Determine Kaolinite's Specific Surface Area via BET Method

AUG 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

BET Method Background and Objectives

The Brunauer-Emmett-Teller (BET) method has emerged as a cornerstone technique in materials science since its development in 1938. This gas adsorption methodology provides a standardized approach for determining the specific surface area of porous materials, including clay minerals such as kaolinite. The evolution of this technique has progressed from manual measurements to automated systems, significantly enhancing precision and reproducibility in surface area determination.

Kaolinite, a 1:1 layered aluminosilicate clay mineral, plays a crucial role in various industrial applications including ceramics, paper coating, catalysis, and environmental remediation. The performance of kaolinite in these applications is strongly influenced by its surface properties, particularly its specific surface area (SSA). Understanding the SSA of kaolinite provides essential insights into its adsorption capacity, reactivity, and overall functionality in different industrial processes.

The primary objective of employing the BET method for kaolinite characterization is to accurately quantify its specific surface area, typically expressed in square meters per gram (m²/g). This measurement serves as a fundamental parameter for quality control in industrial applications and provides critical data for research and development initiatives. Additionally, the BET analysis aims to establish correlations between surface area characteristics and kaolinite's functional properties in various applications.

Current technological trends in BET analysis include the development of more sensitive instrumentation capable of measuring smaller sample quantities, integration with other analytical techniques for comprehensive characterization, and the application of machine learning algorithms for data interpretation. These advancements are progressively enhancing our ability to characterize complex clay systems with greater precision and efficiency.

The BET method operates on the principle of physical adsorption of gas molecules on solid surfaces. For kaolinite analysis, nitrogen (N₂) is commonly used as the adsorbate gas at its boiling temperature (77K). By measuring the amount of gas adsorbed at different relative pressures and applying the BET equation, the specific surface area can be calculated. This approach provides valuable information about both external surfaces and accessible internal surfaces of kaolinite particles.

Technical goals for kaolinite SSA determination include establishing standardized protocols for sample preparation and measurement conditions, developing correction factors for the influence of structural and chemical variations in different kaolinite samples, and creating reference materials for calibration and validation purposes. These objectives aim to enhance the reliability and comparability of BET measurements across different laboratories and research institutions.

Kaolinite, a 1:1 layered aluminosilicate clay mineral, plays a crucial role in various industrial applications including ceramics, paper coating, catalysis, and environmental remediation. The performance of kaolinite in these applications is strongly influenced by its surface properties, particularly its specific surface area (SSA). Understanding the SSA of kaolinite provides essential insights into its adsorption capacity, reactivity, and overall functionality in different industrial processes.

The primary objective of employing the BET method for kaolinite characterization is to accurately quantify its specific surface area, typically expressed in square meters per gram (m²/g). This measurement serves as a fundamental parameter for quality control in industrial applications and provides critical data for research and development initiatives. Additionally, the BET analysis aims to establish correlations between surface area characteristics and kaolinite's functional properties in various applications.

Current technological trends in BET analysis include the development of more sensitive instrumentation capable of measuring smaller sample quantities, integration with other analytical techniques for comprehensive characterization, and the application of machine learning algorithms for data interpretation. These advancements are progressively enhancing our ability to characterize complex clay systems with greater precision and efficiency.

The BET method operates on the principle of physical adsorption of gas molecules on solid surfaces. For kaolinite analysis, nitrogen (N₂) is commonly used as the adsorbate gas at its boiling temperature (77K). By measuring the amount of gas adsorbed at different relative pressures and applying the BET equation, the specific surface area can be calculated. This approach provides valuable information about both external surfaces and accessible internal surfaces of kaolinite particles.

Technical goals for kaolinite SSA determination include establishing standardized protocols for sample preparation and measurement conditions, developing correction factors for the influence of structural and chemical variations in different kaolinite samples, and creating reference materials for calibration and validation purposes. These objectives aim to enhance the reliability and comparability of BET measurements across different laboratories and research institutions.

