Compliance Standards for Battery Management Systems in Global Markets

AUG 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

BMS Compliance Overview

Battery Management Systems (BMS) play a crucial role in ensuring the safety, efficiency, and longevity of battery systems across various applications. As the global market for electric vehicles, renewable energy storage, and portable electronics continues to expand, the need for standardized compliance regulations for BMS has become increasingly important. These standards aim to establish a common framework for the design, manufacturing, and operation of BMS, ensuring consistency and reliability across different markets and applications.

The landscape of BMS compliance standards is complex and diverse, with regulations varying significantly across different regions and industries. In the automotive sector, for instance, standards such as ISO 26262 and IEC 61508 focus on functional safety aspects of BMS in electric vehicles. These standards address critical safety requirements, including fault detection, redundancy, and fail-safe mechanisms to prevent catastrophic failures in battery systems.

In the energy storage sector, standards like UL 1973 and IEC 62619 provide guidelines for the safety and performance of large-format batteries and their management systems. These standards cover aspects such as thermal management, overcharge protection, and cell balancing, which are essential for grid-scale energy storage applications.

For consumer electronics and portable devices, standards like IEC 62133 and UL 2054 govern the safety requirements for lithium-ion batteries and their protection circuits. These standards focus on preventing issues such as overheating, short circuits, and thermal runaway in smaller-scale battery systems.

Global harmonization efforts are underway to streamline these diverse standards and create a more unified approach to BMS compliance. Organizations like the International Electrotechnical Commission (IEC) and the Society of Automotive Engineers (SAE) are working towards developing global standards that can be adopted across different regions and industries. This harmonization aims to reduce regulatory barriers, facilitate international trade, and accelerate the adoption of advanced battery technologies.

Compliance with these standards often requires rigorous testing and certification processes. Third-party testing laboratories and certification bodies play a crucial role in verifying that BMS designs meet the required safety and performance criteria. This certification process typically involves extensive documentation, prototype testing, and ongoing quality assurance measures to ensure continued compliance throughout the product lifecycle.

As battery technologies continue to evolve, compliance standards are also adapting to address new challenges and opportunities. Emerging areas of focus include cybersecurity for connected BMS, sustainability and recyclability of battery systems, and interoperability standards for smart grid applications. These evolving standards reflect the growing complexity and interconnectedness of modern battery systems and their management technologies.

The landscape of BMS compliance standards is complex and diverse, with regulations varying significantly across different regions and industries. In the automotive sector, for instance, standards such as ISO 26262 and IEC 61508 focus on functional safety aspects of BMS in electric vehicles. These standards address critical safety requirements, including fault detection, redundancy, and fail-safe mechanisms to prevent catastrophic failures in battery systems.

In the energy storage sector, standards like UL 1973 and IEC 62619 provide guidelines for the safety and performance of large-format batteries and their management systems. These standards cover aspects such as thermal management, overcharge protection, and cell balancing, which are essential for grid-scale energy storage applications.

For consumer electronics and portable devices, standards like IEC 62133 and UL 2054 govern the safety requirements for lithium-ion batteries and their protection circuits. These standards focus on preventing issues such as overheating, short circuits, and thermal runaway in smaller-scale battery systems.

Global harmonization efforts are underway to streamline these diverse standards and create a more unified approach to BMS compliance. Organizations like the International Electrotechnical Commission (IEC) and the Society of Automotive Engineers (SAE) are working towards developing global standards that can be adopted across different regions and industries. This harmonization aims to reduce regulatory barriers, facilitate international trade, and accelerate the adoption of advanced battery technologies.

Compliance with these standards often requires rigorous testing and certification processes. Third-party testing laboratories and certification bodies play a crucial role in verifying that BMS designs meet the required safety and performance criteria. This certification process typically involves extensive documentation, prototype testing, and ongoing quality assurance measures to ensure continued compliance throughout the product lifecycle.

