Weldability Analysis of 4140 Steel in High-Pressure Environments

JUL 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

4140 Steel Weldability Background and Objectives

The weldability of 4140 steel in high-pressure environments has become a critical focus in various industrial applications, particularly in the oil and gas sector. This high-strength low-alloy steel, known for its excellent combination of strength and toughness, presents unique challenges when subjected to welding processes under elevated pressure conditions.

The historical development of 4140 steel can be traced back to the early 20th century when the demand for stronger and more durable materials in the automotive and aerospace industries led to the creation of various alloy steels. 4140 steel, with its balanced composition of carbon, chromium, and molybdenum, quickly gained popularity due to its versatility and superior mechanical properties.

As industrial applications expanded into more extreme environments, such as deep-sea oil drilling and high-pressure pipelines, the need to understand and improve the weldability of 4140 steel under these conditions became paramount. The evolution of welding techniques and the growing understanding of metallurgical processes have contributed significantly to addressing the challenges associated with welding this material in high-pressure settings.

The primary objective of this technical research is to comprehensively analyze the weldability of 4140 steel in high-pressure environments. This involves investigating the effects of elevated pressure on the steel's microstructure, mechanical properties, and overall weld integrity. Additionally, the research aims to identify optimal welding parameters and techniques that can mitigate potential issues such as hydrogen embrittlement, stress corrosion cracking, and heat-affected zone (HAZ) softening.

Furthermore, this study seeks to explore innovative approaches to enhance the weldability of 4140 steel under high-pressure conditions. This may include the development of new filler materials, the application of advanced pre- and post-weld heat treatments, or the implementation of novel welding processes specifically designed for high-pressure applications.

By addressing these objectives, the research intends to contribute to the advancement of welding technology in challenging environments, ultimately improving the safety, reliability, and efficiency of structures and components made from 4140 steel in high-pressure applications. The findings from this study are expected to have far-reaching implications across multiple industries, potentially leading to the development of new standards and best practices for welding 4140 steel in extreme conditions.

The historical development of 4140 steel can be traced back to the early 20th century when the demand for stronger and more durable materials in the automotive and aerospace industries led to the creation of various alloy steels. 4140 steel, with its balanced composition of carbon, chromium, and molybdenum, quickly gained popularity due to its versatility and superior mechanical properties.

As industrial applications expanded into more extreme environments, such as deep-sea oil drilling and high-pressure pipelines, the need to understand and improve the weldability of 4140 steel under these conditions became paramount. The evolution of welding techniques and the growing understanding of metallurgical processes have contributed significantly to addressing the challenges associated with welding this material in high-pressure settings.

The primary objective of this technical research is to comprehensively analyze the weldability of 4140 steel in high-pressure environments. This involves investigating the effects of elevated pressure on the steel's microstructure, mechanical properties, and overall weld integrity. Additionally, the research aims to identify optimal welding parameters and techniques that can mitigate potential issues such as hydrogen embrittlement, stress corrosion cracking, and heat-affected zone (HAZ) softening.

Furthermore, this study seeks to explore innovative approaches to enhance the weldability of 4140 steel under high-pressure conditions. This may include the development of new filler materials, the application of advanced pre- and post-weld heat treatments, or the implementation of novel welding processes specifically designed for high-pressure applications.

By addressing these objectives, the research intends to contribute to the advancement of welding technology in challenging environments, ultimately improving the safety, reliability, and efficiency of structures and components made from 4140 steel in high-pressure applications. The findings from this study are expected to have far-reaching implications across multiple industries, potentially leading to the development of new standards and best practices for welding 4140 steel in extreme conditions.

High-Pressure Welding Market Analysis

The high-pressure welding market has experienced significant growth in recent years, driven by increasing demand from industries such as oil and gas, aerospace, and automotive. This market segment specifically focuses on welding applications in environments where elevated pressures are a critical factor, such as deep-sea pipelines, high-pressure vessels, and advanced aerospace components.

The global high-pressure welding market is primarily segmented into three main categories: equipment, consumables, and services. Equipment includes specialized welding machines designed to operate in high-pressure environments, while consumables encompass electrodes, filler materials, and shielding gases tailored for these applications. Services in this market involve specialized welding procedures, inspection, and maintenance activities.

