Design of Battery Management Systems for Electric Racing Vehicles

AUG 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

EV Racing BMS Background and Objectives

Battery Management Systems (BMS) for electric racing vehicles have emerged as a critical component in the rapidly evolving world of motorsports. The development of these systems has been driven by the increasing adoption of electric powertrains in racing, reflecting a broader shift towards sustainable technologies in the automotive industry. The primary objective of BMS in electric racing vehicles is to optimize battery performance, ensure safety, and maximize energy efficiency under extreme racing conditions.

The evolution of BMS technology in racing can be traced back to the early 2000s when electric vehicles began to make their mark in motorsports. Initially, these systems were rudimentary, focusing primarily on basic monitoring and protection functions. However, as electric racing gained prominence, the demands on BMS became more sophisticated, necessitating advanced features such as real-time cell balancing, thermal management, and predictive analytics.

In recent years, the development of BMS for electric racing vehicles has been characterized by a push towards higher power densities, faster charging capabilities, and enhanced durability. This trend is driven by the unique challenges posed by racing environments, including rapid acceleration and deceleration, high-speed cornering, and the need for quick pit stops. Consequently, modern racing BMS must not only manage battery health and safety but also contribute to overall vehicle performance and strategy.

The technical goals for BMS in electric racing vehicles are multifaceted. Firstly, there is a continuous drive to improve energy density and power output, allowing for longer race durations and higher top speeds. Secondly, enhancing the accuracy of state-of-charge and state-of-health estimations is crucial for optimizing race strategies and ensuring vehicle reliability. Thirdly, developing more efficient thermal management systems is essential to maintain battery performance under the extreme conditions of competitive racing.

Another key objective in BMS development for racing applications is the integration of advanced data analytics and machine learning algorithms. These technologies enable more precise predictions of battery behavior, allowing teams to fine-tune their strategies in real-time during races. Additionally, there is a growing focus on developing BMS that can support ultra-fast charging technologies, potentially revolutionizing pit stop strategies in electric racing series.

As the field of electric racing continues to expand, with series like Formula E gaining global popularity, the importance of innovative BMS solutions cannot be overstated. The technology developed for these high-performance applications often serves as a testbed for advancements that eventually find their way into consumer electric vehicles, highlighting the broader impact of racing BMS development on the automotive industry as a whole.

The evolution of BMS technology in racing can be traced back to the early 2000s when electric vehicles began to make their mark in motorsports. Initially, these systems were rudimentary, focusing primarily on basic monitoring and protection functions. However, as electric racing gained prominence, the demands on BMS became more sophisticated, necessitating advanced features such as real-time cell balancing, thermal management, and predictive analytics.

In recent years, the development of BMS for electric racing vehicles has been characterized by a push towards higher power densities, faster charging capabilities, and enhanced durability. This trend is driven by the unique challenges posed by racing environments, including rapid acceleration and deceleration, high-speed cornering, and the need for quick pit stops. Consequently, modern racing BMS must not only manage battery health and safety but also contribute to overall vehicle performance and strategy.

The technical goals for BMS in electric racing vehicles are multifaceted. Firstly, there is a continuous drive to improve energy density and power output, allowing for longer race durations and higher top speeds. Secondly, enhancing the accuracy of state-of-charge and state-of-health estimations is crucial for optimizing race strategies and ensuring vehicle reliability. Thirdly, developing more efficient thermal management systems is essential to maintain battery performance under the extreme conditions of competitive racing.

Another key objective in BMS development for racing applications is the integration of advanced data analytics and machine learning algorithms. These technologies enable more precise predictions of battery behavior, allowing teams to fine-tune their strategies in real-time during races. Additionally, there is a growing focus on developing BMS that can support ultra-fast charging technologies, potentially revolutionizing pit stop strategies in electric racing series.

