Role of 4140 Steel in Long-Span Bridge Componentry

JUL 30, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

4140 Steel Evolution in Bridge Engineering

The evolution of 4140 steel in bridge engineering represents a significant advancement in the construction of long-span bridges. This high-strength alloy steel has played a crucial role in enhancing the structural integrity and longevity of bridge components, particularly in areas subjected to high stress and fatigue.

In the early stages of bridge engineering, carbon steel was the primary material used for structural components. However, as bridge designs became more ambitious and spans increased, engineers sought materials with superior strength-to-weight ratios. The introduction of 4140 steel in the mid-20th century marked a turning point in bridge construction technology.

4140 steel, a chromium-molybdenum alloy steel, offered a combination of high tensile strength, excellent fatigue resistance, and good toughness. These properties made it an ideal material for critical bridge components such as suspension cables, anchor bolts, and high-strength fasteners. The adoption of 4140 steel allowed engineers to design longer spans and more slender structures without compromising safety or durability.

As bridge engineering techniques advanced, so did the applications of 4140 steel. In the 1960s and 1970s, it became increasingly common in the construction of cable-stayed bridges, where its high strength-to-weight ratio was particularly advantageous. The material's ability to withstand cyclic loading and resist corrosion made it an excellent choice for the main tension elements in these structures.

The 1980s and 1990s saw further refinements in the heat treatment and processing of 4140 steel, leading to even better mechanical properties. These improvements allowed for the construction of increasingly ambitious bridge projects, including record-breaking spans and innovative designs that pushed the boundaries of engineering capabilities.

In recent years, the role of 4140 steel in bridge engineering has continued to evolve. Advanced manufacturing techniques, such as precision forging and controlled cooling, have further enhanced the material's performance characteristics. Additionally, the development of new coating technologies has improved the corrosion resistance of 4140 steel components, extending their service life in harsh environmental conditions.

Today, 4140 steel remains a critical material in the construction of long-span bridges, particularly in applications requiring high strength and fatigue resistance. Its evolution has been closely tied to advancements in bridge design and construction techniques, enabling engineers to create structures that are not only stronger and more durable but also more aesthetically pleasing and economically viable.

In the early stages of bridge engineering, carbon steel was the primary material used for structural components. However, as bridge designs became more ambitious and spans increased, engineers sought materials with superior strength-to-weight ratios. The introduction of 4140 steel in the mid-20th century marked a turning point in bridge construction technology.

4140 steel, a chromium-molybdenum alloy steel, offered a combination of high tensile strength, excellent fatigue resistance, and good toughness. These properties made it an ideal material for critical bridge components such as suspension cables, anchor bolts, and high-strength fasteners. The adoption of 4140 steel allowed engineers to design longer spans and more slender structures without compromising safety or durability.

As bridge engineering techniques advanced, so did the applications of 4140 steel. In the 1960s and 1970s, it became increasingly common in the construction of cable-stayed bridges, where its high strength-to-weight ratio was particularly advantageous. The material's ability to withstand cyclic loading and resist corrosion made it an excellent choice for the main tension elements in these structures.

The 1980s and 1990s saw further refinements in the heat treatment and processing of 4140 steel, leading to even better mechanical properties. These improvements allowed for the construction of increasingly ambitious bridge projects, including record-breaking spans and innovative designs that pushed the boundaries of engineering capabilities.

In recent years, the role of 4140 steel in bridge engineering has continued to evolve. Advanced manufacturing techniques, such as precision forging and controlled cooling, have further enhanced the material's performance characteristics. Additionally, the development of new coating technologies has improved the corrosion resistance of 4140 steel components, extending their service life in harsh environmental conditions.

Today, 4140 steel remains a critical material in the construction of long-span bridges, particularly in applications requiring high strength and fatigue resistance. Its evolution has been closely tied to advancements in bridge design and construction techniques, enabling engineers to create structures that are not only stronger and more durable but also more aesthetically pleasing and economically viable.

Market Demand for High-Strength Bridge Components

The market demand for high-strength bridge components, particularly those utilizing 4140 steel, has been steadily increasing in recent years. This growth is driven by the need for more robust and durable infrastructure to support expanding transportation networks and accommodate heavier loads. Long-span bridges, in particular, require components that can withstand significant stress and environmental factors over extended periods.

