Development of 4140 Steel for Enhanced Impact Absorption

JUL 30, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

4140 Steel Evolution and Impact Absorption Goals

The evolution of 4140 steel for enhanced impact absorption represents a significant advancement in materials science and engineering. This medium carbon, low alloy steel has been a staple in various industries for decades due to its excellent combination of strength, toughness, and wear resistance. However, the increasing demands for improved safety and performance in automotive, aerospace, and defense applications have driven the need for further enhancements in its impact absorption capabilities.

The development of 4140 steel can be traced back to the early 20th century when the need for high-strength, heat-treatable steels became apparent. Initially used in applications such as aircraft landing gear and automotive components, 4140 steel quickly gained popularity due to its versatility and reliability. As manufacturing processes and heat treatment techniques improved, so did the properties of 4140 steel, allowing for broader applications and more demanding use cases.

In recent years, the focus has shifted towards optimizing 4140 steel specifically for enhanced impact absorption. This goal aligns with the broader trend in materials science of developing multi-functional materials that can withstand complex loading conditions while maintaining structural integrity. The primary objectives in this development include increasing the steel's ability to absorb and dissipate energy during impact events, improving its resistance to crack propagation, and enhancing its overall toughness without significantly compromising its strength or other desirable properties.

To achieve these goals, researchers and engineers have been exploring various strategies. One approach involves refining the microstructure of 4140 steel through advanced heat treatment processes. By carefully controlling the cooling rates and tempering conditions, it is possible to create a more uniform and finer grain structure, which can lead to improved impact toughness and energy absorption capabilities. Another avenue of research focuses on the incorporation of nano-scale precipitates or the introduction of controlled amounts of retained austenite to enhance the steel's ability to absorb energy through phase transformation during impact events.

Additionally, surface engineering techniques such as shot peening, carburizing, or nitriding are being investigated to create compressive residual stresses on the surface of 4140 steel components. These surface treatments can significantly improve the material's resistance to crack initiation and propagation, thereby enhancing its overall impact absorption performance. The integration of computational modeling and simulation tools has also played a crucial role in predicting and optimizing the behavior of 4140 steel under various impact conditions, allowing for more efficient and targeted development efforts.

As the development of 4140 steel for enhanced impact absorption continues, the ultimate goal is to create a material that can offer superior protection and performance in critical applications. This includes improving passenger safety in vehicles, enhancing the durability of aerospace components, and providing better protection for military personnel and equipment. The ongoing research and development in this field not only promise to push the boundaries of what is possible with 4140 steel but also contribute to the broader advancement of high-performance materials for impact-resistant applications.

The development of 4140 steel can be traced back to the early 20th century when the need for high-strength, heat-treatable steels became apparent. Initially used in applications such as aircraft landing gear and automotive components, 4140 steel quickly gained popularity due to its versatility and reliability. As manufacturing processes and heat treatment techniques improved, so did the properties of 4140 steel, allowing for broader applications and more demanding use cases.

In recent years, the focus has shifted towards optimizing 4140 steel specifically for enhanced impact absorption. This goal aligns with the broader trend in materials science of developing multi-functional materials that can withstand complex loading conditions while maintaining structural integrity. The primary objectives in this development include increasing the steel's ability to absorb and dissipate energy during impact events, improving its resistance to crack propagation, and enhancing its overall toughness without significantly compromising its strength or other desirable properties.

To achieve these goals, researchers and engineers have been exploring various strategies. One approach involves refining the microstructure of 4140 steel through advanced heat treatment processes. By carefully controlling the cooling rates and tempering conditions, it is possible to create a more uniform and finer grain structure, which can lead to improved impact toughness and energy absorption capabilities. Another avenue of research focuses on the incorporation of nano-scale precipitates or the introduction of controlled amounts of retained austenite to enhance the steel's ability to absorb energy through phase transformation during impact events.

