Decane in Strategic Design of Abatement Technology for VOC Emissions

JUL 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

VOC Abatement Tech Evolution and Objectives

Volatile Organic Compounds (VOCs) have been a significant environmental concern since the mid-20th century, with their impact on air quality and human health becoming increasingly apparent. The evolution of VOC abatement technology has been driven by a combination of regulatory pressures, technological advancements, and growing environmental awareness.

In the 1970s, the first major wave of VOC regulations emerged, primarily focusing on reducing emissions from industrial sources. This led to the development of basic control technologies such as thermal oxidizers and carbon adsorption systems. As understanding of VOC impacts grew, so did the sophistication of abatement technologies.

The 1990s saw a shift towards more energy-efficient and cost-effective solutions, with the introduction of regenerative thermal oxidizers and bio-filtration systems. These technologies aimed to balance environmental protection with economic feasibility for industries.

Entering the 21st century, the focus has expanded to include a wider range of VOC sources, including those from consumer products and smaller industrial operations. This has driven the development of more versatile and scalable abatement technologies, such as advanced catalytic systems and hybrid solutions combining multiple treatment methods.

Recent years have witnessed a surge in research towards sustainable and low-energy VOC abatement technologies. Innovations in materials science, such as advanced adsorbents and catalysts, are paving the way for more efficient removal of VOCs at lower temperatures and with reduced energy consumption.

The current objectives in VOC abatement technology development are multifaceted. Firstly, there is a push towards improving the efficiency of existing technologies, particularly in terms of energy consumption and operational costs. Secondly, researchers are focusing on developing technologies capable of treating a broader spectrum of VOCs, including those traditionally considered difficult to abate.

Another key objective is the integration of VOC abatement systems with other environmental technologies, such as CO2 capture and utilization. This holistic approach aims to address multiple environmental challenges simultaneously, maximizing resource efficiency.

Looking forward, the field of VOC abatement is likely to see increased emphasis on smart, adaptive systems that can respond dynamically to changing VOC compositions and concentrations. Additionally, there is growing interest in developing technologies that not only remove VOCs but also convert them into valuable products, aligning with circular economy principles.

In the 1970s, the first major wave of VOC regulations emerged, primarily focusing on reducing emissions from industrial sources. This led to the development of basic control technologies such as thermal oxidizers and carbon adsorption systems. As understanding of VOC impacts grew, so did the sophistication of abatement technologies.

The 1990s saw a shift towards more energy-efficient and cost-effective solutions, with the introduction of regenerative thermal oxidizers and bio-filtration systems. These technologies aimed to balance environmental protection with economic feasibility for industries.

Entering the 21st century, the focus has expanded to include a wider range of VOC sources, including those from consumer products and smaller industrial operations. This has driven the development of more versatile and scalable abatement technologies, such as advanced catalytic systems and hybrid solutions combining multiple treatment methods.

Recent years have witnessed a surge in research towards sustainable and low-energy VOC abatement technologies. Innovations in materials science, such as advanced adsorbents and catalysts, are paving the way for more efficient removal of VOCs at lower temperatures and with reduced energy consumption.

The current objectives in VOC abatement technology development are multifaceted. Firstly, there is a push towards improving the efficiency of existing technologies, particularly in terms of energy consumption and operational costs. Secondly, researchers are focusing on developing technologies capable of treating a broader spectrum of VOCs, including those traditionally considered difficult to abate.

Another key objective is the integration of VOC abatement systems with other environmental technologies, such as CO2 capture and utilization. This holistic approach aims to address multiple environmental challenges simultaneously, maximizing resource efficiency.

Looking forward, the field of VOC abatement is likely to see increased emphasis on smart, adaptive systems that can respond dynamically to changing VOC compositions and concentrations. Additionally, there is growing interest in developing technologies that not only remove VOCs but also convert them into valuable products, aligning with circular economy principles.

