Inhibition Techniques for Rust Formation on 4140 Steel

JUL 30, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Rust Inhibition Goals for 4140 Steel

The primary goal of rust inhibition for 4140 steel is to preserve its mechanical properties and structural integrity in corrosive environments. This high-strength alloy steel, widely used in the oil and gas industry, automotive sector, and heavy machinery, requires effective protection against rust formation to maintain its performance and longevity.

One key objective is to develop cost-effective and environmentally friendly inhibition techniques that can be easily applied in various industrial settings. Traditional methods often involve hazardous chemicals, so finding sustainable alternatives is crucial. This includes exploring bio-based inhibitors derived from plant extracts or developing novel green corrosion inhibitors that are both effective and eco-friendly.

Another important goal is to create long-lasting protection systems that can withstand harsh operating conditions. This involves developing multi-layer coating systems or advanced surface treatments that provide a robust barrier against moisture and corrosive agents. The aim is to extend the service life of 4140 steel components, reducing maintenance costs and downtime in industrial applications.

Improving the compatibility of rust inhibition techniques with existing manufacturing processes is also a significant objective. This includes developing inhibition methods that can be seamlessly integrated into current production lines without requiring major modifications or additional equipment. The focus is on solutions that offer minimal disruption to established manufacturing workflows while providing maximum protection.

Furthermore, there is a growing need for smart corrosion protection systems that can adapt to changing environmental conditions. This involves incorporating sensors and responsive materials that can detect and mitigate corrosion in real-time. The goal is to create proactive rust inhibition solutions that can anticipate and prevent corrosion before it causes significant damage.

Lastly, enhancing the understanding of corrosion mechanisms specific to 4140 steel is crucial for developing targeted inhibition strategies. This includes studying the microstructural changes during corrosion and how different alloying elements in 4140 steel influence its corrosion behavior. By gaining deeper insights into these processes, researchers aim to design more effective and tailored rust inhibition techniques for this particular alloy.

One key objective is to develop cost-effective and environmentally friendly inhibition techniques that can be easily applied in various industrial settings. Traditional methods often involve hazardous chemicals, so finding sustainable alternatives is crucial. This includes exploring bio-based inhibitors derived from plant extracts or developing novel green corrosion inhibitors that are both effective and eco-friendly.

Another important goal is to create long-lasting protection systems that can withstand harsh operating conditions. This involves developing multi-layer coating systems or advanced surface treatments that provide a robust barrier against moisture and corrosive agents. The aim is to extend the service life of 4140 steel components, reducing maintenance costs and downtime in industrial applications.

Improving the compatibility of rust inhibition techniques with existing manufacturing processes is also a significant objective. This includes developing inhibition methods that can be seamlessly integrated into current production lines without requiring major modifications or additional equipment. The focus is on solutions that offer minimal disruption to established manufacturing workflows while providing maximum protection.

Furthermore, there is a growing need for smart corrosion protection systems that can adapt to changing environmental conditions. This involves incorporating sensors and responsive materials that can detect and mitigate corrosion in real-time. The goal is to create proactive rust inhibition solutions that can anticipate and prevent corrosion before it causes significant damage.

Lastly, enhancing the understanding of corrosion mechanisms specific to 4140 steel is crucial for developing targeted inhibition strategies. This includes studying the microstructural changes during corrosion and how different alloying elements in 4140 steel influence its corrosion behavior. By gaining deeper insights into these processes, researchers aim to design more effective and tailored rust inhibition techniques for this particular alloy.

Market Analysis for Rust-Resistant 4140 Steel

The market for rust-resistant 4140 steel is experiencing significant growth, driven by increasing demand across various industries. The automotive sector, in particular, shows a strong appetite for this material due to its excellent mechanical properties and potential for enhanced corrosion resistance. As vehicle manufacturers strive to extend the lifespan of critical components, the adoption of rust-resistant 4140 steel is expected to rise.

In the oil and gas industry, there is a growing need for materials that can withstand harsh environments and corrosive substances. Rust-resistant 4140 steel offers a promising solution for equipment such as drilling tools, valves, and pipelines, where durability and reliability are paramount. The market in this sector is projected to expand as exploration and production activities continue to push into more challenging terrains.