Additionally, surface engineering techniques such as shot peening, carburizing, or nitriding are being investigated to create compressive residual stresses on the surface of 4140 steel components. These surface treatments can significantly improve the material's resistance to crack initiation and propagation, thereby enhancing its overall impact absorption performance. The integration of computational modeling and simulation tools has also played a crucial role in predicting and optimizing the behavior of 4140 steel under various impact conditions, allowing for more efficient and targeted development efforts.

As the development of 4140 steel for enhanced impact absorption continues, the ultimate goal is to create a material that can offer superior protection and performance in critical applications. This includes improving passenger safety in vehicles, enhancing the durability of aerospace components, and providing better protection for military personnel and equipment. The ongoing research and development in this field not only promise to push the boundaries of what is possible with 4140 steel but also contribute to the broader advancement of high-performance materials for impact-resistant applications.

Market Demand Analysis for High-Impact 4140 Steel

The market demand for high-impact 4140 steel has been steadily increasing across various industries, driven by the growing need for materials with enhanced impact absorption capabilities. This alloy steel, known for its excellent combination of strength and toughness, has found widespread applications in sectors such as automotive, aerospace, defense, and heavy machinery.

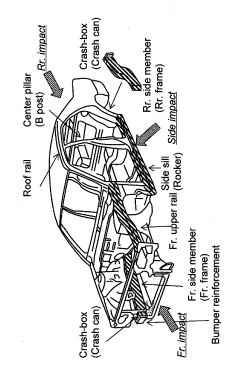

In the automotive industry, the push for improved safety standards and lightweight vehicle designs has led to a surge in demand for high-strength steels like 4140. Manufacturers are increasingly utilizing this material in critical components such as crumple zones, chassis parts, and safety structures to enhance vehicle crashworthiness while maintaining or reducing overall weight.

The aerospace sector has also shown significant interest in high-impact 4140 steel. As aircraft manufacturers strive to improve safety and durability, they are incorporating this material into landing gear components, structural elements, and other high-stress areas that require excellent impact resistance and fatigue strength.

The defense industry represents another major market for enhanced 4140 steel. Military vehicles, armor plating, and weapon systems all benefit from the material's ability to absorb and dissipate impact energy effectively. The ongoing modernization of defense equipment in many countries is expected to further drive demand in this sector.

In the heavy machinery and construction equipment market, 4140 steel with improved impact absorption properties is gaining traction for use in high-wear components such as excavator teeth, crusher parts, and mining equipment. The material's ability to withstand repeated impacts and harsh operating conditions makes it an attractive choice for manufacturers looking to extend equipment lifespan and reduce maintenance costs.

The oil and gas industry has also recognized the potential of high-impact 4140 steel in drilling equipment, wellhead components, and subsea structures. The material's resistance to impact and fatigue in challenging environments has led to increased adoption in this sector.

Market analysts project a compound annual growth rate (CAGR) for high-impact 4140 steel in the range of 5-7% over the next five years. This growth is attributed to the expanding applications across industries and the continuous development of new grades with enhanced properties.

Geographically, North America and Europe currently dominate the market for high-impact 4140 steel, owing to their advanced manufacturing sectors and stringent safety regulations. However, rapid industrialization and infrastructure development in Asia-Pacific countries, particularly China and India, are expected to create significant new opportunities for market expansion in the coming years.

In the automotive industry, the push for improved safety standards and lightweight vehicle designs has led to a surge in demand for high-strength steels like 4140. Manufacturers are increasingly utilizing this material in critical components such as crumple zones, chassis parts, and safety structures to enhance vehicle crashworthiness while maintaining or reducing overall weight.

The aerospace sector has also shown significant interest in high-impact 4140 steel. As aircraft manufacturers strive to improve safety and durability, they are incorporating this material into landing gear components, structural elements, and other high-stress areas that require excellent impact resistance and fatigue strength.

