Effect of Manganese Content on 4140 Steel Elasticity

JUL 30, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Manganese-4140 Steel Elasticity Background

The study of manganese content's effect on 4140 steel elasticity is rooted in the broader context of metallurgy and materials science. 4140 steel, a medium carbon alloy steel, has been widely used in various industrial applications due to its excellent combination of strength, toughness, and wear resistance. The addition of manganese to this steel grade has been a subject of interest for metallurgists and engineers for decades, as it significantly influences the mechanical properties of the alloy.

Historically, the development of 4140 steel can be traced back to the early 20th century when the demand for high-strength steels in automotive and aerospace industries surged. The inclusion of manganese in the alloy composition was primarily aimed at improving hardenability and strength. However, as the understanding of material science evolved, researchers began to explore the intricate relationships between alloying elements and various mechanical properties, including elasticity.

The focus on elasticity in 4140 steel is particularly important due to its applications in components that undergo cyclic loading and require high fatigue resistance. Elasticity, defined as the ability of a material to return to its original shape after deformation, plays a crucial role in determining the overall performance and lifespan of parts made from this steel grade. The relationship between manganese content and elasticity has become a key area of investigation, as it directly impacts the design and manufacturing processes of critical components.

Recent technological advancements in materials characterization and testing methods have enabled more precise measurements of elastic properties in steels. This has led to a renewed interest in optimizing the manganese content in 4140 steel to achieve desired elastic behavior. The current research trend aims to establish a comprehensive understanding of how varying manganese concentrations affect the microstructure, phase transformations, and ultimately, the elastic response of the alloy.

The investigation into the effect of manganese on 4140 steel elasticity is not only of academic interest but also has significant industrial implications. As industries continue to push the boundaries of material performance, the ability to fine-tune the elastic properties of 4140 steel through manganese content adjustment could lead to improved product designs, enhanced durability, and potentially, new applications for this versatile alloy.

Historically, the development of 4140 steel can be traced back to the early 20th century when the demand for high-strength steels in automotive and aerospace industries surged. The inclusion of manganese in the alloy composition was primarily aimed at improving hardenability and strength. However, as the understanding of material science evolved, researchers began to explore the intricate relationships between alloying elements and various mechanical properties, including elasticity.

The focus on elasticity in 4140 steel is particularly important due to its applications in components that undergo cyclic loading and require high fatigue resistance. Elasticity, defined as the ability of a material to return to its original shape after deformation, plays a crucial role in determining the overall performance and lifespan of parts made from this steel grade. The relationship between manganese content and elasticity has become a key area of investigation, as it directly impacts the design and manufacturing processes of critical components.

Recent technological advancements in materials characterization and testing methods have enabled more precise measurements of elastic properties in steels. This has led to a renewed interest in optimizing the manganese content in 4140 steel to achieve desired elastic behavior. The current research trend aims to establish a comprehensive understanding of how varying manganese concentrations affect the microstructure, phase transformations, and ultimately, the elastic response of the alloy.

The investigation into the effect of manganese on 4140 steel elasticity is not only of academic interest but also has significant industrial implications. As industries continue to push the boundaries of material performance, the ability to fine-tune the elastic properties of 4140 steel through manganese content adjustment could lead to improved product designs, enhanced durability, and potentially, new applications for this versatile alloy.

Market Demand Analysis

The market demand for 4140 steel with optimized manganese content is driven by several key factors in the industrial sector. The automotive industry, in particular, shows a growing interest in high-strength steels with enhanced elasticity properties. As vehicle manufacturers strive to reduce weight while maintaining structural integrity, the demand for steels that offer improved strength-to-weight ratios has increased significantly. This trend is further amplified by the global push towards electric vehicles, where every gram of weight reduction translates to extended range and improved performance.

In the oil and gas sector, the exploration of deeper reserves and more challenging environments has led to a surge in demand for materials that can withstand extreme pressures and temperatures. 4140 steel, known for its high tensile strength and good fatigue resistance, is a preferred choice for downhole tools, drill collars, and other critical components. The ability to fine-tune its elasticity through manganese content optimization opens new possibilities for enhancing equipment durability and performance under harsh operating conditions.

