Design Patterns for Modular Battery Management Systems

AUG 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

BMS Design Evolution

The evolution of Battery Management System (BMS) design has been closely tied to the advancements in battery technology and the increasing demands of various applications. In the early stages, BMS designs were relatively simple, focusing primarily on basic monitoring and protection functions. These systems were often centralized, with a single control unit managing the entire battery pack.

As battery technologies progressed, particularly with the rise of lithium-ion batteries, BMS designs became more sophisticated. The need for more accurate monitoring, precise control, and enhanced safety features drove the development of more complex systems. This led to the introduction of distributed BMS architectures, where multiple control units were used to manage different sections of the battery pack, improving overall system reliability and performance.

The concept of modularity in BMS design emerged as a response to the growing complexity and diverse requirements of different applications. Modular BMS designs allow for greater flexibility, scalability, and customization. This approach enables manufacturers to adapt their BMS solutions to various battery configurations and application-specific needs without redesigning the entire system.

One significant trend in BMS design evolution has been the integration of advanced communication protocols and connectivity features. Modern BMS designs incorporate CAN bus, Ethernet, or wireless communication capabilities, enabling seamless integration with other vehicle systems and facilitating remote monitoring and diagnostics.

The advent of electric vehicles (EVs) has been a major driving force in BMS design evolution. EV applications demand high-performance BMS solutions capable of managing large battery packs, ensuring optimal performance, and maximizing driving range. This has led to the development of more advanced algorithms for state estimation, thermal management, and cell balancing.

Another important aspect of BMS design evolution has been the increasing focus on safety and reliability. Modern BMS designs incorporate multiple layers of protection, including hardware-based safety mechanisms and sophisticated software algorithms for fault detection and mitigation. This has become particularly crucial as battery packs have grown in size and energy density.

The trend towards miniaturization and cost reduction has also influenced BMS design evolution. Advancements in semiconductor technology have enabled the development of more compact and efficient BMS solutions, reducing overall system size and cost while improving performance.

Looking ahead, the future of BMS design is likely to be shaped by emerging technologies such as artificial intelligence and machine learning. These technologies hold the potential to enhance BMS capabilities in areas such as predictive maintenance, adaptive control, and optimized battery performance over the entire lifecycle.

As battery technologies progressed, particularly with the rise of lithium-ion batteries, BMS designs became more sophisticated. The need for more accurate monitoring, precise control, and enhanced safety features drove the development of more complex systems. This led to the introduction of distributed BMS architectures, where multiple control units were used to manage different sections of the battery pack, improving overall system reliability and performance.

The concept of modularity in BMS design emerged as a response to the growing complexity and diverse requirements of different applications. Modular BMS designs allow for greater flexibility, scalability, and customization. This approach enables manufacturers to adapt their BMS solutions to various battery configurations and application-specific needs without redesigning the entire system.

One significant trend in BMS design evolution has been the integration of advanced communication protocols and connectivity features. Modern BMS designs incorporate CAN bus, Ethernet, or wireless communication capabilities, enabling seamless integration with other vehicle systems and facilitating remote monitoring and diagnostics.

The advent of electric vehicles (EVs) has been a major driving force in BMS design evolution. EV applications demand high-performance BMS solutions capable of managing large battery packs, ensuring optimal performance, and maximizing driving range. This has led to the development of more advanced algorithms for state estimation, thermal management, and cell balancing.

Another important aspect of BMS design evolution has been the increasing focus on safety and reliability. Modern BMS designs incorporate multiple layers of protection, including hardware-based safety mechanisms and sophisticated software algorithms for fault detection and mitigation. This has become particularly crucial as battery packs have grown in size and energy density.

The trend towards miniaturization and cost reduction has also influenced BMS design evolution. Advancements in semiconductor technology have enabled the development of more compact and efficient BMS solutions, reducing overall system size and cost while improving performance.

Looking ahead, the future of BMS design is likely to be shaped by emerging technologies such as artificial intelligence and machine learning. These technologies hold the potential to enhance BMS capabilities in areas such as predictive maintenance, adaptive control, and optimized battery performance over the entire lifecycle.

