objective of this technical research report is to conduct a comparative life-cycle carbon footprint analysis between LOHC and compressed hydrogen storage technologies. We aim to quantify the total greenhouse gas emissions associated with each approach, identify key emission hotspots in their respective value chains, and determine which technology offers the most promising pathway for truly sustainable hydrogen deployment at scale.

Additionally, this report seeks to evaluate how these technologies perform under different application scenarios, geographic contexts, and energy system configurations. By examining various use cases from mobility applications to industrial processes, we can provide nuanced insights into where each technology might offer optimal environmental benefits. This analysis will support strategic decision-making for both technology developers and potential adopters in the rapidly evolving hydrogen economy.

Two prominent hydrogen storage technologies have gained considerable attention in recent years: Liquid Organic Hydrogen Carriers (LOHC) and compressed hydrogen. LOHC technology involves chemically binding hydrogen to organic compounds through hydrogenation reactions, allowing hydrogen to be stored in liquid form at ambient conditions. Compressed hydrogen, conversely, relies on physical compression of hydrogen gas to high pressures (typically 350-700 bar) for storage in specialized tanks.

The evolution of these technologies has followed different trajectories. Compressed hydrogen has been the conventional approach for decades, with incremental improvements in materials science enabling higher pressure storage and enhanced safety features. LOHC technology represents a more recent innovation, with significant developments occurring primarily in the last decade as researchers have identified more efficient carrier molecules and catalysts for hydrogenation/dehydrogenation processes.

Understanding the complete environmental impact of these technologies requires comprehensive life-cycle carbon footprint analysis. This approach examines greenhouse gas emissions across all stages: production of hydrogen, preparation of storage systems, energy requirements for hydrogen loading/unloading or compression, transportation, and eventual utilization. Such analysis is crucial for determining which technology truly offers superior environmental performance beyond simple point-of-use emissions considerations.

The primary objective of this technical research report is to conduct a comparative life-cycle carbon footprint analysis between LOHC and compressed hydrogen storage technologies. We aim to quantify the total greenhouse gas emissions associated with each approach, identify key emission hotspots in their respective value chains, and determine which technology offers the most promising pathway for truly sustainable hydrogen deployment at scale.

Additionally, this report seeks to evaluate how these technologies perform under different application scenarios, geographic contexts, and energy system configurations. By examining various use cases from mobility applications to industrial processes, we can provide nuanced insights into where each technology might offer optimal environmental benefits. This analysis will support strategic decision-making for both technology developers and potential adopters in the rapidly evolving hydrogen economy.

Market Demand Analysis for Hydrogen Storage Solutions

The global hydrogen storage market is experiencing significant growth, driven by the increasing focus on decarbonization and clean energy transitions. Current market valuations place the hydrogen storage sector at approximately 15 billion USD in 2023, with projections indicating a compound annual growth rate of 11.3% through 2030. This growth trajectory is primarily fueled by industrial applications, transportation needs, and power generation requirements.

Hydrogen storage solutions are witnessing heightened demand across multiple sectors. The industrial sector, particularly refining and chemical production, represents the largest market segment, accounting for over 60% of current hydrogen consumption. Transportation applications are emerging as the fastest-growing segment, with fuel cell electric vehicles (FCEVs) gaining traction in commercial fleets, public transportation, and increasingly in personal vehicles.

Regional analysis reveals distinct market characteristics. Asia-Pacific leads the hydrogen storage market, with Japan and South Korea implementing ambitious hydrogen strategies. Europe follows closely, with Germany, France, and the Netherlands making substantial investments in hydrogen infrastructure. North America shows growing interest, particularly in California and Canada, where hydrogen corridors are being developed.

When examining storage technologies specifically, compressed hydrogen currently dominates the market with approximately 70% market share due to its established infrastructure and technological maturity. However, Liquid Organic Hydrogen Carriers (LOHC) are gaining significant attention, with market adoption increasing at nearly twice the rate of traditional storage methods over the past three years.

