Role of 4140 Steel in Aerospace Landing Gear Systems

JUL 30, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

4140 Steel in Aerospace: Background and Objectives

The aerospace industry has long relied on high-strength materials to meet the demanding requirements of aircraft components, particularly in critical systems such as landing gear. 4140 steel, a medium carbon chromium molybdenum alloy steel, has emerged as a crucial material in this context, offering an exceptional combination of strength, toughness, and wear resistance.

The development of 4140 steel can be traced back to the early 20th century when the need for stronger and more reliable materials in industrial applications became apparent. As the aerospace sector evolved, the unique properties of 4140 steel made it an ideal candidate for use in landing gear systems, which are subjected to extreme stress and fatigue during aircraft takeoffs and landings.

The primary objective of utilizing 4140 steel in aerospace landing gear systems is to ensure the safety and reliability of aircraft during critical phases of flight. This material must withstand high impact loads, resist fatigue failure, and maintain its structural integrity under varying environmental conditions. Additionally, the use of 4140 steel aims to optimize the weight-to-strength ratio of landing gear components, contributing to overall aircraft efficiency.

In recent years, the aerospace industry has witnessed a growing trend towards lighter and more fuel-efficient aircraft designs. This has led to increased focus on advanced materials and manufacturing techniques that can enhance the performance of critical components like landing gear. The ongoing development and refinement of 4140 steel alloys play a crucial role in meeting these evolving requirements.

The technological evolution of 4140 steel in aerospace applications has been marked by continuous improvements in heat treatment processes, surface finishing techniques, and alloy compositions. These advancements have resulted in enhanced mechanical properties, improved corrosion resistance, and extended service life of landing gear components.

As the aerospace industry continues to push the boundaries of aircraft performance and efficiency, the role of 4140 steel in landing gear systems remains pivotal. Future objectives for this material include further optimization of its properties to meet the demands of next-generation aircraft, exploration of novel manufacturing methods to reduce production costs, and investigation of potential hybrid materials that combine the strengths of 4140 steel with other advanced alloys.

The development of 4140 steel can be traced back to the early 20th century when the need for stronger and more reliable materials in industrial applications became apparent. As the aerospace sector evolved, the unique properties of 4140 steel made it an ideal candidate for use in landing gear systems, which are subjected to extreme stress and fatigue during aircraft takeoffs and landings.

The primary objective of utilizing 4140 steel in aerospace landing gear systems is to ensure the safety and reliability of aircraft during critical phases of flight. This material must withstand high impact loads, resist fatigue failure, and maintain its structural integrity under varying environmental conditions. Additionally, the use of 4140 steel aims to optimize the weight-to-strength ratio of landing gear components, contributing to overall aircraft efficiency.

In recent years, the aerospace industry has witnessed a growing trend towards lighter and more fuel-efficient aircraft designs. This has led to increased focus on advanced materials and manufacturing techniques that can enhance the performance of critical components like landing gear. The ongoing development and refinement of 4140 steel alloys play a crucial role in meeting these evolving requirements.

The technological evolution of 4140 steel in aerospace applications has been marked by continuous improvements in heat treatment processes, surface finishing techniques, and alloy compositions. These advancements have resulted in enhanced mechanical properties, improved corrosion resistance, and extended service life of landing gear components.

As the aerospace industry continues to push the boundaries of aircraft performance and efficiency, the role of 4140 steel in landing gear systems remains pivotal. Future objectives for this material include further optimization of its properties to meet the demands of next-generation aircraft, exploration of novel manufacturing methods to reduce production costs, and investigation of potential hybrid materials that combine the strengths of 4140 steel with other advanced alloys.

Market Analysis: Aerospace Landing Gear Demand

The aerospace landing gear market has been experiencing steady growth, driven by increasing air travel demand and the expansion of commercial and military aircraft fleets worldwide. As a critical component of aircraft safety and performance, landing gear systems are subject to rigorous standards and continuous technological advancements, creating a robust and evolving market landscape.

The global aerospace landing gear market is projected to grow significantly in the coming years, with a compound annual growth rate (CAGR) expected to exceed 5% between 2021 and 2026. This growth is primarily attributed to the rising production of commercial aircraft, particularly in emerging economies, and the increasing focus on fuel efficiency and lightweight materials in aerospace engineering.

