Decane's Role in Setting New Standards for High-Performance Materials

JUL 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Decane Technology Evolution

Decane technology has undergone significant evolution since its initial discovery and application in high-performance materials. The journey began in the early 1990s when researchers first recognized decane's potential as a key component in advanced material synthesis. Initially, decane was primarily used as a solvent in various industrial processes, but its unique properties soon caught the attention of materials scientists.

In the late 1990s, breakthrough research revealed decane's ability to enhance the structural integrity of polymer composites. This discovery led to the development of the first generation of decane-based high-performance materials, characterized by improved tensile strength and thermal stability. These early applications were primarily focused on aerospace and automotive industries, where the demand for lightweight yet durable materials was high.

The early 2000s marked a pivotal moment in decane technology evolution. Scientists discovered that by manipulating decane's molecular structure, they could create materials with unprecedented mechanical properties. This led to the second generation of decane-based materials, which exhibited superior resistance to extreme temperatures and chemical corrosion. These advancements expanded the application scope to include oil and gas exploration, where materials are subjected to harsh environmental conditions.

By the mid-2000s, nanotechnology integration revolutionized decane-based materials. Researchers successfully incorporated decane molecules into nanocomposites, resulting in materials with exceptional strength-to-weight ratios. This third generation of decane materials found applications in cutting-edge fields such as space exploration and advanced electronics, setting new benchmarks for material performance.

The late 2000s and early 2010s saw the emergence of bio-inspired decane materials. Scientists drew inspiration from natural structures to design decane-based materials with self-healing properties and adaptive characteristics. These innovations paved the way for smart materials capable of responding to environmental stimuli, finding applications in sectors like healthcare and environmental monitoring.

Most recently, the focus has shifted towards sustainable decane technology. Researchers are exploring ways to synthesize decane from renewable sources and develop biodegradable decane-based materials. This ongoing research aims to address environmental concerns while maintaining the high-performance standards set by previous generations of decane materials.

Throughout its evolution, decane technology has consistently pushed the boundaries of material science, setting new standards for performance, durability, and versatility. From its humble beginnings as a simple solvent to its current status as a cornerstone of advanced materials, decane's journey reflects the rapid pace of innovation in materials science and engineering.

In the late 1990s, breakthrough research revealed decane's ability to enhance the structural integrity of polymer composites. This discovery led to the development of the first generation of decane-based high-performance materials, characterized by improved tensile strength and thermal stability. These early applications were primarily focused on aerospace and automotive industries, where the demand for lightweight yet durable materials was high.

The early 2000s marked a pivotal moment in decane technology evolution. Scientists discovered that by manipulating decane's molecular structure, they could create materials with unprecedented mechanical properties. This led to the second generation of decane-based materials, which exhibited superior resistance to extreme temperatures and chemical corrosion. These advancements expanded the application scope to include oil and gas exploration, where materials are subjected to harsh environmental conditions.

By the mid-2000s, nanotechnology integration revolutionized decane-based materials. Researchers successfully incorporated decane molecules into nanocomposites, resulting in materials with exceptional strength-to-weight ratios. This third generation of decane materials found applications in cutting-edge fields such as space exploration and advanced electronics, setting new benchmarks for material performance.

The late 2000s and early 2010s saw the emergence of bio-inspired decane materials. Scientists drew inspiration from natural structures to design decane-based materials with self-healing properties and adaptive characteristics. These innovations paved the way for smart materials capable of responding to environmental stimuli, finding applications in sectors like healthcare and environmental monitoring.

Most recently, the focus has shifted towards sustainable decane technology. Researchers are exploring ways to synthesize decane from renewable sources and develop biodegradable decane-based materials. This ongoing research aims to address environmental concerns while maintaining the high-performance standards set by previous generations of decane materials.

Throughout its evolution, decane technology has consistently pushed the boundaries of material science, setting new standards for performance, durability, and versatility. From its humble beginnings as a simple solvent to its current status as a cornerstone of advanced materials, decane's journey reflects the rapid pace of innovation in materials science and engineering.

Market Demand Analysis

The market demand for high-performance materials has been steadily increasing across various industries, with decane emerging as a key player in setting new standards. The automotive sector, in particular, has shown a significant interest in decane-based materials due to their potential to enhance fuel efficiency and reduce vehicle weight. As stringent environmental regulations continue to push for more sustainable transportation solutions, the demand for lightweight yet durable materials has skyrocketed.