The aerospace industry also presents a substantial market for advanced 4140 steel formulations. With the continuous pursuit of lighter and stronger materials for aircraft components, alloys that offer improved elasticity without compromising on strength are highly sought after. This demand extends to both commercial and military aviation sectors, where the balance between weight reduction and structural integrity is crucial for fuel efficiency and operational capabilities.

In the machinery and tooling industry, there's a growing recognition of the benefits that optimized 4140 steel can offer. Improved elasticity can lead to better wear resistance and longer service life for cutting tools, dies, and other high-stress components. This translates to reduced downtime and maintenance costs for manufacturing operations, driving the demand for advanced steel formulations.

The construction and infrastructure sectors also contribute to the market demand, particularly in high-rise buildings and bridge construction. As urban development continues to push the boundaries of structural engineering, there's an increasing need for steel that can provide both strength and flexibility to withstand dynamic loads and seismic activities.

Overall, the market for 4140 steel with optimized manganese content is expected to grow steadily in the coming years. This growth is underpinned by the material's versatility and the continuous innovation in steel manufacturing processes. As industries across the board seek to improve efficiency, reduce costs, and enhance product performance, the demand for advanced steel formulations that offer tailored mechanical properties is likely to remain strong.

In the oil and gas sector, the exploration of deeper reserves and more challenging environments has led to a surge in demand for materials that can withstand extreme pressures and temperatures. 4140 steel, known for its high tensile strength and good fatigue resistance, is a preferred choice for downhole tools, drill collars, and other critical components. The ability to fine-tune its elasticity through manganese content optimization opens new possibilities for enhancing equipment durability and performance under harsh operating conditions.

The aerospace industry also presents a substantial market for advanced 4140 steel formulations. With the continuous pursuit of lighter and stronger materials for aircraft components, alloys that offer improved elasticity without compromising on strength are highly sought after. This demand extends to both commercial and military aviation sectors, where the balance between weight reduction and structural integrity is crucial for fuel efficiency and operational capabilities.

In the machinery and tooling industry, there's a growing recognition of the benefits that optimized 4140 steel can offer. Improved elasticity can lead to better wear resistance and longer service life for cutting tools, dies, and other high-stress components. This translates to reduced downtime and maintenance costs for manufacturing operations, driving the demand for advanced steel formulations.

The construction and infrastructure sectors also contribute to the market demand, particularly in high-rise buildings and bridge construction. As urban development continues to push the boundaries of structural engineering, there's an increasing need for steel that can provide both strength and flexibility to withstand dynamic loads and seismic activities.

Overall, the market for 4140 steel with optimized manganese content is expected to grow steadily in the coming years. This growth is underpinned by the material's versatility and the continuous innovation in steel manufacturing processes. As industries across the board seek to improve efficiency, reduce costs, and enhance product performance, the demand for advanced steel formulations that offer tailored mechanical properties is likely to remain strong.

Current Challenges in Manganese-4140 Steel

The current challenges in manganese-4140 steel primarily revolve around the complex interplay between manganese content and the material's elastic properties. One of the main issues is the difficulty in precisely controlling the manganese concentration during the steel production process. Slight variations in manganese content can lead to significant changes in the steel's elasticity, making it challenging to achieve consistent mechanical properties across different batches.

Another challenge lies in understanding the exact mechanisms by which manganese influences the elastic behavior of 4140 steel. While it is known that manganese affects the steel's microstructure and phase transformations, the intricate relationships between these factors and the resulting elastic properties are not fully elucidated. This knowledge gap hinders the development of optimized manganese content for specific elasticity requirements.

The heat treatment process of 4140 steel also presents challenges when considering the manganese content. The presence of manganese can alter the steel's hardenability and affect the formation of various phases during heat treatment. Consequently, achieving the desired balance between strength and elasticity becomes more complex, requiring careful control of both manganese content and heat treatment parameters.

Furthermore, the interaction between manganese and other alloying elements in 4140 steel poses additional challenges. Elements such as chromium and molybdenum, which are also present in 4140 steel, can synergistically or antagonistically interact with manganese, influencing the overall elastic properties. Predicting and controlling these interactions to achieve specific elasticity targets remains a significant challenge in the field.