Commercial aviation remains the largest segment in the aerospace landing gear market, accounting for over 60% of the total market share. The increasing number of air passengers, especially in Asia-Pacific and Middle Eastern regions, has led to a surge in aircraft orders and deliveries, consequently driving the demand for landing gear systems.

Military aviation also contributes substantially to the market, with governments worldwide investing in modernizing their air forces and expanding their fleets. The demand for advanced landing gear systems capable of withstanding extreme conditions and supporting heavier payloads is particularly strong in this sector.

The market for aerospace landing gear is highly concentrated, with a few major players dominating the industry. These companies are continuously investing in research and development to improve the performance, durability, and weight efficiency of landing gear systems. The use of advanced materials, such as high-strength steels like 4140, titanium alloys, and composites, is a key trend in the industry, aimed at reducing weight while maintaining or improving structural integrity.

Geographically, North America holds the largest market share, followed by Europe and Asia-Pacific. The United States, in particular, is a major contributor to the market, housing some of the world's largest aircraft manufacturers and a robust aerospace industry ecosystem. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by increasing air travel, expanding domestic aircraft production capabilities, and rising military expenditures in countries like China and India.

The aftermarket segment for aerospace landing gear is also significant, with maintenance, repair, and overhaul (MRO) services playing a crucial role in the industry. As aircraft fleets age, the demand for replacement parts and regular maintenance of landing gear systems continues to grow, providing a steady revenue stream for manufacturers and service providers.

The global aerospace landing gear market is projected to grow significantly in the coming years, with a compound annual growth rate (CAGR) expected to exceed 5% between 2021 and 2026. This growth is primarily attributed to the rising production of commercial aircraft, particularly in emerging economies, and the increasing focus on fuel efficiency and lightweight materials in aerospace engineering.

Commercial aviation remains the largest segment in the aerospace landing gear market, accounting for over 60% of the total market share. The increasing number of air passengers, especially in Asia-Pacific and Middle Eastern regions, has led to a surge in aircraft orders and deliveries, consequently driving the demand for landing gear systems.

Military aviation also contributes substantially to the market, with governments worldwide investing in modernizing their air forces and expanding their fleets. The demand for advanced landing gear systems capable of withstanding extreme conditions and supporting heavier payloads is particularly strong in this sector.

The market for aerospace landing gear is highly concentrated, with a few major players dominating the industry. These companies are continuously investing in research and development to improve the performance, durability, and weight efficiency of landing gear systems. The use of advanced materials, such as high-strength steels like 4140, titanium alloys, and composites, is a key trend in the industry, aimed at reducing weight while maintaining or improving structural integrity.

Geographically, North America holds the largest market share, followed by Europe and Asia-Pacific. The United States, in particular, is a major contributor to the market, housing some of the world's largest aircraft manufacturers and a robust aerospace industry ecosystem. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by increasing air travel, expanding domestic aircraft production capabilities, and rising military expenditures in countries like China and India.

The aftermarket segment for aerospace landing gear is also significant, with maintenance, repair, and overhaul (MRO) services playing a crucial role in the industry. As aircraft fleets age, the demand for replacement parts and regular maintenance of landing gear systems continues to grow, providing a steady revenue stream for manufacturers and service providers.

Current Challenges in Landing Gear Materials

The aerospace industry continually faces challenges in developing and implementing materials for landing gear systems that can withstand extreme conditions while maintaining optimal performance. One of the primary challenges is the need for materials that can handle high stress and fatigue loads. Landing gear components are subjected to repeated cycles of compression, tension, and torsion during takeoff and landing, requiring materials with exceptional fatigue resistance and strength-to-weight ratios.

Corrosion resistance is another critical challenge in landing gear materials. Exposure to various environmental conditions, including moisture, salt spray, and de-icing chemicals, can lead to accelerated corrosion. This necessitates the use of materials that can withstand these corrosive elements while maintaining structural integrity over the aircraft's lifespan.

Weight reduction remains a constant challenge in aerospace engineering, including landing gear systems. While materials must be strong enough to withstand the forces involved in landing and takeoff, they must also contribute to the overall goal of reducing aircraft weight to improve fuel efficiency and performance. This balance between strength and weight optimization is a significant hurdle in material selection and design.

The need for materials with improved thermal properties is another challenge. Landing gear components can experience rapid temperature changes and high heat generation during operation. Materials must be able to maintain their mechanical properties across a wide temperature range and dissipate heat effectively to prevent thermal fatigue and ensure consistent performance.