As the field of electric racing continues to expand, with series like Formula E gaining global popularity, the importance of innovative BMS solutions cannot be overstated. The technology developed for these high-performance applications often serves as a testbed for advancements that eventually find their way into consumer electric vehicles, highlighting the broader impact of racing BMS development on the automotive industry as a whole.

Market Analysis for High-Performance EV Racing

The electric vehicle (EV) racing market is experiencing rapid growth and transformation, driven by advancements in battery technology and increasing interest in sustainable motorsports. This segment represents a unique intersection of high-performance engineering and eco-friendly innovation, attracting both traditional racing enthusiasts and environmentally conscious consumers.

The global market for high-performance EV racing is projected to expand significantly over the next decade. This growth is fueled by several factors, including stricter emissions regulations in many countries, technological advancements in electric powertrains, and a shift in consumer preferences towards sustainable transportation options. Major automotive manufacturers are increasingly investing in electric racing platforms, recognizing the potential for technology transfer to consumer EVs.

Formula E, the premier electric racing championship, has seen substantial growth since its inception in 2014. The series has attracted participation from renowned automotive brands such as Porsche, Mercedes-Benz, and Jaguar, highlighting the industry's commitment to electric racing. This has led to increased sponsorship deals, media coverage, and spectator interest, further driving market expansion.

The market for high-performance EV racing components, particularly advanced battery management systems (BMS), is also experiencing significant growth. As racing teams seek to optimize performance and energy efficiency, demand for sophisticated BMS solutions has surged. This has created opportunities for specialized engineering firms and technology providers to develop cutting-edge systems tailored for the unique demands of electric racing vehicles.

Emerging trends in the high-performance EV racing market include the development of ultra-fast charging technologies, lightweight battery designs, and advanced thermal management systems. These innovations are crucial for addressing the specific challenges of electric racing, such as maximizing power output while managing battery temperature and longevity.

The market is also seeing increased interest from traditional motorsport events and series. Several iconic races, including the Pikes Peak International Hill Climb and the 24 Hours of Le Mans, have introduced electric vehicle categories, further legitimizing and expanding the high-performance EV racing market.

As the technology matures and costs decrease, there is potential for electric racing to penetrate other motorsport disciplines, creating new market segments and opportunities for innovation. This expansion is likely to drive further investment in research and development, particularly in areas such as battery technology, power electronics, and lightweight materials.

The global market for high-performance EV racing is projected to expand significantly over the next decade. This growth is fueled by several factors, including stricter emissions regulations in many countries, technological advancements in electric powertrains, and a shift in consumer preferences towards sustainable transportation options. Major automotive manufacturers are increasingly investing in electric racing platforms, recognizing the potential for technology transfer to consumer EVs.

Formula E, the premier electric racing championship, has seen substantial growth since its inception in 2014. The series has attracted participation from renowned automotive brands such as Porsche, Mercedes-Benz, and Jaguar, highlighting the industry's commitment to electric racing. This has led to increased sponsorship deals, media coverage, and spectator interest, further driving market expansion.

The market for high-performance EV racing components, particularly advanced battery management systems (BMS), is also experiencing significant growth. As racing teams seek to optimize performance and energy efficiency, demand for sophisticated BMS solutions has surged. This has created opportunities for specialized engineering firms and technology providers to develop cutting-edge systems tailored for the unique demands of electric racing vehicles.

Emerging trends in the high-performance EV racing market include the development of ultra-fast charging technologies, lightweight battery designs, and advanced thermal management systems. These innovations are crucial for addressing the specific challenges of electric racing, such as maximizing power output while managing battery temperature and longevity.

The market is also seeing increased interest from traditional motorsport events and series. Several iconic races, including the Pikes Peak International Hill Climb and the 24 Hours of Le Mans, have introduced electric vehicle categories, further legitimizing and expanding the high-performance EV racing market.

As the technology matures and costs decrease, there is potential for electric racing to penetrate other motorsport disciplines, creating new market segments and opportunities for innovation. This expansion is likely to drive further investment in research and development, particularly in areas such as battery technology, power electronics, and lightweight materials.