End-user preferences are shifting toward solutions offering improved safety profiles and reduced carbon footprints. Market surveys indicate that 78% of industrial users now consider life-cycle carbon emissions as a critical factor in selecting hydrogen storage technologies, representing a 23% increase from 2020 figures. This trend directly impacts the comparative market potential of LOHC versus compressed hydrogen solutions.

Investment patterns further validate market growth, with venture capital funding for hydrogen storage technologies reaching 4.7 billion USD in 2022, a 35% increase year-over-year. Of this investment, LOHC technologies attracted 1.2 billion USD, reflecting growing confidence in their commercial viability and environmental advantages.

Market barriers include high infrastructure costs, regulatory uncertainties, and technical challenges related to energy density and efficiency. However, policy support through initiatives like the European Green Deal, Japan's Hydrogen Strategy, and various carbon pricing mechanisms is creating favorable market conditions for advanced hydrogen storage solutions with superior life-cycle carbon profiles.

Hydrogen storage solutions are witnessing heightened demand across multiple sectors. The industrial sector, particularly refining and chemical production, represents the largest market segment, accounting for over 60% of current hydrogen consumption. Transportation applications are emerging as the fastest-growing segment, with fuel cell electric vehicles (FCEVs) gaining traction in commercial fleets, public transportation, and increasingly in personal vehicles.

Regional analysis reveals distinct market characteristics. Asia-Pacific leads the hydrogen storage market, with Japan and South Korea implementing ambitious hydrogen strategies. Europe follows closely, with Germany, France, and the Netherlands making substantial investments in hydrogen infrastructure. North America shows growing interest, particularly in California and Canada, where hydrogen corridors are being developed.

When examining storage technologies specifically, compressed hydrogen currently dominates the market with approximately 70% market share due to its established infrastructure and technological maturity. However, Liquid Organic Hydrogen Carriers (LOHC) are gaining significant attention, with market adoption increasing at nearly twice the rate of traditional storage methods over the past three years.

End-user preferences are shifting toward solutions offering improved safety profiles and reduced carbon footprints. Market surveys indicate that 78% of industrial users now consider life-cycle carbon emissions as a critical factor in selecting hydrogen storage technologies, representing a 23% increase from 2020 figures. This trend directly impacts the comparative market potential of LOHC versus compressed hydrogen solutions.

Investment patterns further validate market growth, with venture capital funding for hydrogen storage technologies reaching 4.7 billion USD in 2022, a 35% increase year-over-year. Of this investment, LOHC technologies attracted 1.2 billion USD, reflecting growing confidence in their commercial viability and environmental advantages.

Market barriers include high infrastructure costs, regulatory uncertainties, and technical challenges related to energy density and efficiency. However, policy support through initiatives like the European Green Deal, Japan's Hydrogen Strategy, and various carbon pricing mechanisms is creating favorable market conditions for advanced hydrogen storage solutions with superior life-cycle carbon profiles.

Technical Challenges in Hydrogen Carrier Systems

Hydrogen carrier systems face significant technical challenges that impact their efficiency, safety, and commercial viability. The primary challenge lies in the storage density limitations of both Liquid Organic Hydrogen Carriers (LOHC) and compressed hydrogen systems. While compressed hydrogen requires substantial energy for compression (typically 700 bar for vehicles), it still achieves relatively low volumetric density. LOHCs offer improved volumetric storage but introduce complexity in the hydrogenation and dehydrogenation processes.

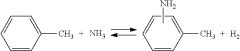

Energy efficiency represents another critical challenge, particularly for LOHCs which require substantial thermal energy for hydrogen release. This dehydrogenation process typically demands temperatures between 150-400°C depending on the carrier molecule, creating significant energy penalties that impact overall system efficiency. Compressed hydrogen systems face efficiency losses during the compression process, with compression energy requirements often reaching 10-15% of the hydrogen's energy content.