Manufacturability and cost-effectiveness pose additional challenges in landing gear material development. Advanced materials with superior properties often come with increased production costs and complexities. The industry must find ways to produce these materials at scale while keeping costs manageable to ensure economic viability.

Lastly, the integration of smart materials and sensors into landing gear systems presents new material challenges. As the industry moves towards more intelligent and self-monitoring systems, materials must be compatible with embedded sensors and capable of supporting advanced health monitoring technologies without compromising structural integrity or performance.

Corrosion resistance is another critical challenge in landing gear materials. Exposure to various environmental conditions, including moisture, salt spray, and de-icing chemicals, can lead to accelerated corrosion. This necessitates the use of materials that can withstand these corrosive elements while maintaining structural integrity over the aircraft's lifespan.

Weight reduction remains a constant challenge in aerospace engineering, including landing gear systems. While materials must be strong enough to withstand the forces involved in landing and takeoff, they must also contribute to the overall goal of reducing aircraft weight to improve fuel efficiency and performance. This balance between strength and weight optimization is a significant hurdle in material selection and design.

The need for materials with improved thermal properties is another challenge. Landing gear components can experience rapid temperature changes and high heat generation during operation. Materials must be able to maintain their mechanical properties across a wide temperature range and dissipate heat effectively to prevent thermal fatigue and ensure consistent performance.

Manufacturability and cost-effectiveness pose additional challenges in landing gear material development. Advanced materials with superior properties often come with increased production costs and complexities. The industry must find ways to produce these materials at scale while keeping costs manageable to ensure economic viability.

Lastly, the integration of smart materials and sensors into landing gear systems presents new material challenges. As the industry moves towards more intelligent and self-monitoring systems, materials must be compatible with embedded sensors and capable of supporting advanced health monitoring technologies without compromising structural integrity or performance.

4140 Steel Properties and Applications in Landing Gear

01 Composition and properties of 4140 steel

4140 steel is a medium carbon, low alloy steel known for its high strength and toughness. It typically contains chromium and molybdenum as alloying elements, which contribute to its improved hardenability and wear resistance. This steel grade is widely used in various applications due to its balanced combination of strength, ductility, and machinability.- Composition and properties of 4140 steel: 4140 steel is a medium carbon, low alloy steel known for its high strength, toughness, and wear resistance. It typically contains chromium and molybdenum as key alloying elements, which contribute to its improved hardenability and mechanical properties. This steel grade is widely used in various industrial applications due to its balanced combination of strength and ductility.

- Heat treatment processes for 4140 steel: Various heat treatment processes can be applied to 4140 steel to enhance its mechanical properties. These may include quenching and tempering, normalizing, and annealing. The specific heat treatment parameters can be adjusted to achieve desired hardness, strength, and toughness levels, making 4140 steel suitable for a wide range of applications in different industries.

- Applications of 4140 steel in oil and gas industry: 4140 steel is commonly used in the oil and gas industry for various components and equipment. Its high strength and resistance to wear and corrosion make it suitable for applications such as drill collars, tool joints, and other downhole tools. The material's properties contribute to improved performance and durability in challenging drilling environments.

- Machining and fabrication of 4140 steel: 4140 steel can be machined and fabricated using various techniques, including turning, milling, drilling, and welding. However, due to its high strength and hardness, special considerations may be required during machining processes. Proper tooling, cutting speeds, and cooling methods are essential to achieve optimal results when working with 4140 steel.

- Surface treatments for 4140 steel: Various surface treatments can be applied to 4140 steel to enhance its properties further. These may include nitriding, carburizing, or the application of protective coatings. Such treatments can improve the steel's wear resistance, corrosion resistance, and surface hardness, extending its service life in demanding applications.