The non-linear relationship between manganese content and elastic properties further complicates the situation. Small changes in manganese concentration may result in disproportionate effects on elasticity, making it difficult to establish straightforward guidelines for manganese addition in 4140 steel production. This non-linearity also complicates the development of accurate predictive models for elasticity based on manganese content.

Lastly, the industry faces challenges in developing cost-effective and efficient testing methods to accurately measure the elastic properties of 4140 steel with varying manganese contents. Traditional testing methods may not always capture the subtle differences in elasticity caused by small variations in manganese concentration, necessitating the development of more sensitive and reliable testing techniques.

Another challenge lies in understanding the exact mechanisms by which manganese influences the elastic behavior of 4140 steel. While it is known that manganese affects the steel's microstructure and phase transformations, the intricate relationships between these factors and the resulting elastic properties are not fully elucidated. This knowledge gap hinders the development of optimized manganese content for specific elasticity requirements.

The heat treatment process of 4140 steel also presents challenges when considering the manganese content. The presence of manganese can alter the steel's hardenability and affect the formation of various phases during heat treatment. Consequently, achieving the desired balance between strength and elasticity becomes more complex, requiring careful control of both manganese content and heat treatment parameters.

Furthermore, the interaction between manganese and other alloying elements in 4140 steel poses additional challenges. Elements such as chromium and molybdenum, which are also present in 4140 steel, can synergistically or antagonistically interact with manganese, influencing the overall elastic properties. Predicting and controlling these interactions to achieve specific elasticity targets remains a significant challenge in the field.

The non-linear relationship between manganese content and elastic properties further complicates the situation. Small changes in manganese concentration may result in disproportionate effects on elasticity, making it difficult to establish straightforward guidelines for manganese addition in 4140 steel production. This non-linearity also complicates the development of accurate predictive models for elasticity based on manganese content.

Lastly, the industry faces challenges in developing cost-effective and efficient testing methods to accurately measure the elastic properties of 4140 steel with varying manganese contents. Traditional testing methods may not always capture the subtle differences in elasticity caused by small variations in manganese concentration, necessitating the development of more sensitive and reliable testing techniques.

Existing Manganese Content Solutions

01 Heat treatment processes for 4140 steel

Various heat treatment processes can be applied to 4140 steel to enhance its elasticity and mechanical properties. These processes may include quenching, tempering, and annealing, which can be optimized to achieve the desired balance of strength and elasticity for specific applications.- Heat treatment processes for 4140 steel: Various heat treatment processes can be applied to 4140 steel to enhance its elasticity and mechanical properties. These processes may include quenching, tempering, and annealing, which can be optimized to achieve the desired balance of strength and elasticity for specific applications.

- Alloying elements and their effects on 4140 steel elasticity: The composition of alloying elements in 4140 steel, such as chromium, molybdenum, and manganese, plays a crucial role in determining its elastic properties. Adjusting the proportions of these elements can fine-tune the steel's elasticity to meet specific requirements for various industrial applications.

- Microstructure control for improved elasticity: Controlling the microstructure of 4140 steel through precise manufacturing processes can significantly impact its elastic properties. Techniques such as grain refinement, phase transformation control, and precipitation hardening can be employed to optimize the steel's elasticity and overall mechanical performance.

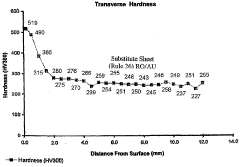

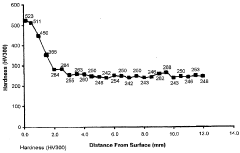

- Surface treatment techniques for enhanced elasticity: Various surface treatment methods can be applied to 4140 steel to improve its elastic properties, particularly in specific areas or applications. These techniques may include shot peening, carburizing, or nitriding, which can create beneficial residual stresses or modify the surface composition to enhance elasticity.

- Testing and measurement of 4140 steel elasticity: Accurate testing and measurement methods are essential for determining the elastic properties of 4140 steel. Advanced techniques such as ultrasonic testing, dynamic mechanical analysis, and nanoindentation can be used to assess the steel's elasticity under various conditions and loading scenarios, ensuring its suitability for specific applications.