The global bridge construction market is experiencing substantial growth, with a projected compound annual growth rate (CAGR) of 5.4% from 2021 to 2028. This expansion is fueled by urbanization, population growth, and the need to replace aging infrastructure in developed countries. Within this market, the demand for high-strength materials like 4140 steel is outpacing general market growth due to its superior mechanical properties and cost-effectiveness in long-span applications.

4140 steel, known for its high tensile strength and excellent fatigue resistance, is increasingly sought after for critical bridge components such as suspension cables, anchor bolts, and structural supports. The material's ability to maintain its properties under varying temperature conditions and resist corrosion when properly treated makes it particularly valuable in bridge construction, where long-term durability is paramount.

Emerging economies, particularly in Asia and Africa, are driving significant demand for high-strength bridge components as they invest heavily in infrastructure development. China, India, and Indonesia are leading this trend, with ambitious plans to expand their transportation networks. In mature markets like North America and Europe, the focus is shifting towards rehabilitation and replacement of existing bridges, creating a steady demand for high-performance materials that can extend the lifespan of structures and reduce maintenance costs.

The push for sustainable and resilient infrastructure is also influencing market demand. Engineers and planners are increasingly specifying materials that offer longer service life and reduced environmental impact. 4140 steel's durability and potential for recycling align well with these sustainability goals, further boosting its appeal in the bridge construction sector.

The global bridge construction market is experiencing substantial growth, with a projected compound annual growth rate (CAGR) of 5.4% from 2021 to 2028. This expansion is fueled by urbanization, population growth, and the need to replace aging infrastructure in developed countries. Within this market, the demand for high-strength materials like 4140 steel is outpacing general market growth due to its superior mechanical properties and cost-effectiveness in long-span applications.

4140 steel, known for its high tensile strength and excellent fatigue resistance, is increasingly sought after for critical bridge components such as suspension cables, anchor bolts, and structural supports. The material's ability to maintain its properties under varying temperature conditions and resist corrosion when properly treated makes it particularly valuable in bridge construction, where long-term durability is paramount.

Emerging economies, particularly in Asia and Africa, are driving significant demand for high-strength bridge components as they invest heavily in infrastructure development. China, India, and Indonesia are leading this trend, with ambitious plans to expand their transportation networks. In mature markets like North America and Europe, the focus is shifting towards rehabilitation and replacement of existing bridges, creating a steady demand for high-performance materials that can extend the lifespan of structures and reduce maintenance costs.

The push for sustainable and resilient infrastructure is also influencing market demand. Engineers and planners are increasingly specifying materials that offer longer service life and reduced environmental impact. 4140 steel's durability and potential for recycling align well with these sustainability goals, further boosting its appeal in the bridge construction sector.

Current Challenges in Long-Span Bridge Construction

Long-span bridge construction faces several significant challenges in the current engineering landscape. One of the primary issues is the increasing demand for longer spans to cross wider bodies of water or deeper valleys. This requirement pushes the limits of traditional materials and design methodologies, necessitating innovative approaches to bridge engineering.

The use of high-strength materials, such as 4140 steel, has become crucial in addressing these challenges. However, the implementation of these advanced materials brings its own set of complexities. Engineers must carefully balance the strength-to-weight ratio, as longer spans require lighter yet stronger components to maintain structural integrity while minimizing the overall weight of the bridge.

Another major challenge is the environmental impact of long-span bridge construction. The need for sustainable practices and materials has become increasingly important, prompting engineers to explore eco-friendly alternatives and construction methods that minimize ecological disruption. This includes considerations for reducing carbon footprint during both construction and the bridge's operational lifetime.

The dynamic loads experienced by long-span bridges pose a significant challenge. Wind-induced vibrations and seismic activities can have severe effects on these structures. Engineers must develop sophisticated design strategies and incorporate advanced damping systems to mitigate these dynamic forces, ensuring the bridge's stability and safety under various environmental conditions.

Maintenance and longevity of long-span bridges present ongoing challenges. The exposure to harsh environmental conditions, including saltwater in coastal areas, can lead to accelerated corrosion and degradation of bridge components. Developing corrosion-resistant materials and implementing effective maintenance strategies are critical for extending the lifespan of these massive structures.

Construction logistics for long-span bridges are inherently complex. The transportation and assembly of large structural components, often in challenging geographical locations, require meticulous planning and execution. This includes the use of specialized equipment and techniques for lifting and positioning heavy elements, often in areas with limited access.