Market Analysis for VOC Emission Control Solutions

The market for VOC emission control solutions has experienced significant growth in recent years, driven by increasing environmental regulations and growing awareness of the health impacts of volatile organic compounds. The global VOC treatment market is projected to reach substantial value in the coming years, with a compound annual growth rate exceeding industry averages.

Key factors fueling market demand include stringent government regulations on air quality, particularly in developed regions like North America and Europe. These regulations have compelled industries to adopt advanced VOC abatement technologies. Additionally, emerging economies in Asia-Pacific and Latin America are implementing stricter environmental policies, further expanding the market potential.

The industrial sector remains the largest end-user of VOC emission control solutions, with chemical processing, petrochemicals, and automotive manufacturing being major contributors. However, the commercial and residential sectors are showing increased adoption rates, particularly in indoor air quality management.

Technological advancements have led to the development of more efficient and cost-effective VOC abatement solutions. Regenerative thermal oxidizers (RTOs) and catalytic oxidizers have gained popularity due to their high destruction efficiency and energy recovery capabilities. Adsorption systems, particularly those using activated carbon, continue to be widely used across various industries.

The market is witnessing a shift towards integrated solutions that combine multiple technologies to address complex VOC emission challenges. This trend is driven by the need for versatile systems capable of handling a wide range of VOC types and concentrations.

Geographically, North America and Europe currently dominate the VOC emission control market, owing to their stringent regulatory frameworks and mature industrial sectors. However, the Asia-Pacific region is expected to exhibit the highest growth rate in the coming years, fueled by rapid industrialization, urbanization, and increasing environmental consciousness.

Key players in the market include multinational corporations with diverse product portfolios and regional specialists focusing on niche technologies. These companies are investing heavily in research and development to improve the efficiency and cost-effectiveness of their solutions, with a growing emphasis on sustainable and energy-efficient technologies.

The COVID-19 pandemic has had a mixed impact on the VOC emission control market. While some industries experienced temporary slowdowns, there has been an increased focus on indoor air quality, potentially opening new opportunities in the commercial and residential sectors.

Key factors fueling market demand include stringent government regulations on air quality, particularly in developed regions like North America and Europe. These regulations have compelled industries to adopt advanced VOC abatement technologies. Additionally, emerging economies in Asia-Pacific and Latin America are implementing stricter environmental policies, further expanding the market potential.

The industrial sector remains the largest end-user of VOC emission control solutions, with chemical processing, petrochemicals, and automotive manufacturing being major contributors. However, the commercial and residential sectors are showing increased adoption rates, particularly in indoor air quality management.

Technological advancements have led to the development of more efficient and cost-effective VOC abatement solutions. Regenerative thermal oxidizers (RTOs) and catalytic oxidizers have gained popularity due to their high destruction efficiency and energy recovery capabilities. Adsorption systems, particularly those using activated carbon, continue to be widely used across various industries.

The market is witnessing a shift towards integrated solutions that combine multiple technologies to address complex VOC emission challenges. This trend is driven by the need for versatile systems capable of handling a wide range of VOC types and concentrations.

Geographically, North America and Europe currently dominate the VOC emission control market, owing to their stringent regulatory frameworks and mature industrial sectors. However, the Asia-Pacific region is expected to exhibit the highest growth rate in the coming years, fueled by rapid industrialization, urbanization, and increasing environmental consciousness.

Key players in the market include multinational corporations with diverse product portfolios and regional specialists focusing on niche technologies. These companies are investing heavily in research and development to improve the efficiency and cost-effectiveness of their solutions, with a growing emphasis on sustainable and energy-efficient technologies.

The COVID-19 pandemic has had a mixed impact on the VOC emission control market. While some industries experienced temporary slowdowns, there has been an increased focus on indoor air quality, potentially opening new opportunities in the commercial and residential sectors.

