High-Speed Forming Developments for Optimized 4140 Steel Use

JUL 30, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

4140 Steel Forming Evolution

The evolution of 4140 steel forming techniques has been marked by significant advancements in high-speed forming processes. Initially, traditional forming methods such as hot forging and cold working were predominantly used for 4140 steel. These processes, while effective, were often time-consuming and limited in their ability to produce complex geometries.

The introduction of computer-controlled forming equipment in the late 20th century marked a turning point in 4140 steel forming. This technology allowed for more precise control over the forming process, resulting in improved dimensional accuracy and consistency. Concurrently, advancements in material science led to a better understanding of 4140 steel's microstructure and behavior under different forming conditions, enabling the development of optimized forming parameters.

High-speed forming techniques for 4140 steel gained momentum in the early 2000s with the advent of servo-driven presses. These machines offered significantly higher stroke rates and improved energy efficiency compared to traditional hydraulic presses. The increased forming speed not only boosted productivity but also allowed for better control over the material's temperature during forming, crucial for maintaining the desired mechanical properties of 4140 steel.

Another milestone in the evolution of 4140 steel forming was the development of advanced simulation software. These tools enabled engineers to model and predict material behavior during high-speed forming processes, leading to optimized die designs and process parameters. This virtual prototyping capability significantly reduced development time and costs associated with trial-and-error approaches.

Recent years have seen the integration of artificial intelligence and machine learning algorithms into high-speed forming processes for 4140 steel. These technologies enable real-time process optimization, adapting forming parameters on-the-fly based on sensor data and predictive models. This has resulted in further improvements in part quality, reduced scrap rates, and enhanced overall process efficiency.

The latest frontier in 4140 steel forming evolution is the development of hybrid forming processes. These techniques combine multiple forming methods, such as high-speed stamping with localized heat treatment, to achieve optimal material properties and geometries that were previously unattainable. This approach has opened up new possibilities for component design and performance, particularly in high-stress applications where 4140 steel is commonly used.

The introduction of computer-controlled forming equipment in the late 20th century marked a turning point in 4140 steel forming. This technology allowed for more precise control over the forming process, resulting in improved dimensional accuracy and consistency. Concurrently, advancements in material science led to a better understanding of 4140 steel's microstructure and behavior under different forming conditions, enabling the development of optimized forming parameters.

High-speed forming techniques for 4140 steel gained momentum in the early 2000s with the advent of servo-driven presses. These machines offered significantly higher stroke rates and improved energy efficiency compared to traditional hydraulic presses. The increased forming speed not only boosted productivity but also allowed for better control over the material's temperature during forming, crucial for maintaining the desired mechanical properties of 4140 steel.

Another milestone in the evolution of 4140 steel forming was the development of advanced simulation software. These tools enabled engineers to model and predict material behavior during high-speed forming processes, leading to optimized die designs and process parameters. This virtual prototyping capability significantly reduced development time and costs associated with trial-and-error approaches.

Recent years have seen the integration of artificial intelligence and machine learning algorithms into high-speed forming processes for 4140 steel. These technologies enable real-time process optimization, adapting forming parameters on-the-fly based on sensor data and predictive models. This has resulted in further improvements in part quality, reduced scrap rates, and enhanced overall process efficiency.

The latest frontier in 4140 steel forming evolution is the development of hybrid forming processes. These techniques combine multiple forming methods, such as high-speed stamping with localized heat treatment, to achieve optimal material properties and geometries that were previously unattainable. This approach has opened up new possibilities for component design and performance, particularly in high-stress applications where 4140 steel is commonly used.

Market Demand Analysis

The market demand for high-speed forming technologies optimized for 4140 steel has been steadily increasing in recent years, driven by the automotive, aerospace, and manufacturing industries' need for stronger, lighter, and more cost-effective components. 4140 steel, known for its excellent combination of strength and toughness, has become a material of choice for many high-performance applications.

In the automotive sector, the push for fuel efficiency and reduced emissions has led to a growing demand for lightweight yet strong materials. High-speed forming of 4140 steel allows for the production of complex, thin-walled components that maintain structural integrity while reducing overall vehicle weight. This trend is expected to continue as automakers strive to meet increasingly stringent environmental regulations.

The aerospace industry has also shown significant interest in advanced forming techniques for 4140 steel. The need for precision-engineered parts with high strength-to-weight ratios has driven the adoption of high-speed forming processes. These technologies enable the production of critical components such as landing gear parts, engine mounts, and structural elements with improved performance characteristics.