02 Heat treatment processes for 4140 steel

Various heat treatment processes can be applied to 4140 steel to enhance its mechanical properties. These may include quenching and tempering, normalizing, and annealing. The specific heat treatment parameters can be adjusted to achieve desired hardness, strength, and toughness levels suitable for different applications.Expand Specific Solutions03 Applications of 4140 steel in oil and gas industry

4140 steel is commonly used in the oil and gas industry for components such as drill collars, tool joints, and other downhole equipment. Its high strength-to-weight ratio and resistance to abrasion make it suitable for demanding drilling operations and harsh environments encountered in oil and gas exploration.Expand Specific Solutions04 Machining and fabrication of 4140 steel

4140 steel can be machined and fabricated using various processes, including turning, milling, drilling, and welding. While it offers good machinability, its higher strength compared to mild steels may require adjusted cutting parameters and tool selection. Proper heat treatment before and after machining can help achieve optimal results.Expand Specific Solutions05 Surface treatments for 4140 steel

Various surface treatments can be applied to 4140 steel to enhance its performance in specific applications. These may include nitriding, carburizing, or the application of protective coatings. Such treatments can improve wear resistance, corrosion resistance, or fatigue strength, extending the service life of components made from 4140 steel.Expand Specific Solutions

Key Players in Aerospace Landing Gear Manufacturing

The aerospace landing gear systems market utilizing 4140 steel is in a mature stage, characterized by established players and steady growth. The market size is significant, driven by increasing aircraft production and the need for reliable, high-strength components. Technologically, 4140 steel applications in landing gear are well-developed, with companies like Boeing, Safran Landing Systems, and Goodrich Corporation leading innovation. These firms, along with others such as QuesTek Innovations and Caterpillar, are continually refining manufacturing processes and material properties to enhance performance and durability. The competitive landscape is marked by a mix of large aerospace conglomerates and specialized material science companies, all striving to improve the strength-to-weight ratio and fatigue resistance of 4140 steel in landing gear applications.

QuesTek Innovations LLC

Technical Solution: QuesTek Innovations has applied its computational materials design approach to optimize 4140 steel for aerospace landing gear applications. Their methodology involves using advanced simulation tools to predict and fine-tune the material's microstructure and properties[10]. QuesTek has developed custom variants of 4140 steel with improved strength, toughness, and fatigue resistance tailored specifically for landing gear requirements[11]. Their approach also includes the integration of additive manufacturing techniques to produce complex 4140 steel components with optimized internal structures, potentially reducing weight and improving performance[12].

Strengths: Cutting-edge computational materials design, customized 4140 steel variants, and integration with advanced manufacturing techniques. Weaknesses: Potentially higher costs associated with specialized materials and manufacturing processes, and the need for extensive testing and certification for new material variants.

The Boeing Co.

Technical Solution: Boeing has developed advanced 4140 steel applications for aerospace landing gear systems, focusing on heat treatment processes to enhance strength and durability. Their approach involves precision quenching and tempering techniques to achieve optimal microstructure and mechanical properties[1]. Boeing's research has led to the development of proprietary surface treatments that improve wear resistance and fatigue life of 4140 steel components in landing gear assemblies[2]. The company has also implemented advanced non-destructive testing methods to ensure the integrity of 4140 steel parts throughout the manufacturing and maintenance processes[3].

Strengths: Extensive experience in aerospace applications, advanced heat treatment processes, and proprietary surface treatments. Weaknesses: Higher production costs due to specialized processes, and potential supply chain dependencies for specialized 4140 steel variants.

Innovations in 4140 Steel Heat Treatment for Aerospace

High fracture toughness, high strength, precipitation hardenable stainless steel

PatentWO2021173976A1

Innovation

- A precipitation hardenable martensitic stainless steel alloy with specific compositions of nickel, cobalt, titanium, chromium, and molybdenum, combined with controlled levels of other elements, is developed to provide high strength, fracture toughness, and corrosion resistance, eliminating the need for cadmium plating.

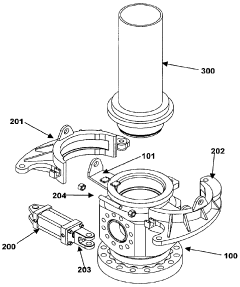

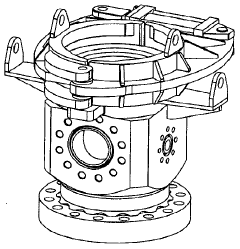

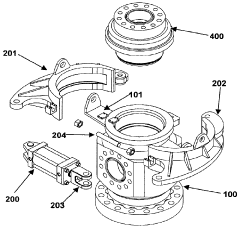

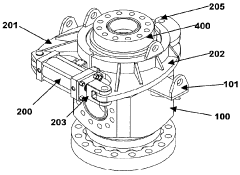

Rotating device having high Anti-corrosion properties for controlling pressures in well heads

PatentWO2015133884A1

Innovation

- A rotary device with high anticorrosive properties, featuring a 4140 material sleeve for wear resistance, polyurethane sealing elements, and a hydraulic piston mechanism, designed to withstand pressures from 1000 to 5000 psi and temperatures up to 300°C, using SKF GRA-EP2-60 grease for lubrication and ISO 68 oil for superior protection against oxidation and wear.