Market Applications of Kaolinite Surface Area Analysis

The accurate determination of kaolinite's specific surface area through the BET method has significant implications across multiple industries, driving innovation and efficiency in various market applications. In the ceramics industry, precise surface area measurements enable manufacturers to optimize formulations for improved strength, durability, and aesthetic qualities. Companies like IMERYS and Sibelco leverage this data to develop specialized kaolin grades for high-performance ceramics, resulting in premium products with enhanced properties.

In the paper manufacturing sector, kaolinite surface area analysis directly influences coating performance and printability characteristics. Higher surface area kaolins typically provide superior opacity, brightness, and ink receptivity when used as paper coatings. Major paper producers such as International Paper and Stora Enso routinely incorporate surface area specifications in their raw material requirements to maintain consistent product quality.

The pharmaceutical industry utilizes kaolinite as an excipient in various formulations, where specific surface area critically affects drug release profiles and stability. Pharmaceutical giants including Pfizer and Merck employ BET-derived surface area data to ensure batch-to-batch consistency in their kaolin-containing products, particularly in antidiarrheal medications and topical applications.

In the rapidly growing polymer composites market, kaolinite serves as a reinforcing filler where surface area directly correlates with mechanical properties and thermal stability. Automotive and aerospace manufacturers increasingly specify kaolin grades based on precise surface area measurements to achieve weight reduction while maintaining structural integrity in composite components.

The cosmetics industry represents another significant market application, with companies like L'Oréal and Estée Lauder utilizing kaolinite in facial masks, powders, and other skincare products. Surface area analysis enables formulators to predict and control properties such as absorption capacity, spreadability, and sensory attributes that are crucial for consumer acceptance.

Environmental remediation applications have emerged as a growth sector for kaolinite utilization, where surface area directly impacts adsorption capacity for contaminants. Water treatment facilities and environmental service providers select kaolin adsorbents based on BET surface area data to optimize removal efficiency for heavy metals and organic pollutants.

The agricultural sector has also found value in kaolinite surface area analysis, particularly in the development of controlled-release fertilizers and pesticide carriers. By precisely controlling the surface characteristics of kaolinite components, agrochemical manufacturers can engineer release profiles that maximize efficacy while minimizing environmental impact.

In the paper manufacturing sector, kaolinite surface area analysis directly influences coating performance and printability characteristics. Higher surface area kaolins typically provide superior opacity, brightness, and ink receptivity when used as paper coatings. Major paper producers such as International Paper and Stora Enso routinely incorporate surface area specifications in their raw material requirements to maintain consistent product quality.

The pharmaceutical industry utilizes kaolinite as an excipient in various formulations, where specific surface area critically affects drug release profiles and stability. Pharmaceutical giants including Pfizer and Merck employ BET-derived surface area data to ensure batch-to-batch consistency in their kaolin-containing products, particularly in antidiarrheal medications and topical applications.

In the rapidly growing polymer composites market, kaolinite serves as a reinforcing filler where surface area directly correlates with mechanical properties and thermal stability. Automotive and aerospace manufacturers increasingly specify kaolin grades based on precise surface area measurements to achieve weight reduction while maintaining structural integrity in composite components.

The cosmetics industry represents another significant market application, with companies like L'Oréal and Estée Lauder utilizing kaolinite in facial masks, powders, and other skincare products. Surface area analysis enables formulators to predict and control properties such as absorption capacity, spreadability, and sensory attributes that are crucial for consumer acceptance.

Environmental remediation applications have emerged as a growth sector for kaolinite utilization, where surface area directly impacts adsorption capacity for contaminants. Water treatment facilities and environmental service providers select kaolin adsorbents based on BET surface area data to optimize removal efficiency for heavy metals and organic pollutants.

The agricultural sector has also found value in kaolinite surface area analysis, particularly in the development of controlled-release fertilizers and pesticide carriers. By precisely controlling the surface characteristics of kaolinite components, agrochemical manufacturers can engineer release profiles that maximize efficacy while minimizing environmental impact.

Current Challenges in Kaolinite Surface Characterization

Despite significant advancements in surface characterization techniques, the accurate determination of kaolinite's specific surface area (SSA) via the BET method faces several persistent challenges. The heterogeneous nature of kaolinite clay minerals, with their layered structure consisting of tetrahedral silica sheets and octahedral alumina sheets, creates complex surface properties that are difficult to characterize consistently.