Current BMS Challenges in EV Racing

Battery Management Systems (BMS) in electric racing vehicles face unique challenges due to the extreme conditions and performance requirements of motorsports. The high-power demands, rapid charging and discharging cycles, and intense thermal management needs push BMS technology to its limits in racing environments.

One of the primary challenges is managing the extreme power outputs required in racing. Electric racing vehicles often demand peak power outputs that far exceed those of conventional electric vehicles. This puts immense stress on the battery cells and requires sophisticated BMS algorithms to balance performance with safety and longevity. The BMS must constantly monitor and adjust power delivery to prevent overheating, cell degradation, and potential safety hazards.

Thermal management presents another significant hurdle. The high-power outputs generate substantial heat, which can rapidly degrade battery performance and lifespan if not properly managed. Racing BMS must incorporate advanced thermal modeling and predictive algorithms to anticipate and mitigate temperature spikes. This often involves complex integration with the vehicle's cooling systems and real-time adjustments based on racing conditions.

The rapid charging requirements of racing also pose unique challenges. To minimize pit stop times, racing EVs need to charge at much higher rates than conventional electric vehicles. This puts additional stress on the battery cells and requires the BMS to carefully manage the charging process to prevent damage and ensure optimal performance. Balancing the need for rapid charging with long-term battery health is a delicate and ongoing challenge.

Weight optimization is crucial in racing, and this extends to the BMS. Engineers must design systems that provide comprehensive battery management while minimizing additional weight. This often requires innovative approaches to sensor placement, wiring, and component selection, as well as the development of more efficient algorithms that can run on lighter, less powerful hardware.

The dynamic and unpredictable nature of racing also presents challenges for BMS design. Rapid acceleration, hard braking, and cornering forces can affect battery performance and require real-time adjustments. The BMS must be capable of adapting to these changing conditions while maintaining optimal performance and safety.

Lastly, the competitive nature of racing drives a constant push for innovation and performance improvements. BMS designers must continually evolve their systems to extract maximum performance from battery technology, often pushing the boundaries of what is considered safe or reliable in more conventional applications. This requires a delicate balance between performance optimization and risk management.

One of the primary challenges is managing the extreme power outputs required in racing. Electric racing vehicles often demand peak power outputs that far exceed those of conventional electric vehicles. This puts immense stress on the battery cells and requires sophisticated BMS algorithms to balance performance with safety and longevity. The BMS must constantly monitor and adjust power delivery to prevent overheating, cell degradation, and potential safety hazards.

Thermal management presents another significant hurdle. The high-power outputs generate substantial heat, which can rapidly degrade battery performance and lifespan if not properly managed. Racing BMS must incorporate advanced thermal modeling and predictive algorithms to anticipate and mitigate temperature spikes. This often involves complex integration with the vehicle's cooling systems and real-time adjustments based on racing conditions.

The rapid charging requirements of racing also pose unique challenges. To minimize pit stop times, racing EVs need to charge at much higher rates than conventional electric vehicles. This puts additional stress on the battery cells and requires the BMS to carefully manage the charging process to prevent damage and ensure optimal performance. Balancing the need for rapid charging with long-term battery health is a delicate and ongoing challenge.

Weight optimization is crucial in racing, and this extends to the BMS. Engineers must design systems that provide comprehensive battery management while minimizing additional weight. This often requires innovative approaches to sensor placement, wiring, and component selection, as well as the development of more efficient algorithms that can run on lighter, less powerful hardware.

The dynamic and unpredictable nature of racing also presents challenges for BMS design. Rapid acceleration, hard braking, and cornering forces can affect battery performance and require real-time adjustments. The BMS must be capable of adapting to these changing conditions while maintaining optimal performance and safety.