Key factors driving market growth include the expansion of offshore oil and gas exploration, increasing investments in deep-sea mining, and the growing demand for high-pressure vessels in various industrial processes. The aerospace industry, in particular, has been a significant contributor to market expansion, with the development of advanced aircraft and spacecraft requiring specialized high-pressure welding techniques.

Geographically, North America and Europe currently dominate the high-pressure welding market, owing to their established oil and gas industries and advanced manufacturing sectors. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, primarily due to rapid industrialization, increasing energy demands, and substantial investments in infrastructure development.

The market for high-pressure welding of 4140 steel, specifically, has shown steady growth due to the material's widespread use in high-stress applications. Industries such as oil and gas, power generation, and heavy machinery manufacturing are the primary consumers of 4140 steel welding services and equipment. The demand for improved weldability of 4140 steel in high-pressure environments has led to ongoing research and development efforts focused on optimizing welding processes and developing specialized filler materials.

Challenges in the high-pressure welding market include stringent safety regulations, the need for highly skilled welders, and the high costs associated with specialized equipment and materials. These factors have contributed to a trend towards automation and the development of advanced welding technologies, such as electron beam welding and laser welding, which offer improved precision and consistency in high-pressure applications.

The global high-pressure welding market is primarily segmented into three main categories: equipment, consumables, and services. Equipment includes specialized welding machines designed to operate in high-pressure environments, while consumables encompass electrodes, filler materials, and shielding gases tailored for these applications. Services in this market involve specialized welding procedures, inspection, and maintenance activities.

Key factors driving market growth include the expansion of offshore oil and gas exploration, increasing investments in deep-sea mining, and the growing demand for high-pressure vessels in various industrial processes. The aerospace industry, in particular, has been a significant contributor to market expansion, with the development of advanced aircraft and spacecraft requiring specialized high-pressure welding techniques.

Geographically, North America and Europe currently dominate the high-pressure welding market, owing to their established oil and gas industries and advanced manufacturing sectors. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, primarily due to rapid industrialization, increasing energy demands, and substantial investments in infrastructure development.

The market for high-pressure welding of 4140 steel, specifically, has shown steady growth due to the material's widespread use in high-stress applications. Industries such as oil and gas, power generation, and heavy machinery manufacturing are the primary consumers of 4140 steel welding services and equipment. The demand for improved weldability of 4140 steel in high-pressure environments has led to ongoing research and development efforts focused on optimizing welding processes and developing specialized filler materials.

Challenges in the high-pressure welding market include stringent safety regulations, the need for highly skilled welders, and the high costs associated with specialized equipment and materials. These factors have contributed to a trend towards automation and the development of advanced welding technologies, such as electron beam welding and laser welding, which offer improved precision and consistency in high-pressure applications.

4140 Steel Welding Challenges in High-Pressure Conditions

The welding of 4140 steel in high-pressure environments presents significant challenges due to the material's unique properties and the demanding conditions. 4140 steel, a medium carbon chromium molybdenum alloy steel, is known for its high strength, toughness, and wear resistance. However, these same properties that make it desirable for various applications also contribute to its welding difficulties.

In high-pressure environments, the challenges of welding 4140 steel are further amplified. The primary concern is the increased risk of hydrogen embrittlement, which can lead to cracking and premature failure of the welded joint. High-pressure conditions can facilitate the diffusion of hydrogen into the steel, particularly in the heat-affected zone (HAZ) of the weld. This hydrogen uptake can result in delayed cracking, a phenomenon where cracks appear hours or even days after the welding process is completed.

Another significant challenge is the potential for stress concentration at the weld joint. High-pressure environments exert additional stresses on the welded structure, which can lead to fatigue failure if not properly addressed. The combination of residual stresses from the welding process and the external pressures can create a complex stress state that may exceed the material's capabilities.

The rapid cooling rates associated with welding in high-pressure environments can also lead to the formation of hard, brittle microstructures in the HAZ. This can result in a loss of ductility and toughness, making the welded joint more susceptible to brittle fracture. The presence of alloying elements in 4140 steel, particularly chromium and molybdenum, can exacerbate this issue by promoting the formation of carbides and increasing hardenability.

Furthermore, the high-pressure environment can affect the stability of the welding arc and the transfer of molten metal, potentially leading to weld defects such as lack of fusion, porosity, or inclusions. These defects can significantly compromise the integrity of the welded joint, especially under the demanding conditions of high-pressure service.