The aerospace industry represents another key market for rust-resistant 4140 steel. With the increasing focus on lightweight yet strong materials, this alloy's potential for improved corrosion resistance without compromising its mechanical properties makes it an attractive option for various aircraft components. The market in this sector is expected to grow steadily as manufacturers seek to enhance the longevity and performance of their products.

In the construction and infrastructure sector, there is a rising demand for materials that can withstand environmental stresses and reduce maintenance costs. Rust-resistant 4140 steel could find applications in structural components, bridges, and marine structures, where exposure to corrosive elements is a constant challenge. The market potential in this area is substantial, given the global focus on infrastructure development and renovation.

The industrial machinery and equipment market also presents opportunities for rust-resistant 4140 steel. Manufacturers of heavy machinery, processing equipment, and industrial tools are increasingly looking for materials that can extend the operational life of their products. The ability to resist corrosion while maintaining high strength and toughness makes this alloy an attractive choice for various components in challenging industrial environments.

Overall, the market for rust-resistant 4140 steel is poised for growth across multiple sectors. The increasing awareness of the long-term cost benefits associated with corrosion-resistant materials, coupled with stricter regulations on product durability and environmental impact, is likely to drive demand. As research and development efforts continue to improve the rust inhibition techniques for 4140 steel, its market potential is expected to expand further, offering new opportunities for manufacturers and end-users alike.

In the oil and gas industry, there is a growing need for materials that can withstand harsh environments and corrosive substances. Rust-resistant 4140 steel offers a promising solution for equipment such as drilling tools, valves, and pipelines, where durability and reliability are paramount. The market in this sector is projected to expand as exploration and production activities continue to push into more challenging terrains.

The aerospace industry represents another key market for rust-resistant 4140 steel. With the increasing focus on lightweight yet strong materials, this alloy's potential for improved corrosion resistance without compromising its mechanical properties makes it an attractive option for various aircraft components. The market in this sector is expected to grow steadily as manufacturers seek to enhance the longevity and performance of their products.

In the construction and infrastructure sector, there is a rising demand for materials that can withstand environmental stresses and reduce maintenance costs. Rust-resistant 4140 steel could find applications in structural components, bridges, and marine structures, where exposure to corrosive elements is a constant challenge. The market potential in this area is substantial, given the global focus on infrastructure development and renovation.

The industrial machinery and equipment market also presents opportunities for rust-resistant 4140 steel. Manufacturers of heavy machinery, processing equipment, and industrial tools are increasingly looking for materials that can extend the operational life of their products. The ability to resist corrosion while maintaining high strength and toughness makes this alloy an attractive choice for various components in challenging industrial environments.

Overall, the market for rust-resistant 4140 steel is poised for growth across multiple sectors. The increasing awareness of the long-term cost benefits associated with corrosion-resistant materials, coupled with stricter regulations on product durability and environmental impact, is likely to drive demand. As research and development efforts continue to improve the rust inhibition techniques for 4140 steel, its market potential is expected to expand further, offering new opportunities for manufacturers and end-users alike.

Current Challenges in 4140 Steel Rust Prevention

Despite significant advancements in metallurgy and corrosion prevention, rust formation on 4140 steel remains a persistent challenge in various industrial applications. The high carbon content and alloying elements that give 4140 steel its desirable mechanical properties also make it susceptible to corrosion under certain conditions. One of the primary challenges is the steel's vulnerability to atmospheric corrosion, particularly in environments with high humidity or exposure to corrosive agents.

The formation of rust on 4140 steel is exacerbated by the presence of chlorides and sulfates, which are common in industrial and marine environments. These compounds can accelerate the corrosion process by breaking down the protective oxide layer that naturally forms on the steel surface. Additionally, the heterogeneous microstructure of 4140 steel, consisting of ferrite and pearlite, can lead to localized corrosion and pitting, further complicating prevention efforts.

Another significant challenge is the difficulty in maintaining effective protective coatings on 4140 steel components. The steel's high strength and hardness can lead to coating adhesion issues, especially under conditions of mechanical stress or thermal cycling. This can result in coating failure and subsequent exposure of the underlying steel to corrosive elements.

The heat treatment processes used to enhance the mechanical properties of 4140 steel can inadvertently increase its susceptibility to stress corrosion cracking (SCC). This phenomenon occurs when the material is subjected to both tensile stress and a corrosive environment, leading to rapid and often catastrophic failure. Preventing SCC requires a delicate balance between maintaining the steel's strength and minimizing its vulnerability to corrosion.