In the manufacturing sector, the demand for high-speed forming of 4140 steel is being fueled by the need for increased productivity and cost reduction. Traditional forming methods often require multiple steps and post-processing, leading to longer production times and higher costs. High-speed forming techniques offer the potential to streamline production processes, reduce material waste, and improve overall efficiency.

The oil and gas industry represents another significant market for optimized 4140 steel forming. The harsh operating conditions in this sector require components with exceptional strength and corrosion resistance. High-speed forming technologies enable the production of complex downhole tools, valve components, and other critical equipment with enhanced performance and durability.

Market analysts project that the global demand for high-speed forming technologies specifically tailored for 4140 steel will continue to grow at a compound annual growth rate (CAGR) of 5-7% over the next five years. This growth is expected to be particularly strong in emerging economies, where rapid industrialization and infrastructure development are driving the need for advanced manufacturing capabilities.

The increasing focus on Industry 4.0 and smart manufacturing is also expected to boost the adoption of high-speed forming technologies for 4140 steel. These advanced processes align well with the principles of digital manufacturing, offering improved process control, real-time monitoring, and data-driven optimization. As manufacturers seek to enhance their competitiveness through technological innovation, the demand for these advanced forming solutions is likely to accelerate.

In the automotive sector, the push for fuel efficiency and reduced emissions has led to a growing demand for lightweight yet strong materials. High-speed forming of 4140 steel allows for the production of complex, thin-walled components that maintain structural integrity while reducing overall vehicle weight. This trend is expected to continue as automakers strive to meet increasingly stringent environmental regulations.

The aerospace industry has also shown significant interest in advanced forming techniques for 4140 steel. The need for precision-engineered parts with high strength-to-weight ratios has driven the adoption of high-speed forming processes. These technologies enable the production of critical components such as landing gear parts, engine mounts, and structural elements with improved performance characteristics.

In the manufacturing sector, the demand for high-speed forming of 4140 steel is being fueled by the need for increased productivity and cost reduction. Traditional forming methods often require multiple steps and post-processing, leading to longer production times and higher costs. High-speed forming techniques offer the potential to streamline production processes, reduce material waste, and improve overall efficiency.

The oil and gas industry represents another significant market for optimized 4140 steel forming. The harsh operating conditions in this sector require components with exceptional strength and corrosion resistance. High-speed forming technologies enable the production of complex downhole tools, valve components, and other critical equipment with enhanced performance and durability.

Market analysts project that the global demand for high-speed forming technologies specifically tailored for 4140 steel will continue to grow at a compound annual growth rate (CAGR) of 5-7% over the next five years. This growth is expected to be particularly strong in emerging economies, where rapid industrialization and infrastructure development are driving the need for advanced manufacturing capabilities.

The increasing focus on Industry 4.0 and smart manufacturing is also expected to boost the adoption of high-speed forming technologies for 4140 steel. These advanced processes align well with the principles of digital manufacturing, offering improved process control, real-time monitoring, and data-driven optimization. As manufacturers seek to enhance their competitiveness through technological innovation, the demand for these advanced forming solutions is likely to accelerate.

Current Challenges

The high-speed forming of 4140 steel presents several significant challenges that hinder its optimal utilization in industrial applications. One of the primary obstacles is the material's high strength and hardness, which make it resistant to rapid deformation processes. This characteristic, while beneficial for many end-use applications, complicates the forming process, often requiring higher energy inputs and specialized equipment.

Temperature control during high-speed forming is another critical challenge. The rapid deformation of 4140 steel generates substantial heat, which can lead to undesired microstructural changes and affect the final properties of the formed components. Maintaining precise temperature control throughout the forming process is essential to ensure consistent material properties and dimensional accuracy.

The strain rate sensitivity of 4140 steel poses additional complications. At high forming speeds, the material's behavior can deviate significantly from its response under conventional forming conditions. This phenomenon necessitates a deep understanding of the material's dynamic properties and the development of accurate predictive models to optimize the forming process.

Tool wear is a persistent issue in high-speed forming of 4140 steel. The material's high strength and hardness accelerate tool degradation, leading to increased production costs and potential quality issues. Developing more durable tooling materials and innovative tool designs is crucial for improving process efficiency and reducing downtime.