To address these challenges, careful control of welding parameters is essential. Preheating and post-weld heat treatment are often necessary to manage the cooling rate and reduce the risk of hydrogen embrittlement. The selection of appropriate filler materials, welding processes, and shielding gases must be tailored to the specific high-pressure application. Advanced welding techniques, such as narrow gap welding or temper bead welding, may be employed to minimize the heat input and control the microstructure of the weld and HAZ.

In conclusion, welding 4140 steel in high-pressure environments requires a comprehensive understanding of the material's behavior, the welding process, and the service conditions. Overcoming these challenges demands a multifaceted approach that combines material science, welding engineering, and rigorous quality control measures to ensure the reliability and longevity of the welded components in these demanding applications.

In high-pressure environments, the challenges of welding 4140 steel are further amplified. The primary concern is the increased risk of hydrogen embrittlement, which can lead to cracking and premature failure of the welded joint. High-pressure conditions can facilitate the diffusion of hydrogen into the steel, particularly in the heat-affected zone (HAZ) of the weld. This hydrogen uptake can result in delayed cracking, a phenomenon where cracks appear hours or even days after the welding process is completed.

Another significant challenge is the potential for stress concentration at the weld joint. High-pressure environments exert additional stresses on the welded structure, which can lead to fatigue failure if not properly addressed. The combination of residual stresses from the welding process and the external pressures can create a complex stress state that may exceed the material's capabilities.

The rapid cooling rates associated with welding in high-pressure environments can also lead to the formation of hard, brittle microstructures in the HAZ. This can result in a loss of ductility and toughness, making the welded joint more susceptible to brittle fracture. The presence of alloying elements in 4140 steel, particularly chromium and molybdenum, can exacerbate this issue by promoting the formation of carbides and increasing hardenability.

Furthermore, the high-pressure environment can affect the stability of the welding arc and the transfer of molten metal, potentially leading to weld defects such as lack of fusion, porosity, or inclusions. These defects can significantly compromise the integrity of the welded joint, especially under the demanding conditions of high-pressure service.

To address these challenges, careful control of welding parameters is essential. Preheating and post-weld heat treatment are often necessary to manage the cooling rate and reduce the risk of hydrogen embrittlement. The selection of appropriate filler materials, welding processes, and shielding gases must be tailored to the specific high-pressure application. Advanced welding techniques, such as narrow gap welding or temper bead welding, may be employed to minimize the heat input and control the microstructure of the weld and HAZ.

In conclusion, welding 4140 steel in high-pressure environments requires a comprehensive understanding of the material's behavior, the welding process, and the service conditions. Overcoming these challenges demands a multifaceted approach that combines material science, welding engineering, and rigorous quality control measures to ensure the reliability and longevity of the welded components in these demanding applications.

Current High-Pressure 4140 Steel Welding Solutions

01 Chemical composition optimization

Optimizing the chemical composition of 4140 steel can improve its weldability. This includes controlling the carbon content and alloying elements to achieve a balance between strength and weldability. Proper composition can reduce the risk of cracking and improve the overall weld quality.- Composition optimization for improved weldability: Adjusting the chemical composition of 4140 steel can enhance its weldability. This includes controlling elements such as carbon, manganese, chromium, and molybdenum to achieve a balance between strength and weldability. Reducing carbon content or adding alloying elements can help minimize the formation of hard and brittle structures in the heat-affected zone during welding.

- Heat treatment processes for weldability enhancement: Implementing specific heat treatment processes before and after welding can significantly improve the weldability of 4140 steel. Pre-heating and post-weld heat treatment (PWHT) can help reduce residual stresses, minimize the risk of cracking, and improve the overall mechanical properties of the welded joint.

- Welding techniques and parameters optimization: Selecting appropriate welding techniques and optimizing welding parameters are crucial for successful welding of 4140 steel. This includes choosing suitable welding processes (e.g., GTAW, SMAW), controlling heat input, and adjusting welding speed and current to minimize the risk of cracking and ensure proper fusion.

- Filler material selection and development: Choosing appropriate filler materials or developing specialized filler metals can improve the weldability of 4140 steel. Filler materials with compatible chemical compositions and mechanical properties can help achieve better fusion, reduce the risk of cracking, and enhance the overall performance of the welded joint.