Environmental Impact of 4140 Steel in Aerospace

The environmental impact of 4140 steel in aerospace applications, particularly in landing gear systems, is a complex issue that requires careful consideration. This high-strength alloy steel, known for its durability and resistance to wear, plays a crucial role in the aerospace industry. However, its production, use, and disposal have significant environmental implications.

The manufacturing process of 4140 steel involves energy-intensive operations, including mining, smelting, and heat treatment. These processes contribute to greenhouse gas emissions and resource depletion. The extraction of raw materials, such as iron ore and alloying elements like chromium and molybdenum, can lead to habitat destruction and soil erosion in mining areas. Furthermore, the steel production process generates substantial amounts of carbon dioxide, contributing to global warming and climate change.

In the context of aerospace applications, the use of 4140 steel in landing gear systems presents both advantages and challenges from an environmental perspective. On the positive side, the steel's durability and strength allow for the production of lightweight yet robust components, which can contribute to improved fuel efficiency in aircraft. This, in turn, can lead to reduced emissions during flight operations. Additionally, the long lifespan of 4140 steel components reduces the frequency of replacements, potentially lowering the overall environmental impact associated with manufacturing and disposal.

However, the maintenance and repair of 4140 steel components in landing gear systems often involve the use of hazardous chemicals and lubricants. These substances can pose risks to soil and water systems if not properly managed. Moreover, the disposal of worn-out or damaged 4140 steel parts at the end of their lifecycle presents challenges. While steel is recyclable, the specialized alloy composition of 4140 steel may complicate the recycling process, potentially leading to increased energy consumption or the need for specialized recycling facilities.

The aerospace industry has been making efforts to mitigate the environmental impact of materials like 4140 steel. These initiatives include improving manufacturing processes to reduce energy consumption and emissions, developing more efficient recycling techniques for specialized alloys, and exploring alternative materials with lower environmental footprints. Some companies are investigating the potential of composite materials or advanced titanium alloys as substitutes for steel in certain landing gear components, aiming to reduce weight and improve fuel efficiency further.

In conclusion, while 4140 steel remains an essential material in aerospace landing gear systems due to its superior mechanical properties, its environmental impact throughout its lifecycle is significant. Balancing the material's performance benefits with environmental considerations will be crucial for the sustainable development of the aerospace industry in the coming years.

The manufacturing process of 4140 steel involves energy-intensive operations, including mining, smelting, and heat treatment. These processes contribute to greenhouse gas emissions and resource depletion. The extraction of raw materials, such as iron ore and alloying elements like chromium and molybdenum, can lead to habitat destruction and soil erosion in mining areas. Furthermore, the steel production process generates substantial amounts of carbon dioxide, contributing to global warming and climate change.

In the context of aerospace applications, the use of 4140 steel in landing gear systems presents both advantages and challenges from an environmental perspective. On the positive side, the steel's durability and strength allow for the production of lightweight yet robust components, which can contribute to improved fuel efficiency in aircraft. This, in turn, can lead to reduced emissions during flight operations. Additionally, the long lifespan of 4140 steel components reduces the frequency of replacements, potentially lowering the overall environmental impact associated with manufacturing and disposal.

However, the maintenance and repair of 4140 steel components in landing gear systems often involve the use of hazardous chemicals and lubricants. These substances can pose risks to soil and water systems if not properly managed. Moreover, the disposal of worn-out or damaged 4140 steel parts at the end of their lifecycle presents challenges. While steel is recyclable, the specialized alloy composition of 4140 steel may complicate the recycling process, potentially leading to increased energy consumption or the need for specialized recycling facilities.

The aerospace industry has been making efforts to mitigate the environmental impact of materials like 4140 steel. These initiatives include improving manufacturing processes to reduce energy consumption and emissions, developing more efficient recycling techniques for specialized alloys, and exploring alternative materials with lower environmental footprints. Some companies are investigating the potential of composite materials or advanced titanium alloys as substitutes for steel in certain landing gear components, aiming to reduce weight and improve fuel efficiency further.