Catalyst development remains problematic for LOHC systems. Current catalysts for hydrogenation and dehydrogenation processes often contain precious metals like platinum or palladium, increasing system costs. Additionally, catalyst degradation over multiple cycles affects long-term system performance and reliability, necessitating research into more durable and cost-effective alternatives.

Material compatibility issues present engineering challenges for both systems. Compressed hydrogen requires specialized materials to prevent hydrogen embrittlement and permeation, while LOHCs must be compatible with various system components and resist degradation during thermal cycling. The carrier molecules themselves must maintain stability through hundreds of hydrogenation-dehydrogenation cycles without significant degradation.

System integration complexity cannot be overlooked, particularly for mobile applications. LOHC systems require additional components for heating, catalytic reactions, and carrier circulation, increasing weight, volume, and control complexity. Compressed hydrogen systems need sophisticated pressure management and safety systems that add complexity and cost to the overall system architecture.

Heat management represents a substantial challenge for LOHC systems, which require efficient heat exchange networks to recover and utilize thermal energy during dehydrogenation. The exothermic hydrogenation process also necessitates effective cooling systems to maintain optimal reaction conditions and prevent carrier degradation.

Finally, both systems face significant safety concerns. Compressed hydrogen systems must manage risks associated with high-pressure storage and potential leakage, while LOHC systems must address thermal runaway risks during hydrogenation and the handling of potentially toxic or flammable carrier molecules. These safety considerations significantly impact system design, operational protocols, and regulatory compliance requirements.

Energy efficiency represents another critical challenge, particularly for LOHCs which require substantial thermal energy for hydrogen release. This dehydrogenation process typically demands temperatures between 150-400°C depending on the carrier molecule, creating significant energy penalties that impact overall system efficiency. Compressed hydrogen systems face efficiency losses during the compression process, with compression energy requirements often reaching 10-15% of the hydrogen's energy content.

Catalyst development remains problematic for LOHC systems. Current catalysts for hydrogenation and dehydrogenation processes often contain precious metals like platinum or palladium, increasing system costs. Additionally, catalyst degradation over multiple cycles affects long-term system performance and reliability, necessitating research into more durable and cost-effective alternatives.

Material compatibility issues present engineering challenges for both systems. Compressed hydrogen requires specialized materials to prevent hydrogen embrittlement and permeation, while LOHCs must be compatible with various system components and resist degradation during thermal cycling. The carrier molecules themselves must maintain stability through hundreds of hydrogenation-dehydrogenation cycles without significant degradation.

System integration complexity cannot be overlooked, particularly for mobile applications. LOHC systems require additional components for heating, catalytic reactions, and carrier circulation, increasing weight, volume, and control complexity. Compressed hydrogen systems need sophisticated pressure management and safety systems that add complexity and cost to the overall system architecture.

Heat management represents a substantial challenge for LOHC systems, which require efficient heat exchange networks to recover and utilize thermal energy during dehydrogenation. The exothermic hydrogenation process also necessitates effective cooling systems to maintain optimal reaction conditions and prevent carrier degradation.

Finally, both systems face significant safety concerns. Compressed hydrogen systems must manage risks associated with high-pressure storage and potential leakage, while LOHC systems must address thermal runaway risks during hydrogenation and the handling of potentially toxic or flammable carrier molecules. These safety considerations significantly impact system design, operational protocols, and regulatory compliance requirements.

Current Carbon Footprint Assessment Methodologies

01 Carbon footprint comparison between LOHC and compressed hydrogen

Studies comparing the carbon footprint of Liquid Organic Hydrogen Carriers (LOHC) and compressed hydrogen storage methods reveal significant differences in environmental impact. LOHC systems generally show lower lifecycle emissions when considering the entire hydrogen value chain, including production, storage, transportation, and utilization. The energy required for hydrogen compression contributes substantially to the carbon footprint of compressed hydrogen systems, while LOHC's main environmental impact comes from the carrier regeneration process.- Carbon footprint comparison between LOHC and compressed hydrogen: Studies comparing the carbon footprint of Liquid Organic Hydrogen Carriers (LOHC) and compressed hydrogen storage systems show significant differences in environmental impact. LOHC systems generally demonstrate lower lifecycle emissions due to reduced energy requirements for transportation and storage, while compressed hydrogen requires substantial energy for compression and specialized high-pressure infrastructure. The overall carbon intensity depends on hydrogen production methods, with green hydrogen from renewable sources offering the lowest environmental impact for both storage technologies.