Current VOC Abatement Challenges and Limitations

Volatile Organic Compounds (VOCs) emissions pose significant environmental and health risks, necessitating effective abatement technologies. However, current VOC abatement methods face several challenges and limitations, particularly in the context of decane emissions.

One of the primary challenges is the low concentration of VOCs in industrial exhaust streams. Decane, being a long-chain hydrocarbon, often exists in relatively low concentrations, making it difficult for conventional abatement technologies to achieve high removal efficiencies. This low concentration issue is compounded by the high flow rates of exhaust gases, requiring large-scale treatment systems that can be both costly and energy-intensive.

The chemical stability of decane presents another significant hurdle. As a saturated hydrocarbon, decane is relatively inert and resistant to oxidation, making it challenging for traditional oxidation-based abatement methods to effectively break down the compound. This stability necessitates more aggressive treatment conditions, which can lead to increased energy consumption and potential formation of harmful by-products.

Temperature fluctuations in industrial processes also pose a challenge for VOC abatement technologies. Many current systems are optimized for specific temperature ranges, and their efficiency can decrease significantly when operating outside these ranges. This is particularly problematic for decane abatement, as its boiling point is relatively high, requiring elevated temperatures for effective treatment.

The diversity of VOC mixtures in industrial emissions further complicates abatement efforts. Decane is often present alongside other VOCs with varying physical and chemical properties. Designing a single abatement system capable of efficiently treating this diverse mixture is challenging, often leading to compromises in overall performance or the need for multiple treatment stages.

Catalyst deactivation is a persistent issue in catalytic oxidation systems, one of the most common VOC abatement technologies. Decane and other long-chain hydrocarbons can cause coking on catalyst surfaces, reducing their effectiveness over time. This necessitates frequent catalyst regeneration or replacement, increasing operational costs and downtime.

Energy efficiency remains a significant limitation for many current VOC abatement technologies. Thermal oxidation methods, while effective, require substantial energy inputs to maintain the high temperatures needed for complete combustion of decane. This high energy consumption not only increases operational costs but also contributes to the overall carbon footprint of the abatement process.

Lastly, the recovery and potential reuse of VOCs like decane present both an opportunity and a challenge. While recovering these compounds could offer economic benefits, current technologies often struggle to selectively capture and purify specific VOCs from complex mixtures, limiting the feasibility of recovery-based abatement strategies.

One of the primary challenges is the low concentration of VOCs in industrial exhaust streams. Decane, being a long-chain hydrocarbon, often exists in relatively low concentrations, making it difficult for conventional abatement technologies to achieve high removal efficiencies. This low concentration issue is compounded by the high flow rates of exhaust gases, requiring large-scale treatment systems that can be both costly and energy-intensive.

The chemical stability of decane presents another significant hurdle. As a saturated hydrocarbon, decane is relatively inert and resistant to oxidation, making it challenging for traditional oxidation-based abatement methods to effectively break down the compound. This stability necessitates more aggressive treatment conditions, which can lead to increased energy consumption and potential formation of harmful by-products.

Temperature fluctuations in industrial processes also pose a challenge for VOC abatement technologies. Many current systems are optimized for specific temperature ranges, and their efficiency can decrease significantly when operating outside these ranges. This is particularly problematic for decane abatement, as its boiling point is relatively high, requiring elevated temperatures for effective treatment.

The diversity of VOC mixtures in industrial emissions further complicates abatement efforts. Decane is often present alongside other VOCs with varying physical and chemical properties. Designing a single abatement system capable of efficiently treating this diverse mixture is challenging, often leading to compromises in overall performance or the need for multiple treatment stages.

Catalyst deactivation is a persistent issue in catalytic oxidation systems, one of the most common VOC abatement technologies. Decane and other long-chain hydrocarbons can cause coking on catalyst surfaces, reducing their effectiveness over time. This necessitates frequent catalyst regeneration or replacement, increasing operational costs and downtime.

