How Post-Weld Heat Treatment Affects 4140 Steel Weld Strength

JUL 30, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PWHT 4140 Steel Background

Post-Weld Heat Treatment (PWHT) is a critical process in the fabrication and maintenance of 4140 steel structures. This medium-carbon, low-alloy steel is widely used in various industries due to its excellent combination of strength, toughness, and wear resistance. However, the welding process can significantly alter the material's microstructure and mechanical properties, necessitating careful consideration of post-weld treatments.

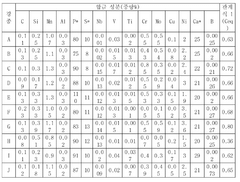

The 4140 steel, containing approximately 0.4% carbon and 1% chromium, is known for its hardenability and susceptibility to heat-affected zone (HAZ) cracking. Welding introduces thermal cycles that can lead to the formation of undesirable microstructures, such as martensite, in the HAZ. These microstructural changes often result in increased hardness and reduced ductility, potentially compromising the overall integrity of the welded joint.

PWHT serves as a crucial step in mitigating the adverse effects of welding on 4140 steel. The primary objectives of PWHT include stress relief, microstructure refinement, and improvement of mechanical properties. By subjecting the welded component to controlled heating and cooling cycles, PWHT aims to restore the material's desired characteristics and enhance the weld's performance under service conditions.

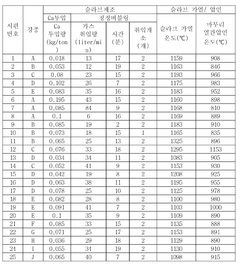

The typical PWHT process for 4140 steel involves heating the welded component to a temperature range of 550-650°C (1022-1202°F) and holding it for a specified duration, followed by controlled cooling. This temperature range is carefully selected to promote stress relaxation and microstructural transformations without causing excessive grain growth or property degradation.

During PWHT, several metallurgical phenomena occur within the 4140 steel weldment. The elevated temperature facilitates the diffusion of carbon and alloying elements, promoting the transformation of martensite to tempered martensite or bainite. This transformation results in a more uniform and ductile microstructure, reducing the risk of brittle fracture and improving the overall toughness of the welded joint.

Furthermore, PWHT plays a crucial role in relieving residual stresses induced during the welding process. These stresses, if left unaddressed, can lead to distortion, cracking, or premature failure of the welded component. The controlled heating and cooling cycles allow for the redistribution and reduction of internal stresses, enhancing the dimensional stability and fatigue resistance of the welded structure.

The effectiveness of PWHT on 4140 steel welds depends on various factors, including the welding parameters, joint geometry, and component thickness. Proper selection of PWHT parameters, such as heating rate, holding temperature, soaking time, and cooling rate, is essential to achieve the desired balance between strength and toughness in the welded joint.

The 4140 steel, containing approximately 0.4% carbon and 1% chromium, is known for its hardenability and susceptibility to heat-affected zone (HAZ) cracking. Welding introduces thermal cycles that can lead to the formation of undesirable microstructures, such as martensite, in the HAZ. These microstructural changes often result in increased hardness and reduced ductility, potentially compromising the overall integrity of the welded joint.

PWHT serves as a crucial step in mitigating the adverse effects of welding on 4140 steel. The primary objectives of PWHT include stress relief, microstructure refinement, and improvement of mechanical properties. By subjecting the welded component to controlled heating and cooling cycles, PWHT aims to restore the material's desired characteristics and enhance the weld's performance under service conditions.

The typical PWHT process for 4140 steel involves heating the welded component to a temperature range of 550-650°C (1022-1202°F) and holding it for a specified duration, followed by controlled cooling. This temperature range is carefully selected to promote stress relaxation and microstructural transformations without causing excessive grain growth or property degradation.