- Surface preparation and cleanliness: Proper surface preparation and maintaining cleanliness of the welding area are essential for improving the weldability of 4140 steel. This includes removing contaminants, oxides, and moisture from the surface, as well as implementing appropriate cleaning techniques to ensure a high-quality weld joint.

02 Heat treatment processes

Implementing appropriate heat treatment processes before and after welding can enhance the weldability of 4140 steel. This may include pre-heating, controlled cooling, and post-weld heat treatment to manage residual stresses and microstructure changes in the heat-affected zone.Expand Specific Solutions03 Welding technique selection

Choosing suitable welding techniques and parameters can significantly impact the weldability of 4140 steel. This includes selecting appropriate welding processes, filler materials, and welding parameters such as current, voltage, and travel speed to ensure optimal weld quality and minimize defects.Expand Specific Solutions04 Surface preparation and cleanliness

Proper surface preparation and maintaining cleanliness of the welding area are crucial for improving the weldability of 4140 steel. This involves removing contaminants, oxides, and other impurities that could negatively affect weld quality and lead to defects or reduced strength.Expand Specific Solutions05 Monitoring and control of welding parameters

Implementing advanced monitoring and control systems for welding parameters can enhance the weldability of 4140 steel. This includes real-time adjustment of welding conditions, temperature monitoring, and precise control of heat input to ensure consistent weld quality and minimize the risk of defects.Expand Specific Solutions

Key Players in High-Pressure Steel Welding Industry

The weldability analysis of 4140 steel in high-pressure environments represents a niche but critical area in the steel industry. The market is in a mature stage, with established players like NIPPON STEEL CORP., JFE Steel Corp., and POSCO Holdings leading research and development efforts. The global market size for specialized steel applications, including high-pressure environments, is estimated to be in the billions of dollars. Technologically, companies such as Baoshan Iron & Steel Co., Ltd. and The Japan Steel Works Ltd. have made significant advancements in developing and refining 4140 steel compositions suitable for high-pressure welding applications. However, ongoing research by institutions like Northeastern University and Northwestern University continues to push the boundaries of material science in this field.

NIPPON STEEL CORP.

Technical Solution: NIPPON STEEL CORP. has developed advanced welding techniques for 4140 steel in high-pressure environments. Their approach involves a combination of pre-heating, controlled cooling, and specialized filler materials. They utilize a proprietary heat treatment process that reduces the formation of brittle martensite in the heat-affected zone (HAZ). This process involves precise temperature control during welding, maintaining the workpiece at 250-300°C to minimize thermal shock[1]. Additionally, they have developed a low-hydrogen electrode specifically designed for 4140 steel, which helps prevent hydrogen embrittlement in high-pressure applications[3]. The company also employs advanced non-destructive testing methods, including phased array ultrasonic testing, to ensure weld integrity in high-pressure vessels and pipelines[5].

Strengths: Proprietary heat treatment process reduces brittle martensite formation; Specialized low-hydrogen electrodes for high-pressure applications; Advanced non-destructive testing methods. Weaknesses: Process may be more time-consuming and costly than standard welding techniques; Requires specialized equipment and highly trained personnel.

JFE Steel Corp.

Technical Solution: JFE Steel Corp. has developed a comprehensive approach to welding 4140 steel in high-pressure environments. Their method incorporates advanced alloy design and precise welding parameter control. They have engineered a modified 4140 steel composition with improved weldability, featuring slightly reduced carbon content and carefully balanced alloying elements[2]. This modification helps to control the hardenability of the steel, making it less susceptible to cracking during welding in high-pressure conditions. JFE Steel also employs a sophisticated pulsed gas metal arc welding (GMAW-P) technique, which allows for better control of heat input and reduces the risk of hydrogen-induced cracking[4]. Their process includes strict control of interpass temperature and cooling rates, monitored by infrared thermography to ensure optimal microstructure development in the weld and HAZ[6].

Strengths: Modified 4140 steel composition with improved weldability; Advanced pulsed GMAW technique for better heat control; Sophisticated temperature monitoring system. Weaknesses: Modified steel composition may have slightly different mechanical properties compared to standard 4140; Process requires high-end welding equipment and expertise.