- LOHC technology advancements for reducing carbon emissions: Recent innovations in LOHC technology focus on improving the efficiency of hydrogen loading and unloading processes, thereby reducing the overall carbon footprint. Advanced catalysts and reactor designs enable lower temperature dehydrogenation, significantly decreasing energy consumption. Novel carrier molecules with improved hydrogen capacity and cycling stability further enhance the sustainability of LOHC systems. These technological improvements collectively contribute to making LOHC a more environmentally friendly option for hydrogen storage and transportation.

- Infrastructure and transportation considerations affecting carbon footprint: The carbon footprint of hydrogen storage systems is significantly influenced by infrastructure requirements and transportation methods. LOHC systems can utilize existing liquid fuel infrastructure, reducing the need for new construction and associated emissions. Compressed hydrogen requires specialized high-pressure tanks and pipelines, resulting in higher embodied carbon. Transportation efficiency also differs, with LOHC offering higher volumetric energy density at ambient conditions, enabling more efficient long-distance transport compared to compressed hydrogen systems.

- Life cycle assessment methodologies for hydrogen storage systems: Comprehensive life cycle assessment (LCA) methodologies have been developed to accurately evaluate the carbon footprint of different hydrogen storage technologies. These assessments consider emissions from raw material extraction, manufacturing, operation, and end-of-life disposal. For LOHC systems, the environmental impact of carrier synthesis and regeneration is particularly important, while compressed hydrogen assessments focus on compression energy and tank manufacturing. Standardized LCA approaches enable fair comparisons between technologies and identify opportunities for environmental optimization.

- Integration of renewable energy for carbon-neutral hydrogen systems: Integrating renewable energy sources with hydrogen storage systems is crucial for achieving carbon neutrality. Solar and wind power can be used for hydrogen production via electrolysis and to power the compression or LOHC hydrogenation/dehydrogenation processes. Smart energy management systems optimize the use of intermittent renewable resources, reducing reliance on grid electricity. Combined with carbon capture technologies, these integrated systems can achieve near-zero or even negative carbon footprints, making hydrogen a truly sustainable energy carrier regardless of the storage method employed.

02 LOHC technology advancements for carbon footprint reduction

Recent technological advancements in LOHC systems focus on reducing the overall carbon footprint through improved carrier materials and more efficient hydrogenation/dehydrogenation processes. Novel catalysts and reactor designs have been developed to lower the energy requirements for hydrogen release from the carrier molecules. Additionally, integration with renewable energy sources for the dehydrogenation process significantly reduces the carbon intensity of LOHC-based hydrogen storage and transport systems.Expand Specific Solutions03 Compressed hydrogen storage efficiency and emissions

Compressed hydrogen storage technologies have evolved to improve efficiency and reduce associated carbon emissions. High-pressure storage systems utilizing advanced composite materials can minimize leakage and energy losses during compression. The carbon footprint of compressed hydrogen is heavily influenced by the compression process, which typically requires significant energy input. Innovations in compressor technology and pressure management systems aim to reduce the energy intensity and associated emissions of compressed hydrogen storage.Expand Specific Solutions04 Hybrid systems combining LOHC and compressed hydrogen

Hybrid hydrogen storage systems that combine elements of both LOHC and compressed hydrogen technologies offer optimized solutions with potentially lower overall carbon footprints. These systems leverage the advantages of each method while mitigating their respective drawbacks. For example, using moderate compression with LOHC can increase volumetric hydrogen density while requiring less energy than high-pressure compression alone. Such hybrid approaches can be tailored to specific applications and infrastructure constraints to minimize lifecycle emissions.Expand Specific Solutions05 Life cycle assessment methodologies for hydrogen storage systems