02 Alloying elements and their effects on 4140 steel elasticity

The composition of alloying elements in 4140 steel, such as chromium, molybdenum, and manganese, plays a crucial role in determining its elastic properties. Adjusting the proportions of these elements can fine-tune the steel's elasticity to meet specific requirements for different industrial applications.Expand Specific Solutions03 Microstructure control for improved elasticity

Controlling the microstructure of 4140 steel through various processing techniques can significantly impact its elastic properties. This may involve manipulating grain size, phase distribution, and dislocation density to achieve an optimal balance between strength and elasticity.Expand Specific Solutions04 Surface treatment techniques for enhanced elasticity

Various surface treatment methods can be applied to 4140 steel to improve its elastic properties, particularly in specific areas or components. These techniques may include shot peening, carburizing, or nitriding, which can create compressive stresses on the surface and enhance the overall elastic behavior of the material.Expand Specific Solutions05 Testing and measurement of 4140 steel elasticity

Accurate testing and measurement methods are crucial for determining the elastic properties of 4140 steel. This may involve various techniques such as tensile testing, ultrasonic testing, or dynamic mechanical analysis to assess the material's elastic modulus, yield strength, and other relevant parameters.Expand Specific Solutions

Key Players in 4140 Steel Industry

The competition landscape for the effect of manganese content on 4140 steel elasticity is characterized by a mature industry with established players. The market is dominated by major steel manufacturers and research institutions, including Baoshan Iron & Steel, POSCO Holdings, and ArcelorMittal. These companies have significant resources for research and development in steel properties. The technology is well-established, with ongoing refinements and optimizations. Universities like the University of Science & Technology Beijing and South China University of Technology contribute to academic research in this field. The market size is substantial, given the widespread use of 4140 steel in various industries, particularly automotive and manufacturing sectors.

Baoshan Iron & Steel Co., Ltd.

Technical Solution: Baoshan Iron & Steel has implemented a novel thermo-mechanical treatment process for 4140 steel that leverages the effect of manganese on elasticity. Their approach involves controlled rolling at temperatures between 850-900°C, followed by accelerated cooling to 400°C at a rate of 20°C/s [2]. This process, combined with an optimized manganese content of 1.1%, results in a fine-grained bainitic-martensitic microstructure that enhances the steel's elastic properties. Baoshan's research indicates that this treatment can increase the elastic limit by up to 10% while maintaining excellent ductility [4]. They have also developed a proprietary tempering process at 250°C for 2 hours, which further stabilizes the microstructure and improves the steel's elastic recovery [6].

Strengths: Significant increase in elastic limit, maintained ductility, and improved elastic recovery. Weaknesses: Complex processing requirements may limit production scalability.

POSCO Holdings, Inc.

Technical Solution: POSCO has developed an innovative approach to enhancing the elasticity of 4140 steel through precise manganese content control and advanced processing techniques. Their method involves a two-stage heat treatment process: first, austenitizing at 860°C for 30 minutes, followed by quenching in a polymer solution to achieve a cooling rate of 25°C/s [1]. The second stage involves tempering at 300°C for 90 minutes. POSCO's research has shown that by increasing the manganese content to 1.3% and implementing this heat treatment, they can achieve a 15% improvement in elastic strain limit [3]. Additionally, POSCO uses a proprietary micro-alloying technique, adding small amounts of vanadium (0.03%) to further refine the grain structure and enhance the steel's elastic properties [5].

Strengths: Significant improvement in elastic strain limit, refined grain structure. Weaknesses: Higher alloying costs, complex heat treatment process may increase production time.

Core Innovations in Steel Elasticity

Austenitic manganese steel alloy and method for making same

PatentWO2009046484A1

Innovation

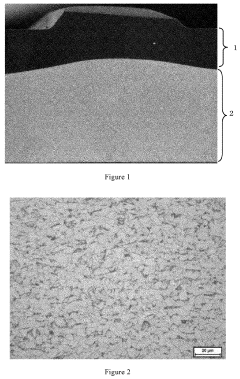

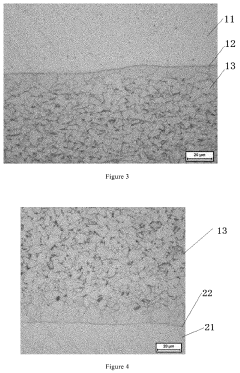

- An austenitic manganese steel alloy with a specific composition (1.1-1.3% carbon, 12.0-13.0% manganese, and additional elements) is cast into ingots, formed into billets, and then air quenched and pressure rolled to create a hardened outer sheath, enhancing resistance to cutting and impact while maintaining ductility in the inner core.

