Development of Battery Management Systems for Solid-State Batteries

AUG 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

SSB BMS Tech Background

Solid-state batteries (SSBs) represent a significant leap forward in energy storage technology, promising higher energy density, improved safety, and longer lifespan compared to traditional lithium-ion batteries. The development of Battery Management Systems (BMS) for SSBs is a critical area of research and innovation, as it addresses the unique challenges and opportunities presented by this emerging technology.

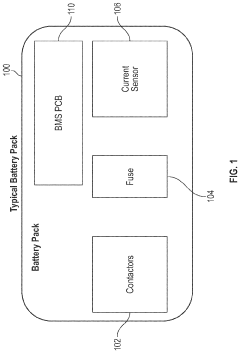

The evolution of battery management systems has been closely tied to the advancement of battery technologies. Traditional BMS were designed primarily for liquid electrolyte-based batteries, focusing on monitoring cell voltage, temperature, and state of charge. However, the introduction of solid-state batteries has necessitated a paradigm shift in BMS design and functionality.

SSBs utilize solid electrolytes instead of liquid ones, which fundamentally alters the electrochemical processes within the battery. This change impacts various aspects of battery management, including thermal regulation, charge/discharge control, and safety monitoring. As a result, BMS for SSBs must be re-engineered to account for these differences and optimize battery performance.

One of the key challenges in developing BMS for SSBs is accurately measuring and predicting the state of charge (SOC) and state of health (SOH). The solid electrolyte's behavior differs significantly from liquid electrolytes, requiring new algorithms and sensing technologies to provide accurate real-time data on battery status.

Thermal management is another critical area where SSB BMS diverges from traditional systems. While SSBs generally operate at higher temperatures than conventional lithium-ion batteries, they also have different thermal characteristics and requirements. BMS for SSBs must be capable of precise temperature control to maintain optimal operating conditions and prevent thermal runaway.

The integration of advanced sensors and monitoring systems is crucial for SSB BMS development. These systems must be capable of detecting minute changes in battery parameters, such as internal resistance and ion conductivity, which are key indicators of battery health and performance in solid-state configurations.

As the technology progresses, there is a growing focus on developing intelligent BMS that incorporate machine learning and artificial intelligence. These advanced systems aim to improve predictive maintenance, optimize charging strategies, and enhance overall battery life and performance for SSBs.

The development of BMS for solid-state batteries is not only a technological challenge but also a strategic imperative for companies looking to lead in the next generation of energy storage solutions. As such, it represents a critical area of research and development in the broader context of sustainable energy and electric mobility.

The evolution of battery management systems has been closely tied to the advancement of battery technologies. Traditional BMS were designed primarily for liquid electrolyte-based batteries, focusing on monitoring cell voltage, temperature, and state of charge. However, the introduction of solid-state batteries has necessitated a paradigm shift in BMS design and functionality.

SSBs utilize solid electrolytes instead of liquid ones, which fundamentally alters the electrochemical processes within the battery. This change impacts various aspects of battery management, including thermal regulation, charge/discharge control, and safety monitoring. As a result, BMS for SSBs must be re-engineered to account for these differences and optimize battery performance.

One of the key challenges in developing BMS for SSBs is accurately measuring and predicting the state of charge (SOC) and state of health (SOH). The solid electrolyte's behavior differs significantly from liquid electrolytes, requiring new algorithms and sensing technologies to provide accurate real-time data on battery status.

Thermal management is another critical area where SSB BMS diverges from traditional systems. While SSBs generally operate at higher temperatures than conventional lithium-ion batteries, they also have different thermal characteristics and requirements. BMS for SSBs must be capable of precise temperature control to maintain optimal operating conditions and prevent thermal runaway.

The integration of advanced sensors and monitoring systems is crucial for SSB BMS development. These systems must be capable of detecting minute changes in battery parameters, such as internal resistance and ion conductivity, which are key indicators of battery health and performance in solid-state configurations.

As the technology progresses, there is a growing focus on developing intelligent BMS that incorporate machine learning and artificial intelligence. These advanced systems aim to improve predictive maintenance, optimize charging strategies, and enhance overall battery life and performance for SSBs.

The development of BMS for solid-state batteries is not only a technological challenge but also a strategic imperative for companies looking to lead in the next generation of energy storage solutions. As such, it represents a critical area of research and development in the broader context of sustainable energy and electric mobility.