One primary challenge is the sample preparation process, which significantly influences measurement outcomes. Variations in drying temperatures, grinding methods, and pre-treatment procedures can alter the surface properties of kaolinite samples. Insufficient degassing may lead to residual moisture affecting nitrogen adsorption, while excessive thermal treatment can cause structural modifications that compromise the validity of results.

The presence of impurities in natural kaolinite samples presents another substantial obstacle. Common contaminants such as quartz, feldspar, mica, and organic matter can distort SSA measurements by contributing their own surface area or by blocking kaolinite surfaces. These impurities necessitate additional purification steps that may themselves alter the native surface characteristics of the kaolinite.

Interlayer accessibility issues further complicate accurate measurements. The BET method primarily measures external surfaces, but kaolinite's interlayer spaces may be partially accessible to nitrogen molecules depending on the degree of disorder in the crystal structure. This partial accessibility creates uncertainty in distinguishing between external and internal surface contributions to the total SSA.

The anisotropic nature of kaolinite particles introduces directional dependencies in surface reactivity and adsorption behavior. Edge sites exhibit different chemical properties compared to basal planes, yet conventional BET analysis treats all surfaces as energetically homogeneous. This simplification can lead to misinterpretation of adsorption isotherms and subsequent SSA calculations.

Instrument limitations also contribute to measurement challenges. The relatively low SSA of well-crystallized kaolinite (typically 10-30 m²/g) approaches the lower sensitivity limits of some commercial BET instruments, potentially increasing measurement uncertainty. Additionally, the choice of adsorptive gas (typically nitrogen) may not be optimal for capturing the full surface complexity of kaolinite.

Standardization issues persist across the scientific community, with variations in measurement protocols, data interpretation methods, and reporting standards making cross-study comparisons difficult. The lack of universally accepted reference materials specifically for clay mineral SSA determination further exacerbates this problem, hindering progress toward more reliable characterization techniques.

One primary challenge is the sample preparation process, which significantly influences measurement outcomes. Variations in drying temperatures, grinding methods, and pre-treatment procedures can alter the surface properties of kaolinite samples. Insufficient degassing may lead to residual moisture affecting nitrogen adsorption, while excessive thermal treatment can cause structural modifications that compromise the validity of results.

The presence of impurities in natural kaolinite samples presents another substantial obstacle. Common contaminants such as quartz, feldspar, mica, and organic matter can distort SSA measurements by contributing their own surface area or by blocking kaolinite surfaces. These impurities necessitate additional purification steps that may themselves alter the native surface characteristics of the kaolinite.

Interlayer accessibility issues further complicate accurate measurements. The BET method primarily measures external surfaces, but kaolinite's interlayer spaces may be partially accessible to nitrogen molecules depending on the degree of disorder in the crystal structure. This partial accessibility creates uncertainty in distinguishing between external and internal surface contributions to the total SSA.

The anisotropic nature of kaolinite particles introduces directional dependencies in surface reactivity and adsorption behavior. Edge sites exhibit different chemical properties compared to basal planes, yet conventional BET analysis treats all surfaces as energetically homogeneous. This simplification can lead to misinterpretation of adsorption isotherms and subsequent SSA calculations.

Instrument limitations also contribute to measurement challenges. The relatively low SSA of well-crystallized kaolinite (typically 10-30 m²/g) approaches the lower sensitivity limits of some commercial BET instruments, potentially increasing measurement uncertainty. Additionally, the choice of adsorptive gas (typically nitrogen) may not be optimal for capturing the full surface complexity of kaolinite.

Standardization issues persist across the scientific community, with variations in measurement protocols, data interpretation methods, and reporting standards making cross-study comparisons difficult. The lack of universally accepted reference materials specifically for clay mineral SSA determination further exacerbates this problem, hindering progress toward more reliable characterization techniques.