Market Demand Analysis

The market demand for modular battery management systems (BMS) has been experiencing significant growth, driven by the rapid expansion of electric vehicles (EVs) and renewable energy storage solutions. As the automotive industry shifts towards electrification, the need for efficient and reliable BMS has become paramount. Major automakers are investing heavily in EV technology, with many committing to all-electric lineups within the next decade. This transition is creating a substantial market for modular BMS that can adapt to various battery configurations and vehicle types.

In the renewable energy sector, the increasing adoption of solar and wind power has led to a growing demand for large-scale energy storage systems. These systems require sophisticated BMS to manage complex battery arrays, optimize performance, and ensure safety. The modularity of BMS designs allows for scalability and flexibility, making them ideal for both residential and utility-scale applications.

The industrial sector is another key driver of market demand for modular BMS. As factories and warehouses increasingly adopt automated systems and electric machinery, the need for reliable power management solutions has grown. Modular BMS offers the advantage of easy integration with existing infrastructure and the ability to scale as energy needs evolve.

Consumer electronics represent another significant market segment for modular BMS. With the proliferation of portable devices and the trend towards longer battery life and faster charging, there is a growing demand for advanced BMS solutions that can optimize battery performance and extend device longevity.

Market analysts project the global BMS market to reach substantial valuations in the coming years, with modular systems expected to capture a significant share. The Asia-Pacific region, particularly China, is anticipated to lead in market growth due to its dominant position in EV manufacturing and battery production.

Key factors driving the demand for modular BMS include the need for improved battery life, enhanced safety features, and increased energy efficiency. As battery technologies continue to advance, BMS must evolve to manage more complex chemistries and higher energy densities. The modular approach allows for easier updates and adaptations to new battery technologies without requiring a complete system overhaul.

Furthermore, regulatory pressures and environmental concerns are pushing industries towards more sustainable practices, which in turn drives the adoption of electric and battery-powered solutions. This trend is expected to continue, further fueling the demand for sophisticated BMS across various sectors.

In the renewable energy sector, the increasing adoption of solar and wind power has led to a growing demand for large-scale energy storage systems. These systems require sophisticated BMS to manage complex battery arrays, optimize performance, and ensure safety. The modularity of BMS designs allows for scalability and flexibility, making them ideal for both residential and utility-scale applications.

The industrial sector is another key driver of market demand for modular BMS. As factories and warehouses increasingly adopt automated systems and electric machinery, the need for reliable power management solutions has grown. Modular BMS offers the advantage of easy integration with existing infrastructure and the ability to scale as energy needs evolve.

Consumer electronics represent another significant market segment for modular BMS. With the proliferation of portable devices and the trend towards longer battery life and faster charging, there is a growing demand for advanced BMS solutions that can optimize battery performance and extend device longevity.

Market analysts project the global BMS market to reach substantial valuations in the coming years, with modular systems expected to capture a significant share. The Asia-Pacific region, particularly China, is anticipated to lead in market growth due to its dominant position in EV manufacturing and battery production.

Key factors driving the demand for modular BMS include the need for improved battery life, enhanced safety features, and increased energy efficiency. As battery technologies continue to advance, BMS must evolve to manage more complex chemistries and higher energy densities. The modular approach allows for easier updates and adaptations to new battery technologies without requiring a complete system overhaul.

Furthermore, regulatory pressures and environmental concerns are pushing industries towards more sustainable practices, which in turn drives the adoption of electric and battery-powered solutions. This trend is expected to continue, further fueling the demand for sophisticated BMS across various sectors.

Technical Challenges

The development of modular Battery Management Systems (BMS) faces several significant technical challenges that need to be addressed for widespread adoption and optimal performance. One of the primary obstacles is the complexity of integrating multiple battery modules with varying characteristics and states of charge. This integration requires sophisticated algorithms and control systems to ensure balanced charging, discharging, and overall system stability.

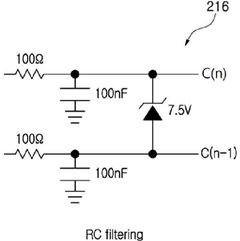

Another critical challenge lies in the realm of communication protocols. As modular BMS designs incorporate numerous sensors and control units across multiple battery modules, establishing reliable, low-latency communication becomes crucial. Existing protocols may struggle to handle the increased data flow and real-time requirements of large-scale modular systems, necessitating the development of more robust and efficient communication standards.