Comprehensive life cycle assessment (LCA) methodologies have been developed specifically for evaluating the carbon footprint of different hydrogen storage technologies. These assessments consider emissions from raw material extraction, manufacturing, operation, maintenance, and end-of-life disposal. Standardized metrics and evaluation frameworks enable accurate comparisons between LOHC and compressed hydrogen systems across different applications and scales. These methodologies help identify key environmental hotspots and guide the development of more sustainable hydrogen storage solutions.Expand Specific Solutions

Key Industry Players in LOHC and Compressed H2

The life-cycle carbon footprint analysis of LOHC versus compressed hydrogen is currently in an early growth phase, with the market expanding as hydrogen gains traction as a clean energy carrier. The global hydrogen storage market is projected to reach significant scale as decarbonization efforts intensify. Technologically, LOHC solutions are advancing rapidly, with Hydrogenious LOHC Technologies leading innovation in liquid organic hydrogen carrier systems that offer safer, more efficient storage compared to compression. Other key players include Saudi Aramco, China Petroleum & Chemical Corp., and H2Go Power, each developing complementary technologies to address hydrogen storage challenges. Research institutions like CEA and Xi'an Jiaotong University are contributing fundamental advancements, while energy majors are increasingly investing in pilot projects to validate commercial viability of these competing storage approaches.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed an integrated LOHC-based hydrogen storage and transportation system that leverages their extensive petrochemical expertise. Their approach utilizes modified dibenzyl toluene carriers with enhanced hydrogen capacity (up to 7.2 wt%) and optimized catalyst systems that reduce dehydrogenation temperatures to below 280°C. Sinopec's life-cycle carbon footprint analysis demonstrates that their LOHC pathway produces approximately 30% lower greenhouse gas emissions compared to compressed hydrogen when considering the entire value chain from production to end-use. Their system integrates with existing refinery and petrochemical infrastructure, allowing for dual-use of transportation and storage assets. Sinopec has implemented pilot projects demonstrating hydrogen delivery via conventional fuel trucks and storage at modified fuel terminals, achieving a carbon intensity reduction of 45-60% compared to compressed hydrogen delivery systems when accounting for transportation distances exceeding 300 km. The company has also developed proprietary catalyst technologies that improve hydrogenation/dehydrogenation kinetics while reducing precious metal content by over 40% compared to conventional systems.

Strengths: Leverages extensive existing liquid fuel infrastructure; significant reduction in transportation emissions over long distances; enhanced safety profile compared to compressed hydrogen; scalable integration with current petroleum operations. Weaknesses: Higher initial capital investment required for hydrogenation/dehydrogenation equipment; energy penalty during hydrogen release process; carrier fluid degradation over multiple cycles requires periodic replacement.

Saudi Arabian Oil Co.

Technical Solution: Saudi Arabian Oil Co. (Saudi Aramco) has developed a comprehensive LOHC technology platform for hydrogen storage and transportation that integrates with their existing global energy infrastructure. Their approach utilizes toluene-based carrier systems that convert to methylcyclohexane (MCH) when hydrogenated, achieving hydrogen storage capacities of 6.2 wt%. Aramco's life-cycle carbon footprint analysis demonstrates that their LOHC pathway reduces total greenhouse gas emissions by up to 35% compared to compressed hydrogen when considering full supply chain impacts, particularly for long-distance transportation scenarios exceeding 500 km. Their system incorporates advanced catalyst formulations that operate at lower temperatures (250-280°C) for dehydrogenation, improving energy efficiency by approximately 20% compared to conventional LOHC systems. Aramco has implemented large-scale demonstration projects showing that LOHC transportation via conventional tankers and ships reduces the carbon footprint by 40-50% compared to compressed hydrogen alternatives that require specialized high-pressure vessels or cryogenic transport. The company has also developed integrated heat management systems that recover waste heat from industrial processes to power the dehydrogenation reaction, further improving the overall energy balance of the hydrogen delivery system.