SSB Market Analysis

The solid-state battery (SSB) market is experiencing rapid growth and attracting significant attention from both established players and new entrants in the energy storage sector. This emerging technology promises to revolutionize the battery industry by offering higher energy density, improved safety, and longer lifespan compared to traditional lithium-ion batteries. The global SSB market is projected to expand at a compound annual growth rate (CAGR) of over 30% in the coming years, driven by increasing demand for electric vehicles (EVs) and portable electronic devices.

The automotive industry is expected to be the primary driver of SSB market growth, as major automakers are investing heavily in this technology to overcome the limitations of current EV batteries. The push for longer driving ranges, faster charging times, and enhanced safety features aligns perfectly with the advantages offered by solid-state batteries. Several leading car manufacturers have announced plans to incorporate SSBs into their future EV models, which is likely to accelerate market adoption and technological advancements.

Consumer electronics represent another significant market segment for SSBs. The demand for longer-lasting, more compact, and safer batteries in smartphones, laptops, and wearable devices is fueling research and development efforts in this area. As SSB technology matures and production costs decrease, it is anticipated that these batteries will gradually replace conventional lithium-ion batteries in a wide range of portable devices.

The energy storage sector is also showing keen interest in SSB technology. Grid-scale energy storage systems could benefit from the improved safety and longer cycle life of SSBs, potentially reducing maintenance costs and enhancing overall system reliability. This application is particularly relevant in the context of renewable energy integration and grid stabilization.

Geographically, Asia-Pacific is expected to dominate the SSB market, with Japan and South Korea leading in terms of technological advancements and patent filings. North America and Europe are also significant players, with substantial investments in research and development. The market landscape is characterized by a mix of established battery manufacturers, automotive companies, and technology startups, all vying for a competitive edge in this rapidly evolving field.

Despite the promising outlook, several challenges need to be addressed before widespread commercialization of SSBs can be achieved. These include scaling up production processes, reducing manufacturing costs, and overcoming technical hurdles related to interface stability and ion conductivity. The development of efficient and reliable battery management systems (BMS) specifically tailored for SSBs is crucial to fully realize their potential and ensure optimal performance and safety in various applications.

The automotive industry is expected to be the primary driver of SSB market growth, as major automakers are investing heavily in this technology to overcome the limitations of current EV batteries. The push for longer driving ranges, faster charging times, and enhanced safety features aligns perfectly with the advantages offered by solid-state batteries. Several leading car manufacturers have announced plans to incorporate SSBs into their future EV models, which is likely to accelerate market adoption and technological advancements.

Consumer electronics represent another significant market segment for SSBs. The demand for longer-lasting, more compact, and safer batteries in smartphones, laptops, and wearable devices is fueling research and development efforts in this area. As SSB technology matures and production costs decrease, it is anticipated that these batteries will gradually replace conventional lithium-ion batteries in a wide range of portable devices.

The energy storage sector is also showing keen interest in SSB technology. Grid-scale energy storage systems could benefit from the improved safety and longer cycle life of SSBs, potentially reducing maintenance costs and enhancing overall system reliability. This application is particularly relevant in the context of renewable energy integration and grid stabilization.

Geographically, Asia-Pacific is expected to dominate the SSB market, with Japan and South Korea leading in terms of technological advancements and patent filings. North America and Europe are also significant players, with substantial investments in research and development. The market landscape is characterized by a mix of established battery manufacturers, automotive companies, and technology startups, all vying for a competitive edge in this rapidly evolving field.

Despite the promising outlook, several challenges need to be addressed before widespread commercialization of SSBs can be achieved. These include scaling up production processes, reducing manufacturing costs, and overcoming technical hurdles related to interface stability and ion conductivity. The development of efficient and reliable battery management systems (BMS) specifically tailored for SSBs is crucial to fully realize their potential and ensure optimal performance and safety in various applications.

SSB BMS Challenges

The development of Battery Management Systems (BMS) for Solid-State Batteries (SSBs) presents several unique challenges that differ from those encountered in traditional lithium-ion battery systems. One of the primary obstacles is the accurate measurement and estimation of the State of Charge (SOC) in SSBs. Unlike liquid electrolyte batteries, SSBs exhibit different voltage-SOC relationships, making conventional estimation methods less effective.