In conclusion, while 4140 steel remains an essential material in aerospace landing gear systems due to its superior mechanical properties, its environmental impact throughout its lifecycle is significant. Balancing the material's performance benefits with environmental considerations will be crucial for the sustainable development of the aerospace industry in the coming years.

Regulatory Standards for Aerospace Landing Gear Materials

Regulatory standards for aerospace landing gear materials are critical in ensuring the safety, reliability, and performance of aircraft. These standards are established and enforced by various international and national aviation authorities, with the Federal Aviation Administration (FAA) and the European Union Aviation Safety Agency (EASA) being two of the most prominent regulatory bodies.

The FAA's Federal Aviation Regulations (FARs) and EASA's Certification Specifications (CS) provide comprehensive guidelines for the design, manufacture, and maintenance of landing gear systems. Specifically, FAR Part 25 and CS-25 address the airworthiness standards for transport category airplanes, including requirements for landing gear materials.

These regulations mandate that landing gear materials must meet stringent criteria for strength, durability, and resistance to fatigue and corrosion. The materials used in aerospace landing gear systems, such as 4140 steel, must undergo rigorous testing and certification processes to ensure compliance with these standards.

One of the key requirements is the ability of the material to withstand the extreme loads and stresses experienced during takeoff, landing, and ground operations. The regulations specify minimum factors of safety that must be met, typically ranging from 1.5 to 3.0, depending on the specific component and loading condition.

Additionally, the standards require manufacturers to demonstrate the material's resistance to environmental factors, including temperature extremes, humidity, and exposure to various chemicals and fluids commonly encountered in aerospace operations. This is particularly important for 4140 steel, which must maintain its mechanical properties across a wide range of operating conditions.

The regulations also address the need for non-destructive testing (NDT) methods to detect potential flaws or defects in landing gear components. Manufacturers must establish and follow approved inspection procedures to ensure the integrity of the materials throughout the lifecycle of the aircraft.

Furthermore, the standards emphasize the importance of material traceability and quality control. Manufacturers are required to maintain detailed records of material sourcing, heat treatment processes, and testing results for each batch of 4140 steel used in landing gear production.

To comply with these regulatory standards, aerospace companies must work closely with material suppliers and testing laboratories to ensure that 4140 steel and other landing gear materials meet or exceed the specified requirements. This often involves extensive material characterization, including mechanical property testing, microstructural analysis, and fatigue testing under simulated service conditions.

The FAA's Federal Aviation Regulations (FARs) and EASA's Certification Specifications (CS) provide comprehensive guidelines for the design, manufacture, and maintenance of landing gear systems. Specifically, FAR Part 25 and CS-25 address the airworthiness standards for transport category airplanes, including requirements for landing gear materials.

These regulations mandate that landing gear materials must meet stringent criteria for strength, durability, and resistance to fatigue and corrosion. The materials used in aerospace landing gear systems, such as 4140 steel, must undergo rigorous testing and certification processes to ensure compliance with these standards.

One of the key requirements is the ability of the material to withstand the extreme loads and stresses experienced during takeoff, landing, and ground operations. The regulations specify minimum factors of safety that must be met, typically ranging from 1.5 to 3.0, depending on the specific component and loading condition.

Additionally, the standards require manufacturers to demonstrate the material's resistance to environmental factors, including temperature extremes, humidity, and exposure to various chemicals and fluids commonly encountered in aerospace operations. This is particularly important for 4140 steel, which must maintain its mechanical properties across a wide range of operating conditions.

The regulations also address the need for non-destructive testing (NDT) methods to detect potential flaws or defects in landing gear components. Manufacturers must establish and follow approved inspection procedures to ensure the integrity of the materials throughout the lifecycle of the aircraft.

Furthermore, the standards emphasize the importance of material traceability and quality control. Manufacturers are required to maintain detailed records of material sourcing, heat treatment processes, and testing results for each batch of 4140 steel used in landing gear production.

To comply with these regulatory standards, aerospace companies must work closely with material suppliers and testing laboratories to ensure that 4140 steel and other landing gear materials meet or exceed the specified requirements. This often involves extensive material characterization, including mechanical property testing, microstructural analysis, and fatigue testing under simulated service conditions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!