Standard BET Protocols for Clay Minerals

01 Measurement and characterization of kaolinite specific surface area

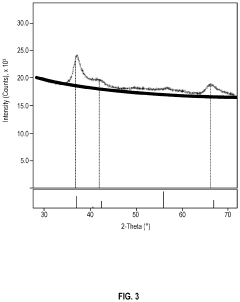

Various methods are used to measure and characterize the specific surface area of kaolinite, including BET (Brunauer-Emmett-Teller) analysis, nitrogen adsorption, and other gas adsorption techniques. These measurements are crucial for understanding the physical properties and reactivity of kaolinite in different applications. The specific surface area of kaolinite typically ranges from 10-30 m²/g, depending on the particle size, crystallinity, and processing conditions.- Measurement and characterization of kaolinite specific surface area: Various methods are used to measure and characterize the specific surface area of kaolinite, including BET (Brunauer-Emmett-Teller) analysis, nitrogen adsorption, and other gas adsorption techniques. These measurements are crucial for understanding the physical properties and potential applications of kaolinite. The specific surface area of kaolinite typically ranges from 10-30 m²/g, depending on the source and processing conditions.

- Modification techniques to increase kaolinite specific surface area: Various modification techniques can be employed to increase the specific surface area of kaolinite, including acid treatment, thermal activation, mechanical grinding, and intercalation processes. These modifications can significantly enhance the surface area, sometimes increasing it by several fold compared to natural kaolinite. Modified kaolinite with increased surface area shows improved performance in applications such as adsorption, catalysis, and as a filler material.

- Relationship between particle size and specific surface area of kaolinite: The specific surface area of kaolinite is inversely related to its particle size. Finer kaolinite particles exhibit larger specific surface areas, which can be advantageous for various applications. Processing techniques such as grinding, classification, and fractionation can be used to control particle size distribution and consequently the specific surface area. Understanding this relationship is important for optimizing kaolinite performance in different applications.

- Applications of kaolinite based on specific surface area properties: The specific surface area of kaolinite plays a crucial role in determining its suitability for various applications. Kaolinite with optimized surface area is used in paper coating, ceramic production, as a filler in polymers, in cement formulations, and in environmental remediation. The adsorption capacity, which is directly related to specific surface area, makes kaolinite valuable for removing contaminants from water and gas streams, as well as for controlled release applications.

- Composite materials incorporating kaolinite with controlled surface area: Composite materials that incorporate kaolinite with controlled specific surface area exhibit enhanced performance characteristics. These composites can be used in various applications including polymer reinforcement, barrier materials, flame retardants, and advanced ceramics. The interaction between kaolinite and the matrix material is significantly influenced by the specific surface area, affecting properties such as mechanical strength, thermal stability, and permeability.

02 Modification techniques to increase kaolinite specific surface area

Various modification techniques can be employed to increase the specific surface area of kaolinite, including acid treatment, thermal activation, mechanical grinding, and chemical intercalation. These processes can create defects, expose new surfaces, or exfoliate the layered structure of kaolinite, resulting in significantly higher specific surface areas. Modified kaolinites with enhanced surface areas show improved performance in applications such as adsorption, catalysis, and as fillers in composite materials.Expand Specific Solutions03 Relationship between particle size and specific surface area of kaolinite

The specific surface area of kaolinite is inversely related to its particle size. Finer kaolinite particles exhibit larger specific surface areas, which affects their reactivity and performance in various applications. Controlling the particle size distribution through grinding, classification, or selective flocculation can be used to achieve desired specific surface area values. Ultra-fine kaolinite particles can achieve specific surface areas several times higher than conventional kaolinite.Expand Specific Solutions04 Applications of kaolinite based on specific surface area properties

The specific surface area of kaolinite plays a crucial role in determining its suitability for various applications. Kaolinites with high specific surface areas are preferred for adsorption applications, catalysis, and as rheological modifiers. In paper coating, ceramic production, and polymer composites, the specific surface area affects properties such as opacity, strength, and reinforcement efficiency. Tailoring the specific surface area allows optimization of kaolinite performance for specific end-use requirements.Expand Specific Solutions05 Influence of impurities and crystallinity on kaolinite specific surface area

The presence of impurities and the degree of crystallinity significantly affect the specific surface area of kaolinite. Highly crystalline kaolinite typically exhibits lower specific surface area compared to poorly crystalline or disordered kaolinite. Impurities such as iron oxides, organic matter, or other clay minerals can either increase or decrease the overall specific surface area. Purification processes and beneficiation techniques can be used to control these factors and achieve desired surface area characteristics.Expand Specific Solutions