Thermal management presents a formidable challenge in modular BMS design. Each battery module may experience different thermal conditions based on its position, usage, and environmental factors. Designing a system that can effectively monitor and regulate temperature across all modules while maintaining overall efficiency is a complex task that requires innovative cooling solutions and thermal modeling techniques.

The scalability of modular BMS designs poses another significant hurdle. As the number of battery modules increases, the system's complexity grows exponentially. Ensuring that the BMS can seamlessly adapt to different configurations and sizes without compromising performance or reliability is a major technical challenge that demands flexible and scalable architecture designs.

Safety considerations in modular BMS designs are paramount and present their own set of challenges. Implementing robust fault detection, isolation, and recovery mechanisms across a distributed system of battery modules requires advanced diagnostic algorithms and fail-safe protocols. Additionally, ensuring uniform safety standards across all modules, regardless of their individual states or conditions, is a complex undertaking.

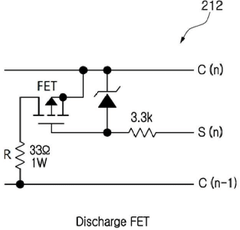

Power electronics and efficient energy management within modular BMS designs also present significant technical challenges. Optimizing power conversion and distribution across multiple modules while minimizing losses and maintaining system stability requires advanced circuit designs and control strategies. This becomes particularly challenging when dealing with modules of different capacities or chemistries within the same system.

Lastly, the development of accurate and reliable State of Health (SoH) and State of Charge (SoC) estimation algorithms for modular systems presents a unique challenge. These algorithms must account for the individual characteristics of each module while providing a cohesive overview of the entire battery system's status, a task that becomes increasingly complex as the number of modules grows.

Another critical challenge lies in the realm of communication protocols. As modular BMS designs incorporate numerous sensors and control units across multiple battery modules, establishing reliable, low-latency communication becomes crucial. Existing protocols may struggle to handle the increased data flow and real-time requirements of large-scale modular systems, necessitating the development of more robust and efficient communication standards.

Thermal management presents a formidable challenge in modular BMS design. Each battery module may experience different thermal conditions based on its position, usage, and environmental factors. Designing a system that can effectively monitor and regulate temperature across all modules while maintaining overall efficiency is a complex task that requires innovative cooling solutions and thermal modeling techniques.

The scalability of modular BMS designs poses another significant hurdle. As the number of battery modules increases, the system's complexity grows exponentially. Ensuring that the BMS can seamlessly adapt to different configurations and sizes without compromising performance or reliability is a major technical challenge that demands flexible and scalable architecture designs.

Safety considerations in modular BMS designs are paramount and present their own set of challenges. Implementing robust fault detection, isolation, and recovery mechanisms across a distributed system of battery modules requires advanced diagnostic algorithms and fail-safe protocols. Additionally, ensuring uniform safety standards across all modules, regardless of their individual states or conditions, is a complex undertaking.

Power electronics and efficient energy management within modular BMS designs also present significant technical challenges. Optimizing power conversion and distribution across multiple modules while minimizing losses and maintaining system stability requires advanced circuit designs and control strategies. This becomes particularly challenging when dealing with modules of different capacities or chemistries within the same system.

Lastly, the development of accurate and reliable State of Health (SoH) and State of Charge (SoC) estimation algorithms for modular systems presents a unique challenge. These algorithms must account for the individual characteristics of each module while providing a cohesive overview of the entire battery system's status, a task that becomes increasingly complex as the number of modules grows.

Current Modular BMS

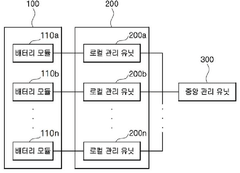

01 Modular architecture for battery management systems

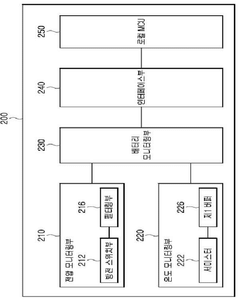

Battery management systems can be designed with a modular architecture, allowing for flexible configuration and easy scalability. This approach enables the system to be adapted to different battery types and sizes, as well as facilitating easier maintenance and upgrades. Modular designs can include separate modules for monitoring, control, and communication functions.- Modular architecture for battery management systems: Battery management systems can be designed with a modular architecture, allowing for flexible configuration and easy scalability. This approach enables the system to be adapted to different battery types, sizes, and applications. Modular designs can include separate modules for functions like cell monitoring, balancing, and communication, which can be combined as needed.