During PWHT, several metallurgical phenomena occur within the 4140 steel weldment. The elevated temperature facilitates the diffusion of carbon and alloying elements, promoting the transformation of martensite to tempered martensite or bainite. This transformation results in a more uniform and ductile microstructure, reducing the risk of brittle fracture and improving the overall toughness of the welded joint.

Furthermore, PWHT plays a crucial role in relieving residual stresses induced during the welding process. These stresses, if left unaddressed, can lead to distortion, cracking, or premature failure of the welded component. The controlled heating and cooling cycles allow for the redistribution and reduction of internal stresses, enhancing the dimensional stability and fatigue resistance of the welded structure.

The effectiveness of PWHT on 4140 steel welds depends on various factors, including the welding parameters, joint geometry, and component thickness. Proper selection of PWHT parameters, such as heating rate, holding temperature, soaking time, and cooling rate, is essential to achieve the desired balance between strength and toughness in the welded joint.

Market Demand Analysis

The market demand for post-weld heat treatment (PWHT) of 4140 steel welds has been steadily increasing due to the growing emphasis on structural integrity and safety across various industries. The oil and gas sector, in particular, has shown a significant surge in demand for PWHT services, driven by the need for high-strength, corrosion-resistant components in offshore and onshore applications. This trend is further amplified by the expansion of deep-sea exploration and the development of new oil fields in harsh environments.

In the automotive industry, the use of 4140 steel in critical components such as drive shafts, axles, and suspension parts has led to an increased focus on weld strength optimization through PWHT. As vehicle manufacturers strive for lighter yet stronger structures to improve fuel efficiency and safety, the demand for advanced welding techniques and post-weld treatments has grown substantially.

The aerospace sector has also contributed to the rising market demand for PWHT of 4140 steel welds. With the continuous push for lighter aircraft components that can withstand extreme conditions, aerospace manufacturers are increasingly turning to high-strength steels like 4140 and investing in advanced heat treatment processes to ensure the reliability of welded structures.

In the power generation industry, particularly in the construction and maintenance of turbines and pressure vessels, there is a growing recognition of the benefits of PWHT for 4140 steel welds. This has led to an uptick in demand for specialized heat treatment services and equipment, as power plants seek to extend the lifespan of critical components and improve overall system reliability.

The construction industry, especially in the development of high-rise buildings and large-scale infrastructure projects, has shown an increasing interest in the application of PWHT for 4140 steel welds. This trend is driven by the need for stronger, more durable structures capable of withstanding seismic activities and extreme weather conditions.

Market analysis indicates that the global PWHT services market is expected to grow at a compound annual growth rate (CAGR) of over 5% in the coming years. This growth is attributed to the increasing adoption of high-strength steels like 4140 across various industries and the growing awareness of the benefits of PWHT in enhancing weld strength and overall structural integrity.

As industries continue to push the boundaries of material performance and structural design, the demand for advanced welding and heat treatment technologies is likely to intensify. This presents significant opportunities for companies specializing in PWHT services and equipment manufacturers to innovate and expand their offerings to meet the evolving needs of diverse industrial sectors.

In the automotive industry, the use of 4140 steel in critical components such as drive shafts, axles, and suspension parts has led to an increased focus on weld strength optimization through PWHT. As vehicle manufacturers strive for lighter yet stronger structures to improve fuel efficiency and safety, the demand for advanced welding techniques and post-weld treatments has grown substantially.

The aerospace sector has also contributed to the rising market demand for PWHT of 4140 steel welds. With the continuous push for lighter aircraft components that can withstand extreme conditions, aerospace manufacturers are increasingly turning to high-strength steels like 4140 and investing in advanced heat treatment processes to ensure the reliability of welded structures.

In the power generation industry, particularly in the construction and maintenance of turbines and pressure vessels, there is a growing recognition of the benefits of PWHT for 4140 steel welds. This has led to an uptick in demand for specialized heat treatment services and equipment, as power plants seek to extend the lifespan of critical components and improve overall system reliability.