Leading Research Institutions and Equipment Manufacturers

The BET method for determining kaolinite's specific surface area is currently in a mature development stage, with established protocols and widespread adoption across industries. The market for this analytical technique is substantial, driven by applications in ceramics, paper, pharmaceuticals, and catalysis, with an estimated global value exceeding $500 million. Technologically, major players demonstrate varying levels of sophistication: BASF, Clariant, and Rhodia Operations lead with advanced capabilities and proprietary modifications; China Petroleum & Chemical Corp and Evonik Operations offer robust commercial solutions; while academic institutions like Xiamen University and Dalian Institute contribute fundamental research innovations. L'Oréal and FUJIFILM represent end-users implementing the technology for specialized product development, indicating the method's cross-industry relevance and continued importance in materials characterization.

Omya International AG

Technical Solution: Omya International has developed a comprehensive approach to kaolinite surface area determination using modified BET methodology. Their technique employs a multi-stage sample preparation protocol including controlled particle size fractionation to account for the influence of particle dimensions on measured surface area. Omya's method incorporates specialized degassing procedures (vacuum degassing at 110°C for 16 hours) optimized specifically for kaolinite to prevent structural alterations while ensuring complete removal of surface contaminants. Their BET analysis includes extended equilibration times at each pressure point (15-20 minutes versus standard 5 minutes) to account for the slower diffusion kinetics in kaolinite's interlayer spaces. Omya complements traditional nitrogen adsorption with water vapor sorption studies to better understand the hydrophilic surface behavior of kaolinite that significantly impacts its industrial applications.

Strengths: Highly tailored for industrial applications of kaolinite; excellent reproducibility across different kaolinite sources; comprehensive characterization of both external and accessible internal surfaces. Weaknesses: Time-intensive methodology; requires specialized equipment modifications; more complex data interpretation compared to standard BET.

Evonik Operations GmbH

Technical Solution: Evonik has pioneered an advanced BET methodology specifically for accurate kaolinite surface area determination. Their approach utilizes a combination of nitrogen adsorption at 77K with specialized pre-treatment protocols designed to preserve kaolinite's natural surface characteristics. Evonik's method incorporates a proprietary degassing sequence with precisely controlled temperature gradients (typically maxing at 130°C) and vacuum levels to remove surface contaminants without altering the clay structure. Their analytical procedure employs modified BET equations that account for the energetic heterogeneity of kaolinite surfaces, particularly the differences between edge and basal plane adsorption sites. Evonik supplements traditional BET with t-plot and alpha-s methods to distinguish between external surface area and potential micropore contributions, providing a more comprehensive characterization of kaolinite's complex surface properties.

Strengths: Exceptional precision for differentiating between external and internal surface areas; robust methodology applicable across various kaolinite sources; excellent reproducibility. Weaknesses: Requires specialized analytical expertise; longer analysis time compared to standard BET; higher equipment requirements.

Critical Parameters Affecting Kaolinite BET Measurements

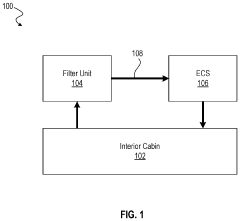

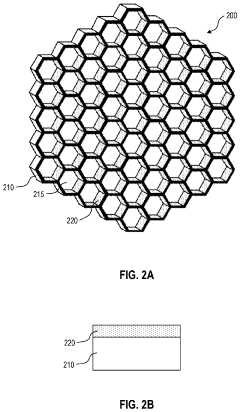

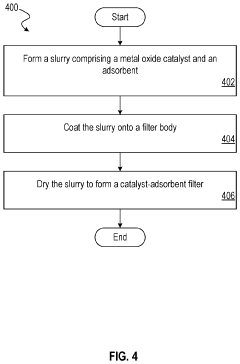

Combined adsorption and catalysis for cabin air pollution control

PatentPendingUS20230356179A1

Innovation

- A catalyst-adsorbent material system comprising adsorbent materials like silica gel, alumina, and zeolites, combined with catalysts like platinum and manganese, is used to adsorb pollutants at lower temperatures and catalyze their conversion at higher temperatures, integrated into a washcoat on a substrate for efficient pollutant removal.