Energy efficiency remains a significant limitation for many current VOC abatement technologies. Thermal oxidation methods, while effective, require substantial energy inputs to maintain the high temperatures needed for complete combustion of decane. This high energy consumption not only increases operational costs but also contributes to the overall carbon footprint of the abatement process.

Lastly, the recovery and potential reuse of VOCs like decane present both an opportunity and a challenge. While recovering these compounds could offer economic benefits, current technologies often struggle to selectively capture and purify specific VOCs from complex mixtures, limiting the feasibility of recovery-based abatement strategies.

Existing Decane Emission Control Strategies

01 Adsorption-based VOC removal

Adsorption technology is widely used for VOC abatement, including decane emissions. This method employs materials with high surface area, such as activated carbon or zeolites, to capture VOC molecules from gas streams. The process can be enhanced by using specialized adsorbents or by combining adsorption with other techniques like thermal desorption for regeneration.- Adsorption-based VOC removal: Adsorption technology is widely used for VOC abatement, including decane emissions. This method employs materials with high surface area, such as activated carbon or zeolites, to capture VOC molecules from gas streams. The process can be enhanced by using regenerative systems or combining with other technologies for improved efficiency.

- Catalytic oxidation for VOC destruction: Catalytic oxidation is an effective method for destroying VOCs, including decane. This process uses catalysts to lower the activation energy required for oxidation, allowing the reaction to occur at lower temperatures compared to thermal oxidation. Various catalyst materials and reactor designs can be employed to optimize the process for specific VOC compositions.

- Membrane separation techniques: Membrane separation technology can be applied to remove VOCs like decane from gas streams. This method uses selective membranes that allow certain molecules to pass through while retaining others. Different membrane materials and configurations can be used to achieve high separation efficiency for specific VOC compounds.

- Cryogenic condensation for VOC recovery: Cryogenic condensation is a technique used to recover VOCs, including decane, by cooling the gas stream to very low temperatures. This causes the VOCs to condense and separate from the gas phase. The method is particularly effective for high-boiling point VOCs and can achieve high recovery rates.

- Biological treatment of VOC emissions: Biological treatment methods, such as biofilters and biotrickling filters, can be used to degrade VOCs like decane. These systems employ microorganisms that metabolize the VOCs, converting them into harmless byproducts. Biological treatments are often cost-effective and environmentally friendly alternatives for VOC abatement.

02 Catalytic oxidation for VOC destruction

Catalytic oxidation is an effective method for destroying VOCs, including decane. This process uses catalysts to lower the activation energy required for oxidation, allowing the reaction to occur at lower temperatures compared to thermal oxidation. Various catalyst materials and reactor designs can be employed to optimize the destruction efficiency of decane and other VOCs.Expand Specific Solutions03 Membrane separation techniques

Membrane separation technology can be applied to remove VOCs like decane from gas streams. This method uses selective membranes that allow certain molecules to pass through while retaining others. Different membrane materials and configurations can be used to achieve high separation efficiency for specific VOCs, including decane.Expand Specific Solutions04 Cryogenic condensation for VOC recovery

Cryogenic condensation is a technique used to recover VOCs, including decane, from gas streams by cooling the mixture to very low temperatures. This causes the VOCs to condense and separate from the gas phase. The method is particularly effective for high-boiling point VOCs like decane and can achieve high recovery rates.Expand Specific Solutions05 Biological treatment of VOC emissions

Biological treatment methods, such as biofilters and biotrickling filters, can be used to degrade VOCs including decane. These systems employ microorganisms that metabolize the VOCs, converting them into harmless byproducts. The efficiency of biological treatment for decane abatement can be improved by selecting appropriate microbial strains and optimizing operating conditions.Expand Specific Solutions

Key Players in VOC Abatement Industry

The competitive landscape for decane in strategic design of abatement technology for VOC emissions is characterized by a mature market with established players and ongoing technological advancements. The market size is substantial, driven by stringent environmental regulations and increasing industrial awareness of VOC emission control. Key players like LG Chem, Sinopec, and Mitsubishi Heavy Industries are investing in R&D to develop innovative solutions. The technology is relatively mature, with companies like Industrial Technology Research Institute and Korea Research Institute of Chemical Technology contributing to its advancement. However, there is still room for improvement in efficiency and cost-effectiveness, creating opportunities for new entrants and collaborations between industry and research institutions.