Innovative Approaches for 4140 Steel High-Pressure Welding

High-tensile steel with excellent weldability and toughness and with tensile strength of 550 MPa class or more and method of production of the same

PatentInactiveUS8882936B2

Innovation

- A high-tensile steel composition with specific mass percentages of C, Si, Mn, Al, W, V, Nb, and controlled precipitation of W, along with accelerated cooling and heat treatment to maintain a bainite structure and minimize W precipitation, ensuring equal strength and toughness in both the matrix and weld zone.

Material Properties and Metallurgical Considerations

The weldability analysis of 4140 steel in high-pressure environments requires a thorough understanding of the material's properties and metallurgical considerations. 4140 steel is a medium carbon, low alloy steel known for its high strength and toughness. Its chemical composition typically includes 0.38-0.43% carbon, 0.75-1.00% manganese, 0.15-0.30% silicon, 0.80-1.10% chromium, and 0.15-0.25% molybdenum.

The microstructure of 4140 steel plays a crucial role in its weldability. In its normalized condition, the steel exhibits a fine-grained structure consisting of ferrite and pearlite. This microstructure provides a good balance of strength and ductility, which is beneficial for welding applications. However, when subjected to high-pressure environments, the material's behavior can change significantly.

One of the primary metallurgical considerations for welding 4140 steel is its hardenability. The presence of alloying elements, particularly chromium and molybdenum, increases the steel's hardenability, making it susceptible to the formation of martensite in the heat-affected zone (HAZ) during welding. This can lead to increased hardness and brittleness, potentially compromising the weld's integrity in high-pressure environments.

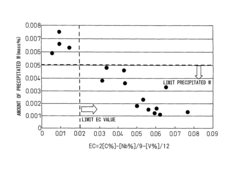

The carbon equivalent (CE) of 4140 steel is another critical factor affecting its weldability. With a CE value typically ranging from 0.62 to 0.72, 4140 steel is considered to have moderate to poor weldability. Higher CE values indicate a greater tendency for the formation of hard, brittle microstructures during welding, which can be particularly problematic in high-pressure applications.

In high-pressure environments, the mechanical properties of 4140 steel can be significantly affected. The yield strength and tensile strength may increase, while ductility and toughness may decrease. This alteration in properties can impact the material's response to welding processes and subsequent performance of the welded joint under high-pressure conditions.

The heat treatment history of 4140 steel also plays a vital role in its weldability. Depending on the prior heat treatment (e.g., quenched and tempered, normalized, or annealed), the steel's microstructure and mechanical properties can vary, influencing its behavior during welding and in high-pressure service.

Hydrogen embrittlement is another critical consideration when welding 4140 steel, especially in high-pressure environments. The steel's susceptibility to hydrogen-induced cracking increases with higher strength levels and in the presence of residual stresses, which are common in welded structures. Proper control of hydrogen levels during welding and post-weld heat treatment are essential to mitigate this risk.

The microstructure of 4140 steel plays a crucial role in its weldability. In its normalized condition, the steel exhibits a fine-grained structure consisting of ferrite and pearlite. This microstructure provides a good balance of strength and ductility, which is beneficial for welding applications. However, when subjected to high-pressure environments, the material's behavior can change significantly.

One of the primary metallurgical considerations for welding 4140 steel is its hardenability. The presence of alloying elements, particularly chromium and molybdenum, increases the steel's hardenability, making it susceptible to the formation of martensite in the heat-affected zone (HAZ) during welding. This can lead to increased hardness and brittleness, potentially compromising the weld's integrity in high-pressure environments.

The carbon equivalent (CE) of 4140 steel is another critical factor affecting its weldability. With a CE value typically ranging from 0.62 to 0.72, 4140 steel is considered to have moderate to poor weldability. Higher CE values indicate a greater tendency for the formation of hard, brittle microstructures during welding, which can be particularly problematic in high-pressure applications.

In high-pressure environments, the mechanical properties of 4140 steel can be significantly affected. The yield strength and tensile strength may increase, while ductility and toughness may decrease. This alteration in properties can impact the material's response to welding processes and subsequent performance of the welded joint under high-pressure conditions.

The heat treatment history of 4140 steel also plays a vital role in its weldability. Depending on the prior heat treatment (e.g., quenched and tempered, normalized, or annealed), the steel's microstructure and mechanical properties can vary, influencing its behavior during welding and in high-pressure service.