As battery technologies continue to evolve, compliance standards are also adapting to address new challenges and opportunities. Emerging areas of focus include cybersecurity for connected BMS, sustainability and recyclability of battery systems, and interoperability standards for smart grid applications. These evolving standards reflect the growing complexity and interconnectedness of modern battery systems and their management technologies.

Global Market Demand

The global market demand for Battery Management Systems (BMS) is experiencing significant growth, driven by the rapid expansion of electric vehicles (EVs) and renewable energy storage systems. As countries worldwide push for cleaner energy solutions and stricter emissions regulations, the need for advanced BMS technologies has become paramount.

In the automotive sector, the shift towards electrification has created a surge in demand for BMS. Major markets such as China, Europe, and North America are leading this transition, with governments implementing policies to phase out internal combustion engine vehicles. This has resulted in a substantial increase in EV production and sales, consequently boosting the demand for sophisticated BMS solutions.

The renewable energy sector is another key driver of BMS market growth. As countries invest in large-scale energy storage projects to support their renewable energy infrastructure, the need for efficient and reliable BMS has intensified. Grid-scale energy storage systems require advanced BMS to ensure optimal performance, safety, and longevity of battery installations.

Consumer electronics continue to be a significant market for BMS, with the proliferation of smartphones, laptops, and other portable devices. The demand for longer battery life and faster charging capabilities has pushed manufacturers to adopt more advanced BMS technologies.

Geographically, Asia-Pacific dominates the BMS market, with China being the largest contributor due to its massive EV market and battery production capacity. Europe follows closely, driven by stringent environmental regulations and ambitious EV adoption targets. North America is also showing strong growth, particularly in the United States, where both the automotive and energy storage sectors are expanding rapidly.

The industrial sector presents another growing market for BMS, as factories and manufacturing facilities increasingly adopt automated systems and electric machinery. This trend is particularly evident in developed economies where Industry 4.0 initiatives are gaining traction.

Market analysts project the global BMS market to grow at a compound annual growth rate (CAGR) of over 15% in the coming years. This growth is underpinned by the increasing energy density of batteries, the need for more efficient power management, and the rising importance of battery safety and longevity.

As the market expands, there is a growing demand for standardized BMS solutions that can meet diverse compliance requirements across different regions. This has led to increased collaboration between industry players and regulatory bodies to develop unified standards that can facilitate global market access while ensuring safety and performance.

In the automotive sector, the shift towards electrification has created a surge in demand for BMS. Major markets such as China, Europe, and North America are leading this transition, with governments implementing policies to phase out internal combustion engine vehicles. This has resulted in a substantial increase in EV production and sales, consequently boosting the demand for sophisticated BMS solutions.

The renewable energy sector is another key driver of BMS market growth. As countries invest in large-scale energy storage projects to support their renewable energy infrastructure, the need for efficient and reliable BMS has intensified. Grid-scale energy storage systems require advanced BMS to ensure optimal performance, safety, and longevity of battery installations.

Consumer electronics continue to be a significant market for BMS, with the proliferation of smartphones, laptops, and other portable devices. The demand for longer battery life and faster charging capabilities has pushed manufacturers to adopt more advanced BMS technologies.

Geographically, Asia-Pacific dominates the BMS market, with China being the largest contributor due to its massive EV market and battery production capacity. Europe follows closely, driven by stringent environmental regulations and ambitious EV adoption targets. North America is also showing strong growth, particularly in the United States, where both the automotive and energy storage sectors are expanding rapidly.

The industrial sector presents another growing market for BMS, as factories and manufacturing facilities increasingly adopt automated systems and electric machinery. This trend is particularly evident in developed economies where Industry 4.0 initiatives are gaining traction.

Market analysts project the global BMS market to grow at a compound annual growth rate (CAGR) of over 15% in the coming years. This growth is underpinned by the increasing energy density of batteries, the need for more efficient power management, and the rising importance of battery safety and longevity.