The construction industry, especially in the development of high-rise buildings and large-scale infrastructure projects, has shown an increasing interest in the application of PWHT for 4140 steel welds. This trend is driven by the need for stronger, more durable structures capable of withstanding seismic activities and extreme weather conditions.

Market analysis indicates that the global PWHT services market is expected to grow at a compound annual growth rate (CAGR) of over 5% in the coming years. This growth is attributed to the increasing adoption of high-strength steels like 4140 across various industries and the growing awareness of the benefits of PWHT in enhancing weld strength and overall structural integrity.

As industries continue to push the boundaries of material performance and structural design, the demand for advanced welding and heat treatment technologies is likely to intensify. This presents significant opportunities for companies specializing in PWHT services and equipment manufacturers to innovate and expand their offerings to meet the evolving needs of diverse industrial sectors.

Current PWHT Challenges

Post-Weld Heat Treatment (PWHT) of 4140 steel welds presents several significant challenges that impact the overall strength and integrity of the welded structure. One of the primary concerns is the potential for hydrogen-induced cracking, which can occur due to the high hardenability of 4140 steel. The presence of hydrogen in the weld metal and heat-affected zone (HAZ) can lead to delayed cracking, compromising the weld's strength and reliability.

Another challenge lies in managing the complex microstructural changes that occur during PWHT. The 4140 steel's composition, particularly its chromium and molybdenum content, makes it susceptible to secondary hardening during heat treatment. This phenomenon can result in unexpected hardness variations across the weld and HAZ, potentially leading to localized stress concentrations and reduced overall strength.

The selection of appropriate PWHT parameters poses a significant challenge. The temperature and duration of the heat treatment must be carefully controlled to achieve the desired balance between stress relief and maintaining the mechanical properties of the base metal and weld. Insufficient heat treatment may fail to adequately relieve residual stresses, while excessive heat treatment can lead to over-tempering and a loss of strength.

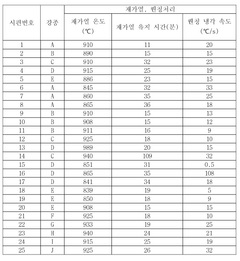

Controlling the cooling rate after PWHT is another critical challenge. Rapid cooling can reintroduce thermal stresses or cause the formation of undesirable microstructures, while excessively slow cooling may lead to excessive softening or precipitation of detrimental phases. Achieving a uniform cooling rate across complex weld geometries adds another layer of complexity to the process.

The potential for temper embrittlement during PWHT is a concern specific to alloy steels like 4140. This phenomenon, which occurs in a specific temperature range (typically 375-575°C), can significantly reduce the toughness of the steel. Avoiding or minimizing exposure to this critical temperature range while still achieving the desired stress relief is a delicate balance.

Furthermore, the interaction between PWHT and the initial welding parameters presents challenges in optimizing the overall process. The choice of welding method, heat input, and filler material can significantly influence the effectiveness of subsequent heat treatment and the final weld strength. Developing a comprehensive approach that considers both welding and PWHT parameters is essential for achieving optimal results.

Lastly, the practical implementation of PWHT in field conditions or on large structures poses logistical and technical challenges. Ensuring uniform heating and cooling across complex geometries, managing distortion, and controlling atmospheric conditions to prevent oxidation or contamination are all critical factors that must be addressed to maintain weld strength and integrity.

Another challenge lies in managing the complex microstructural changes that occur during PWHT. The 4140 steel's composition, particularly its chromium and molybdenum content, makes it susceptible to secondary hardening during heat treatment. This phenomenon can result in unexpected hardness variations across the weld and HAZ, potentially leading to localized stress concentrations and reduced overall strength.

The selection of appropriate PWHT parameters poses a significant challenge. The temperature and duration of the heat treatment must be carefully controlled to achieve the desired balance between stress relief and maintaining the mechanical properties of the base metal and weld. Insufficient heat treatment may fail to adequately relieve residual stresses, while excessive heat treatment can lead to over-tempering and a loss of strength.