Another challenge lies in achieving uniform deformation across complex geometries. High-speed forming can result in non-uniform material flow, leading to variations in thickness and properties across the formed part. This is particularly problematic for components with intricate shapes or those requiring tight tolerances.

The springback effect, common in high-strength steels like 4140, is exacerbated in high-speed forming processes. Predicting and compensating for springback becomes more challenging as forming speeds increase, necessitating advanced simulation techniques and adaptive control strategies.

Lastly, the integration of high-speed forming processes for 4140 steel into existing production lines presents logistical and technical hurdles. Many manufacturing facilities are not equipped to handle the unique requirements of high-speed forming, such as rapid material handling, enhanced safety measures, and specialized quality control procedures. Overcoming these challenges requires significant investment in equipment, training, and process development.

Temperature control during high-speed forming is another critical challenge. The rapid deformation of 4140 steel generates substantial heat, which can lead to undesired microstructural changes and affect the final properties of the formed components. Maintaining precise temperature control throughout the forming process is essential to ensure consistent material properties and dimensional accuracy.

The strain rate sensitivity of 4140 steel poses additional complications. At high forming speeds, the material's behavior can deviate significantly from its response under conventional forming conditions. This phenomenon necessitates a deep understanding of the material's dynamic properties and the development of accurate predictive models to optimize the forming process.

Tool wear is a persistent issue in high-speed forming of 4140 steel. The material's high strength and hardness accelerate tool degradation, leading to increased production costs and potential quality issues. Developing more durable tooling materials and innovative tool designs is crucial for improving process efficiency and reducing downtime.

Another challenge lies in achieving uniform deformation across complex geometries. High-speed forming can result in non-uniform material flow, leading to variations in thickness and properties across the formed part. This is particularly problematic for components with intricate shapes or those requiring tight tolerances.

The springback effect, common in high-strength steels like 4140, is exacerbated in high-speed forming processes. Predicting and compensating for springback becomes more challenging as forming speeds increase, necessitating advanced simulation techniques and adaptive control strategies.

Lastly, the integration of high-speed forming processes for 4140 steel into existing production lines presents logistical and technical hurdles. Many manufacturing facilities are not equipped to handle the unique requirements of high-speed forming, such as rapid material handling, enhanced safety measures, and specialized quality control procedures. Overcoming these challenges requires significant investment in equipment, training, and process development.

Existing Forming Solutions

01 Optimizing forming speed for 4140 steel

The forming speed of 4140 steel can be optimized by considering factors such as temperature, strain rate, and microstructure. Proper control of these parameters can lead to improved formability and final product quality. Advanced process control systems and simulation tools can be used to determine the optimal forming speed for specific applications.- Optimizing forming speed for 4140 steel: The forming speed of 4140 steel can be optimized by considering factors such as temperature, strain rate, and microstructure. Proper control of these parameters can lead to improved formability and final product quality. Advanced process control systems and simulation techniques can be employed to determine the ideal forming speed for specific applications.

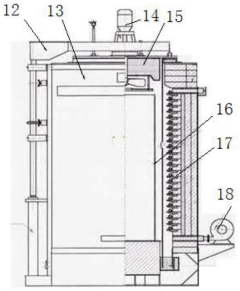

- Heat treatment effects on 4140 steel forming: Heat treatment processes, such as quenching and tempering, significantly influence the formability and mechanical properties of 4140 steel. Proper heat treatment can enhance the material's ductility and reduce the required forming force, potentially allowing for higher forming speeds. The heat treatment parameters should be carefully controlled to achieve the desired balance between strength and formability.

- Lubrication techniques for high-speed forming of 4140 steel: Effective lubrication is crucial for high-speed forming of 4140 steel. Advanced lubricants and application methods can reduce friction and heat generation during the forming process, allowing for increased forming speeds without compromising part quality. Proper lubrication can also extend tool life and improve surface finish of the formed parts.

- Tool design for rapid forming of 4140 steel: Innovative tool designs can facilitate faster forming speeds for 4140 steel. This includes optimized die geometries, advanced cooling systems, and the use of high-performance tool materials. Computer-aided engineering and simulation tools can be utilized to develop and refine tool designs that enable higher forming speeds while maintaining part quality and dimensional accuracy.

- Monitoring and control systems for high-speed 4140 steel forming: Advanced monitoring and control systems can be implemented to ensure consistent quality during high-speed forming of 4140 steel. These systems may include real-time sensors for temperature, pressure, and dimensional measurements, coupled with adaptive control algorithms. Such systems can automatically adjust forming parameters to maintain optimal speed and quality throughout the production process.