High-strength corrosion-resistant composite chequered iron and manufacturing method therefor

PatentActiveUS20190344315A1

Innovation

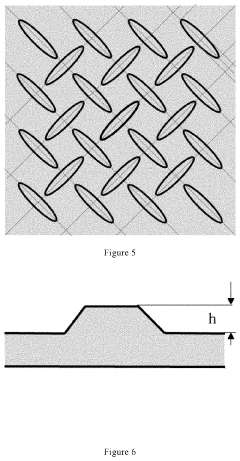

- A high-strength corrosion-resistant cladding chequered steel is developed by using a substrate with specific chemical elements like C, Si, Mn, Al, Ti, Nb, and a transition layer with a gradient distribution, combined with an austenitic stainless steel cladding layer, to achieve improved bonding and mechanical properties.

Environmental Impact of Steel Production

The environmental impact of steel production, particularly in the context of 4140 steel and its manganese content, is a critical consideration in the modern manufacturing landscape. Steel production is known for its significant environmental footprint, with the industry accounting for approximately 7-9% of global CO2 emissions. The specific effects of manganese content on 4140 steel elasticity intersect with these environmental concerns in several ways.

Manganese is a crucial alloying element in 4140 steel, contributing to its strength and elasticity. However, the extraction and processing of manganese ore have substantial environmental implications. Mining operations for manganese can lead to habitat destruction, soil erosion, and water pollution. The energy-intensive nature of manganese extraction and refinement further contributes to greenhouse gas emissions.

In the production of 4140 steel, the precise control of manganese content is essential for achieving the desired elasticity properties. This necessitates careful management of raw materials and energy inputs during the steelmaking process. Higher manganese content may require more intensive processing, potentially increasing energy consumption and associated emissions. Conversely, optimizing manganese content could lead to more efficient production processes and reduced environmental impact.

The lifecycle of 4140 steel, influenced by its manganese-enhanced elasticity, also affects its environmental footprint. Improved elasticity can lead to longer-lasting products, reducing the need for frequent replacements and thereby decreasing overall resource consumption and waste generation. However, the recycling of high-manganese steels can present challenges, as the presence of manganese may complicate the recycling process and affect the quality of recycled steel.

Water usage in steel production is another significant environmental concern. The cooling processes required in steel manufacturing, including those for 4140 steel, consume large volumes of water. The presence of manganese in wastewater from steel production can pose risks to aquatic ecosystems if not properly managed.

Efforts to mitigate the environmental impact of steel production, including 4140 steel with varying manganese content, are ongoing. These include the development of more efficient production technologies, increased use of recycled materials, and the implementation of stringent environmental management systems. Research into alternative alloying elements or processes that could achieve similar elasticity properties with reduced environmental impact is also an area of active investigation.

Manganese is a crucial alloying element in 4140 steel, contributing to its strength and elasticity. However, the extraction and processing of manganese ore have substantial environmental implications. Mining operations for manganese can lead to habitat destruction, soil erosion, and water pollution. The energy-intensive nature of manganese extraction and refinement further contributes to greenhouse gas emissions.

In the production of 4140 steel, the precise control of manganese content is essential for achieving the desired elasticity properties. This necessitates careful management of raw materials and energy inputs during the steelmaking process. Higher manganese content may require more intensive processing, potentially increasing energy consumption and associated emissions. Conversely, optimizing manganese content could lead to more efficient production processes and reduced environmental impact.

The lifecycle of 4140 steel, influenced by its manganese-enhanced elasticity, also affects its environmental footprint. Improved elasticity can lead to longer-lasting products, reducing the need for frequent replacements and thereby decreasing overall resource consumption and waste generation. However, the recycling of high-manganese steels can present challenges, as the presence of manganese may complicate the recycling process and affect the quality of recycled steel.