Controlling the cooling rate after PWHT is another critical challenge. Rapid cooling can reintroduce thermal stresses or cause the formation of undesirable microstructures, while excessively slow cooling may lead to excessive softening or precipitation of detrimental phases. Achieving a uniform cooling rate across complex weld geometries adds another layer of complexity to the process.

The potential for temper embrittlement during PWHT is a concern specific to alloy steels like 4140. This phenomenon, which occurs in a specific temperature range (typically 375-575°C), can significantly reduce the toughness of the steel. Avoiding or minimizing exposure to this critical temperature range while still achieving the desired stress relief is a delicate balance.

Furthermore, the interaction between PWHT and the initial welding parameters presents challenges in optimizing the overall process. The choice of welding method, heat input, and filler material can significantly influence the effectiveness of subsequent heat treatment and the final weld strength. Developing a comprehensive approach that considers both welding and PWHT parameters is essential for achieving optimal results.

Lastly, the practical implementation of PWHT in field conditions or on large structures poses logistical and technical challenges. Ensuring uniform heating and cooling across complex geometries, managing distortion, and controlling atmospheric conditions to prevent oxidation or contamination are all critical factors that must be addressed to maintain weld strength and integrity.

Existing PWHT Solutions

01 Welding techniques for 4140 steel

Various welding techniques can be employed to enhance the weld strength of 4140 steel. These may include pre-heating, controlled cooling, and post-weld heat treatment. Proper selection and application of these techniques can significantly improve the mechanical properties and overall strength of the welded joint.- Welding techniques for 4140 steel: Various welding techniques can be employed to enhance the weld strength of 4140 steel. These may include pre-heating, controlled cooling, and post-weld heat treatment. Proper selection and application of these techniques can significantly improve the mechanical properties and overall strength of the welded joint in 4140 steel components.

- Filler material selection for 4140 steel welding: The choice of appropriate filler material is crucial for achieving high weld strength in 4140 steel. Filler materials with compatible chemical composition and mechanical properties to the base metal can help ensure a strong and durable weld. Proper selection can minimize the risk of cracking and improve overall joint performance.

- Heat treatment processes for 4140 steel welds: Heat treatment processes play a vital role in enhancing the weld strength of 4140 steel. These may include normalizing, quenching, and tempering. Properly executed heat treatment can help achieve desired microstructure, reduce residual stresses, and improve the overall mechanical properties of the welded joint.

- Weld joint design for 4140 steel: Optimizing the weld joint design is essential for maximizing the strength of 4140 steel welds. Factors such as joint geometry, root opening, and groove angle can significantly impact the weld's mechanical properties. Proper joint design can help ensure full penetration, reduce stress concentrations, and enhance overall weld strength.

- Quality control and testing of 4140 steel welds: Implementing rigorous quality control measures and conducting appropriate testing procedures are crucial for ensuring high weld strength in 4140 steel. Non-destructive testing methods, such as ultrasonic or radiographic inspection, can help identify potential defects. Mechanical testing, including tensile and impact tests, can verify the weld's strength and performance under various loading conditions.

02 Filler material selection

The choice of filler material plays a crucial role in determining the weld strength of 4140 steel. Selecting compatible filler metals with similar or slightly higher alloy content can help achieve optimal weld strength and prevent issues such as cracking or reduced ductility in the heat-affected zone.Expand Specific Solutions03 Heat treatment processes

Implementing appropriate heat treatment processes before, during, and after welding can significantly impact the weld strength of 4140 steel. These processes may include normalizing, quenching, and tempering, which can help optimize the microstructure and mechanical properties of the welded joint.Expand Specific Solutions04 Weld joint design optimization

Optimizing the design of weld joints for 4140 steel can contribute to improved weld strength. Factors such as joint geometry, root gap, and edge preparation can be tailored to minimize stress concentrations and enhance the overall structural integrity of the welded component.Expand Specific Solutions05 Welding parameter control