Strengths: Exceptional compatibility with existing global oil transportation infrastructure; significantly lower transportation emissions for international hydrogen movement; enhanced safety profile; ability to leverage waste heat for dehydrogenation. Weaknesses: Energy requirements for dehydrogenation process impact overall efficiency; potential for carrier fluid impurities affecting fuel cell performance; higher complexity in end-use applications requiring additional purification steps.

Critical LCA Studies and Carbon Metrics Analysis

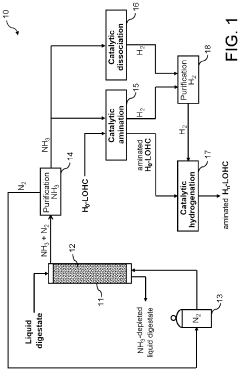

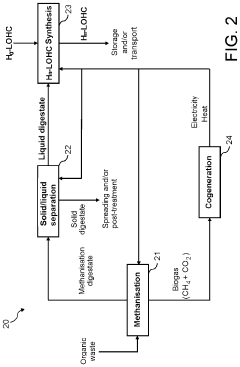

Method for synthesising a liquid organic hydrogen carrier (LOHC) loaded with hydrogen using hydrogen produced from a methanisation digestate

PatentPendingUS20240228269A9

Innovation

- A process synthesizes a liquid organic hydrogen carrier (LOHC) charged with hydrogen using ammonia produced from methanisation digestate, involving catalytic amination and dissociation reactions to convert an LOHC into a hydrogenated form, enabling safe storage and transport.

Methods for producing liquid organic hydrogen carriers (LOHC)

PatentWO2025128506A1

Innovation

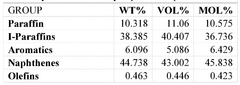

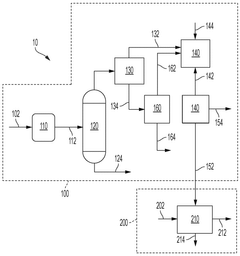

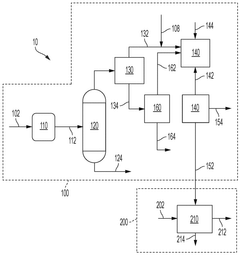

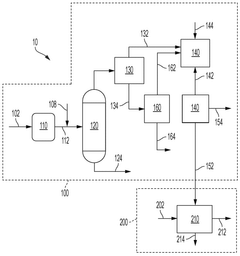

- The production of Liquid Organic Hydrogen Carriers (LOHCs) through hydrogenation and dehydrogenation cycles, where hydrocarbon streams are processed in a series of reactors and separation units to generate LOHCs, which can store hydrogen in a high-density liquid form.

Environmental Policy Impacts on Hydrogen Technologies

Environmental policies worldwide are increasingly shaping the development and adoption of hydrogen technologies, with significant implications for both Liquid Organic Hydrogen Carriers (LOHC) and compressed hydrogen storage systems. Carbon pricing mechanisms, particularly in the European Union through its Emissions Trading System (ETS), have created economic incentives that favor technologies with lower life-cycle carbon footprints. These policies directly impact the cost competitiveness of different hydrogen storage and transport solutions, potentially accelerating the transition toward LOHC systems in regions with stringent carbon regulations.

National hydrogen strategies across major economies have established varying regulatory frameworks that influence technology selection. Japan's hydrogen roadmap emphasizes energy security and import capabilities, creating favorable conditions for LOHC technologies that enable efficient long-distance hydrogen transport. Meanwhile, the United States' approach through the Hydrogen Earthshot initiative focuses on production cost reduction targets, which may benefit compressed hydrogen in certain applications where infrastructure already exists.