Hydrogen embrittlement is another critical consideration when welding 4140 steel, especially in high-pressure environments. The steel's susceptibility to hydrogen-induced cracking increases with higher strength levels and in the presence of residual stresses, which are common in welded structures. Proper control of hydrogen levels during welding and post-weld heat treatment are essential to mitigate this risk.

Safety Standards and Regulations for High-Pressure Welding

Safety standards and regulations play a crucial role in ensuring the integrity and reliability of high-pressure welding operations, particularly when working with materials like 4140 steel. These standards are designed to protect workers, equipment, and the environment from potential hazards associated with welding under high-pressure conditions.

The American Society of Mechanical Engineers (ASME) has developed comprehensive guidelines for pressure vessel and piping systems, including the ASME Boiler and Pressure Vessel Code (BPVC). This code provides specific requirements for welding procedures, welder qualifications, and inspection methods for high-pressure applications. Section IX of the ASME BPVC focuses on welding and brazing qualifications, outlining the necessary steps to ensure proper welding techniques and quality control.

In addition to ASME standards, the American Welding Society (AWS) has established specific codes for welding in high-pressure environments. The AWS D10.10 standard, "Recommended Practices for Local Heating of Welds in Piping and Tubing," addresses the unique challenges of welding in pressurized systems. This standard provides guidance on preheating, post-weld heat treatment, and other critical factors that affect the weldability of materials like 4140 steel under high-pressure conditions.

Occupational Safety and Health Administration (OSHA) regulations also play a significant role in ensuring worker safety during high-pressure welding operations. OSHA standard 1910.252 outlines general requirements for welding, cutting, and brazing, including specific provisions for working in confined spaces and with pressurized systems. These regulations mandate the use of appropriate personal protective equipment, proper ventilation, and fire prevention measures.

The European Union has established its own set of standards for pressure equipment through the Pressure Equipment Directive (PED) 2014/68/EU. This directive sets out essential safety requirements for the design, manufacture, and conformity assessment of pressure equipment and assemblies. It includes specific provisions for welding processes and the qualification of welding personnel working with high-pressure systems.

Compliance with these safety standards and regulations is essential for ensuring the structural integrity of welded components in high-pressure environments. Regular inspections, non-destructive testing, and documentation of welding procedures are integral parts of maintaining compliance. As technology and materials evolve, these standards are periodically updated to address new challenges and incorporate best practices in the field of high-pressure welding.

The American Society of Mechanical Engineers (ASME) has developed comprehensive guidelines for pressure vessel and piping systems, including the ASME Boiler and Pressure Vessel Code (BPVC). This code provides specific requirements for welding procedures, welder qualifications, and inspection methods for high-pressure applications. Section IX of the ASME BPVC focuses on welding and brazing qualifications, outlining the necessary steps to ensure proper welding techniques and quality control.

In addition to ASME standards, the American Welding Society (AWS) has established specific codes for welding in high-pressure environments. The AWS D10.10 standard, "Recommended Practices for Local Heating of Welds in Piping and Tubing," addresses the unique challenges of welding in pressurized systems. This standard provides guidance on preheating, post-weld heat treatment, and other critical factors that affect the weldability of materials like 4140 steel under high-pressure conditions.

Occupational Safety and Health Administration (OSHA) regulations also play a significant role in ensuring worker safety during high-pressure welding operations. OSHA standard 1910.252 outlines general requirements for welding, cutting, and brazing, including specific provisions for working in confined spaces and with pressurized systems. These regulations mandate the use of appropriate personal protective equipment, proper ventilation, and fire prevention measures.

The European Union has established its own set of standards for pressure equipment through the Pressure Equipment Directive (PED) 2014/68/EU. This directive sets out essential safety requirements for the design, manufacture, and conformity assessment of pressure equipment and assemblies. It includes specific provisions for welding processes and the qualification of welding personnel working with high-pressure systems.

Compliance with these safety standards and regulations is essential for ensuring the structural integrity of welded components in high-pressure environments. Regular inspections, non-destructive testing, and documentation of welding procedures are integral parts of maintaining compliance. As technology and materials evolve, these standards are periodically updated to address new challenges and incorporate best practices in the field of high-pressure welding.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!