Furthermore, the use of 4140 steel in high-temperature applications presents additional challenges for rust prevention. At elevated temperatures, the kinetics of corrosion reactions accelerate, and traditional protective measures may become less effective. The formation of high-temperature oxides can lead to scaling and spallation, compromising the integrity of the steel components.

The economic impact of rust formation on 4140 steel is substantial, encompassing not only the direct costs of material replacement but also the indirect costs associated with equipment downtime, maintenance, and potential safety hazards. Developing cost-effective and long-lasting rust prevention techniques that do not compromise the steel's mechanical properties remains a significant challenge for researchers and engineers in the field.

The formation of rust on 4140 steel is exacerbated by the presence of chlorides and sulfates, which are common in industrial and marine environments. These compounds can accelerate the corrosion process by breaking down the protective oxide layer that naturally forms on the steel surface. Additionally, the heterogeneous microstructure of 4140 steel, consisting of ferrite and pearlite, can lead to localized corrosion and pitting, further complicating prevention efforts.

Another significant challenge is the difficulty in maintaining effective protective coatings on 4140 steel components. The steel's high strength and hardness can lead to coating adhesion issues, especially under conditions of mechanical stress or thermal cycling. This can result in coating failure and subsequent exposure of the underlying steel to corrosive elements.

The heat treatment processes used to enhance the mechanical properties of 4140 steel can inadvertently increase its susceptibility to stress corrosion cracking (SCC). This phenomenon occurs when the material is subjected to both tensile stress and a corrosive environment, leading to rapid and often catastrophic failure. Preventing SCC requires a delicate balance between maintaining the steel's strength and minimizing its vulnerability to corrosion.

Furthermore, the use of 4140 steel in high-temperature applications presents additional challenges for rust prevention. At elevated temperatures, the kinetics of corrosion reactions accelerate, and traditional protective measures may become less effective. The formation of high-temperature oxides can lead to scaling and spallation, compromising the integrity of the steel components.

The economic impact of rust formation on 4140 steel is substantial, encompassing not only the direct costs of material replacement but also the indirect costs associated with equipment downtime, maintenance, and potential safety hazards. Developing cost-effective and long-lasting rust prevention techniques that do not compromise the steel's mechanical properties remains a significant challenge for researchers and engineers in the field.

Existing Rust Inhibition Solutions for 4140 Steel

01 Composition and heat treatment of 4140 steel

4140 steel is a medium carbon alloy steel containing chromium and molybdenum. Its composition and heat treatment processes significantly influence its susceptibility to rust formation. Proper heat treatment can improve the steel's corrosion resistance by altering its microstructure and surface properties.- Composition and heat treatment of 4140 steel: The composition and heat treatment of 4140 steel play crucial roles in its rust formation characteristics. The steel's carbon content, alloying elements, and heat treatment processes can significantly affect its corrosion resistance. Proper heat treatment can improve the steel's microstructure, leading to enhanced resistance to rust formation.

- Surface treatment methods for rust prevention: Various surface treatment methods can be applied to 4140 steel to prevent or minimize rust formation. These may include chemical treatments, coatings, or surface modifications that create a protective layer on the steel surface, inhibiting the oxidation process that leads to rust.

- Environmental factors affecting rust formation: Environmental conditions such as humidity, temperature, and exposure to corrosive substances significantly influence the rate of rust formation on 4140 steel. Understanding and controlling these factors can help in developing effective rust prevention strategies for specific applications of the steel.

- Corrosion inhibitors and additives: The use of corrosion inhibitors and additives can effectively reduce rust formation in 4140 steel. These substances can be incorporated into coatings, lubricants, or directly applied to the steel surface to create a protective barrier against corrosive elements.

- Monitoring and maintenance techniques: Regular monitoring and maintenance of 4140 steel components are essential for early detection and prevention of rust formation. This includes periodic inspections, cleaning procedures, and the application of protective measures to extend the lifespan of the steel in corrosive environments.