As the market expands, there is a growing demand for standardized BMS solutions that can meet diverse compliance requirements across different regions. This has led to increased collaboration between industry players and regulatory bodies to develop unified standards that can facilitate global market access while ensuring safety and performance.

Current BMS Standards

Battery Management System (BMS) standards play a crucial role in ensuring the safety, reliability, and performance of battery systems across various industries. Currently, several key standards govern BMS design and implementation in global markets.

The International Electrotechnical Commission (IEC) has developed a series of standards specifically addressing BMS requirements. IEC 62619 focuses on safety requirements for lithium-ion batteries in industrial applications, while IEC 62660 covers performance and life testing of lithium-ion batteries for electric vehicle applications. These standards provide comprehensive guidelines for BMS design, including cell monitoring, thermal management, and safety features.

In the automotive sector, ISO 26262 is widely recognized as the primary standard for functional safety in road vehicles. It includes specific requirements for BMS in electric and hybrid vehicles, emphasizing risk assessment and mitigation strategies. Additionally, the United Nations Economic Commission for Europe (UNECE) has established Regulation No. 100, which outlines safety requirements for electric power train of road vehicles, including BMS specifications.

For consumer electronics, UL 1642 and IEC 62133 are prominent standards addressing safety requirements for lithium batteries in portable devices. These standards encompass BMS functionalities such as overcharge protection, over-discharge prevention, and short-circuit protection.

In the aerospace industry, DO-311A, developed by RTCA, provides guidelines for rechargeable lithium batteries and battery systems in aerospace applications. This standard includes specific requirements for BMS in terms of monitoring, control, and safety features for airborne use.

The energy storage sector relies on standards such as UL 9540 and IEC 62933, which cover safety and performance requirements for energy storage systems, including BMS specifications for grid-connected applications.

China, as a major player in the battery industry, has developed its own set of standards. GB/T 31467 series focuses on lithium-ion traction battery packs and systems for electric vehicles, including BMS requirements. These standards are increasingly influential in the global market due to China's significant role in battery production and electric vehicle manufacturing.

Compliance with these standards is essential for market access and product acceptance. However, the landscape of BMS standards is continuously evolving to keep pace with technological advancements and emerging safety concerns. Manufacturers and developers must stay informed about updates and new standards to ensure their BMS designs remain compliant across different global markets.

The International Electrotechnical Commission (IEC) has developed a series of standards specifically addressing BMS requirements. IEC 62619 focuses on safety requirements for lithium-ion batteries in industrial applications, while IEC 62660 covers performance and life testing of lithium-ion batteries for electric vehicle applications. These standards provide comprehensive guidelines for BMS design, including cell monitoring, thermal management, and safety features.

In the automotive sector, ISO 26262 is widely recognized as the primary standard for functional safety in road vehicles. It includes specific requirements for BMS in electric and hybrid vehicles, emphasizing risk assessment and mitigation strategies. Additionally, the United Nations Economic Commission for Europe (UNECE) has established Regulation No. 100, which outlines safety requirements for electric power train of road vehicles, including BMS specifications.

For consumer electronics, UL 1642 and IEC 62133 are prominent standards addressing safety requirements for lithium batteries in portable devices. These standards encompass BMS functionalities such as overcharge protection, over-discharge prevention, and short-circuit protection.

In the aerospace industry, DO-311A, developed by RTCA, provides guidelines for rechargeable lithium batteries and battery systems in aerospace applications. This standard includes specific requirements for BMS in terms of monitoring, control, and safety features for airborne use.

The energy storage sector relies on standards such as UL 9540 and IEC 62933, which cover safety and performance requirements for energy storage systems, including BMS specifications for grid-connected applications.

China, as a major player in the battery industry, has developed its own set of standards. GB/T 31467 series focuses on lithium-ion traction battery packs and systems for electric vehicles, including BMS requirements. These standards are increasingly influential in the global market due to China's significant role in battery production and electric vehicle manufacturing.