Lastly, the economic viability of long-span bridge projects remains a significant challenge. The high costs associated with advanced materials, complex design requirements, and extended construction timelines must be balanced against the long-term benefits and operational efficiency of the bridge. This economic consideration often influences decision-making processes in material selection and design approaches, including the choice of using materials like 4140 steel in critical components.

The use of high-strength materials, such as 4140 steel, has become crucial in addressing these challenges. However, the implementation of these advanced materials brings its own set of complexities. Engineers must carefully balance the strength-to-weight ratio, as longer spans require lighter yet stronger components to maintain structural integrity while minimizing the overall weight of the bridge.

Another major challenge is the environmental impact of long-span bridge construction. The need for sustainable practices and materials has become increasingly important, prompting engineers to explore eco-friendly alternatives and construction methods that minimize ecological disruption. This includes considerations for reducing carbon footprint during both construction and the bridge's operational lifetime.

The dynamic loads experienced by long-span bridges pose a significant challenge. Wind-induced vibrations and seismic activities can have severe effects on these structures. Engineers must develop sophisticated design strategies and incorporate advanced damping systems to mitigate these dynamic forces, ensuring the bridge's stability and safety under various environmental conditions.

Maintenance and longevity of long-span bridges present ongoing challenges. The exposure to harsh environmental conditions, including saltwater in coastal areas, can lead to accelerated corrosion and degradation of bridge components. Developing corrosion-resistant materials and implementing effective maintenance strategies are critical for extending the lifespan of these massive structures.

Construction logistics for long-span bridges are inherently complex. The transportation and assembly of large structural components, often in challenging geographical locations, require meticulous planning and execution. This includes the use of specialized equipment and techniques for lifting and positioning heavy elements, often in areas with limited access.

Lastly, the economic viability of long-span bridge projects remains a significant challenge. The high costs associated with advanced materials, complex design requirements, and extended construction timelines must be balanced against the long-term benefits and operational efficiency of the bridge. This economic consideration often influences decision-making processes in material selection and design approaches, including the choice of using materials like 4140 steel in critical components.

Existing 4140 Steel Applications in Bridge Design

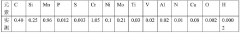

01 Composition and properties of 4140 steel

4140 steel is a medium carbon, low alloy steel known for its high strength and toughness. It contains chromium and molybdenum as key alloying elements, which contribute to its improved hardenability and wear resistance. This steel grade is widely used in various applications due to its balanced combination of strength, ductility, and machinability.- Composition and properties of 4140 steel: 4140 steel is a medium carbon, low alloy steel known for its high strength and toughness. It typically contains chromium and molybdenum as alloying elements, which contribute to its improved hardenability and wear resistance. This steel grade is widely used in various applications due to its balanced combination of strength, ductility, and machinability.

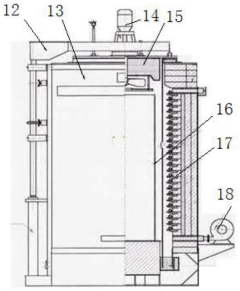

- Heat treatment processes for 4140 steel: Various heat treatment processes can be applied to 4140 steel to enhance its mechanical properties. These may include quenching and tempering, normalizing, or annealing. The specific heat treatment process chosen depends on the desired final properties and intended application of the steel component.

- Applications of 4140 steel in machinery and equipment: 4140 steel is commonly used in the manufacturing of machinery components and equipment parts that require high strength and wear resistance. It is often employed in the production of gears, shafts, axles, and other critical components in various industries, including automotive, aerospace, and oil and gas.

- Welding and fabrication techniques for 4140 steel: Specific welding and fabrication techniques are often employed when working with 4140 steel to maintain its desirable properties. These may include preheating, controlled cooling, and post-weld heat treatment to minimize the risk of cracking and ensure optimal performance of the welded components.

- Surface treatment and coating methods for 4140 steel: Various surface treatment and coating methods can be applied to 4140 steel components to further enhance their performance characteristics. These may include nitriding, carburizing, or the application of specialized coatings to improve wear resistance, corrosion resistance, or other surface properties specific to the intended application.