Lastly, the competitive nature of racing drives a constant push for innovation and performance improvements. BMS designers must continually evolve their systems to extract maximum performance from battery technology, often pushing the boundaries of what is considered safe or reliable in more conventional applications. This requires a delicate balance between performance optimization and risk management.

Existing BMS Solutions for Racing EVs

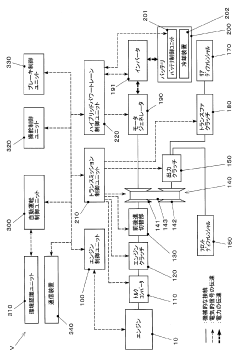

01 Battery monitoring and control systems

These systems monitor various parameters of batteries, such as voltage, current, temperature, and state of charge. They use this information to optimize battery performance, extend battery life, and ensure safe operation. Advanced algorithms are employed to estimate battery health and predict remaining useful life.- Battery monitoring and control systems: These systems monitor various parameters of battery cells or packs, such as voltage, current, temperature, and state of charge. They use this data to optimize battery performance, ensure safe operation, and extend battery life through intelligent charging and discharging strategies.

- Thermal management in battery systems: Thermal management is crucial for battery performance and safety. These systems employ various cooling or heating methods to maintain optimal operating temperatures, prevent overheating, and ensure uniform temperature distribution across battery packs.

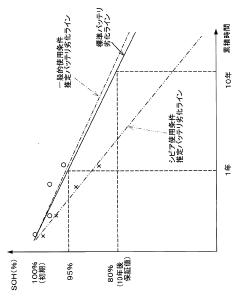

- Battery state estimation techniques: Advanced algorithms and methods are used to estimate critical battery states such as state of charge (SOC), state of health (SOH), and remaining useful life (RUL). These estimations help in optimizing battery usage and predicting maintenance needs.

- Cell balancing and charge equalization: These systems ensure that individual cells within a battery pack maintain similar charge levels. This balancing improves overall battery performance, extends lifespan, and prevents premature failure of individual cells.

- Integration with energy management systems: Battery management systems are increasingly integrated with broader energy management systems in applications such as electric vehicles and smart grids. This integration allows for optimized energy distribution, demand response, and grid stabilization.

02 Thermal management in battery systems

Thermal management is crucial for battery performance and safety. These systems regulate battery temperature through cooling or heating mechanisms, preventing overheating and maintaining optimal operating conditions. They may include liquid cooling systems, air cooling, or phase change materials for efficient heat dissipation.Expand Specific Solutions03 Cell balancing techniques

Cell balancing is essential for maintaining uniform charge levels across multiple cells in a battery pack. This involves redistributing charge between cells to prevent overcharging or undercharging, which can lead to reduced battery life or safety issues. Various methods, including passive and active balancing, are used to achieve this.Expand Specific Solutions04 State of charge and state of health estimation

Accurate estimation of a battery's state of charge (SoC) and state of health (SoH) is crucial for effective battery management. Advanced algorithms, including machine learning techniques, are used to analyze battery data and provide real-time estimates of these parameters. This information is vital for optimizing battery usage and predicting maintenance needs.Expand Specific Solutions05 Integration with energy management systems

Battery management systems are increasingly integrated with broader energy management systems, particularly in applications like electric vehicles and renewable energy storage. This integration allows for optimized energy distribution, demand response capabilities, and improved overall system efficiency. It may include features like smart charging and vehicle-to-grid technology.Expand Specific Solutions

Key Players in EV Racing BMS Industry

The competitive landscape for Battery Management Systems (BMS) in electric racing vehicles is evolving rapidly, reflecting the industry's early growth stage. The market size is expanding as more automotive companies enter the electric vehicle space, with established players like Renault, Hyundai, and Kia investing heavily. Technological maturity varies, with companies like Samsung SDI and Robert Bosch GmbH leading in battery technology. Emerging players such as Thunder Power and Turntide Technologies are bringing innovative approaches to BMS design. The involvement of traditional racing-focused companies like Brembo indicates the growing importance of specialized BMS for high-performance applications. Universities and research institutions are also contributing significantly to advancing BMS technology, suggesting a dynamic and collaborative ecosystem.