LG Chem Ltd.

Technical Solution: LG Chem has developed an innovative VOC abatement technology using catalytic oxidation combined with adsorption. Their system employs a dual-bed reactor with a zeolite-based adsorbent and a noble metal catalyst. This design allows for efficient capture and destruction of VOCs at lower temperatures, reducing energy consumption by up to 40% compared to traditional thermal oxidation methods [1]. The process incorporates a heat recovery system that preheats incoming air, further improving overall efficiency. LG Chem's technology also features a real-time monitoring system that adjusts operating parameters based on VOC concentration and composition, ensuring optimal performance across varying industrial conditions [3].

Strengths: High VOC removal efficiency (>99%), lower energy consumption, adaptable to various industries. Weaknesses: Higher initial capital cost, potential catalyst deactivation over time.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed a multi-stage VOC abatement system specifically designed for petrochemical facilities. Their approach combines membrane separation, cryogenic condensation, and catalytic oxidation technologies. The membrane separation stage removes high-molecular-weight VOCs, while cryogenic condensation targets mid-range compounds. The final catalytic oxidation stage handles remaining low-concentration VOCs [2]. This integrated system achieves over 98% VOC removal efficiency while recovering valuable hydrocarbons. Sinopec's technology also incorporates advanced process control algorithms that optimize energy usage based on real-time VOC composition data, resulting in up to 30% reduction in operating costs compared to conventional thermal oxidizers [4].

Strengths: High VOC removal efficiency, hydrocarbon recovery, energy-efficient operation. Weaknesses: Complex system design, high initial investment, requires skilled operators.

Innovative Decane Abatement Technologies

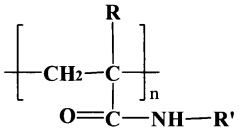

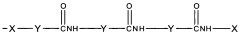

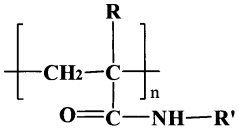

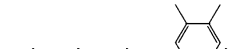

Adsorbent of volatile organic compounds and adsorption method using thereof

PatentWO2012057444A2

Innovation

- A novel acrylamide-based polymer with a specific repeating unit structure is developed, forming a mesoporous polymer that exhibits improved adsorption properties through radical polymerization, creating a crystalline material with uniform mesopores for enhanced VOC capture.

VOC emission control process and system

PatentInactiveUS20110171106A1

Innovation

- A process and system for decomposing VOCs from a composition by obtaining content data and operation conditions for a decomposer, selecting the appropriate decomposer, collecting VOCs, and decomposing them under specific conditions, using thermal, catalytic, or plasma energy sources to convert VOCs into carbon dioxide and water.

Environmental Regulations Impact on VOC Control

Environmental regulations have become increasingly stringent in recent years, significantly impacting the strategic design and implementation of abatement technologies for Volatile Organic Compound (VOC) emissions. These regulations, driven by growing concerns over air quality and public health, have created a complex landscape for industries dealing with VOC emissions, particularly in the context of decane abatement.

The regulatory framework for VOC control varies across different regions and countries, but generally follows a trend of tightening restrictions. In the United States, the Clean Air Act and its amendments have set the foundation for VOC emission standards, with the Environmental Protection Agency (EPA) playing a crucial role in enforcement. The EPA's National Emission Standards for Hazardous Air Pollutants (NESHAP) and New Source Performance Standards (NSPS) directly affect industries that emit decane and other VOCs.