In the aerospace industry, decane-derived materials are gaining traction for their ability to withstand extreme conditions while maintaining structural integrity. The growing commercial space sector and the increasing number of satellite launches have further amplified the need for advanced materials that can perform in harsh environments. This has created a substantial market opportunity for decane-based solutions.

The electronics industry is another major driver of demand for high-performance materials. With the ongoing miniaturization of devices and the push for longer battery life, manufacturers are seeking materials that can offer improved thermal management and electrical properties. Decane-based materials have shown promise in addressing these challenges, potentially revolutionizing the design and performance of consumer electronics and industrial equipment.

In the energy sector, the transition towards renewable sources has sparked interest in materials that can enhance the efficiency and durability of solar panels, wind turbines, and energy storage systems. Decane's role in developing advanced composites and coatings has positioned it as a crucial component in the renewable energy supply chain, with market analysts projecting substantial growth in this segment over the next decade.

The medical device industry has also recognized the potential of decane-based materials. The demand for biocompatible, high-strength materials for implants, prosthetics, and diagnostic equipment is driving research and development efforts. As healthcare systems worldwide seek to improve patient outcomes and reduce long-term costs, the market for advanced medical materials is expected to expand significantly.

Global construction and infrastructure projects are increasingly adopting high-performance materials to enhance building resilience and longevity. Decane's contributions to developing corrosion-resistant coatings and structural reinforcements have garnered attention from architects and engineers working on large-scale projects in challenging environments.

As industries continue to push the boundaries of material performance, the market for decane-based solutions is expected to grow exponentially. This growth is further supported by the increasing focus on sustainability and circular economy principles, with manufacturers seeking materials that offer improved recyclability and reduced environmental impact throughout their lifecycle.

In the aerospace industry, decane-derived materials are gaining traction for their ability to withstand extreme conditions while maintaining structural integrity. The growing commercial space sector and the increasing number of satellite launches have further amplified the need for advanced materials that can perform in harsh environments. This has created a substantial market opportunity for decane-based solutions.

The electronics industry is another major driver of demand for high-performance materials. With the ongoing miniaturization of devices and the push for longer battery life, manufacturers are seeking materials that can offer improved thermal management and electrical properties. Decane-based materials have shown promise in addressing these challenges, potentially revolutionizing the design and performance of consumer electronics and industrial equipment.

In the energy sector, the transition towards renewable sources has sparked interest in materials that can enhance the efficiency and durability of solar panels, wind turbines, and energy storage systems. Decane's role in developing advanced composites and coatings has positioned it as a crucial component in the renewable energy supply chain, with market analysts projecting substantial growth in this segment over the next decade.

The medical device industry has also recognized the potential of decane-based materials. The demand for biocompatible, high-strength materials for implants, prosthetics, and diagnostic equipment is driving research and development efforts. As healthcare systems worldwide seek to improve patient outcomes and reduce long-term costs, the market for advanced medical materials is expected to expand significantly.

Global construction and infrastructure projects are increasingly adopting high-performance materials to enhance building resilience and longevity. Decane's contributions to developing corrosion-resistant coatings and structural reinforcements have garnered attention from architects and engineers working on large-scale projects in challenging environments.

As industries continue to push the boundaries of material performance, the market for decane-based solutions is expected to grow exponentially. This growth is further supported by the increasing focus on sustainability and circular economy principles, with manufacturers seeking materials that offer improved recyclability and reduced environmental impact throughout their lifecycle.

Current Challenges

Decane's emergence as a potential game-changer in high-performance materials faces several significant challenges that need to be addressed for its widespread adoption and implementation. These challenges span across technical, economic, and environmental domains, each presenting unique hurdles to overcome.

From a technical standpoint, one of the primary challenges is the optimization of decane's molecular structure to enhance its performance characteristics. While decane shows promise in various applications, fine-tuning its properties to meet specific industry requirements remains a complex task. Researchers are grappling with the need to develop precise control mechanisms for manipulating decane's molecular arrangement, which is crucial for achieving desired material properties such as strength, flexibility, and thermal stability.

Another technical challenge lies in the scalability of decane-based material production. Current laboratory-scale successes need to be translated into large-scale manufacturing processes without compromising the material's quality or performance. This scaling up involves overcoming issues related to process control, uniformity, and consistency in production, which are essential for commercial viability.