Samsung SDI Co., Ltd.

Technical Solution: Samsung SDI has developed a cutting-edge BMS for electric racing vehicles, focusing on high energy density and rapid charging capabilities. Their system utilizes advanced lithium-ion cell technology coupled with a smart BMS that features dynamic power allocation[7]. This allows for optimal energy distribution during different racing phases, such as acceleration, cornering, and regenerative braking. Samsung's BMS incorporates ultra-fast charging protocols that can replenish up to 80% of the battery capacity in under 15 minutes, crucial for pit stop strategies in endurance races[8]. The system also employs AI-driven predictive maintenance algorithms to anticipate potential battery issues before they affect race performance[9].

Strengths: High energy density, ultra-fast charging capabilities, and AI-driven predictive maintenance. Weaknesses: Potentially higher initial cost and may require specialized charging infrastructure.

Renault SA

Technical Solution: Renault has developed a comprehensive BMS for electric racing vehicles, drawing from their extensive experience in Formula E and electric vehicle production. Their system employs a modular architecture that allows for easy scalability and adaptation to different racing vehicle configurations[13]. Renault's BMS features advanced cell chemistry management, optimizing performance and longevity across various temperature ranges and charge/discharge cycles. The system incorporates a predictive energy management algorithm that continuously adjusts power output based on race strategy, track conditions, and real-time telemetry data[14]. Additionally, Renault's BMS includes an innovative regenerative braking optimization system that maximizes energy recovery during deceleration and cornering[15].

Strengths: Modular and scalable architecture, advanced energy management, and optimized regenerative braking. Weaknesses: May require fine-tuning for specific racing applications outside of Formula E.

Core BMS Innovations for EV Racing

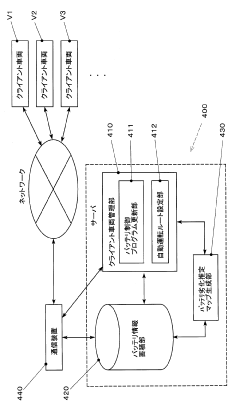

Battery management system for electric vehicle and electric vehicle

PatentActiveJP2022059540A

Innovation

- A battery management system that utilizes a network of electric vehicles to share deterioration and usage data, enabling accurate estimation of battery health and future deterioration, and adjusts vehicle control strategies to mitigate battery degradation through route optimization and power management.

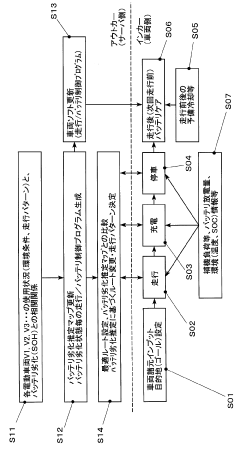

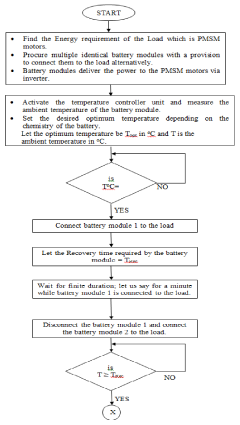

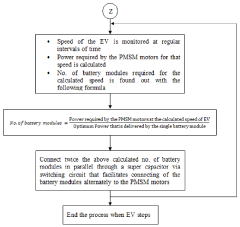

Battery management system for electric vehicles

PatentPendingIN201941044275A

Innovation

- A battery management system utilizing multiple battery modules, where a microcontroller alternately connects and rests modules to optimize power delivery and maintain ambient temperature, calculating the required number of modules based on vehicle speed and using a super capacitor for alternate switching to mitigate rate-capacity effects.