- Software modularity in battery management systems: Implementing modular software architecture in battery management systems allows for easier updates, maintenance, and customization. This approach can include separate software modules for different functions, such as state estimation, thermal management, and diagnostics. Modular software design also facilitates the integration of new features and algorithms without affecting the entire system.

- Standardized interfaces for modular BMS components: Developing standardized interfaces between modular components of battery management systems enhances interoperability and simplifies integration. These interfaces can cover both hardware connections and communication protocols, allowing for easier replacement or upgrade of individual modules without affecting the entire system.

- Scalable power management in modular BMS: Modular battery management systems can be designed to scale power management capabilities based on the size and requirements of the battery pack. This approach allows for efficient use of resources in smaller systems while providing the ability to expand for larger installations. Scalable power management can include adjustable current handling, voltage monitoring, and thermal management.

- Fault tolerance and redundancy in modular BMS: Modular designs in battery management systems can incorporate fault tolerance and redundancy features. This can include redundant modules for critical functions, distributed processing to prevent single points of failure, and hot-swappable components for maintenance without system downtime. Such designs enhance the overall reliability and availability of the battery management system.

02 Software modularity in battery management systems

Implementing software modularity in battery management systems allows for easier updates, customization, and integration of new features. This approach can include modular firmware, configurable software components, and standardized interfaces for communication between different modules. Software modularity enhances system flexibility and reduces development time for new battery management solutions.Expand Specific Solutions03 Modular power electronics for battery management

Battery management systems can incorporate modular power electronics components, such as interchangeable converters, chargers, and protection circuits. This modularity allows for easy replacement of individual components, customization of power handling capabilities, and adaptation to different battery chemistries and voltage levels.Expand Specific Solutions04 Standardized communication interfaces for modular BMS

Implementing standardized communication interfaces in modular battery management systems enables seamless integration of different modules and components. This approach facilitates interoperability between modules from different manufacturers and allows for easy expansion of system capabilities. Standardized interfaces can include both hardware connections and communication protocols.Expand Specific Solutions05 Modular thermal management integration in BMS

Battery management systems can incorporate modular thermal management components to address varying cooling and heating requirements. This approach allows for the integration of different cooling technologies, such as air cooling, liquid cooling, or phase-change materials, depending on the specific application and battery type. Modular thermal management enhances overall system efficiency and battery longevity.Expand Specific Solutions

Key BMS Manufacturers

The market for modular Battery Management Systems (BMS) is in a growth phase, driven by increasing demand for electric vehicles and energy storage solutions. The global BMS market size is projected to reach significant value in the coming years, indicating substantial opportunities. Technologically, the field is advancing rapidly, with companies like Samsung SDI, LG Energy Solution, and BYD leading innovation in battery technology and management systems. These industry giants are investing heavily in R&D to improve BMS efficiency, safety, and scalability. Emerging players such as Hyperdrive Innovation and BattGenie are also contributing to the technological evolution, focusing on specialized BMS solutions and software-driven approaches. The competitive landscape is characterized by a mix of established electronics manufacturers and innovative startups, all vying to develop more sophisticated, reliable, and cost-effective BMS designs.

Samsung SDI Co., Ltd.

Technical Solution: Samsung SDI has developed a modular battery management system (BMS) design pattern that emphasizes scalability and flexibility. Their approach utilizes a distributed architecture with intelligent cell modules, each equipped with its own microcontroller for local monitoring and balancing[1]. The central BMS controller communicates with these modules via a robust CAN bus network, allowing for easy expansion or reconfiguration of the battery pack[2]. Samsung's design incorporates advanced algorithms for state estimation and predictive maintenance, leveraging machine learning techniques to improve accuracy over time[3]. The system also features a hierarchical safety structure, with multiple layers of protection against thermal runaway and other potential failures[4].