02 Heat treatment effects on 4140 steel forming

Heat treatment processes, such as quenching and tempering, can significantly influence the formability and forming speed of 4140 steel. Proper heat treatment can enhance the material's ductility and reduce the required forming force, potentially allowing for higher forming speeds. The heat treatment parameters should be carefully controlled to achieve the desired mechanical properties.Expand Specific Solutions03 Lubrication techniques for high-speed forming of 4140 steel

Effective lubrication is crucial for high-speed forming of 4140 steel. Advanced lubricants and application methods can reduce friction and heat generation during the forming process, allowing for increased forming speeds. Proper lubrication can also improve surface finish and tool life.Expand Specific Solutions04 Tool design for rapid 4140 steel forming

Specialized tool designs can facilitate faster forming speeds for 4140 steel. Features such as optimized die geometry, cooling channels, and wear-resistant coatings can improve heat dissipation and reduce friction, enabling higher forming speeds. Computer-aided design and simulation tools can be used to develop and optimize tool designs for specific applications.Expand Specific Solutions05 Monitoring and control systems for high-speed 4140 steel forming

Advanced monitoring and control systems can be implemented to maintain consistent quality during high-speed forming of 4140 steel. Real-time sensors and feedback mechanisms can detect and adjust for variations in temperature, pressure, and material flow, ensuring optimal forming conditions are maintained at higher speeds. These systems can also help prevent defects and improve overall process efficiency.Expand Specific Solutions

Key Industry Players

The high-speed forming developments for optimized 4140 steel use represent a competitive landscape in an evolving industry. The market is in a growth phase, driven by increasing demand for high-performance steel in automotive, aerospace, and industrial applications. While the market size is substantial, it's not yet reached maturity, indicating potential for further expansion. Technologically, the field is advancing rapidly, with companies like Steel Authority of India, JSW Steel, and ArcelorMittal leading innovation. These firms, along with research institutions such as Huazhong University of Science & Technology, are pushing the boundaries of 4140 steel optimization, focusing on improving formability, strength, and cost-effectiveness in high-speed forming processes.

Hitachi Ltd.

Technical Solution: Hitachi has developed an innovative high-speed forming process for 4140 steel, leveraging their expertise in materials science and advanced manufacturing technologies. Their approach combines rapid heating using high-frequency induction with precision-controlled deformation and quenching. Hitachi's process utilizes advanced robotics and AI-driven control systems to achieve high-speed forming while maintaining tight tolerances and consistent material properties[8]. The company has also developed proprietary simulation software that accurately predicts material behavior during high-speed forming, allowing for optimized process parameters and reduced development time for new components[10]. Furthermore, Hitachi has implemented advanced non-destructive testing techniques, including in-line ultrasonic inspection, to ensure the integrity of formed parts at high production rates[12].

Strengths: Integration of AI and robotics enables high-speed production with excellent precision. Advanced simulation and testing capabilities ensure product quality. Weaknesses: Complex technology integration may require specialized training and maintenance.

Tata Steel Ltd.

Technical Solution: Tata Steel has pioneered a novel approach to high-speed forming of 4140 steel, incorporating advanced thermo-mechanical processing techniques. Their method involves carefully controlled deformation at elevated temperatures, followed by rapid cooling to achieve an optimal balance of strength and ductility. The company has developed a proprietary heat treatment process that allows for the formation of a fine-grained bainitic-martensitic microstructure, resulting in improved toughness and fatigue resistance[2]. Tata Steel has also implemented in-line monitoring systems using advanced sensors and machine learning algorithms to ensure consistent quality during high-speed forming operations[4]. Furthermore, they have developed specialized surface treatments to enhance wear resistance and reduce friction during the forming process, enabling higher production speeds and improved tool life[6].

Strengths: Innovative microstructure control techniques lead to superior mechanical properties. Advanced in-line monitoring ensures consistent quality. Weaknesses: Specialized surface treatments may increase production costs.