Compliance with these standards is essential for market access and product acceptance. However, the landscape of BMS standards is continuously evolving to keep pace with technological advancements and emerging safety concerns. Manufacturers and developers must stay informed about updates and new standards to ensure their BMS designs remain compliant across different global markets.

Existing BMS Solutions

01 Battery monitoring and control systems

These systems monitor various parameters of batteries, such as voltage, current, temperature, and state of charge. They use this information to optimize battery performance, extend battery life, and ensure safe operation. Advanced algorithms are employed to estimate battery health and predict remaining useful life.- Battery monitoring and control systems: These systems monitor various parameters of battery cells or packs, such as voltage, current, temperature, and state of charge. They use this data to optimize battery performance, ensure safe operation, and extend battery life through intelligent charge/discharge management.

- Thermal management in battery systems: Thermal management solutions for battery systems focus on maintaining optimal operating temperatures. This includes cooling systems, heat dissipation methods, and temperature regulation strategies to prevent overheating and ensure efficient battery performance across various environmental conditions.

- Battery balancing techniques: Battery balancing methods are employed to equalize the charge levels across multiple cells in a battery pack. This helps to maximize overall capacity, prevent overcharging of individual cells, and extend the lifespan of the entire battery system by ensuring uniform degradation.

- Predictive maintenance and diagnostics: Advanced algorithms and machine learning techniques are used to predict battery health, estimate remaining useful life, and identify potential issues before they become critical. This enables proactive maintenance scheduling and optimization of battery replacement strategies.

- Integration with energy management systems: Battery management systems are increasingly integrated with broader energy management systems, particularly in applications like electric vehicles and smart grids. This integration allows for optimized energy distribution, improved grid stability, and more efficient use of renewable energy sources in conjunction with battery storage.

02 Thermal management in battery systems

Thermal management is crucial for battery performance and safety. These systems regulate battery temperature through cooling or heating mechanisms, preventing overheating and maintaining optimal operating conditions. They may include sensors, cooling circuits, and control algorithms to manage heat distribution across battery packs.Expand Specific Solutions03 Cell balancing techniques

Cell balancing ensures that all cells in a battery pack maintain similar voltage levels, improving overall battery performance and lifespan. Various methods are used, including passive and active balancing techniques, to redistribute charge among cells and prevent overcharging or undercharging of individual cells.Expand Specific Solutions04 State of charge and state of health estimation

Advanced algorithms and techniques are used to accurately estimate the state of charge (SoC) and state of health (SoH) of batteries. These estimations are crucial for optimizing battery usage, predicting remaining range in electric vehicles, and scheduling maintenance. Machine learning and data-driven approaches are increasingly being used to improve accuracy.Expand Specific Solutions05 Integration with energy management systems

Battery management systems are increasingly integrated with broader energy management systems, particularly in applications like electric vehicles and grid storage. This integration allows for optimized energy flow, demand response capabilities, and improved overall system efficiency. It may include features like vehicle-to-grid (V2G) technology and smart charging strategies.Expand Specific Solutions

Key BMS Manufacturers

The global market for Battery Management Systems (BMS) in compliance with international standards is experiencing rapid growth, driven by the increasing adoption of electric vehicles and renewable energy storage solutions. The industry is in a phase of dynamic expansion, with market size projected to reach billions of dollars in the coming years. Technological maturity varies across different segments, with established players like Contemporary Amperex Technology, LG Energy Solution, and Samsung SDI leading in innovation and market share. Emerging companies such as BYD and A123 Systems are also making significant strides in BMS technology development. The competitive landscape is characterized by a mix of large multinational corporations and specialized tech firms, all striving to meet evolving regulatory requirements and enhance battery performance, safety, and longevity across global markets.

Contemporary Amperex Technology Co., Ltd.