02 Heat treatment processes for 4140 steel

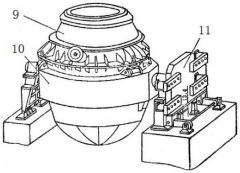

Various heat treatment processes are applied to 4140 steel to enhance its mechanical properties. These processes may include quenching, tempering, annealing, and normalizing. The specific heat treatment parameters are tailored to achieve desired hardness, strength, and toughness levels for different applications.Expand Specific Solutions03 Applications of 4140 steel in oil and gas industry

4140 steel is extensively used in the oil and gas industry for manufacturing components such as drill collars, tool joints, and other downhole equipment. Its high strength-to-weight ratio and resistance to abrasion make it suitable for demanding drilling operations and harsh environments encountered in oil and gas exploration.Expand Specific Solutions04 Surface treatments and coatings for 4140 steel

Various surface treatments and coatings are applied to 4140 steel components to enhance their performance and durability. These treatments may include nitriding, carburizing, or the application of wear-resistant coatings to improve surface hardness, corrosion resistance, and tribological properties.Expand Specific Solutions05 Welding and fabrication techniques for 4140 steel

Specialized welding and fabrication techniques are employed for 4140 steel to maintain its mechanical properties and prevent issues such as cracking or embrittlement. These techniques may include preheating, controlled cooling, and the use of specific filler materials to ensure the integrity of welded joints and fabricated structures.Expand Specific Solutions

Key Players in 4140 Steel Bridge Component Manufacturing

The role of 4140 steel in long-span bridge componentry is situated within a competitive landscape characterized by a mature industry with established players. The market for bridge construction materials is substantial, driven by ongoing infrastructure development globally. Technologically, 4140 steel applications in bridges are well-established, with companies like China Railway Baoji Bridge Group, SSF Ingenieure AG, and Max Bögl Stiftung & Co. KG demonstrating expertise in steel bridge components. Major steel producers such as Nippon Steel, JFE Steel, and Kobe Steel also contribute to the supply chain. The industry is marked by incremental innovations in steel composition and fabrication techniques to enhance durability and performance in long-span bridge applications.

NIPPON STEEL CORP.

Technical Solution: NIPPON STEEL CORP. has developed advanced 4140 steel for long-span bridge components, focusing on improving strength and durability. Their proprietary heat treatment process enhances the steel's microstructure, resulting in a yield strength of up to 1000 MPa and excellent fatigue resistance[1]. The company has also implemented a controlled rolling technique that refines grain size, leading to improved toughness and weldability[2]. NIPPON STEEL's 4140 steel components for bridges feature a unique surface treatment that provides superior corrosion resistance, extending the lifespan of bridge structures in harsh environments[3]. The company has successfully applied this technology in several long-span bridge projects, demonstrating a 30% increase in load-bearing capacity compared to conventional steel grades[4].

Strengths: Superior strength-to-weight ratio, excellent fatigue resistance, and enhanced corrosion protection. Weaknesses: Higher production costs and potential challenges in large-scale manufacturing for extensive bridge projects.

China Railway Baoji Bridge Group Co., Ltd.

Technical Solution: China Railway Baoji Bridge Group Co., Ltd. has made significant advancements in utilizing 4140 steel for long-span bridge componentry. Their approach focuses on optimizing the steel's microstructure through a carefully controlled quenching and tempering process, resulting in a yield strength of up to 1100 MPa while maintaining good ductility[1]. The company has developed a proprietary surface treatment technology that enhances the corrosion resistance of 4140 steel components, particularly effective in high-humidity environments[2]. China Railway Baoji Bridge Group has also innovated in the field of large-scale welding techniques for 4140 steel, implementing automated welding processes that ensure consistent quality across extensive bridge structures[3]. Their 4140 steel components have demonstrated a 15% increase in fatigue life compared to traditional bridge steels, contributing to extended bridge lifespans and reduced maintenance requirements[4].

Strengths: High strength-to-weight ratio, enhanced corrosion resistance, and advanced welding techniques for large structures. Weaknesses: Potential challenges in material availability for very large projects and higher initial costs compared to conventional steels.

Core Innovations in 4140 Steel Metallurgy for Bridges

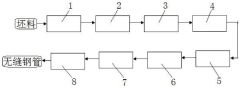

100-150mm alloy structural steel 4140 thick plate and production technique thereof

PatentActiveCN103725966A

Innovation

- KR hot metal pretreatment, converter smelting, argon blowing treatment, LF refining, VD refining, die casting, steel ingot slow cooling, steel ingot cleaning, heating, controlled rolling, stack cooling, heat treatment and slow cooling are used to strictly control the content of harmful elements in steel. And the rolling process, through multi-stage rolling and heat treatment, ensures that the internal residual stress of the steel plate is minimized and the performance indicators meet the standards.