Temperature management poses another significant challenge for SSB BMS. While SSBs generally operate at higher temperatures than their liquid counterparts, they are more sensitive to temperature fluctuations. This necessitates the development of advanced thermal management strategies within the BMS to maintain optimal operating conditions and prevent thermal runaway.

The solid electrolyte in SSBs introduces complexities in monitoring internal resistance and impedance. Traditional techniques for measuring these parameters may not be directly applicable, requiring innovative approaches to assess battery health and performance accurately. This challenge extends to the development of new algorithms for State of Health (SOH) estimation, as the degradation mechanisms in SSBs differ from those in conventional batteries.

Safety monitoring and control systems for SSBs also present unique challenges. While SSBs are generally considered safer due to their non-flammable electrolytes, they still require robust safety measures. The BMS must be capable of detecting and mitigating potential issues such as dendrite formation or mechanical stress, which can lead to internal short circuits or cell failure.

Another critical challenge lies in the cell balancing strategies for SSB packs. The solid electrolyte's properties can lead to variations in cell performance within a pack, necessitating more sophisticated balancing algorithms to ensure uniform charge distribution and maximize overall pack performance and lifespan.

The integration of SSB BMS with existing vehicle systems presents interoperability challenges. As SSBs have different charging profiles and performance characteristics, the BMS must be designed to communicate effectively with other vehicle subsystems, ensuring seamless operation and optimal energy management.

Lastly, the development of predictive maintenance capabilities for SSB BMS is crucial yet challenging. The unique aging and degradation patterns of SSBs require new models and algorithms to accurately predict battery life and performance over time, enabling proactive maintenance and optimized battery utilization in various applications.

Temperature management poses another significant challenge for SSB BMS. While SSBs generally operate at higher temperatures than their liquid counterparts, they are more sensitive to temperature fluctuations. This necessitates the development of advanced thermal management strategies within the BMS to maintain optimal operating conditions and prevent thermal runaway.

The solid electrolyte in SSBs introduces complexities in monitoring internal resistance and impedance. Traditional techniques for measuring these parameters may not be directly applicable, requiring innovative approaches to assess battery health and performance accurately. This challenge extends to the development of new algorithms for State of Health (SOH) estimation, as the degradation mechanisms in SSBs differ from those in conventional batteries.

Safety monitoring and control systems for SSBs also present unique challenges. While SSBs are generally considered safer due to their non-flammable electrolytes, they still require robust safety measures. The BMS must be capable of detecting and mitigating potential issues such as dendrite formation or mechanical stress, which can lead to internal short circuits or cell failure.

Another critical challenge lies in the cell balancing strategies for SSB packs. The solid electrolyte's properties can lead to variations in cell performance within a pack, necessitating more sophisticated balancing algorithms to ensure uniform charge distribution and maximize overall pack performance and lifespan.

The integration of SSB BMS with existing vehicle systems presents interoperability challenges. As SSBs have different charging profiles and performance characteristics, the BMS must be designed to communicate effectively with other vehicle subsystems, ensuring seamless operation and optimal energy management.

Lastly, the development of predictive maintenance capabilities for SSB BMS is crucial yet challenging. The unique aging and degradation patterns of SSBs require new models and algorithms to accurately predict battery life and performance over time, enabling proactive maintenance and optimized battery utilization in various applications.

Current SSB BMS Solutions

01 Thermal management for solid-state batteries

Battery management systems for solid-state batteries incorporate advanced thermal management techniques. These systems monitor and control temperature distribution within the battery to optimize performance, prevent thermal runaway, and extend battery life. Thermal management strategies may include active cooling systems, heat dissipation mechanisms, and temperature sensors integrated throughout the battery pack.- Thermal management for solid-state batteries: Battery management systems for solid-state batteries incorporate advanced thermal management techniques. These systems monitor and control temperature distribution within the battery to optimize performance, prevent thermal runaway, and extend battery life. Thermal management strategies may include active cooling systems, heat dissipation mechanisms, and temperature sensors integrated throughout the battery pack.

- State of charge estimation for solid-state batteries: Accurate state of charge (SOC) estimation is crucial for solid-state battery management. Advanced algorithms and sensing techniques are employed to determine the battery's charge level, considering the unique characteristics of solid-state electrolytes. These systems may use voltage measurements, current integration, and impedance spectroscopy to provide precise SOC information, enabling efficient battery utilization and preventing overcharging or deep discharging.