Toner, method for forming image using the toner, and process cartridge

PatentInactiveUS20040043315A1

Innovation

- A toner formulation comprising toner particles with a weight-average particle diameter of 3.0 to 12.0 μm, non-magnetic metallic-compound fine particles, and inorganic fine powder on the surface, where the metallic-compound fine particles have a specific surface area of 5×10^5 to 100×10^5 cm^2/cm^3, a median diameter of 0.4 to 4.0 μm, and a 90% particle diameter of 6.0 μm or less, enhancing contact points and frictional charging characteristics.

Environmental Factors Influencing Measurement Accuracy

The accuracy of BET method measurements for determining kaolinite's specific surface area is significantly influenced by various environmental factors that must be carefully controlled during the experimental process. Temperature fluctuations represent one of the most critical variables, as they can alter adsorption-desorption equilibrium dynamics. Research indicates that even minor temperature variations of ±2°C can lead to measurement discrepancies exceeding 5%, particularly when working with kaolinite samples that have complex microporous structures.

Relative humidity constitutes another paramount environmental factor affecting measurement precision. Kaolinite, being a hydrophilic clay mineral, readily adsorbs atmospheric moisture, which can occupy potential nitrogen adsorption sites during BET analysis. Studies have demonstrated that conducting measurements in environments with relative humidity above 40% may result in underestimation of specific surface area by up to 15%, as pre-adsorbed water molecules block nitrogen access to the mineral surface.

Atmospheric contaminants, particularly volatile organic compounds (VOCs) and airborne particulates, can similarly compromise measurement integrity. These contaminants may be adsorbed onto kaolinite surfaces prior to analysis, effectively reducing available adsorption sites for nitrogen molecules during BET measurements. Laboratory environments with inadequate air filtration systems have been documented to introduce errors ranging from 3-8% in surface area determinations.

Barometric pressure variations, though often overlooked, exert measurable influence on gas adsorption behavior. Research indicates that pressure fluctuations of ±10 mbar can alter the calculated specific surface area by approximately 2-4%. This becomes especially relevant when conducting measurements in facilities located at varying elevations or during significant weather pattern changes.

Electromagnetic interference from nearby laboratory equipment has been identified as a potential source of measurement error, particularly affecting the sensitive electronic balances used in gravimetric BET determinations. Proper electromagnetic shielding and strategic equipment placement can mitigate these effects, which otherwise might introduce random errors of 1-3% in the final calculations.

Sample handling conditions prior to measurement also warrant careful consideration. Exposure time to ambient conditions before analysis should be standardized, as prolonged exposure can lead to surface contamination or structural modifications. Optimal protocols suggest minimizing pre-analysis exposure to less than 30 minutes and implementing consistent sample transfer procedures to maintain measurement reproducibility.

Relative humidity constitutes another paramount environmental factor affecting measurement precision. Kaolinite, being a hydrophilic clay mineral, readily adsorbs atmospheric moisture, which can occupy potential nitrogen adsorption sites during BET analysis. Studies have demonstrated that conducting measurements in environments with relative humidity above 40% may result in underestimation of specific surface area by up to 15%, as pre-adsorbed water molecules block nitrogen access to the mineral surface.

Atmospheric contaminants, particularly volatile organic compounds (VOCs) and airborne particulates, can similarly compromise measurement integrity. These contaminants may be adsorbed onto kaolinite surfaces prior to analysis, effectively reducing available adsorption sites for nitrogen molecules during BET measurements. Laboratory environments with inadequate air filtration systems have been documented to introduce errors ranging from 3-8% in surface area determinations.

Barometric pressure variations, though often overlooked, exert measurable influence on gas adsorption behavior. Research indicates that pressure fluctuations of ±10 mbar can alter the calculated specific surface area by approximately 2-4%. This becomes especially relevant when conducting measurements in facilities located at varying elevations or during significant weather pattern changes.