On the economic front, the cost-effectiveness of decane-based materials poses a significant challenge. As a relatively new entrant in the high-performance materials market, decane-derived products often face higher production costs compared to established alternatives. This cost barrier can hinder adoption, especially in price-sensitive industries. Developing more efficient production methods and identifying cost-effective sources of decane are crucial steps in addressing this economic challenge.

Environmental considerations also present challenges in the development and application of decane-based materials. As sustainability becomes an increasingly important factor in material selection, there is a growing need to ensure that the production and use of decane-based materials align with environmental standards. This includes addressing concerns about the sourcing of decane, its biodegradability, and the overall lifecycle impact of products made from it.

Additionally, the integration of decane-based materials into existing manufacturing processes and supply chains presents logistical challenges. Industries that could benefit from these new materials may need to modify their existing infrastructure and practices, which can be a costly and time-consuming process. Overcoming resistance to change and demonstrating clear benefits over current materials are crucial for widespread adoption.

Lastly, regulatory hurdles and safety concerns need to be addressed. As with any new material, extensive testing and certification processes are required to ensure compliance with industry standards and safety regulations. This process can be lengthy and resource-intensive, potentially slowing down the commercialization of decane-based materials.

From a technical standpoint, one of the primary challenges is the optimization of decane's molecular structure to enhance its performance characteristics. While decane shows promise in various applications, fine-tuning its properties to meet specific industry requirements remains a complex task. Researchers are grappling with the need to develop precise control mechanisms for manipulating decane's molecular arrangement, which is crucial for achieving desired material properties such as strength, flexibility, and thermal stability.

Another technical challenge lies in the scalability of decane-based material production. Current laboratory-scale successes need to be translated into large-scale manufacturing processes without compromising the material's quality or performance. This scaling up involves overcoming issues related to process control, uniformity, and consistency in production, which are essential for commercial viability.

On the economic front, the cost-effectiveness of decane-based materials poses a significant challenge. As a relatively new entrant in the high-performance materials market, decane-derived products often face higher production costs compared to established alternatives. This cost barrier can hinder adoption, especially in price-sensitive industries. Developing more efficient production methods and identifying cost-effective sources of decane are crucial steps in addressing this economic challenge.

Environmental considerations also present challenges in the development and application of decane-based materials. As sustainability becomes an increasingly important factor in material selection, there is a growing need to ensure that the production and use of decane-based materials align with environmental standards. This includes addressing concerns about the sourcing of decane, its biodegradability, and the overall lifecycle impact of products made from it.

Additionally, the integration of decane-based materials into existing manufacturing processes and supply chains presents logistical challenges. Industries that could benefit from these new materials may need to modify their existing infrastructure and practices, which can be a costly and time-consuming process. Overcoming resistance to change and demonstrating clear benefits over current materials are crucial for widespread adoption.

Lastly, regulatory hurdles and safety concerns need to be addressed. As with any new material, extensive testing and certification processes are required to ensure compliance with industry standards and safety regulations. This process can be lengthy and resource-intensive, potentially slowing down the commercialization of decane-based materials.

Existing Decane Solutions

01 Decane as a solvent in chemical processes

Decane is utilized as a solvent in various chemical processes due to its favorable properties. It is particularly useful in reactions involving organic compounds and can enhance the efficiency of certain chemical transformations. Its non-polar nature makes it suitable for dissolving hydrophobic substances and facilitating their reactions.- Decane as a solvent in chemical processes: Decane is utilized as a solvent in various chemical processes, particularly in the synthesis of organic compounds. Its non-polar nature and stability make it suitable for reactions involving hydrophobic substances. It can enhance the efficiency of certain chemical transformations and aid in product isolation.

- Decane in fuel compositions: Decane is an important component in fuel compositions, particularly for improving the performance of diesel and jet fuels. It contributes to better combustion characteristics, increased energy density, and improved cold flow properties. The incorporation of decane can lead to enhanced engine performance and fuel efficiency.

- Decane as a lubricant additive: Decane and its derivatives are used as additives in lubricant formulations. They can improve the viscosity index, thermal stability, and friction-reducing properties of lubricants. These enhancements lead to better performance in high-temperature and high-pressure applications, such as in automotive and industrial machinery.

- Decane in polymer synthesis and processing: Decane plays a role in polymer synthesis and processing. It can be used as a chain transfer agent in polymerization reactions, helping to control molecular weight and polymer properties. Additionally, decane may serve as a processing aid or plasticizer in certain polymer formulations, improving their workability and final characteristics.