The defense industry represents another major market for enhanced 4140 steel. Military vehicles, armor plating, and weapon systems all benefit from the material's ability to absorb and dissipate impact energy effectively. The ongoing modernization of defense equipment in many countries is expected to further drive demand in this sector.

In the heavy machinery and construction equipment market, 4140 steel with improved impact absorption properties is gaining traction for use in high-wear components such as excavator teeth, crusher parts, and mining equipment. The material's ability to withstand repeated impacts and harsh operating conditions makes it an attractive choice for manufacturers looking to extend equipment lifespan and reduce maintenance costs.

The oil and gas industry has also recognized the potential of high-impact 4140 steel in drilling equipment, wellhead components, and subsea structures. The material's resistance to impact and fatigue in challenging environments has led to increased adoption in this sector.

Market analysts project a compound annual growth rate (CAGR) for high-impact 4140 steel in the range of 5-7% over the next five years. This growth is attributed to the expanding applications across industries and the continuous development of new grades with enhanced properties.

Geographically, North America and Europe currently dominate the market for high-impact 4140 steel, owing to their advanced manufacturing sectors and stringent safety regulations. However, rapid industrialization and infrastructure development in Asia-Pacific countries, particularly China and India, are expected to create significant new opportunities for market expansion in the coming years.

Current Challenges in 4140 Steel Impact Absorption

Despite the widespread use of 4140 steel in impact-absorbing applications, several challenges persist in enhancing its performance. One of the primary obstacles is the trade-off between strength and ductility. While increasing the strength of 4140 steel can improve its impact resistance, it often comes at the cost of reduced ductility, which is crucial for energy absorption during impact events. This balance is particularly challenging to achieve in high-strain-rate scenarios typical of impact situations.

Another significant challenge lies in the microstructural control of 4140 steel. The complex interplay between various phases, such as martensite, bainite, and retained austenite, greatly influences the material's impact absorption capabilities. Achieving an optimal microstructure that combines high strength with sufficient toughness remains a formidable task, especially when considering the variability in heat treatment processes and the sensitivity of 4140 steel to processing parameters.

The strain rate sensitivity of 4140 steel presents an additional hurdle. The material's behavior under high-strain-rate loading conditions, typical in impact scenarios, can differ significantly from its static properties. This discrepancy complicates the design process and necessitates extensive testing under dynamic conditions, which can be both time-consuming and costly.

Furthermore, the anisotropic nature of 4140 steel's mechanical properties poses challenges in predicting and optimizing its impact absorption behavior. The directional dependence of strength and toughness, influenced by the material's processing history, can lead to inconsistent performance in different loading orientations.

Fatigue resistance is another critical aspect that requires attention. While 4140 steel generally exhibits good fatigue properties, repeated impact loading can lead to localized damage accumulation and eventual failure. Enhancing the material's resistance to cyclic loading without compromising other mechanical properties remains a significant challenge.

Lastly, the cost-effectiveness of enhancing 4140 steel's impact absorption capabilities is a persistent concern. Advanced processing techniques or alloying strategies that could potentially improve performance often come with increased production costs, limiting their widespread adoption in cost-sensitive applications.

Another significant challenge lies in the microstructural control of 4140 steel. The complex interplay between various phases, such as martensite, bainite, and retained austenite, greatly influences the material's impact absorption capabilities. Achieving an optimal microstructure that combines high strength with sufficient toughness remains a formidable task, especially when considering the variability in heat treatment processes and the sensitivity of 4140 steel to processing parameters.

The strain rate sensitivity of 4140 steel presents an additional hurdle. The material's behavior under high-strain-rate loading conditions, typical in impact scenarios, can differ significantly from its static properties. This discrepancy complicates the design process and necessitates extensive testing under dynamic conditions, which can be both time-consuming and costly.

Furthermore, the anisotropic nature of 4140 steel's mechanical properties poses challenges in predicting and optimizing its impact absorption behavior. The directional dependence of strength and toughness, influenced by the material's processing history, can lead to inconsistent performance in different loading orientations.