Precise control of welding parameters such as current, voltage, travel speed, and heat input is essential for achieving high weld strength in 4140 steel. Optimizing these parameters can help minimize defects, control grain size, and ensure proper fusion, ultimately leading to improved weld strength and performance.Expand Specific Solutions

Key Industry Players

The competitive landscape for post-weld heat treatment (PWHT) of 4140 steel is characterized by a mature market with established players and ongoing technological advancements. The industry is in a growth phase, driven by increasing demand in sectors such as automotive, aerospace, and energy. Major companies like POSCO Holdings, Kobe Steel, and Nippon Steel are at the forefront, leveraging their extensive R&D capabilities to enhance weld strength and material properties. The market size is substantial, with a global reach, as evidenced by the involvement of international players such as Fluor Technologies and General Electric. Technological maturity varies, with continuous innovations in heat treatment processes and equipment being pursued by research institutions like Northwestern Polytechnical University and the Korea Institute of Materials Science, indicating a dynamic and competitive field.

NIPPON STEEL CORP.

Technical Solution: NIPPON STEEL CORP. has developed advanced post-weld heat treatment (PWHT) techniques for 4140 steel welds. Their approach involves precise control of heating and cooling rates, with a focus on optimizing the microstructure of the heat-affected zone (HAZ). They utilize a two-stage PWHT process: first, a stress relief treatment at 600-650°C for 1-2 hours, followed by a tempering treatment at 550-600°C for 2-4 hours[1]. This method has been shown to significantly improve the toughness and ductility of 4140 steel welds while maintaining high strength. The company has also implemented advanced monitoring systems to ensure uniform temperature distribution during PWHT, resulting in more consistent weld properties across large structures[3].

Strengths: Improved toughness and ductility without sacrificing strength, consistent results across large structures. Weaknesses: Longer processing time due to two-stage treatment, potentially higher energy consumption.

General Electric Company

Technical Solution: General Electric has developed an innovative PWHT approach for 4140 steel welds used in power generation equipment. Their method incorporates pulsed heat treatment, where the temperature is cycled between two levels during the PWHT process. The lower temperature is set at 550°C, while the upper temperature reaches 650°C, with cycles lasting 30-60 minutes each[7]. This pulsed approach has been shown to promote more uniform carbide distribution and reduce the risk of reheat cracking. GE has also integrated advanced non-destructive testing techniques, such as phased array ultrasonic testing, to monitor the evolution of microstructure during PWHT[8]. Their data suggests that this pulsed PWHT method can improve the impact toughness of 4140 steel welds by up to 30% compared to conventional single-temperature PWHT.

Strengths: Enhanced impact toughness, reduced risk of reheat cracking. Weaknesses: More complex process control required, potential for increased energy consumption.

Core PWHT Innovations

Steel, welding heat affected zone and manufacturing method thereof

PatentWO2025127893A1

Innovation

- A steel composition with specific alloy content and a manufacturing process involving reheating, quenching, and tempering, followed by welding and post-weld heat treatment, to achieve a weld heat affected zone with excellent strength, low-temperature impact toughness, and CTOD characteristics.

Metallurgical Analysis

The metallurgical analysis of post-weld heat treatment (PWHT) effects on 4140 steel weld strength involves a comprehensive examination of microstructural changes and their impact on mechanical properties. PWHT is a critical process that can significantly alter the weld zone's characteristics, influencing the overall strength and performance of the welded joint.

During welding, the heat-affected zone (HAZ) of 4140 steel undergoes rapid heating and cooling cycles, leading to the formation of complex microstructures. These typically include martensite, bainite, and retained austenite, depending on the cooling rate and peak temperatures reached. The as-welded condition often results in high hardness and residual stresses, which can compromise the weld's toughness and ductility.