- Safety monitoring and protection systems: Battery management systems for solid-state batteries incorporate advanced safety features to prevent potential hazards. These systems continuously monitor various parameters such as voltage, current, and internal resistance to detect abnormalities. In case of any irregularities, protective measures are activated, which may include disconnecting the battery, limiting current flow, or initiating emergency shutdown procedures to ensure safe operation.

- Cell balancing techniques for solid-state battery packs: Efficient cell balancing is essential for maximizing the performance and lifespan of solid-state battery packs. Battery management systems employ sophisticated balancing algorithms to ensure uniform charge distribution across all cells. This may involve active or passive balancing techniques, considering the unique characteristics of solid-state cells, to prevent capacity degradation and extend overall battery life.

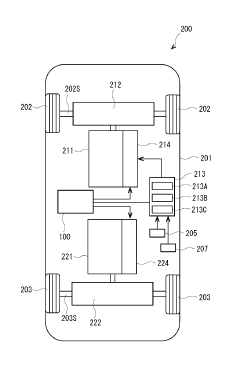

- Integration with vehicle systems and charging infrastructure: Battery management systems for solid-state batteries in electric vehicles are designed to integrate seamlessly with other vehicle systems and charging infrastructure. These systems optimize charging processes, manage power distribution during vehicle operation, and communicate with external charging stations. They may also incorporate predictive algorithms to estimate range and adjust vehicle performance based on battery conditions and driving patterns.

02 State of charge estimation for solid-state batteries

Accurate state of charge (SOC) estimation is crucial for solid-state battery management. Advanced algorithms and sensing techniques are employed to determine the battery's charge level, considering the unique characteristics of solid-state electrolytes. These systems may use voltage measurements, current integration, and impedance spectroscopy to provide precise SOC information, enabling efficient battery utilization and preventing over-discharge or overcharge.Expand Specific Solutions03 Cell balancing and voltage management

Battery management systems for solid-state batteries implement sophisticated cell balancing and voltage management techniques. These systems ensure uniform charge distribution across multiple cells, preventing capacity imbalances and extending overall battery life. Advanced voltage monitoring and control mechanisms are employed to maintain each cell within its optimal operating range, considering the specific voltage characteristics of solid-state electrolytes.Expand Specific Solutions04 Safety monitoring and fault detection

Safety is a critical aspect of solid-state battery management systems. These systems incorporate advanced monitoring and fault detection mechanisms to identify potential issues such as internal short circuits, electrolyte degradation, or mechanical stress. Real-time diagnostics and predictive analytics are employed to detect anomalies and trigger appropriate safety measures, ensuring the safe operation of solid-state batteries in various applications.Expand Specific Solutions05 Integration with power electronics and charging systems

Battery management systems for solid-state batteries are designed to seamlessly integrate with power electronics and charging systems. These systems optimize charging protocols to suit the unique characteristics of solid-state electrolytes, potentially enabling faster charging rates and improved efficiency. Advanced power management techniques are implemented to regulate power flow between the battery, charging infrastructure, and connected devices or vehicles.Expand Specific Solutions

Key SSB BMS Players

The development of Battery Management Systems (BMS) for Solid-State Batteries is in an early growth stage, with significant market potential as the automotive industry shifts towards electrification. The market size is expanding rapidly, driven by increasing demand for high-performance, safe, and long-lasting energy storage solutions. Technologically, the field is still evolving, with companies like LG Energy Solution, LG Chem, and Contemporary Amperex Technology Co. (CATL) leading the charge in research and development. These firms are investing heavily in advancing BMS technology for solid-state batteries, aiming to overcome challenges related to thermal management, cell balancing, and overall system efficiency. Other players like Samsung SDI and Stellantis are also making strides, indicating a competitive and dynamic landscape in this emerging sector.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has developed a comprehensive BMS for solid-state batteries, focusing on enhancing safety and performance. Their system employs machine learning algorithms to adapt to the unique characteristics of solid-state cells, including their higher energy density and different thermal properties[3]. The BMS features a sophisticated thermal management system that maintains optimal operating temperatures for solid-state batteries, which is crucial for their performance and longevity. LG's solution also includes advanced cell balancing techniques to ensure uniform degradation across the battery pack, extending overall lifespan[4]. The system incorporates predictive maintenance capabilities, using data analytics to forecast potential issues before they occur.