Fatigue resistance is another critical aspect that requires attention. While 4140 steel generally exhibits good fatigue properties, repeated impact loading can lead to localized damage accumulation and eventual failure. Enhancing the material's resistance to cyclic loading without compromising other mechanical properties remains a significant challenge.

Lastly, the cost-effectiveness of enhancing 4140 steel's impact absorption capabilities is a persistent concern. Advanced processing techniques or alloying strategies that could potentially improve performance often come with increased production costs, limiting their widespread adoption in cost-sensitive applications.

Existing Solutions for Enhancing 4140 Steel Properties

01 Composition and heat treatment of 4140 steel for impact absorption

The composition and heat treatment of 4140 steel can be optimized to enhance its impact absorption properties. This includes adjusting the carbon content, alloying elements, and applying specific heat treatment processes to achieve the desired microstructure and mechanical properties for improved impact resistance.- Composition and heat treatment of 4140 steel for impact absorption: The composition and heat treatment of 4140 steel can be optimized to enhance its impact absorption properties. This includes adjusting the carbon content, alloying elements, and applying specific heat treatment processes to achieve the desired microstructure and mechanical properties for improved impact resistance.

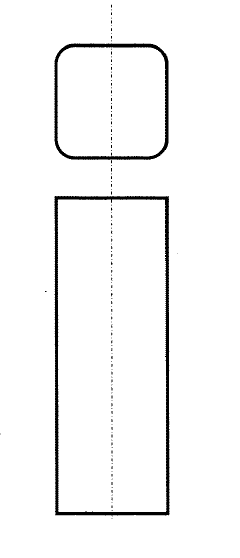

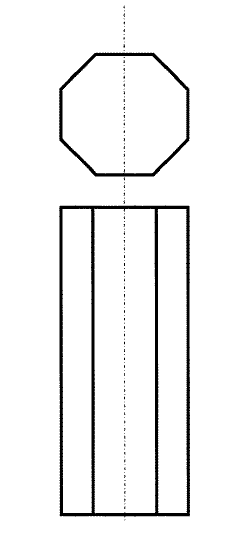

- Structural design for impact absorption using 4140 steel: Various structural designs can be implemented to improve the impact absorption capabilities of 4140 steel components. This includes the use of reinforced sections, energy-absorbing geometries, and strategic placement of 4140 steel elements in impact-prone areas to enhance overall safety and performance.

- Surface treatments for enhanced impact resistance of 4140 steel: Surface treatments can be applied to 4140 steel to further improve its impact absorption properties. These treatments may include carburizing, nitriding, or the application of protective coatings to enhance the surface hardness and wear resistance while maintaining the core toughness of the material.

- Composite structures incorporating 4140 steel for impact absorption: Composite structures that combine 4140 steel with other materials can be designed to optimize impact absorption. This may involve layering different materials or creating hybrid structures that leverage the strengths of 4140 steel along with complementary materials to achieve superior impact resistance.

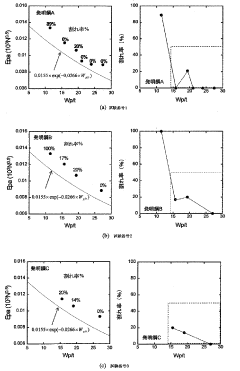

- Testing and simulation methods for 4140 steel impact absorption: Advanced testing and simulation methods can be employed to evaluate and optimize the impact absorption properties of 4140 steel components. These may include dynamic impact testing, finite element analysis, and computer simulations to predict and improve the performance of 4140 steel under various impact scenarios.