Safety Regulations for EV Racing

Safety regulations for electric vehicle (EV) racing are crucial to ensure the protection of drivers, spectators, and the environment. These regulations are continuously evolving to keep pace with advancements in EV technology, particularly in the realm of battery management systems (BMS) for racing vehicles. The International Automobile Federation (FIA) plays a pivotal role in establishing and enforcing these safety standards across various motorsport categories.

One of the primary focuses of EV racing safety regulations is the protection against electrical hazards. High-voltage systems in racing EVs require stringent insulation and isolation measures to prevent electrical shock risks. Regulations typically mandate the use of reinforced insulation materials, regular electrical safety checks, and the implementation of fail-safe mechanisms to quickly disconnect power in case of accidents or system failures.

Thermal management is another critical aspect addressed by safety regulations. The high-performance nature of racing EVs can lead to significant heat generation in battery packs. Regulations often specify maximum operating temperatures and require sophisticated cooling systems to prevent thermal runaway. Additionally, fire suppression systems specifically designed for lithium-ion battery fires are mandatory in many racing categories.

Crash safety is a paramount concern in EV racing regulations. The placement and protection of battery packs are strictly regulated to minimize the risk of damage during collisions. Reinforced battery enclosures, impact-absorbing structures, and strategic positioning of high-voltage components are typically required to enhance overall vehicle safety in the event of a crash.

Regulations also address the unique challenges of EV racing, such as the potential for silent operation. Many racing series mandate the use of artificial sound generators to alert track marshals and spectators of approaching vehicles, enhancing overall safety on and around the track.

The management of state of charge (SoC) and state of health (SoH) of batteries is another key area covered by safety regulations. Accurate monitoring and reporting of these parameters are essential to prevent over-discharge or overcharging scenarios that could compromise safety. Regulations often specify the required accuracy and reliability of BMS systems in tracking and reporting these critical battery parameters.

As EV racing technology continues to advance, safety regulations are adapting to address emerging challenges. For instance, recent updates have focused on the safe handling and disposal of damaged battery packs, as well as protocols for emergency responders dealing with EV racing accidents. These regulations are crucial in ensuring that the excitement of EV racing does not come at the cost of safety.

One of the primary focuses of EV racing safety regulations is the protection against electrical hazards. High-voltage systems in racing EVs require stringent insulation and isolation measures to prevent electrical shock risks. Regulations typically mandate the use of reinforced insulation materials, regular electrical safety checks, and the implementation of fail-safe mechanisms to quickly disconnect power in case of accidents or system failures.

Thermal management is another critical aspect addressed by safety regulations. The high-performance nature of racing EVs can lead to significant heat generation in battery packs. Regulations often specify maximum operating temperatures and require sophisticated cooling systems to prevent thermal runaway. Additionally, fire suppression systems specifically designed for lithium-ion battery fires are mandatory in many racing categories.

Crash safety is a paramount concern in EV racing regulations. The placement and protection of battery packs are strictly regulated to minimize the risk of damage during collisions. Reinforced battery enclosures, impact-absorbing structures, and strategic positioning of high-voltage components are typically required to enhance overall vehicle safety in the event of a crash.

Regulations also address the unique challenges of EV racing, such as the potential for silent operation. Many racing series mandate the use of artificial sound generators to alert track marshals and spectators of approaching vehicles, enhancing overall safety on and around the track.

The management of state of charge (SoC) and state of health (SoH) of batteries is another key area covered by safety regulations. Accurate monitoring and reporting of these parameters are essential to prevent over-discharge or overcharging scenarios that could compromise safety. Regulations often specify the required accuracy and reliability of BMS systems in tracking and reporting these critical battery parameters.

As EV racing technology continues to advance, safety regulations are adapting to address emerging challenges. For instance, recent updates have focused on the safe handling and disposal of damaged battery packs, as well as protocols for emergency responders dealing with EV racing accidents. These regulations are crucial in ensuring that the excitement of EV racing does not come at the cost of safety.