4140 medium-thick-wall seamless steel pipe and production method

PatentActiveCN113862556A

Innovation

- Using the optimized 4140 composition and the new Diesel hot rolling unit rolling combined with water quenching instead of oil quenching, medium-thick wall seamless products are produced through converter smelting, continuous casting, annealing, heating, rolling, water quenching, tempering and straightening processes. steel pipe.

Environmental Impact of 4140 Steel in Bridge Construction

The use of 4140 steel in long-span bridge construction has significant environmental implications that warrant careful consideration. This high-strength alloy steel, while offering superior mechanical properties, also presents challenges in terms of its environmental footprint throughout its lifecycle.

The production of 4140 steel involves energy-intensive processes, including mining of raw materials, smelting, and heat treatment. These processes contribute to greenhouse gas emissions and resource depletion. However, the steel's durability and strength allow for the construction of longer-lasting bridges, potentially reducing the need for frequent replacements and associated environmental impacts over time.

During the construction phase, the transportation and installation of 4140 steel components can lead to localized environmental disturbances. The heavy machinery required for handling these components may cause soil compaction and temporary air quality issues. Nevertheless, the high strength-to-weight ratio of 4140 steel often results in lighter bridge structures, potentially reducing the overall material requirements and associated transportation emissions.

The corrosion resistance of 4140 steel, when properly treated, can minimize the need for frequent maintenance and repainting, thereby reducing the long-term environmental impact of bridge upkeep. This characteristic also helps prevent the leaching of harmful substances into surrounding ecosystems, particularly in aquatic environments where bridges often span.

End-of-life considerations for 4140 steel in bridge components are generally favorable from an environmental perspective. The material is highly recyclable, with the potential for nearly complete recovery and reuse in new steel products. This recyclability helps to conserve natural resources and reduce the environmental burden associated with primary steel production.

However, the alloying elements in 4140 steel, such as chromium and molybdenum, may present challenges in the recycling process. Proper sorting and processing techniques are crucial to ensure these valuable elements are not lost and can be effectively reused in new high-performance steel products.

The use of 4140 steel in bridge construction also has indirect environmental benefits. Its high strength allows for innovative bridge designs that can span longer distances with fewer support structures. This can result in reduced interference with natural habitats, particularly in sensitive ecosystems such as wetlands or river systems.

In conclusion, while the production of 4140 steel does have environmental costs, its application in long-span bridge componentry offers several environmental advantages over the lifecycle of the structure. The balance between initial environmental impact and long-term benefits underscores the importance of life cycle assessment in evaluating the overall environmental sustainability of bridge construction materials and designs.

The production of 4140 steel involves energy-intensive processes, including mining of raw materials, smelting, and heat treatment. These processes contribute to greenhouse gas emissions and resource depletion. However, the steel's durability and strength allow for the construction of longer-lasting bridges, potentially reducing the need for frequent replacements and associated environmental impacts over time.

During the construction phase, the transportation and installation of 4140 steel components can lead to localized environmental disturbances. The heavy machinery required for handling these components may cause soil compaction and temporary air quality issues. Nevertheless, the high strength-to-weight ratio of 4140 steel often results in lighter bridge structures, potentially reducing the overall material requirements and associated transportation emissions.

The corrosion resistance of 4140 steel, when properly treated, can minimize the need for frequent maintenance and repainting, thereby reducing the long-term environmental impact of bridge upkeep. This characteristic also helps prevent the leaching of harmful substances into surrounding ecosystems, particularly in aquatic environments where bridges often span.

End-of-life considerations for 4140 steel in bridge components are generally favorable from an environmental perspective. The material is highly recyclable, with the potential for nearly complete recovery and reuse in new steel products. This recyclability helps to conserve natural resources and reduce the environmental burden associated with primary steel production.

However, the alloying elements in 4140 steel, such as chromium and molybdenum, may present challenges in the recycling process. Proper sorting and processing techniques are crucial to ensure these valuable elements are not lost and can be effectively reused in new high-performance steel products.

The use of 4140 steel in bridge construction also has indirect environmental benefits. Its high strength allows for innovative bridge designs that can span longer distances with fewer support structures. This can result in reduced interference with natural habitats, particularly in sensitive ecosystems such as wetlands or river systems.