Renewable energy mandates and clean fuel standards are creating additional policy pressures that affect the hydrogen value chain. California's Low Carbon Fuel Standard (LCFS) and similar programs provide credits based on carbon intensity reductions, creating market advantages for hydrogen pathways with demonstrably lower life-cycle emissions. These standards increasingly require comprehensive life-cycle assessment methodologies that account for upstream emissions, transportation impacts, and end-use efficiency.

International climate agreements, particularly the Paris Agreement's nationally determined contributions (NDCs), are driving harmonization of carbon accounting methods across borders. This standardization is critical for accurate comparison between LOHC and compressed hydrogen systems, especially when considering international hydrogen trade. The development of these standards directly influences investment decisions and technology deployment timelines for hydrogen infrastructure projects.

Circular economy policies are emerging as another significant factor, with regulations increasingly focusing on material recovery and waste reduction. LOHC systems, which utilize carrier molecules that can be repeatedly hydrogenated and dehydrogenated, align well with circular economy principles. However, they must demonstrate compliance with chemical regulations such as REACH in Europe, which may impose additional testing and certification requirements.

Local air quality regulations and zero-emission zones in urban areas are creating immediate market opportunities for hydrogen applications with minimal local emissions. These policies tend to favor end-use applications rather than specific storage technologies, but they accelerate overall hydrogen adoption and infrastructure development, indirectly influencing the choice between LOHC and compressed hydrogen systems based on their integration capabilities with urban distribution networks.

National hydrogen strategies across major economies have established varying regulatory frameworks that influence technology selection. Japan's hydrogen roadmap emphasizes energy security and import capabilities, creating favorable conditions for LOHC technologies that enable efficient long-distance hydrogen transport. Meanwhile, the United States' approach through the Hydrogen Earthshot initiative focuses on production cost reduction targets, which may benefit compressed hydrogen in certain applications where infrastructure already exists.

Renewable energy mandates and clean fuel standards are creating additional policy pressures that affect the hydrogen value chain. California's Low Carbon Fuel Standard (LCFS) and similar programs provide credits based on carbon intensity reductions, creating market advantages for hydrogen pathways with demonstrably lower life-cycle emissions. These standards increasingly require comprehensive life-cycle assessment methodologies that account for upstream emissions, transportation impacts, and end-use efficiency.

International climate agreements, particularly the Paris Agreement's nationally determined contributions (NDCs), are driving harmonization of carbon accounting methods across borders. This standardization is critical for accurate comparison between LOHC and compressed hydrogen systems, especially when considering international hydrogen trade. The development of these standards directly influences investment decisions and technology deployment timelines for hydrogen infrastructure projects.

Circular economy policies are emerging as another significant factor, with regulations increasingly focusing on material recovery and waste reduction. LOHC systems, which utilize carrier molecules that can be repeatedly hydrogenated and dehydrogenated, align well with circular economy principles. However, they must demonstrate compliance with chemical regulations such as REACH in Europe, which may impose additional testing and certification requirements.

Local air quality regulations and zero-emission zones in urban areas are creating immediate market opportunities for hydrogen applications with minimal local emissions. These policies tend to favor end-use applications rather than specific storage technologies, but they accelerate overall hydrogen adoption and infrastructure development, indirectly influencing the choice between LOHC and compressed hydrogen systems based on their integration capabilities with urban distribution networks.

Economic Viability of LOHC vs Compressed H2 Systems

The economic viability of LOHC (Liquid Organic Hydrogen Carriers) versus compressed hydrogen systems represents a critical factor in determining the future hydrogen transportation and storage infrastructure. When comparing these technologies from a financial perspective, several key parameters must be considered, including capital expenditure, operational costs, energy efficiency, and scalability.

Initial investment costs for LOHC systems typically include hydrogenation and dehydrogenation plants, storage tanks, and the carrier material itself. While these upfront costs are substantial, they offer the advantage of utilizing existing liquid fuel infrastructure for transportation and storage, potentially reducing overall infrastructure development costs compared to compressed hydrogen systems.