02 Surface treatment methods for rust prevention

Various surface treatment methods can be applied to 4140 steel to prevent rust formation. These include chemical passivation, electroplating, and the application of protective coatings. Such treatments create a barrier between the steel surface and corrosive environments, thereby reducing the likelihood of rust formation.Expand Specific Solutions03 Environmental factors affecting rust formation

Environmental factors such as humidity, temperature, and exposure to corrosive substances play a crucial role in the rust formation of 4140 steel. Understanding and controlling these factors can help in developing effective rust prevention strategies and in selecting appropriate protective measures for specific applications.Expand Specific Solutions04 Corrosion inhibitors and additives

The use of corrosion inhibitors and additives can significantly reduce the rust formation in 4140 steel. These substances can be incorporated into coatings, lubricants, or directly applied to the steel surface. They work by forming a protective film or by altering the electrochemical properties of the steel surface to resist corrosion.Expand Specific Solutions05 Monitoring and maintenance techniques

Regular monitoring and maintenance are essential for preventing rust formation in 4140 steel components. This includes periodic inspections, cleaning, and reapplication of protective treatments. Advanced techniques such as electrochemical monitoring and non-destructive testing can be employed to detect early signs of corrosion and take preventive measures.Expand Specific Solutions

Key Players in Steel Corrosion Prevention

The inhibition of rust formation on 4140 steel is a mature field with ongoing research and development. The market for rust prevention solutions is substantial, driven by the widespread use of 4140 steel in various industries. Major players like Tata Steel, Baoshan Iron & Steel, and POSCO Holdings are investing in advanced coating technologies and surface treatments to address this issue. The competitive landscape is characterized by a mix of established steel manufacturers and specialized coating companies, such as Nakata Coating and Dai Nippon Toryo. These firms are focusing on developing environmentally friendly and cost-effective rust inhibition techniques, reflecting the industry's shift towards sustainable solutions and improved performance in challenging environments.

Tata Steel Ltd.

Technical Solution: Tata Steel has developed advanced corrosion inhibition techniques for 4140 steel, focusing on surface modification and protective coatings. Their approach involves a multi-layer coating system that combines zinc-rich primers with high-performance topcoats[1]. This system creates a barrier against moisture and corrosive agents while providing cathodic protection. Additionally, Tata Steel has implemented controlled atmosphere heat treatment processes to reduce surface oxidation during manufacturing[3]. They have also explored the use of nano-structured inhibitors that can be incorporated into the steel matrix during production, providing long-term protection against rust formation[5].

Strengths: Comprehensive approach combining surface treatments and advanced coatings. Integration of corrosion protection into the manufacturing process. Weaknesses: Potential increased production costs due to additional processing steps. May require specialized equipment for application and maintenance.

Baoshan Iron & Steel Co., Ltd.

Technical Solution: Baoshan Iron & Steel has developed a comprehensive rust inhibition strategy for 4140 steel that combines metallurgical modifications with advanced surface treatments. Their approach begins with controlled additions of copper and nickel during the steelmaking process to enhance the inherent corrosion resistance of the alloy[13]. This is followed by a two-step surface treatment: first, a phosphating process that creates a conversion coating, and then the application of a nano-composite coating containing graphene oxide and cerium oxide particles[15]. The company has also implemented a novel plasma electrolytic oxidation (PEO) technique to create a highly adherent, ceramic-like surface layer that provides excellent corrosion resistance[17].

Strengths: Integrated approach from alloy design to surface protection. Utilization of advanced materials like graphene for enhanced performance. Weaknesses: Complex multi-step process may increase production time and costs. Specialized equipment required for some treatments.

Innovative Anti-Corrosion Technologies for 4140 Steel

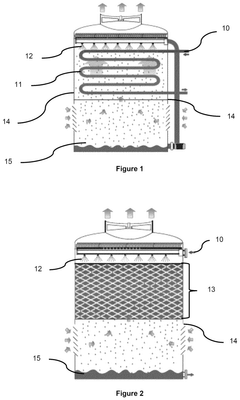

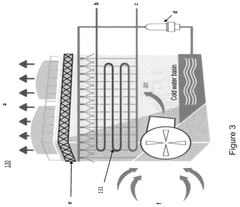

Method for preventing the formation of white rust on a zinc-coated steel surface

PatentActiveUS12203175B2

Innovation

- A water conditioning process is implemented to prevent and inhibit zinc corrosion on galvanized steel surfaces in cooling towers. This process involves bringing the surface into contact with an aqueous composition with a pH between 6.5 and 8.5, containing an organic acid of formula (I), which forms a protective passivation layer.