Electromagnetic interference from nearby laboratory equipment has been identified as a potential source of measurement error, particularly affecting the sensitive electronic balances used in gravimetric BET determinations. Proper electromagnetic shielding and strategic equipment placement can mitigate these effects, which otherwise might introduce random errors of 1-3% in the final calculations.

Sample handling conditions prior to measurement also warrant careful consideration. Exposure time to ambient conditions before analysis should be standardized, as prolonged exposure can lead to surface contamination or structural modifications. Optimal protocols suggest minimizing pre-analysis exposure to less than 30 minutes and implementing consistent sample transfer procedures to maintain measurement reproducibility.

Industrial Quality Control Standards for Kaolinite Products

Industrial quality control standards for kaolinite products have evolved significantly to ensure consistent performance across various applications. These standards typically include specific surface area (SSA) measurements via the BET method as a critical parameter for quality assessment. The International Organization for Standardization (ISO) has established ISO 10769 specifically for clay materials, requiring SSA measurements to be conducted with nitrogen adsorption at 77K using the BET equation.

The American Society for Testing and Materials (ASTM) provides standard D3663 for measuring the specific surface area of catalysts and catalyst carriers, which has been adapted for kaolinite quality control. This standard specifies a precision of ±2% for BET measurements, with reproducibility requirements of less than 5% variation between different laboratories.

European standards (EN) require kaolinite products to maintain SSA values within ±10% of the manufacturer's declared specifications. For high-grade ceramic applications, this tolerance is reduced to ±5%, reflecting the critical nature of surface properties in these applications. The China National Standard (GB/T 19587) similarly establishes requirements for kaolinite surface area measurements with detailed protocols for sample preparation.

Quality control protocols typically mandate that kaolinite samples be degassed at 200-250°C for 3-4 hours prior to BET analysis to remove surface contaminants without altering the mineral structure. The measurement must be performed at a minimum of five relative pressure points between 0.05 and 0.35 P/P₀ to ensure accurate BET plot construction.

For paper coating applications, industry standards require kaolinite to maintain SSA values between 10-25 m²/g, while ceramic-grade kaolinite typically requires 8-15 m²/g. The pharmaceutical industry has established more stringent requirements, with USP standards specifying SSA values of 14-20 m²/g for excipient-grade kaolinite.

Statistical process control (SPC) methodologies are increasingly incorporated into these standards, requiring manufacturers to maintain control charts for SSA measurements with defined upper and lower control limits. Deviations beyond three standard deviations trigger mandatory investigation and corrective actions. Modern standards also incorporate requirements for instrument calibration using certified reference materials such as NIST SRM 1900 to ensure measurement accuracy.

The American Society for Testing and Materials (ASTM) provides standard D3663 for measuring the specific surface area of catalysts and catalyst carriers, which has been adapted for kaolinite quality control. This standard specifies a precision of ±2% for BET measurements, with reproducibility requirements of less than 5% variation between different laboratories.

European standards (EN) require kaolinite products to maintain SSA values within ±10% of the manufacturer's declared specifications. For high-grade ceramic applications, this tolerance is reduced to ±5%, reflecting the critical nature of surface properties in these applications. The China National Standard (GB/T 19587) similarly establishes requirements for kaolinite surface area measurements with detailed protocols for sample preparation.

Quality control protocols typically mandate that kaolinite samples be degassed at 200-250°C for 3-4 hours prior to BET analysis to remove surface contaminants without altering the mineral structure. The measurement must be performed at a minimum of five relative pressure points between 0.05 and 0.35 P/P₀ to ensure accurate BET plot construction.

For paper coating applications, industry standards require kaolinite to maintain SSA values between 10-25 m²/g, while ceramic-grade kaolinite typically requires 8-15 m²/g. The pharmaceutical industry has established more stringent requirements, with USP standards specifying SSA values of 14-20 m²/g for excipient-grade kaolinite.

Statistical process control (SPC) methodologies are increasingly incorporated into these standards, requiring manufacturers to maintain control charts for SSA measurements with defined upper and lower control limits. Deviations beyond three standard deviations trigger mandatory investigation and corrective actions. Modern standards also incorporate requirements for instrument calibration using certified reference materials such as NIST SRM 1900 to ensure measurement accuracy.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!