Compressed hydrogen systems, conversely, require significant investments in high-pressure storage vessels, specialized compressors, and dedicated transportation infrastructure. The capital costs per unit of hydrogen stored tend to be higher for compressed systems, particularly at larger scales, due to the specialized materials needed to safely contain hydrogen at pressures of 350-700 bar.

Operational expenditures present another dimension of economic comparison. LOHC systems incur recurring costs related to the carrier material (including potential degradation and replacement), energy requirements for hydrogenation and dehydrogenation processes, and thermal management. These energy penalties significantly impact the overall efficiency and operating costs of LOHC systems.

For compressed hydrogen, operational costs primarily revolve around compression energy requirements, maintenance of high-pressure equipment, and transportation logistics. While compression consumes substantial energy (typically 10-15% of the hydrogen's energy content), the absence of chemical conversion steps provides certain operational simplicity advantages.

Scale economics favor different technologies depending on the application context. LOHC systems demonstrate better economic scaling for large-volume, long-distance transportation scenarios, where their compatibility with existing infrastructure becomes particularly valuable. Compressed hydrogen systems may prove more economical for smaller-scale, localized applications where the complexity of LOHC conversion processes would be disproportionately expensive.

Market maturity also influences economic viability. Compressed hydrogen technologies benefit from decades of industrial experience, resulting in established supply chains and standardized equipment. LOHC technologies, while promising, face higher technology risk premiums in financing and less mature supply chains, potentially increasing costs in the near term.

The economic comparison ultimately depends on specific deployment scenarios, including transportation distances, storage durations, and required hydrogen purity for end applications. A comprehensive life-cycle cost analysis must account for these variables alongside the carbon footprint considerations to determine the most economically viable hydrogen carrier solution for specific use cases.

Initial investment costs for LOHC systems typically include hydrogenation and dehydrogenation plants, storage tanks, and the carrier material itself. While these upfront costs are substantial, they offer the advantage of utilizing existing liquid fuel infrastructure for transportation and storage, potentially reducing overall infrastructure development costs compared to compressed hydrogen systems.

Compressed hydrogen systems, conversely, require significant investments in high-pressure storage vessels, specialized compressors, and dedicated transportation infrastructure. The capital costs per unit of hydrogen stored tend to be higher for compressed systems, particularly at larger scales, due to the specialized materials needed to safely contain hydrogen at pressures of 350-700 bar.

Operational expenditures present another dimension of economic comparison. LOHC systems incur recurring costs related to the carrier material (including potential degradation and replacement), energy requirements for hydrogenation and dehydrogenation processes, and thermal management. These energy penalties significantly impact the overall efficiency and operating costs of LOHC systems.

For compressed hydrogen, operational costs primarily revolve around compression energy requirements, maintenance of high-pressure equipment, and transportation logistics. While compression consumes substantial energy (typically 10-15% of the hydrogen's energy content), the absence of chemical conversion steps provides certain operational simplicity advantages.

Scale economics favor different technologies depending on the application context. LOHC systems demonstrate better economic scaling for large-volume, long-distance transportation scenarios, where their compatibility with existing infrastructure becomes particularly valuable. Compressed hydrogen systems may prove more economical for smaller-scale, localized applications where the complexity of LOHC conversion processes would be disproportionately expensive.

Market maturity also influences economic viability. Compressed hydrogen technologies benefit from decades of industrial experience, resulting in established supply chains and standardized equipment. LOHC technologies, while promising, face higher technology risk premiums in financing and less mature supply chains, potentially increasing costs in the near term.

The economic comparison ultimately depends on specific deployment scenarios, including transportation distances, storage durations, and required hydrogen purity for end applications. A comprehensive life-cycle cost analysis must account for these variables alongside the carbon footprint considerations to determine the most economically viable hydrogen carrier solution for specific use cases.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!