Technical Solution: CATL has developed a comprehensive Battery Management System (BMS) that complies with global standards, including UN ECE R100, ISO 26262, and IEC 61508. Their BMS utilizes advanced algorithms for accurate State of Charge (SOC) and State of Health (SOH) estimation, with a reported accuracy of over 95%[1]. The system incorporates real-time monitoring of cell voltage, temperature, and current, with a sampling rate of up to 1 kHz[2]. CATL's BMS also features a multi-level safety protection mechanism, including hardware protection circuits and software-based fault detection algorithms, ensuring compliance with safety standards such as GB/T 31467.3 and UL 2054[3].

Strengths: High accuracy in battery state estimation, robust safety features, and compliance with multiple international standards. Weaknesses: May have higher implementation costs due to advanced features, potentially limiting adoption in lower-cost applications.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has developed a sophisticated BMS that adheres to global compliance standards, including UL 1642, IEC 62133, and UN 38.3. Their system employs a distributed architecture, with local monitoring units for each module and a central control unit for overall management[4]. The BMS utilizes machine learning algorithms for predictive maintenance and adaptive control, reportedly reducing battery degradation by up to 20%[5]. LG's solution also incorporates wireless communication protocols compliant with automotive standards like CAN FD and FlexRay, enabling seamless integration with various vehicle systems[6].

Strengths: Advanced predictive maintenance capabilities, automotive-grade communication protocols, and proven reduction in battery degradation. Weaknesses: The complex distributed architecture may increase system complexity and potential points of failure.

Core BMS Technologies

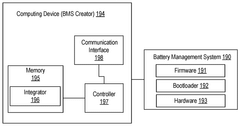

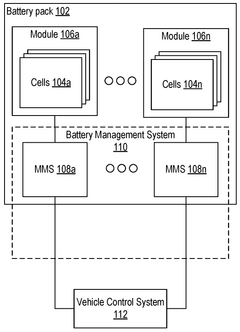

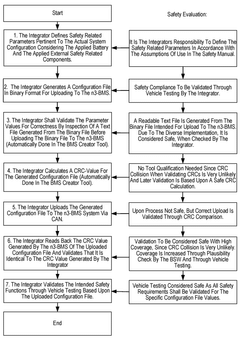

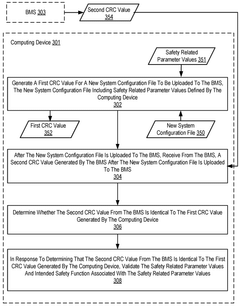

Calibrating a battery management system

PatentWO2025137220A1

Innovation

- A method and system that allow vehicle integrators to modify and validate safety-critical parameters in the field by generating and comparing CRC values between a computing device and the BMS, ensuring compliance with ISO 26262 ASIL-C standards without manufacturer involvement.

System for diagnosing battery cell provided in electric vehicle

PatentPendingUS20240336159A1

Innovation

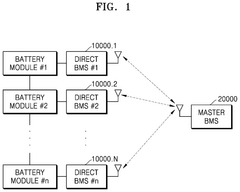

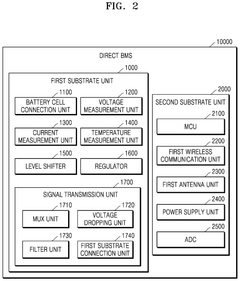

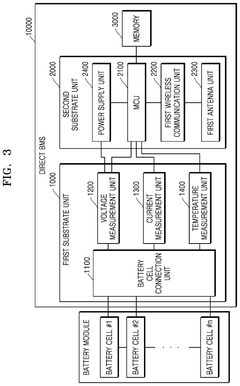

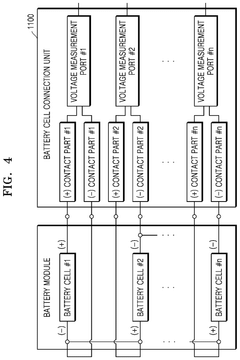

- A system comprising a master BMS and direct BMSs with a battery cell connection unit that directly contacts battery cell terminals to measure voltage, current, and temperature, and a substrate unit that converts analog signals to digital for wireless transmission, implemented using different processes on a single semiconductor chip, allowing for precise and reliable data collection without channel switching noise.