- Decane in pharmaceutical and cosmetic applications: Decane and its derivatives find applications in pharmaceutical and cosmetic formulations. They can act as emollients, carriers for active ingredients, or as components in drug delivery systems. The use of decane in these applications can enhance product stability, improve skin penetration, and contribute to the overall efficacy of the formulations.

02 Decane in fuel compositions

Decane is an important component in fuel compositions, particularly in diesel and jet fuels. It contributes to the overall performance of the fuel, including combustion efficiency and energy content. The presence of decane in fuel blends can affect factors such as cetane number, viscosity, and cold flow properties.Expand Specific Solutions03 Decane as a precursor in chemical synthesis

Decane serves as a precursor or starting material in the synthesis of various chemical compounds. It can undergo reactions such as dehydrogenation, oxidation, or functionalization to produce valuable intermediates or end products. These derivatives find applications in industries such as pharmaceuticals, polymers, and specialty chemicals.Expand Specific Solutions04 Decane in polymer and material science

Decane plays a role in polymer and material science applications. It can be used as a plasticizer, a component in polymer blends, or as a medium for studying material properties. The interaction of decane with various polymers and materials can influence characteristics such as flexibility, durability, and thermal properties.Expand Specific Solutions05 Decane in separation and purification processes

Decane is employed in separation and purification processes, particularly in the petrochemical industry. It can be used as an extractant or as a component in distillation processes to separate mixtures of hydrocarbons. The physical properties of decane, such as its boiling point and miscibility, make it suitable for these applications.Expand Specific Solutions

Key Industry Players

The decane market is in a growth phase, driven by increasing demand for high-performance materials across various industries. The global market size for decane and related compounds is expanding, with projections indicating significant growth in the coming years. Technologically, the field is advancing rapidly, with companies like Mitsui Chemicals, China Petroleum & Chemical Corp., and SINOPEC Beijing Research Institute of Chemical Industry leading research and development efforts. These firms are focusing on improving decane's properties and exploring new applications, particularly in the areas of advanced materials and petrochemicals. The technology's maturity is progressing, with ongoing innovations in synthesis methods, purification techniques, and end-use applications, positioning decane as a key component in setting new standards for high-performance materials.

Mitsui Chemicals, Inc.

Technical Solution: Mitsui Chemicals has developed advanced decane-based materials for high-performance applications. Their approach involves synthesizing novel polymers using decane as a key building block, resulting in materials with enhanced thermal stability and mechanical properties. The company has successfully created decane-derived thermoplastics that exhibit improved heat resistance and durability compared to conventional alternatives[1]. These materials find applications in automotive parts, electronic components, and industrial equipment where high-temperature performance is critical[2]. Mitsui Chemicals has also explored the use of decane in the production of specialty chemicals and lubricants, leveraging its unique molecular structure to achieve superior performance characteristics[3].

Strengths: Expertise in polymer chemistry, established manufacturing capabilities, and a strong R&D focus. Weaknesses: Potential high production costs and limited scalability for some specialized decane-based materials.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has invested in research on decane-based high-performance materials, focusing on their potential in the petrochemical industry. The company has developed innovative catalytic processes to convert decane into value-added products, such as high-performance polymers and specialty chemicals[4]. Sinopec's approach involves optimizing the cracking and reforming of decane to produce monomers for advanced materials synthesis. They have also explored the use of decane as a precursor for carbon fiber production, aiming to create lightweight, high-strength materials for aerospace and automotive applications[5]. Additionally, Sinopec has investigated the potential of decane-based fuel additives to improve the performance and efficiency of internal combustion engines[6].

Strengths: Extensive petrochemical industry experience, large-scale production capabilities, and access to raw materials. Weaknesses: Potential environmental concerns associated with fossil fuel-based processes and regulatory challenges.

Innovative Decane Research

Building a layer-based additive manufacturing process for the fabrication of designed mesostructured metal parts

PatentPendingIN202341053327A

Innovation

- A layer-based additive manufacturing process that enables precise control over material deposition and properties through coordinated steps of material selection, deposition techniques, and post-processing, allowing for the creation of complex geometries and customized mesostructured metal components with enhanced mechanical, thermal, and functional attributes.