European regulations, such as the Industrial Emissions Directive (IED) and the VOC Solvents Emissions Directive, have also significantly influenced abatement technology strategies. These directives set emission limit values and require the use of best available techniques (BAT) for VOC control, pushing industries to adopt more advanced and efficient abatement technologies.

The impact of these regulations on decane abatement technology design is multifaceted. Firstly, they have driven innovation in abatement technologies, encouraging the development of more efficient and cost-effective solutions. This has led to advancements in thermal oxidation, catalytic oxidation, and adsorption technologies specifically tailored for decane and similar VOCs.

Secondly, regulations have influenced the selection criteria for abatement technologies. Industries must now consider not only the efficiency of VOC removal but also the environmental impact of the abatement process itself. This has led to a growing interest in technologies that minimize secondary pollutants and energy consumption, such as regenerative thermal oxidizers and bio-filtration systems.

Furthermore, regulatory requirements have necessitated more comprehensive monitoring and reporting systems. This has spurred the development of advanced continuous emission monitoring systems (CEMS) and predictive emission monitoring systems (PEMS), which are now integral components of VOC abatement strategies.

The economic implications of these regulations are significant. Industries must balance the costs of compliance with potential penalties for non-compliance, often leading to substantial investments in abatement technologies. This has created a market for innovative financing models and service-based solutions in the VOC abatement sector.

Looking ahead, the trend towards stricter environmental regulations is expected to continue, with potential focus areas including lower emission thresholds, broader coverage of VOC species, and increased emphasis on energy efficiency in abatement processes. This evolving regulatory landscape will continue to shape the strategic design of abatement technologies for decane and other VOCs, driving further innovation and technological advancement in the field.

The regulatory framework for VOC control varies across different regions and countries, but generally follows a trend of tightening restrictions. In the United States, the Clean Air Act and its amendments have set the foundation for VOC emission standards, with the Environmental Protection Agency (EPA) playing a crucial role in enforcement. The EPA's National Emission Standards for Hazardous Air Pollutants (NESHAP) and New Source Performance Standards (NSPS) directly affect industries that emit decane and other VOCs.

European regulations, such as the Industrial Emissions Directive (IED) and the VOC Solvents Emissions Directive, have also significantly influenced abatement technology strategies. These directives set emission limit values and require the use of best available techniques (BAT) for VOC control, pushing industries to adopt more advanced and efficient abatement technologies.

The impact of these regulations on decane abatement technology design is multifaceted. Firstly, they have driven innovation in abatement technologies, encouraging the development of more efficient and cost-effective solutions. This has led to advancements in thermal oxidation, catalytic oxidation, and adsorption technologies specifically tailored for decane and similar VOCs.

Secondly, regulations have influenced the selection criteria for abatement technologies. Industries must now consider not only the efficiency of VOC removal but also the environmental impact of the abatement process itself. This has led to a growing interest in technologies that minimize secondary pollutants and energy consumption, such as regenerative thermal oxidizers and bio-filtration systems.

Furthermore, regulatory requirements have necessitated more comprehensive monitoring and reporting systems. This has spurred the development of advanced continuous emission monitoring systems (CEMS) and predictive emission monitoring systems (PEMS), which are now integral components of VOC abatement strategies.

The economic implications of these regulations are significant. Industries must balance the costs of compliance with potential penalties for non-compliance, often leading to substantial investments in abatement technologies. This has created a market for innovative financing models and service-based solutions in the VOC abatement sector.

Looking ahead, the trend towards stricter environmental regulations is expected to continue, with potential focus areas including lower emission thresholds, broader coverage of VOC species, and increased emphasis on energy efficiency in abatement processes. This evolving regulatory landscape will continue to shape the strategic design of abatement technologies for decane and other VOCs, driving further innovation and technological advancement in the field.

Cost-Benefit Analysis of Decane Abatement Solutions

The cost-benefit analysis of decane abatement solutions is a critical component in evaluating the strategic design of VOC emission control technologies. This analysis encompasses both the economic and environmental aspects of implementing decane abatement measures.