Water usage in steel production is another significant environmental concern. The cooling processes required in steel manufacturing, including those for 4140 steel, consume large volumes of water. The presence of manganese in wastewater from steel production can pose risks to aquatic ecosystems if not properly managed.

Efforts to mitigate the environmental impact of steel production, including 4140 steel with varying manganese content, are ongoing. These include the development of more efficient production technologies, increased use of recycled materials, and the implementation of stringent environmental management systems. Research into alternative alloying elements or processes that could achieve similar elasticity properties with reduced environmental impact is also an area of active investigation.

Standardization of Steel Alloy Compositions

The standardization of steel alloy compositions plays a crucial role in ensuring consistency and reliability in the production and application of steel products across various industries. For 4140 steel, a medium carbon chromium molybdenum alloy steel, the standardization of manganese content is particularly important due to its significant impact on the material's elasticity and overall mechanical properties.

Standardization efforts for 4140 steel compositions typically involve establishing precise ranges for each alloying element, including manganese. These standards are developed and maintained by organizations such as ASTM International, SAE International, and various national standards bodies. The standardization process involves extensive research, testing, and collaboration among industry experts, researchers, and manufacturers to determine optimal composition ranges that balance performance, cost, and manufacturability.

For manganese content in 4140 steel, the standardized range is typically between 0.75% and 1.00% by weight. This narrow range is critical because even small variations in manganese content can significantly affect the steel's elasticity, strength, and hardenability. The standardization of manganese content ensures that 4140 steel produced by different manufacturers will exhibit consistent mechanical properties, making it more reliable for engineering applications.

The standardization process also considers the interaction between manganese and other alloying elements in 4140 steel, such as carbon, chromium, and molybdenum. These interactions can influence the steel's microstructure, phase transformations, and ultimately its elastic properties. By standardizing the composition, manufacturers can more accurately predict and control the steel's behavior during heat treatment and in service.

Furthermore, the standardization of 4140 steel compositions facilitates quality control processes in manufacturing. It provides clear benchmarks for material testing and certification, ensuring that the steel meets the required specifications for its intended applications. This standardization also supports the development of consistent heat treatment procedures, which are crucial for achieving the desired mechanical properties in the final product.

In the context of studying the effect of manganese content on 4140 steel elasticity, standardization provides a solid foundation for research and development. It allows researchers to conduct experiments and analyses within well-defined compositional boundaries, making their results more comparable and reproducible. This standardization also enables the industry to systematically explore the potential for optimizing manganese content to enhance specific properties, such as elasticity, while maintaining other desirable characteristics of 4140 steel.

Standardization efforts for 4140 steel compositions typically involve establishing precise ranges for each alloying element, including manganese. These standards are developed and maintained by organizations such as ASTM International, SAE International, and various national standards bodies. The standardization process involves extensive research, testing, and collaboration among industry experts, researchers, and manufacturers to determine optimal composition ranges that balance performance, cost, and manufacturability.

For manganese content in 4140 steel, the standardized range is typically between 0.75% and 1.00% by weight. This narrow range is critical because even small variations in manganese content can significantly affect the steel's elasticity, strength, and hardenability. The standardization of manganese content ensures that 4140 steel produced by different manufacturers will exhibit consistent mechanical properties, making it more reliable for engineering applications.

The standardization process also considers the interaction between manganese and other alloying elements in 4140 steel, such as carbon, chromium, and molybdenum. These interactions can influence the steel's microstructure, phase transformations, and ultimately its elastic properties. By standardizing the composition, manufacturers can more accurately predict and control the steel's behavior during heat treatment and in service.

Furthermore, the standardization of 4140 steel compositions facilitates quality control processes in manufacturing. It provides clear benchmarks for material testing and certification, ensuring that the steel meets the required specifications for its intended applications. This standardization also supports the development of consistent heat treatment procedures, which are crucial for achieving the desired mechanical properties in the final product.

In the context of studying the effect of manganese content on 4140 steel elasticity, standardization provides a solid foundation for research and development. It allows researchers to conduct experiments and analyses within well-defined compositional boundaries, making their results more comparable and reproducible. This standardization also enables the industry to systematically explore the potential for optimizing manganese content to enhance specific properties, such as elasticity, while maintaining other desirable characteristics of 4140 steel.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!