PWHT aims to mitigate these issues by promoting diffusion-controlled processes that modify the microstructure. The primary metallurgical changes observed during PWHT include tempering of martensite, decomposition of retained austenite, and precipitation of carbides. The extent of these transformations depends on the PWHT parameters, particularly temperature and holding time.

At lower PWHT temperatures (around 300-400°C), the dominant mechanism is stress relief through dislocation movement and rearrangement. This process helps reduce residual stresses without significantly altering the microstructure. As PWHT temperatures increase (400-600°C), more pronounced changes occur. Martensite begins to temper, forming a fine dispersion of carbides within a ferrite matrix. This transformation generally leads to a reduction in hardness but an improvement in toughness and ductility.

Higher PWHT temperatures (600-700°C) can result in more extensive carbide precipitation and growth. While this can further reduce hardness, it may also lead to a loss of strength if not carefully controlled. The formation of alloy carbides, such as Mo2C in 4140 steel, can contribute to secondary hardening effects, potentially offsetting some of the strength reduction.

The balance between strength and toughness in 4140 steel welds is heavily influenced by the PWHT regime. Optimal treatment conditions typically aim to achieve a fine dispersion of carbides within a tempered martensitic or bainitic matrix. This microstructure provides a good combination of strength, toughness, and ductility, essential for many applications of 4140 steel.

It's important to note that the initial weld microstructure, which is influenced by factors such as heat input and cooling rate during welding, plays a crucial role in determining the effectiveness of PWHT. Welds with higher initial hardness and more martensitic structures may require different PWHT parameters compared to those with more bainitic or mixed microstructures.

During welding, the heat-affected zone (HAZ) of 4140 steel undergoes rapid heating and cooling cycles, leading to the formation of complex microstructures. These typically include martensite, bainite, and retained austenite, depending on the cooling rate and peak temperatures reached. The as-welded condition often results in high hardness and residual stresses, which can compromise the weld's toughness and ductility.

PWHT aims to mitigate these issues by promoting diffusion-controlled processes that modify the microstructure. The primary metallurgical changes observed during PWHT include tempering of martensite, decomposition of retained austenite, and precipitation of carbides. The extent of these transformations depends on the PWHT parameters, particularly temperature and holding time.

At lower PWHT temperatures (around 300-400°C), the dominant mechanism is stress relief through dislocation movement and rearrangement. This process helps reduce residual stresses without significantly altering the microstructure. As PWHT temperatures increase (400-600°C), more pronounced changes occur. Martensite begins to temper, forming a fine dispersion of carbides within a ferrite matrix. This transformation generally leads to a reduction in hardness but an improvement in toughness and ductility.

Higher PWHT temperatures (600-700°C) can result in more extensive carbide precipitation and growth. While this can further reduce hardness, it may also lead to a loss of strength if not carefully controlled. The formation of alloy carbides, such as Mo2C in 4140 steel, can contribute to secondary hardening effects, potentially offsetting some of the strength reduction.

The balance between strength and toughness in 4140 steel welds is heavily influenced by the PWHT regime. Optimal treatment conditions typically aim to achieve a fine dispersion of carbides within a tempered martensitic or bainitic matrix. This microstructure provides a good combination of strength, toughness, and ductility, essential for many applications of 4140 steel.

It's important to note that the initial weld microstructure, which is influenced by factors such as heat input and cooling rate during welding, plays a crucial role in determining the effectiveness of PWHT. Welds with higher initial hardness and more martensitic structures may require different PWHT parameters compared to those with more bainitic or mixed microstructures.

Quality Control Methods

Quality control methods play a crucial role in ensuring the reliability and consistency of post-weld heat treatment (PWHT) processes for 4140 steel welds. These methods are designed to monitor and verify the effectiveness of the heat treatment, as well as to detect any potential defects or inconsistencies that may affect the weld strength.