Innovative Forming Methods

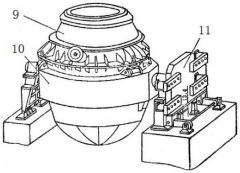

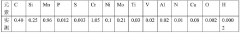

100-150mm alloy structural steel 4140 thick plate and production technique thereof

PatentActiveCN103725966A

Innovation

- KR hot metal pretreatment, converter smelting, argon blowing treatment, LF refining, VD refining, die casting, steel ingot slow cooling, steel ingot cleaning, heating, controlled rolling, stack cooling, heat treatment and slow cooling are used to strictly control the content of harmful elements in steel. And the rolling process, through multi-stage rolling and heat treatment, ensures that the internal residual stress of the steel plate is minimized and the performance indicators meet the standards.

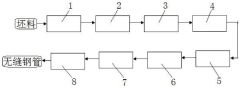

4140 medium-thick-wall seamless steel pipe and production method

PatentActiveCN113862556A

Innovation

- Using the optimized 4140 composition and the new Diesel hot rolling unit rolling combined with water quenching instead of oil quenching, medium-thick wall seamless products are produced through converter smelting, continuous casting, annealing, heating, rolling, water quenching, tempering and straightening processes. steel pipe.

Material Properties Impact

The material properties of 4140 steel play a crucial role in high-speed forming developments. This medium carbon, low alloy steel is known for its excellent combination of strength, toughness, and wear resistance, making it a popular choice in various industrial applications. However, when subjected to high-speed forming processes, the material's behavior can significantly impact the final product quality and process efficiency.

One of the key material properties affecting high-speed forming is the strain rate sensitivity of 4140 steel. As the strain rate increases during rapid deformation, the material's flow stress and yield strength tend to increase. This phenomenon, known as strain rate hardening, can lead to higher forming forces and potentially affect the final part geometry. Understanding and accounting for this behavior is essential in optimizing the forming process parameters.

The thermal properties of 4140 steel also play a significant role in high-speed forming. During rapid deformation, a substantial amount of heat is generated due to plastic work and friction. The material's thermal conductivity and specific heat capacity influence how this heat is distributed and dissipated. Localized heating can lead to changes in microstructure and mechanical properties, potentially affecting the final product's performance.

Another critical aspect is the material's microstructure and its evolution during high-speed forming. 4140 steel's initial microstructure, typically consisting of ferrite and pearlite, can undergo dynamic transformations under high strain rates and temperatures. These transformations can result in grain refinement, phase changes, or the formation of adiabatic shear bands, all of which can significantly alter the material's mechanical properties.

The surface properties of 4140 steel, including roughness and friction coefficient, also impact high-speed forming processes. These properties influence the material flow, tool wear, and the quality of the formed surface. Proper surface preparation and lubrication strategies are essential to optimize the forming process and ensure consistent product quality.

Furthermore, the material's anisotropy and texture can affect its formability and the uniformity of deformation during high-speed forming. Understanding and accounting for these directional properties is crucial in predicting and controlling the material flow and final part geometry.

In conclusion, the material properties of 4140 steel significantly influence the high-speed forming process and the quality of the final product. Optimizing these processes requires a comprehensive understanding of the material's behavior under high strain rates, elevated temperatures, and complex stress states. This knowledge forms the foundation for developing advanced forming techniques and improving process efficiency for 4140 steel applications.

One of the key material properties affecting high-speed forming is the strain rate sensitivity of 4140 steel. As the strain rate increases during rapid deformation, the material's flow stress and yield strength tend to increase. This phenomenon, known as strain rate hardening, can lead to higher forming forces and potentially affect the final part geometry. Understanding and accounting for this behavior is essential in optimizing the forming process parameters.

The thermal properties of 4140 steel also play a significant role in high-speed forming. During rapid deformation, a substantial amount of heat is generated due to plastic work and friction. The material's thermal conductivity and specific heat capacity influence how this heat is distributed and dissipated. Localized heating can lead to changes in microstructure and mechanical properties, potentially affecting the final product's performance.

Another critical aspect is the material's microstructure and its evolution during high-speed forming. 4140 steel's initial microstructure, typically consisting of ferrite and pearlite, can undergo dynamic transformations under high strain rates and temperatures. These transformations can result in grain refinement, phase changes, or the formation of adiabatic shear bands, all of which can significantly alter the material's mechanical properties.

The surface properties of 4140 steel, including roughness and friction coefficient, also impact high-speed forming processes. These properties influence the material flow, tool wear, and the quality of the formed surface. Proper surface preparation and lubrication strategies are essential to optimize the forming process and ensure consistent product quality.