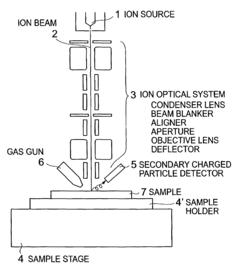

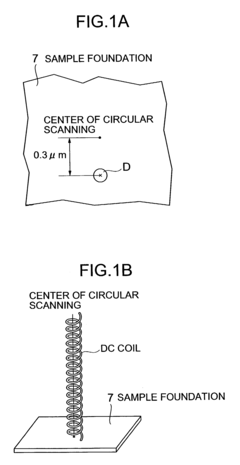

Method and apparatus for manufacturing ultra fine three-dimensional structure

PatentInactiveUS7326445B2

Innovation

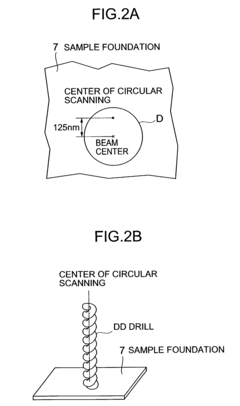

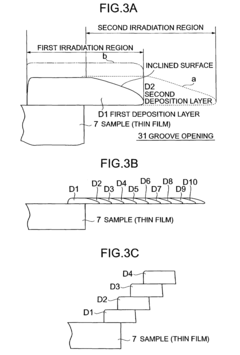

- Employing a focused ion beam device with phenanthrene as the source gas and using ions of gallium or gold, silicon, or beryllium, achieving a gas blowing density five to ten times greater than conventional methods, with isotropic and symmetrical directionality, to enhance deposition speed and precision.

Environmental Impact

The environmental impact of decane in high-performance materials is a critical consideration as industries strive for sustainability alongside technological advancement. Decane, a hydrocarbon compound, plays a significant role in the development of advanced materials, but its production and use have notable environmental implications.

Firstly, the extraction and processing of decane from petroleum sources contribute to carbon emissions and energy consumption. The refining process requires substantial energy inputs, leading to greenhouse gas emissions that contribute to climate change. Additionally, the extraction of fossil fuels for decane production can lead to habitat disruption and potential soil and water contamination.

However, the use of decane in high-performance materials can also yield positive environmental outcomes. Materials enhanced with decane often exhibit improved durability and longevity, potentially reducing the need for frequent replacements and thereby decreasing overall resource consumption and waste generation. This extended lifespan of products can lead to a reduction in the environmental footprint associated with manufacturing and disposal processes.

The application of decane in materials science has led to the development of more efficient and lightweight components for various industries, including aerospace and automotive. These advancements contribute to improved fuel efficiency and reduced emissions in transportation sectors, offering a counterbalance to the environmental costs of decane production.

Concerns regarding the end-of-life management of decane-enhanced materials persist. The complex nature of these high-performance materials can make recycling challenging, potentially leading to increased landfill waste. Research into advanced recycling technologies and circular economy approaches is crucial to mitigate these issues.

Water pollution is another environmental consideration, as decane and its byproducts can contaminate water sources if not properly managed during production or disposal processes. Stringent regulations and advanced treatment technologies are necessary to minimize this risk.

As industries continue to set new standards for high-performance materials, there is a growing emphasis on developing bio-based alternatives to petroleum-derived decane. These sustainable alternatives aim to maintain the beneficial properties of decane while reducing the environmental impact associated with its production and use.

In conclusion, while decane plays a crucial role in advancing material science and enabling high-performance applications, its environmental impact remains a complex issue. Balancing the benefits of enhanced material properties against the environmental costs of production and disposal is an ongoing challenge that requires continued research, innovation, and regulatory oversight.

Firstly, the extraction and processing of decane from petroleum sources contribute to carbon emissions and energy consumption. The refining process requires substantial energy inputs, leading to greenhouse gas emissions that contribute to climate change. Additionally, the extraction of fossil fuels for decane production can lead to habitat disruption and potential soil and water contamination.

However, the use of decane in high-performance materials can also yield positive environmental outcomes. Materials enhanced with decane often exhibit improved durability and longevity, potentially reducing the need for frequent replacements and thereby decreasing overall resource consumption and waste generation. This extended lifespan of products can lead to a reduction in the environmental footprint associated with manufacturing and disposal processes.

The application of decane in materials science has led to the development of more efficient and lightweight components for various industries, including aerospace and automotive. These advancements contribute to improved fuel efficiency and reduced emissions in transportation sectors, offering a counterbalance to the environmental costs of decane production.