One of the primary quality control methods employed in PWHT of 4140 steel welds is temperature monitoring. This involves the use of thermocouples strategically placed throughout the weldment to ensure uniform heating and cooling rates. Advanced temperature monitoring systems can provide real-time data and alerts if temperature deviations occur, allowing for immediate corrective actions.

Non-destructive testing (NDT) techniques are also extensively used for quality control in PWHT processes. Ultrasonic testing is particularly effective for detecting internal defects, such as cracks or inclusions, that may have formed during the welding or heat treatment process. Radiographic testing can provide detailed images of the weld structure, allowing for the identification of any anomalies or inconsistencies.

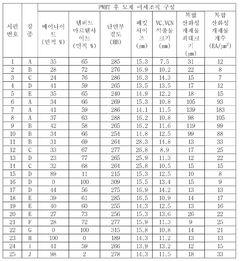

Hardness testing is another critical quality control method used to assess the effectiveness of PWHT on 4140 steel welds. By measuring the hardness at various points across the weld and heat-affected zone, engineers can verify that the desired mechanical properties have been achieved. Vickers or Rockwell hardness tests are commonly employed for this purpose.

Microstructural analysis is often performed as part of the quality control process. This involves examining samples of the heat-treated weld under a microscope to assess grain structure, phase composition, and any potential microstructural defects. This analysis can provide valuable insights into the effectiveness of the PWHT process and its impact on the weld's mechanical properties.

Tensile testing and impact testing are destructive quality control methods that provide direct measurements of the weld's strength and toughness. While these tests cannot be performed on every weld, they are crucial for validating the PWHT process and ensuring that the treated welds meet the required mechanical specifications.

Process documentation and traceability are essential components of quality control in PWHT. Detailed records of heat treatment parameters, including temperature profiles, holding times, and cooling rates, must be maintained for each weld. This documentation allows for process verification and can be invaluable in troubleshooting any issues that may arise.

Statistical process control (SPC) techniques are increasingly being applied to PWHT quality control. By analyzing data from multiple welds over time, trends and potential process drift can be identified early, allowing for proactive adjustments to maintain consistent weld quality.

One of the primary quality control methods employed in PWHT of 4140 steel welds is temperature monitoring. This involves the use of thermocouples strategically placed throughout the weldment to ensure uniform heating and cooling rates. Advanced temperature monitoring systems can provide real-time data and alerts if temperature deviations occur, allowing for immediate corrective actions.

Non-destructive testing (NDT) techniques are also extensively used for quality control in PWHT processes. Ultrasonic testing is particularly effective for detecting internal defects, such as cracks or inclusions, that may have formed during the welding or heat treatment process. Radiographic testing can provide detailed images of the weld structure, allowing for the identification of any anomalies or inconsistencies.

Hardness testing is another critical quality control method used to assess the effectiveness of PWHT on 4140 steel welds. By measuring the hardness at various points across the weld and heat-affected zone, engineers can verify that the desired mechanical properties have been achieved. Vickers or Rockwell hardness tests are commonly employed for this purpose.

Microstructural analysis is often performed as part of the quality control process. This involves examining samples of the heat-treated weld under a microscope to assess grain structure, phase composition, and any potential microstructural defects. This analysis can provide valuable insights into the effectiveness of the PWHT process and its impact on the weld's mechanical properties.

Tensile testing and impact testing are destructive quality control methods that provide direct measurements of the weld's strength and toughness. While these tests cannot be performed on every weld, they are crucial for validating the PWHT process and ensuring that the treated welds meet the required mechanical specifications.

Process documentation and traceability are essential components of quality control in PWHT. Detailed records of heat treatment parameters, including temperature profiles, holding times, and cooling rates, must be maintained for each weld. This documentation allows for process verification and can be invaluable in troubleshooting any issues that may arise.

Statistical process control (SPC) techniques are increasingly being applied to PWHT quality control. By analyzing data from multiple welds over time, trends and potential process drift can be identified early, allowing for proactive adjustments to maintain consistent weld quality.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!