Regional BMS Regulations

Battery Management System (BMS) regulations vary significantly across global markets, reflecting the diverse approaches to safety, performance, and environmental standards in different regions. In North America, the United States and Canada have established stringent regulations through agencies such as the National Highway Traffic Safety Administration (NHTSA) and Transport Canada. These regulations focus on safety requirements, including thermal management, overcharge protection, and crash resistance for electric vehicle batteries.

The European Union has implemented a comprehensive regulatory framework for BMS through the United Nations Economic Commission for Europe (UNECE) regulations, particularly UNECE Regulation No. 100. This regulation sets standards for the safety of rechargeable energy storage systems in electric and hybrid vehicles, covering aspects such as vibration resistance, thermal shock, and fire protection. Additionally, the EU's General Safety Regulation (GSR) and type-approval requirements for electric vehicles incorporate BMS-specific standards.

In Asia, China has emerged as a leader in electric vehicle production and has developed robust BMS regulations. The GB/T 31467 standard series, issued by the Standardization Administration of China, provides detailed requirements for lithium-ion traction battery packs and systems in electric vehicles. Japan, another significant player in the automotive industry, has established its own set of regulations through the Japan Automobile Standards Internationalization Center (JASIC), focusing on battery safety and performance in electric and hybrid vehicles.

Emerging markets, such as India and Brazil, are in the process of developing and refining their BMS regulations. India's Automotive Industry Standards (AIS) include specific provisions for electric vehicle batteries, while Brazil's National Institute of Metrology, Quality and Technology (INMETRO) is working on adapting international standards to local conditions.

Global harmonization efforts are underway to streamline BMS regulations across markets. The International Electrotechnical Commission (IEC) and the Society of Automotive Engineers (SAE) are developing international standards that aim to provide a unified approach to BMS compliance. However, regional differences in regulatory priorities and implementation timelines continue to pose challenges for manufacturers operating in multiple markets.

The European Union has implemented a comprehensive regulatory framework for BMS through the United Nations Economic Commission for Europe (UNECE) regulations, particularly UNECE Regulation No. 100. This regulation sets standards for the safety of rechargeable energy storage systems in electric and hybrid vehicles, covering aspects such as vibration resistance, thermal shock, and fire protection. Additionally, the EU's General Safety Regulation (GSR) and type-approval requirements for electric vehicles incorporate BMS-specific standards.

In Asia, China has emerged as a leader in electric vehicle production and has developed robust BMS regulations. The GB/T 31467 standard series, issued by the Standardization Administration of China, provides detailed requirements for lithium-ion traction battery packs and systems in electric vehicles. Japan, another significant player in the automotive industry, has established its own set of regulations through the Japan Automobile Standards Internationalization Center (JASIC), focusing on battery safety and performance in electric and hybrid vehicles.

Emerging markets, such as India and Brazil, are in the process of developing and refining their BMS regulations. India's Automotive Industry Standards (AIS) include specific provisions for electric vehicle batteries, while Brazil's National Institute of Metrology, Quality and Technology (INMETRO) is working on adapting international standards to local conditions.

Global harmonization efforts are underway to streamline BMS regulations across markets. The International Electrotechnical Commission (IEC) and the Society of Automotive Engineers (SAE) are developing international standards that aim to provide a unified approach to BMS compliance. However, regional differences in regulatory priorities and implementation timelines continue to pose challenges for manufacturers operating in multiple markets.