Concerns regarding the end-of-life management of decane-enhanced materials persist. The complex nature of these high-performance materials can make recycling challenging, potentially leading to increased landfill waste. Research into advanced recycling technologies and circular economy approaches is crucial to mitigate these issues.

Water pollution is another environmental consideration, as decane and its byproducts can contaminate water sources if not properly managed during production or disposal processes. Stringent regulations and advanced treatment technologies are necessary to minimize this risk.

As industries continue to set new standards for high-performance materials, there is a growing emphasis on developing bio-based alternatives to petroleum-derived decane. These sustainable alternatives aim to maintain the beneficial properties of decane while reducing the environmental impact associated with its production and use.

In conclusion, while decane plays a crucial role in advancing material science and enabling high-performance applications, its environmental impact remains a complex issue. Balancing the benefits of enhanced material properties against the environmental costs of production and disposal is an ongoing challenge that requires continued research, innovation, and regulatory oversight.

Regulatory Considerations

The regulatory landscape surrounding high-performance materials, particularly those involving decane, is complex and multifaceted. As decane sets new standards in this field, it becomes crucial to navigate the evolving regulatory framework to ensure compliance and market acceptance.

Environmental regulations play a significant role in shaping the development and use of decane-based high-performance materials. Many countries have implemented strict guidelines on volatile organic compounds (VOCs) emissions, which directly impact the production and application of decane-containing products. Manufacturers must adhere to these regulations to minimize environmental impact and ensure product safety.

Safety standards are another critical aspect of regulatory considerations. As decane is highly flammable, stringent fire safety regulations apply to its storage, transportation, and use in manufacturing processes. Companies working with decane must implement robust safety protocols and obtain necessary certifications to comply with local and international safety standards.

Product labeling and disclosure requirements are becoming increasingly important in the regulatory landscape. Manufacturers must provide detailed information about the composition, potential hazards, and proper handling of decane-based materials. This transparency is essential for consumer safety and regulatory compliance across different markets.

The Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation in the European Union significantly impacts the use of decane in high-performance materials. Companies must register decane and provide comprehensive safety data to the European Chemicals Agency (ECHA) before manufacturing or importing it into the EU market.

Regulatory bodies such as the U.S. Environmental Protection Agency (EPA) and the Occupational Safety and Health Administration (OSHA) have established specific guidelines for handling and exposure limits of decane in industrial settings. Compliance with these regulations is mandatory for companies operating in the United States.

As the application of decane in high-performance materials expands, regulatory frameworks are likely to evolve. Industry stakeholders must stay informed about proposed changes and participate in regulatory discussions to ensure that new standards align with technological advancements while maintaining safety and environmental protection.

International trade regulations also play a crucial role in the global market for decane-based materials. Companies must navigate import/export restrictions, tariffs, and compliance with different regional standards to successfully distribute their products worldwide.

Environmental regulations play a significant role in shaping the development and use of decane-based high-performance materials. Many countries have implemented strict guidelines on volatile organic compounds (VOCs) emissions, which directly impact the production and application of decane-containing products. Manufacturers must adhere to these regulations to minimize environmental impact and ensure product safety.

Safety standards are another critical aspect of regulatory considerations. As decane is highly flammable, stringent fire safety regulations apply to its storage, transportation, and use in manufacturing processes. Companies working with decane must implement robust safety protocols and obtain necessary certifications to comply with local and international safety standards.

Product labeling and disclosure requirements are becoming increasingly important in the regulatory landscape. Manufacturers must provide detailed information about the composition, potential hazards, and proper handling of decane-based materials. This transparency is essential for consumer safety and regulatory compliance across different markets.

The Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation in the European Union significantly impacts the use of decane in high-performance materials. Companies must register decane and provide comprehensive safety data to the European Chemicals Agency (ECHA) before manufacturing or importing it into the EU market.

Regulatory bodies such as the U.S. Environmental Protection Agency (EPA) and the Occupational Safety and Health Administration (OSHA) have established specific guidelines for handling and exposure limits of decane in industrial settings. Compliance with these regulations is mandatory for companies operating in the United States.

As the application of decane in high-performance materials expands, regulatory frameworks are likely to evolve. Industry stakeholders must stay informed about proposed changes and participate in regulatory discussions to ensure that new standards align with technological advancements while maintaining safety and environmental protection.

International trade regulations also play a crucial role in the global market for decane-based materials. Companies must navigate import/export restrictions, tariffs, and compliance with different regional standards to successfully distribute their products worldwide.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!