RUST inhibitor

PatentInactiveBRPI0500540A2

Innovation

- A rust inhibitor is prepared by mixing zinc and aluminum flakes with a modified silicone resin solution, forming a chemical bond between the metals and the surface, creating a flake zinc-aluminum binder layer that acts as a sacrificial anode, eliminating the need for pre-treatment and specialized equipment.

Environmental Impact of Rust Inhibitors

The environmental impact of rust inhibitors used for 4140 steel is a critical consideration in the development and application of these protective measures. Traditional rust inhibitors often contain harmful chemicals that can have detrimental effects on ecosystems and human health. Many conventional inhibitors include heavy metals, volatile organic compounds (VOCs), and other toxic substances that can leach into soil and water systems, causing long-term environmental damage.

Recent research has focused on developing more environmentally friendly rust inhibitors for 4140 steel. Green inhibitors derived from plant extracts, such as tannins and polyphenols, have shown promising results in preventing rust formation while minimizing ecological harm. These natural compounds are biodegradable and non-toxic, reducing the risk of environmental contamination.

Another approach to mitigating the environmental impact of rust inhibitors is the use of nano-based technologies. Nanoparticles and nanocomposites have demonstrated effective rust inhibition properties while requiring smaller quantities of active ingredients. This reduction in material usage can lead to decreased environmental exposure and waste generation.

The lifecycle assessment of rust inhibitors is becoming increasingly important in evaluating their overall environmental impact. Factors such as production processes, application methods, and disposal techniques all contribute to the ecological footprint of these products. Manufacturers are now focusing on developing inhibitors with improved biodegradability and reduced persistence in the environment.

Water-based rust inhibitors are gaining popularity as alternatives to solvent-based formulations. These aqueous solutions typically have lower VOC emissions and reduced toxicity, making them more environmentally friendly. However, their effectiveness on 4140 steel may vary depending on the specific application and environmental conditions.

The regulatory landscape surrounding rust inhibitors is evolving to address environmental concerns. Many countries have implemented stricter guidelines on the use of certain chemicals in rust prevention products, encouraging the development of more sustainable alternatives. This shift has led to increased investment in research and development of eco-friendly rust inhibition techniques for 4140 steel and other alloys.

As industries strive for more sustainable practices, the demand for environmentally responsible rust inhibitors continues to grow. This trend is driving innovation in the field, with a focus on balancing effective corrosion protection for 4140 steel with minimal environmental impact. The future of rust inhibition lies in the development of smart, targeted solutions that can provide long-lasting protection while adhering to stringent environmental standards.

Recent research has focused on developing more environmentally friendly rust inhibitors for 4140 steel. Green inhibitors derived from plant extracts, such as tannins and polyphenols, have shown promising results in preventing rust formation while minimizing ecological harm. These natural compounds are biodegradable and non-toxic, reducing the risk of environmental contamination.

Another approach to mitigating the environmental impact of rust inhibitors is the use of nano-based technologies. Nanoparticles and nanocomposites have demonstrated effective rust inhibition properties while requiring smaller quantities of active ingredients. This reduction in material usage can lead to decreased environmental exposure and waste generation.

The lifecycle assessment of rust inhibitors is becoming increasingly important in evaluating their overall environmental impact. Factors such as production processes, application methods, and disposal techniques all contribute to the ecological footprint of these products. Manufacturers are now focusing on developing inhibitors with improved biodegradability and reduced persistence in the environment.

Water-based rust inhibitors are gaining popularity as alternatives to solvent-based formulations. These aqueous solutions typically have lower VOC emissions and reduced toxicity, making them more environmentally friendly. However, their effectiveness on 4140 steel may vary depending on the specific application and environmental conditions.

The regulatory landscape surrounding rust inhibitors is evolving to address environmental concerns. Many countries have implemented stricter guidelines on the use of certain chemicals in rust prevention products, encouraging the development of more sustainable alternatives. This shift has led to increased investment in research and development of eco-friendly rust inhibition techniques for 4140 steel and other alloys.