02 Structural design for impact absorption using 4140 steel

Various structural designs incorporating 4140 steel can be implemented to enhance impact absorption. This may include the use of hollow sections, corrugated structures, or energy-absorbing geometries that utilize the material properties of 4140 steel to dissipate impact energy effectively.Expand Specific Solutions03 Surface treatments for 4140 steel to improve impact resistance

Surface treatments can be applied to 4140 steel components to enhance their impact absorption capabilities. These treatments may include coatings, case hardening, or surface texturing to improve the material's ability to withstand and absorb impact forces.Expand Specific Solutions04 Composite structures incorporating 4140 steel for impact absorption

Composite structures that combine 4140 steel with other materials can be designed to optimize impact absorption. These structures may utilize the strength of 4140 steel in conjunction with energy-absorbing materials or designs to create effective impact-resistant components.Expand Specific Solutions05 Testing and simulation methods for 4140 steel impact absorption

Advanced testing and simulation methods can be employed to evaluate and optimize the impact absorption properties of 4140 steel components. These may include dynamic impact testing, finite element analysis, and material modeling to predict and improve the performance of 4140 steel under impact conditions.Expand Specific Solutions

Key Players in 4140 Steel Manufacturing and Research

The development of 4140 steel for enhanced impact absorption is in a mature phase, with significant market potential in automotive, aerospace, and industrial applications. The global market for high-strength steels is expanding, driven by demand for lightweight, durable materials. Key players like Nippon Steel, JFE Steel, and Wuhan Iron & Steel are at the forefront of innovation, leveraging advanced manufacturing processes and alloy compositions. The technology's maturity is evident in the diverse range of companies involved, from established steel giants to specialized manufacturers like Jiangyin XingCheng Special Steel Works and Nanyang Hanye Special Steel, indicating a competitive and evolving landscape in this sector.

NIPPON STEEL CORP.

Technical Solution: NIPPON STEEL has developed an advanced 4140 steel with enhanced impact absorption properties. Their approach involves a sophisticated heat treatment process that optimizes the microstructure of the steel. This process includes precise control of austenitizing, quenching, and tempering parameters to achieve a fine-grained martensitic structure with dispersed carbides[1]. The company has also implemented a controlled rolling technique to refine the grain size further, resulting in improved toughness and ductility[3]. Additionally, NIPPON STEEL has incorporated micro-alloying elements such as vanadium and niobium to enhance the steel's strength without compromising its impact absorption capabilities[5].

Strengths: Superior impact absorption, high strength-to-weight ratio, and excellent fatigue resistance. Weaknesses: Potentially higher production costs and more complex manufacturing process compared to standard 4140 steel.

JFE Steel Corp.

Technical Solution: JFE Steel has innovated in the development of 4140 steel for enhanced impact absorption through a multi-stage thermomechanical treatment process. Their approach involves controlled deformation at specific temperature ranges to induce dynamic recrystallization, resulting in a refined and homogeneous microstructure[2]. The company has also implemented an advanced quenching technique using a specially formulated polymer quenchant to achieve an optimal balance between strength and toughness[4]. Furthermore, JFE Steel has developed a proprietary tempering process that involves cyclic heating and cooling to create a more uniform distribution of carbides, enhancing the steel's impact absorption capabilities[6].

Strengths: Excellent balance of strength and toughness, improved impact resistance, and consistent mechanical properties. Weaknesses: May require specialized equipment for production, potentially limiting widespread adoption.

Core Innovations in 4140 Steel Microstructure Engineering

Steel material and impact absorption member

PatentActiveJP2012001773A

Innovation

- A dual-phase steel material with a specific chemical composition and microstructure, including ferrite and a second phase of bainite, martensite, or austenite, optimized to enhance yield strength, work hardening coefficient, and local ductility, suppressing crack formation during impact loads.

Special steels; cryogenic process for the production thereof; use of special steels in a saline and/or high-pressure environment

PatentWO2014008564A1

Innovation

- A specific cryogenic treatment process involving tempering, cooling, immersion in cryogenic material, and subsequent tempering is applied to carbon steels, reducing retained austenite content and precipitating carbides, transforming martensite morphology and improving mechanical properties.