Furthermore, the material's anisotropy and texture can affect its formability and the uniformity of deformation during high-speed forming. Understanding and accounting for these directional properties is crucial in predicting and controlling the material flow and final part geometry.

In conclusion, the material properties of 4140 steel significantly influence the high-speed forming process and the quality of the final product. Optimizing these processes requires a comprehensive understanding of the material's behavior under high strain rates, elevated temperatures, and complex stress states. This knowledge forms the foundation for developing advanced forming techniques and improving process efficiency for 4140 steel applications.

Environmental Considerations

The environmental impact of high-speed forming processes for 4140 steel is a critical consideration in modern manufacturing. These processes, while offering significant advantages in terms of production efficiency and material optimization, also present unique environmental challenges that must be addressed.

Energy consumption is a primary environmental concern in high-speed forming of 4140 steel. The rapid deformation rates required for these processes typically demand substantial power inputs, leading to increased energy usage and associated carbon emissions. However, recent advancements in process optimization and equipment design have shown promising results in reducing energy requirements. For instance, the implementation of regenerative braking systems in hydraulic presses has demonstrated potential energy savings of up to 30% in some applications.

Material waste reduction is another key environmental aspect of high-speed forming for 4140 steel. Traditional forming methods often result in significant material loss due to trimming and scrap generation. High-speed forming techniques, when properly optimized, can achieve near-net-shape components, minimizing waste and reducing the overall environmental footprint of the manufacturing process. Studies have shown that optimized high-speed forming can reduce material waste by up to 15% compared to conventional methods.

The use of lubricants in high-speed forming processes also poses environmental challenges. These lubricants, essential for reducing friction and wear during forming, can contain harmful chemicals that may contaminate water sources or contribute to air pollution if not properly managed. Recent research has focused on developing environmentally friendly lubricants, such as water-based formulations and biodegradable options, which offer comparable performance while minimizing ecological impact.

Noise pollution is an often-overlooked environmental consideration in high-speed forming operations. The rapid deformation of 4140 steel can generate significant noise levels, potentially affecting worker health and the surrounding environment. Implementing advanced acoustic insulation and redesigning equipment to reduce vibration can help mitigate these issues, ensuring compliance with increasingly stringent environmental regulations.

Recycling and end-of-life considerations for 4140 steel components produced through high-speed forming are also crucial environmental factors. The high-strength properties of 4140 steel make it an excellent candidate for recycling, with the potential to significantly reduce the environmental impact of raw material extraction and processing. Implementing efficient recycling systems and designing components with recyclability in mind can further enhance the environmental sustainability of high-speed forming processes for 4140 steel.

Energy consumption is a primary environmental concern in high-speed forming of 4140 steel. The rapid deformation rates required for these processes typically demand substantial power inputs, leading to increased energy usage and associated carbon emissions. However, recent advancements in process optimization and equipment design have shown promising results in reducing energy requirements. For instance, the implementation of regenerative braking systems in hydraulic presses has demonstrated potential energy savings of up to 30% in some applications.

Material waste reduction is another key environmental aspect of high-speed forming for 4140 steel. Traditional forming methods often result in significant material loss due to trimming and scrap generation. High-speed forming techniques, when properly optimized, can achieve near-net-shape components, minimizing waste and reducing the overall environmental footprint of the manufacturing process. Studies have shown that optimized high-speed forming can reduce material waste by up to 15% compared to conventional methods.

The use of lubricants in high-speed forming processes also poses environmental challenges. These lubricants, essential for reducing friction and wear during forming, can contain harmful chemicals that may contaminate water sources or contribute to air pollution if not properly managed. Recent research has focused on developing environmentally friendly lubricants, such as water-based formulations and biodegradable options, which offer comparable performance while minimizing ecological impact.

Noise pollution is an often-overlooked environmental consideration in high-speed forming operations. The rapid deformation of 4140 steel can generate significant noise levels, potentially affecting worker health and the surrounding environment. Implementing advanced acoustic insulation and redesigning equipment to reduce vibration can help mitigate these issues, ensuring compliance with increasingly stringent environmental regulations.

Recycling and end-of-life considerations for 4140 steel components produced through high-speed forming are also crucial environmental factors. The high-strength properties of 4140 steel make it an excellent candidate for recycling, with the potential to significantly reduce the environmental impact of raw material extraction and processing. Implementing efficient recycling systems and designing components with recyclability in mind can further enhance the environmental sustainability of high-speed forming processes for 4140 steel.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!