From an economic standpoint, the initial capital investment for decane abatement technologies can be substantial. This includes the cost of equipment such as thermal oxidizers, catalytic oxidizers, or adsorption systems specifically designed for decane removal. Additionally, installation and integration expenses within existing industrial processes must be considered.

Operational costs form a significant portion of the overall expenditure. These include energy consumption, particularly for thermal oxidation methods, which require high temperatures to effectively break down decane molecules. Maintenance and replacement of catalysts or adsorbent materials also contribute to ongoing expenses.

However, these costs must be weighed against the potential benefits. Improved air quality resulting from reduced decane emissions can lead to decreased healthcare costs associated with respiratory illnesses and other health issues. This societal benefit, while challenging to quantify precisely, is a crucial factor in the overall analysis.

From a regulatory perspective, implementing effective decane abatement solutions can help industries avoid costly fines and penalties associated with non-compliance of VOC emission standards. Moreover, it can enhance a company's reputation, potentially leading to improved stakeholder relations and market positioning.

Energy recovery systems integrated with thermal oxidation technologies can partially offset operational costs by utilizing the heat generated during the decane abatement process. This recovered energy can be redirected to other industrial processes, reducing overall energy consumption and associated costs.

Long-term benefits may include increased process efficiency and product quality. By removing decane from industrial emissions, certain manufacturing processes may experience improvements in yield or product purity, indirectly contributing to the cost-benefit balance.

The environmental benefits of decane abatement extend beyond local air quality improvement. Reduction in VOC emissions contributes to the mitigation of ground-level ozone formation, a significant environmental and health concern in many urban and industrial areas.

In conclusion, while the upfront and operational costs of decane abatement solutions can be significant, the long-term economic, environmental, and societal benefits often justify the investment. A comprehensive cost-benefit analysis should consider both quantifiable factors such as equipment and energy costs, and less tangible aspects like public health improvements and regulatory compliance.

From an economic standpoint, the initial capital investment for decane abatement technologies can be substantial. This includes the cost of equipment such as thermal oxidizers, catalytic oxidizers, or adsorption systems specifically designed for decane removal. Additionally, installation and integration expenses within existing industrial processes must be considered.

Operational costs form a significant portion of the overall expenditure. These include energy consumption, particularly for thermal oxidation methods, which require high temperatures to effectively break down decane molecules. Maintenance and replacement of catalysts or adsorbent materials also contribute to ongoing expenses.

However, these costs must be weighed against the potential benefits. Improved air quality resulting from reduced decane emissions can lead to decreased healthcare costs associated with respiratory illnesses and other health issues. This societal benefit, while challenging to quantify precisely, is a crucial factor in the overall analysis.

From a regulatory perspective, implementing effective decane abatement solutions can help industries avoid costly fines and penalties associated with non-compliance of VOC emission standards. Moreover, it can enhance a company's reputation, potentially leading to improved stakeholder relations and market positioning.

Energy recovery systems integrated with thermal oxidation technologies can partially offset operational costs by utilizing the heat generated during the decane abatement process. This recovered energy can be redirected to other industrial processes, reducing overall energy consumption and associated costs.

Long-term benefits may include increased process efficiency and product quality. By removing decane from industrial emissions, certain manufacturing processes may experience improvements in yield or product purity, indirectly contributing to the cost-benefit balance.

The environmental benefits of decane abatement extend beyond local air quality improvement. Reduction in VOC emissions contributes to the mitigation of ground-level ozone formation, a significant environmental and health concern in many urban and industrial areas.

In conclusion, while the upfront and operational costs of decane abatement solutions can be significant, the long-term economic, environmental, and societal benefits often justify the investment. A comprehensive cost-benefit analysis should consider both quantifiable factors such as equipment and energy costs, and less tangible aspects like public health improvements and regulatory compliance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!