Environmental Impact of 4140 Steel Production

The production of 4140 steel, while essential for developing enhanced impact absorption materials, carries significant environmental implications. The manufacturing process involves energy-intensive operations and the use of raw materials, contributing to various environmental concerns. One of the primary issues is the high energy consumption required for steel production, particularly during the smelting and heat treatment stages. This energy demand often relies on fossil fuels, leading to substantial greenhouse gas emissions and contributing to climate change.

Furthermore, the extraction of raw materials for 4140 steel production, such as iron ore and alloying elements like chromium and molybdenum, can result in habitat destruction, soil erosion, and water pollution. Mining activities associated with these materials often involve large-scale land disturbance and can lead to the release of toxic substances into the environment.

Water usage is another critical environmental factor in 4140 steel production. The manufacturing process requires significant amounts of water for cooling and cleaning, potentially straining local water resources. Additionally, wastewater from steel production may contain contaminants that, if not properly treated, can harm aquatic ecosystems and human health.

Air pollution is a notable concern in steel production, with emissions of particulate matter, sulfur dioxide, and nitrogen oxides being common. These pollutants can contribute to respiratory issues and acid rain, affecting both human health and the surrounding environment. The production of 4140 steel also generates solid waste, including slag and dust, which requires proper management and disposal to prevent soil and groundwater contamination.

However, it's important to note that the steel industry has been making efforts to reduce its environmental impact. Advancements in production technologies, such as electric arc furnaces and continuous casting, have improved energy efficiency and reduced emissions. Recycling of steel scrap has also become increasingly prevalent, helping to conserve raw materials and reduce energy consumption. Furthermore, the development of cleaner production methods and the implementation of stringent environmental regulations are driving the industry towards more sustainable practices.

In the context of developing 4140 steel for enhanced impact absorption, researchers and manufacturers must consider these environmental factors. Balancing the need for improved material properties with environmental sustainability is crucial. This may involve exploring alternative production methods, optimizing resource use, and incorporating life cycle assessments into the development process to minimize the overall environmental footprint of 4140 steel production.

Furthermore, the extraction of raw materials for 4140 steel production, such as iron ore and alloying elements like chromium and molybdenum, can result in habitat destruction, soil erosion, and water pollution. Mining activities associated with these materials often involve large-scale land disturbance and can lead to the release of toxic substances into the environment.

Water usage is another critical environmental factor in 4140 steel production. The manufacturing process requires significant amounts of water for cooling and cleaning, potentially straining local water resources. Additionally, wastewater from steel production may contain contaminants that, if not properly treated, can harm aquatic ecosystems and human health.

Air pollution is a notable concern in steel production, with emissions of particulate matter, sulfur dioxide, and nitrogen oxides being common. These pollutants can contribute to respiratory issues and acid rain, affecting both human health and the surrounding environment. The production of 4140 steel also generates solid waste, including slag and dust, which requires proper management and disposal to prevent soil and groundwater contamination.

However, it's important to note that the steel industry has been making efforts to reduce its environmental impact. Advancements in production technologies, such as electric arc furnaces and continuous casting, have improved energy efficiency and reduced emissions. Recycling of steel scrap has also become increasingly prevalent, helping to conserve raw materials and reduce energy consumption. Furthermore, the development of cleaner production methods and the implementation of stringent environmental regulations are driving the industry towards more sustainable practices.

In the context of developing 4140 steel for enhanced impact absorption, researchers and manufacturers must consider these environmental factors. Balancing the need for improved material properties with environmental sustainability is crucial. This may involve exploring alternative production methods, optimizing resource use, and incorporating life cycle assessments into the development process to minimize the overall environmental footprint of 4140 steel production.

Safety Standards for High-Impact 4140 Steel Applications

The development of safety standards for high-impact 4140 steel applications is crucial to ensure the reliability and performance of components in demanding environments. These standards encompass a wide range of considerations, including material properties, design specifications, testing protocols, and quality control measures.