As industries strive for more sustainable practices, the demand for environmentally responsible rust inhibitors continues to grow. This trend is driving innovation in the field, with a focus on balancing effective corrosion protection for 4140 steel with minimal environmental impact. The future of rust inhibition lies in the development of smart, targeted solutions that can provide long-lasting protection while adhering to stringent environmental standards.

Cost-Benefit Analysis of Rust Prevention Methods

The cost-benefit analysis of rust prevention methods for 4140 steel is a critical consideration for industries utilizing this high-strength alloy. Various techniques offer different levels of protection at varying costs, necessitating a thorough evaluation to determine the most economically viable solution.

Conventional methods such as painting and galvanization provide a baseline for comparison. Painting, while relatively inexpensive initially, requires frequent reapplication, increasing long-term costs. Galvanization offers more durable protection but comes with higher upfront expenses and potential environmental concerns.

Advanced coatings, including ceramic and polymer-based solutions, present a higher initial investment but promise extended protection periods. These coatings can significantly reduce maintenance frequency, potentially offsetting their higher upfront costs over time. However, their application may require specialized equipment and expertise, factors that must be considered in the overall cost analysis.

Cathodic protection systems, particularly impressed current cathodic protection (ICCP), offer excellent rust prevention for large-scale applications. While the initial setup costs are substantial, including the installation of anodes and a power source, the long-term benefits can be significant, especially for structures with extended lifespans. The ongoing operational costs, primarily electricity consumption, must be factored into the long-term financial assessment.

Emerging technologies, such as self-healing coatings and nanotechnology-based solutions, show promise in providing superior protection with potentially lower lifecycle costs. However, their relatively recent development means higher initial costs and less predictable long-term performance, introducing an element of risk into the cost-benefit calculation.

When evaluating these methods, it's crucial to consider not only the direct costs of materials and application but also indirect expenses such as downtime during treatment, potential environmental impact, and regulatory compliance. The specific application environment of the 4140 steel components also plays a significant role in determining the most cost-effective solution, as factors like exposure to corrosive elements, mechanical stress, and temperature fluctuations can greatly influence the effectiveness and longevity of different rust prevention techniques.

Ultimately, the optimal rust prevention strategy may involve a combination of methods, tailored to specific components and their operating conditions. This approach allows for the maximization of protection while optimizing costs across different areas of application. Regular monitoring and data collection on the performance of chosen methods can provide valuable insights for future cost-benefit analyses, enabling continuous improvement in rust prevention strategies for 4140 steel.

Conventional methods such as painting and galvanization provide a baseline for comparison. Painting, while relatively inexpensive initially, requires frequent reapplication, increasing long-term costs. Galvanization offers more durable protection but comes with higher upfront expenses and potential environmental concerns.

Advanced coatings, including ceramic and polymer-based solutions, present a higher initial investment but promise extended protection periods. These coatings can significantly reduce maintenance frequency, potentially offsetting their higher upfront costs over time. However, their application may require specialized equipment and expertise, factors that must be considered in the overall cost analysis.

Cathodic protection systems, particularly impressed current cathodic protection (ICCP), offer excellent rust prevention for large-scale applications. While the initial setup costs are substantial, including the installation of anodes and a power source, the long-term benefits can be significant, especially for structures with extended lifespans. The ongoing operational costs, primarily electricity consumption, must be factored into the long-term financial assessment.

Emerging technologies, such as self-healing coatings and nanotechnology-based solutions, show promise in providing superior protection with potentially lower lifecycle costs. However, their relatively recent development means higher initial costs and less predictable long-term performance, introducing an element of risk into the cost-benefit calculation.

When evaluating these methods, it's crucial to consider not only the direct costs of materials and application but also indirect expenses such as downtime during treatment, potential environmental impact, and regulatory compliance. The specific application environment of the 4140 steel components also plays a significant role in determining the most cost-effective solution, as factors like exposure to corrosive elements, mechanical stress, and temperature fluctuations can greatly influence the effectiveness and longevity of different rust prevention techniques.

Ultimately, the optimal rust prevention strategy may involve a combination of methods, tailored to specific components and their operating conditions. This approach allows for the maximization of protection while optimizing costs across different areas of application. Regular monitoring and data collection on the performance of chosen methods can provide valuable insights for future cost-benefit analyses, enabling continuous improvement in rust prevention strategies for 4140 steel.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!