Environmental Impact

The environmental impact of battery management systems (BMS) in global markets is a critical consideration for compliance standards. As the adoption of electric vehicles and energy storage systems continues to grow, the environmental footprint of BMS becomes increasingly significant. These systems play a crucial role in optimizing battery performance, extending battery life, and ensuring safety, all of which have direct implications for environmental sustainability.

One of the primary environmental benefits of effective BMS is the extension of battery lifespan. By carefully managing charge and discharge cycles, temperature, and overall battery health, BMS can significantly prolong the useful life of batteries. This reduction in battery replacement frequency leads to decreased resource consumption and waste generation, aligning with global sustainability goals.

However, the production and disposal of BMS components themselves present environmental challenges. The manufacturing process involves the use of various materials, including rare earth elements and precious metals, which have significant environmental impacts during extraction and processing. Compliance standards must address the sourcing of these materials, promoting responsible mining practices and encouraging the use of recycled materials where possible.

End-of-life management for BMS is another crucial aspect of their environmental impact. As batteries and their management systems reach the end of their operational life, proper recycling and disposal procedures are essential to prevent environmental contamination. Compliance standards should mandate recycling programs and establish guidelines for the safe dismantling and recovery of valuable materials from BMS components.

The energy efficiency of BMS also plays a role in their overall environmental impact. Advanced BMS designs that minimize power consumption while maximizing battery performance can contribute to reduced energy demand and, consequently, lower greenhouse gas emissions. Compliance standards should set benchmarks for BMS energy efficiency, encouraging continuous improvement in this area.

Furthermore, the integration of BMS with renewable energy systems presents opportunities for environmental benefits. By optimizing energy storage and distribution, BMS can enhance the efficiency of renewable energy installations, facilitating greater adoption of clean energy sources and reducing reliance on fossil fuels.

As global markets increasingly prioritize sustainability, compliance standards for BMS must evolve to address these environmental considerations comprehensively. This includes lifecycle assessments, eco-design principles, and the promotion of circular economy practices in the BMS industry. By setting rigorous environmental standards, regulatory bodies can drive innovation towards more sustainable BMS solutions, ultimately contributing to global efforts in combating climate change and preserving natural resources.

One of the primary environmental benefits of effective BMS is the extension of battery lifespan. By carefully managing charge and discharge cycles, temperature, and overall battery health, BMS can significantly prolong the useful life of batteries. This reduction in battery replacement frequency leads to decreased resource consumption and waste generation, aligning with global sustainability goals.

However, the production and disposal of BMS components themselves present environmental challenges. The manufacturing process involves the use of various materials, including rare earth elements and precious metals, which have significant environmental impacts during extraction and processing. Compliance standards must address the sourcing of these materials, promoting responsible mining practices and encouraging the use of recycled materials where possible.

End-of-life management for BMS is another crucial aspect of their environmental impact. As batteries and their management systems reach the end of their operational life, proper recycling and disposal procedures are essential to prevent environmental contamination. Compliance standards should mandate recycling programs and establish guidelines for the safe dismantling and recovery of valuable materials from BMS components.

The energy efficiency of BMS also plays a role in their overall environmental impact. Advanced BMS designs that minimize power consumption while maximizing battery performance can contribute to reduced energy demand and, consequently, lower greenhouse gas emissions. Compliance standards should set benchmarks for BMS energy efficiency, encouraging continuous improvement in this area.

Furthermore, the integration of BMS with renewable energy systems presents opportunities for environmental benefits. By optimizing energy storage and distribution, BMS can enhance the efficiency of renewable energy installations, facilitating greater adoption of clean energy sources and reducing reliance on fossil fuels.

As global markets increasingly prioritize sustainability, compliance standards for BMS must evolve to address these environmental considerations comprehensively. This includes lifecycle assessments, eco-design principles, and the promotion of circular economy practices in the BMS industry. By setting rigorous environmental standards, regulatory bodies can drive innovation towards more sustainable BMS solutions, ultimately contributing to global efforts in combating climate change and preserving natural resources.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!