One of the primary focuses of safety standards for 4140 steel in high-impact applications is the establishment of minimum mechanical property requirements. These typically include specifications for tensile strength, yield strength, elongation, and impact toughness. For enhanced impact absorption, particular emphasis is placed on the material's ability to absorb energy without catastrophic failure.

Testing protocols form a significant part of these safety standards. Impact testing, such as the Charpy V-notch test, is commonly employed to assess the material's toughness and its ability to resist brittle fracture under dynamic loading conditions. Fatigue testing is also critical, as many high-impact applications involve cyclic loading. Standards often specify the number of cycles and stress levels that the material must withstand without failure.

Microstructural requirements are another key aspect of safety standards for 4140 steel. The heat treatment process, which significantly influences the steel's microstructure and, consequently, its mechanical properties, is carefully regulated. Standards may specify acceptable ranges for hardness, grain size, and phase composition to ensure optimal impact absorption characteristics.

Quality control measures are integral to these safety standards. They typically include requirements for non-destructive testing methods such as ultrasonic inspection, magnetic particle testing, or dye penetrant testing to detect potential flaws or defects in the material that could compromise its performance under high-impact conditions.

Design considerations are also addressed in safety standards for high-impact 4140 steel applications. These may include guidelines for minimum section thicknesses, stress concentration factors, and design safety factors. The standards often provide recommendations for avoiding sharp corners or sudden changes in cross-section that could lead to stress concentrations and premature failure.

Environmental factors are taken into account in these safety standards, recognizing that the performance of 4140 steel can be affected by temperature extremes, corrosive environments, or exposure to certain chemicals. Standards may specify additional protective measures or modified material properties for applications in challenging environments.

Lastly, safety standards for high-impact 4140 steel applications often include provisions for traceability and documentation. This ensures that the material's history, from production through processing and testing, can be fully tracked and verified, providing an additional layer of quality assurance and facilitating root cause analysis in the event of any failures.

One of the primary focuses of safety standards for 4140 steel in high-impact applications is the establishment of minimum mechanical property requirements. These typically include specifications for tensile strength, yield strength, elongation, and impact toughness. For enhanced impact absorption, particular emphasis is placed on the material's ability to absorb energy without catastrophic failure.

Testing protocols form a significant part of these safety standards. Impact testing, such as the Charpy V-notch test, is commonly employed to assess the material's toughness and its ability to resist brittle fracture under dynamic loading conditions. Fatigue testing is also critical, as many high-impact applications involve cyclic loading. Standards often specify the number of cycles and stress levels that the material must withstand without failure.

Microstructural requirements are another key aspect of safety standards for 4140 steel. The heat treatment process, which significantly influences the steel's microstructure and, consequently, its mechanical properties, is carefully regulated. Standards may specify acceptable ranges for hardness, grain size, and phase composition to ensure optimal impact absorption characteristics.

Quality control measures are integral to these safety standards. They typically include requirements for non-destructive testing methods such as ultrasonic inspection, magnetic particle testing, or dye penetrant testing to detect potential flaws or defects in the material that could compromise its performance under high-impact conditions.

Design considerations are also addressed in safety standards for high-impact 4140 steel applications. These may include guidelines for minimum section thicknesses, stress concentration factors, and design safety factors. The standards often provide recommendations for avoiding sharp corners or sudden changes in cross-section that could lead to stress concentrations and premature failure.

Environmental factors are taken into account in these safety standards, recognizing that the performance of 4140 steel can be affected by temperature extremes, corrosive environments, or exposure to certain chemicals. Standards may specify additional protective measures or modified material properties for applications in challenging environments.

Lastly, safety standards for high-impact 4140 steel applications often include provisions for traceability and documentation. This ensures that the material's history, from production through processing and testing, can be fully tracked and verified, providing an additional layer of quality assurance and facilitating root cause analysis in the event of any failures.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!