Thermal Management in Racing EV BMS

Thermal management is a critical aspect of Battery Management Systems (BMS) for electric racing vehicles. The high-performance nature of racing EVs demands efficient and robust thermal control strategies to maintain optimal battery performance and longevity. Racing conditions subject the battery pack to extreme temperature fluctuations and high discharge rates, necessitating advanced cooling solutions.

One of the primary challenges in racing EV thermal management is the rapid heat generation during high-power discharge events. To address this, liquid cooling systems have become increasingly prevalent in racing BMS designs. These systems utilize a coolant circulated through channels or plates in direct contact with battery cells, allowing for more efficient heat dissipation compared to traditional air cooling methods. The coolant is then passed through radiators or heat exchangers to release the absorbed heat.

Advanced thermal management systems in racing EVs often incorporate phase-change materials (PCMs) to provide additional thermal buffering. PCMs absorb excess heat during high-load conditions and release it during cooler periods, helping to maintain more stable battery temperatures throughout the race. This technology is particularly beneficial in managing temperature spikes during acceleration and regenerative braking events.

Intelligent thermal management algorithms play a crucial role in optimizing battery performance and safety. These algorithms continuously monitor cell temperatures and adjust cooling system parameters in real-time. By predicting thermal behavior based on driving conditions and battery state, the BMS can proactively manage temperature distribution across the pack, preventing localized hotspots and ensuring uniform cell aging.

The integration of thermal management with overall vehicle dynamics is another key consideration in racing EV BMS design. Heat generated by the battery pack can be strategically utilized to warm up other vehicle systems, such as the drivetrain or cabin, improving overall energy efficiency. Additionally, some racing teams are exploring the use of regenerative cooling systems that can recover waste heat and convert it back into usable energy, further enhancing the vehicle's performance envelope.

As racing EV technology continues to evolve, emerging trends in thermal management include the development of novel cell chemistries with improved thermal stability and the integration of artificial intelligence for more sophisticated thermal prediction and control. These advancements aim to push the boundaries of EV racing performance while maintaining the highest standards of safety and reliability.

One of the primary challenges in racing EV thermal management is the rapid heat generation during high-power discharge events. To address this, liquid cooling systems have become increasingly prevalent in racing BMS designs. These systems utilize a coolant circulated through channels or plates in direct contact with battery cells, allowing for more efficient heat dissipation compared to traditional air cooling methods. The coolant is then passed through radiators or heat exchangers to release the absorbed heat.

Advanced thermal management systems in racing EVs often incorporate phase-change materials (PCMs) to provide additional thermal buffering. PCMs absorb excess heat during high-load conditions and release it during cooler periods, helping to maintain more stable battery temperatures throughout the race. This technology is particularly beneficial in managing temperature spikes during acceleration and regenerative braking events.

Intelligent thermal management algorithms play a crucial role in optimizing battery performance and safety. These algorithms continuously monitor cell temperatures and adjust cooling system parameters in real-time. By predicting thermal behavior based on driving conditions and battery state, the BMS can proactively manage temperature distribution across the pack, preventing localized hotspots and ensuring uniform cell aging.

The integration of thermal management with overall vehicle dynamics is another key consideration in racing EV BMS design. Heat generated by the battery pack can be strategically utilized to warm up other vehicle systems, such as the drivetrain or cabin, improving overall energy efficiency. Additionally, some racing teams are exploring the use of regenerative cooling systems that can recover waste heat and convert it back into usable energy, further enhancing the vehicle's performance envelope.

As racing EV technology continues to evolve, emerging trends in thermal management include the development of novel cell chemistries with improved thermal stability and the integration of artificial intelligence for more sophisticated thermal prediction and control. These advancements aim to push the boundaries of EV racing performance while maintaining the highest standards of safety and reliability.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!