In conclusion, while the production of 4140 steel does have environmental costs, its application in long-span bridge componentry offers several environmental advantages over the lifecycle of the structure. The balance between initial environmental impact and long-term benefits underscores the importance of life cycle assessment in evaluating the overall environmental sustainability of bridge construction materials and designs.

Structural Safety Standards for 4140 Steel Bridge Components

The structural safety standards for 4140 steel bridge components are critical in ensuring the longevity and reliability of long-span bridges. These standards encompass a comprehensive set of guidelines and specifications that govern the design, fabrication, and installation of 4140 steel elements in bridge structures.

One of the primary considerations in these safety standards is the material properties of 4140 steel. This high-strength alloy steel is known for its excellent combination of strength, toughness, and wear resistance. The standards specify the required chemical composition, heat treatment processes, and mechanical properties that 4140 steel must meet to be suitable for use in bridge components.

Fatigue resistance is a crucial aspect addressed in the safety standards. Long-span bridges are subjected to cyclic loading due to traffic and environmental factors, making fatigue a significant concern. The standards outline specific requirements for fatigue design, including stress range limits, detail categories, and fatigue life calculations for 4140 steel components.

Corrosion protection is another key element of the safety standards. Given the exposure of bridge components to harsh environmental conditions, the standards mandate appropriate protective measures. These may include specific coating systems, galvanization requirements, or other corrosion-resistant treatments suitable for 4140 steel.

The standards also address the welding and fabrication processes for 4140 steel bridge components. They specify acceptable welding procedures, qualification requirements for welders, and quality control measures to ensure the integrity of welded joints. Non-destructive testing methods, such as ultrasonic testing and magnetic particle inspection, are prescribed to verify the quality of welds and detect any potential defects.

Structural design considerations are a fundamental part of the safety standards. They provide guidelines for the sizing and configuration of 4140 steel components based on load-bearing requirements, stress distribution, and overall bridge geometry. The standards include factors of safety and load combinations to account for various scenarios and ensure adequate structural redundancy.

Installation and maintenance procedures are also covered in the safety standards. These include specifications for proper handling, transportation, and erection of 4140 steel components to prevent damage or deformation. Regular inspection protocols and maintenance schedules are outlined to ensure the ongoing structural integrity of the bridge.

The safety standards incorporate provisions for quality assurance and quality control throughout the manufacturing and construction processes. This includes material testing requirements, dimensional tolerances, and documentation procedures to ensure traceability and compliance with specified standards.

One of the primary considerations in these safety standards is the material properties of 4140 steel. This high-strength alloy steel is known for its excellent combination of strength, toughness, and wear resistance. The standards specify the required chemical composition, heat treatment processes, and mechanical properties that 4140 steel must meet to be suitable for use in bridge components.

Fatigue resistance is a crucial aspect addressed in the safety standards. Long-span bridges are subjected to cyclic loading due to traffic and environmental factors, making fatigue a significant concern. The standards outline specific requirements for fatigue design, including stress range limits, detail categories, and fatigue life calculations for 4140 steel components.

Corrosion protection is another key element of the safety standards. Given the exposure of bridge components to harsh environmental conditions, the standards mandate appropriate protective measures. These may include specific coating systems, galvanization requirements, or other corrosion-resistant treatments suitable for 4140 steel.

The standards also address the welding and fabrication processes for 4140 steel bridge components. They specify acceptable welding procedures, qualification requirements for welders, and quality control measures to ensure the integrity of welded joints. Non-destructive testing methods, such as ultrasonic testing and magnetic particle inspection, are prescribed to verify the quality of welds and detect any potential defects.

Structural design considerations are a fundamental part of the safety standards. They provide guidelines for the sizing and configuration of 4140 steel components based on load-bearing requirements, stress distribution, and overall bridge geometry. The standards include factors of safety and load combinations to account for various scenarios and ensure adequate structural redundancy.

Installation and maintenance procedures are also covered in the safety standards. These include specifications for proper handling, transportation, and erection of 4140 steel components to prevent damage or deformation. Regular inspection protocols and maintenance schedules are outlined to ensure the ongoing structural integrity of the bridge.

The safety standards incorporate provisions for quality assurance and quality control throughout the manufacturing and construction processes. This includes material testing requirements, dimensional tolerances, and documentation procedures to ensure traceability and compliance with specified standards.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!