Strengths: Highly scalable and adaptable to various battery configurations; advanced algorithms for improved performance and safety. Weaknesses: Potentially higher initial cost due to distributed architecture; increased complexity in system integration.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has implemented a modular BMS design pattern focusing on high-performance and reliability for large-scale energy storage systems and electric vehicles. Their approach utilizes a master-slave architecture, where a central master BMS coordinates multiple slave modules responsible for cell-level management[1]. LG's design incorporates advanced power electronics for efficient cell balancing and features a redundant communication system to ensure uninterrupted operation[2]. The company has also developed proprietary algorithms for accurate state-of-charge and state-of-health estimation, which adapt to different battery chemistries and aging profiles[3]. LG's modular BMS includes a comprehensive diagnostic system that can detect and isolate faults at the cell, module, and pack levels, enhancing overall system reliability and safety[4].

Strengths: High reliability and performance for large-scale applications; adaptive algorithms for various battery types. Weaknesses: Potentially less flexible for smaller-scale applications; may require specialized training for maintenance and troubleshooting.

Innovative BMS Patterns

Modular battery management system

PatentActiveKR1020220129735A

Innovation

- Distributed architecture with local management units for each battery module, enabling more efficient and accurate monitoring.

- Centralized data collection and analysis through a central management unit, allowing for comprehensive battery pack monitoring.

- Scalable design that can accommodate various battery pack configurations and sizes.

Modular battery system and method

PatentWO2023041913A3

Innovation

- Hierarchical battery management system with type A and type B units, allowing for centralized control and decision-making.

- Modular design allowing for flexible configuration of battery units with different management system types.

- Centralized control architecture where type A BMS controls both itself and type B units based on comprehensive system data.

Regulatory Compliance

Regulatory compliance is a critical aspect of designing and implementing modular battery management systems (BMS) for electric vehicles and energy storage applications. The complex nature of these systems, coupled with their potential safety risks, necessitates adherence to a wide range of standards and regulations across different jurisdictions.

In the United States, the primary regulatory body overseeing BMS safety is the National Highway Traffic Safety Administration (NHTSA). The NHTSA has established Federal Motor Vehicle Safety Standards (FMVSS) that include specific requirements for electric vehicle battery systems. These standards focus on crash safety, thermal runaway prevention, and electrical isolation.

The European Union has its own set of regulations, primarily governed by the United Nations Economic Commission for Europe (UNECE). The UNECE Regulation No. 100 specifically addresses the safety requirements for rechargeable energy storage systems in electric vehicles. This regulation covers aspects such as vibration resistance, thermal shock, and fire resistance.

In Asia, countries like China and Japan have also developed their own regulatory frameworks. China's GB/T 31467 standard series provides comprehensive guidelines for the safety of traction battery packs and systems for electric vehicles. Japan's regulatory approach is guided by the Japan Electrical Safety and Environment Technology Laboratories (JET), which certifies BMS components and systems.

Internationally, the International Electrotechnical Commission (IEC) has developed several standards relevant to BMS design. The IEC 62619 standard, for instance, provides safety requirements for secondary lithium cells and batteries for use in industrial applications. This standard is particularly relevant for large-scale energy storage systems utilizing modular BMS architectures.

Compliance with these regulations often requires extensive testing and certification processes. For modular BMS designs, this can be particularly challenging as each module may need to be certified individually, as well as the system as a whole. Designers must consider how to implement safety features such as cell balancing, temperature monitoring, and fault detection in a way that meets regulatory requirements while maintaining the flexibility and scalability of the modular architecture.

Furthermore, as the technology and applications of battery systems continue to evolve, regulatory frameworks are also adapting. This dynamic regulatory environment necessitates a proactive approach to compliance, with BMS designers needing to anticipate future regulatory changes and design systems with the flexibility to accommodate these changes.

In the United States, the primary regulatory body overseeing BMS safety is the National Highway Traffic Safety Administration (NHTSA). The NHTSA has established Federal Motor Vehicle Safety Standards (FMVSS) that include specific requirements for electric vehicle battery systems. These standards focus on crash safety, thermal runaway prevention, and electrical isolation.

The European Union has its own set of regulations, primarily governed by the United Nations Economic Commission for Europe (UNECE). The UNECE Regulation No. 100 specifically addresses the safety requirements for rechargeable energy storage systems in electric vehicles. This regulation covers aspects such as vibration resistance, thermal shock, and fire resistance.

In Asia, countries like China and Japan have also developed their own regulatory frameworks. China's GB/T 31467 standard series provides comprehensive guidelines for the safety of traction battery packs and systems for electric vehicles. Japan's regulatory approach is guided by the Japan Electrical Safety and Environment Technology Laboratories (JET), which certifies BMS components and systems.

Internationally, the International Electrotechnical Commission (IEC) has developed several standards relevant to BMS design. The IEC 62619 standard, for instance, provides safety requirements for secondary lithium cells and batteries for use in industrial applications. This standard is particularly relevant for large-scale energy storage systems utilizing modular BMS architectures.

Compliance with these regulations often requires extensive testing and certification processes. For modular BMS designs, this can be particularly challenging as each module may need to be certified individually, as well as the system as a whole. Designers must consider how to implement safety features such as cell balancing, temperature monitoring, and fault detection in a way that meets regulatory requirements while maintaining the flexibility and scalability of the modular architecture.

Furthermore, as the technology and applications of battery systems continue to evolve, regulatory frameworks are also adapting. This dynamic regulatory environment necessitates a proactive approach to compliance, with BMS designers needing to anticipate future regulatory changes and design systems with the flexibility to accommodate these changes.

Scalability Strategies

Scalability strategies for modular Battery Management Systems (BMS) are crucial for adapting to varying battery configurations and capacities. A key approach is the implementation of a distributed architecture, where multiple BMS modules work in tandem to manage larger battery packs. This design allows for easy expansion by adding more modules as the battery system grows, without requiring a complete overhaul of the existing setup.

One effective strategy is the use of a master-slave configuration. In this setup, a master BMS unit coordinates the activities of multiple slave units, each responsible for monitoring and controlling a subset of cells or modules within the battery pack. This hierarchical structure enables efficient communication and control, while also providing a scalable framework for managing batteries of different sizes and complexities.

Another important aspect of scalability is the adoption of standardized communication protocols. By utilizing industry-standard interfaces such as CAN (Controller Area Network) or Modbus, BMS modules can easily integrate with various components and systems, regardless of the manufacturer or specific implementation. This interoperability ensures that the BMS can be scaled up or down without compatibility issues.

Modular software design is equally critical for scalability. Implementing a flexible firmware architecture that can be easily updated and reconfigured allows the BMS to adapt to changing battery configurations or new features without requiring a complete software overhaul. This can be achieved through the use of modular code structures, parameterized configurations, and over-the-air update capabilities.

To further enhance scalability, designers should consider implementing dynamic cell balancing algorithms that can automatically adjust to varying numbers of cells or modules. These algorithms should be capable of optimizing the balancing process based on the current battery configuration, ensuring efficient operation regardless of the system's size or complexity.

Lastly, scalability strategies should include provisions for future expansion of monitoring and control capabilities. This may involve designing the BMS with excess processing power and memory, as well as incorporating additional sensor inputs and control outputs that can be activated as needed. By anticipating future requirements, the BMS can be more easily adapted to evolving battery technologies and energy management strategies without requiring a complete redesign.

One effective strategy is the use of a master-slave configuration. In this setup, a master BMS unit coordinates the activities of multiple slave units, each responsible for monitoring and controlling a subset of cells or modules within the battery pack. This hierarchical structure enables efficient communication and control, while also providing a scalable framework for managing batteries of different sizes and complexities.

Another important aspect of scalability is the adoption of standardized communication protocols. By utilizing industry-standard interfaces such as CAN (Controller Area Network) or Modbus, BMS modules can easily integrate with various components and systems, regardless of the manufacturer or specific implementation. This interoperability ensures that the BMS can be scaled up or down without compatibility issues.

Modular software design is equally critical for scalability. Implementing a flexible firmware architecture that can be easily updated and reconfigured allows the BMS to adapt to changing battery configurations or new features without requiring a complete software overhaul. This can be achieved through the use of modular code structures, parameterized configurations, and over-the-air update capabilities.

To further enhance scalability, designers should consider implementing dynamic cell balancing algorithms that can automatically adjust to varying numbers of cells or modules. These algorithms should be capable of optimizing the balancing process based on the current battery configuration, ensuring efficient operation regardless of the system's size or complexity.

Lastly, scalability strategies should include provisions for future expansion of monitoring and control capabilities. This may involve designing the BMS with excess processing power and memory, as well as incorporating additional sensor inputs and control outputs that can be activated as needed. By anticipating future requirements, the BMS can be more easily adapted to evolving battery technologies and energy management strategies without requiring a complete redesign.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!