Strengths: Advanced thermal management, adaptive machine learning algorithms, and predictive maintenance capabilities. Weaknesses: May require significant computational resources, potentially increasing system complexity and cost.

ABB Group

Technical Solution: ABB has developed a robust BMS for solid-state batteries, focusing on industrial and grid-scale applications. Their system incorporates advanced power electronics and control algorithms to manage large-scale solid-state battery installations efficiently[9]. The BMS features a distributed architecture that allows for seamless scalability from small to utility-scale battery systems. ABB's solution includes sophisticated grid integration capabilities, enabling solid-state batteries to provide ancillary services such as frequency regulation and voltage support[10]. The system also incorporates predictive maintenance features and advanced diagnostics to ensure optimal performance and longevity of solid-state battery installations in demanding industrial environments.

Strengths: Scalable architecture, advanced grid integration capabilities, and robust design for industrial applications. Weaknesses: May be overly complex for smaller-scale or mobile applications, and could require specialized expertise for implementation and maintenance.

SSB BMS Core Tech

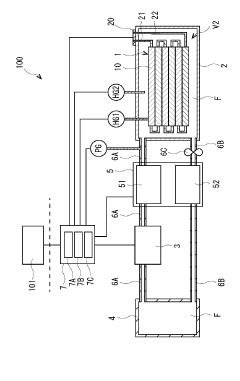

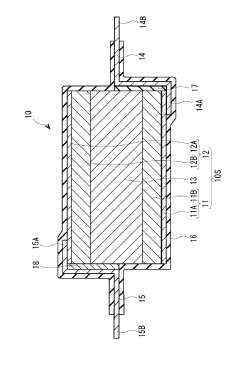

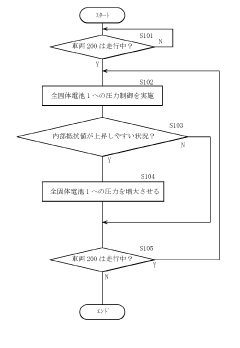

All-solid-state battery control system

PatentActiveJP2022163356A

Innovation

- An all-solid-state battery control system that applies pressure to the battery via a fluid medium, controlled by a unit that adjusts pressure based on temperature and State Of Charge (SOC) to stabilize ionic conductivity.

Solid-State Battery Management System for High Current Applications

PatentPendingUS20230395876A1

Innovation

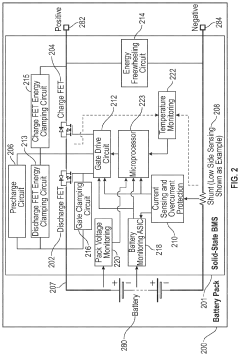

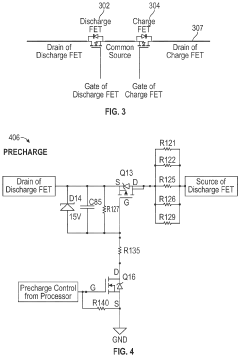

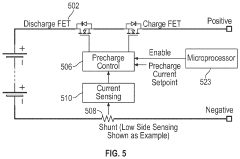

- Integration of solid-state FETs, current sensing, and other battery management components onto a single printed circuit board assembly (PCBA) with advanced monitoring, driving, protection, and thermal management systems, including solid-state precharge circuits, fast gate turn-off circuits, energy clamping, and redundant overcharge/overvoltage detection, to enhance efficiency, reliability, and safety.

SSB Safety Regulations

The development of solid-state batteries (SSBs) has brought new challenges to the field of battery safety regulations. As these innovative energy storage devices gain traction, regulatory bodies are working to establish comprehensive safety standards tailored to their unique characteristics.

One of the primary focuses of SSB safety regulations is addressing the potential risks associated with the solid electrolyte. Unlike traditional lithium-ion batteries with liquid electrolytes, SSBs use solid materials, which can reduce the risk of leakage and thermal runaway. However, new safety concerns arise, such as the formation of dendrites and mechanical stress on the solid electrolyte. Regulatory frameworks are being developed to ensure manufacturers implement appropriate safeguards against these specific risks.

Thermal management is another critical aspect of SSB safety regulations. While SSBs generally have better thermal stability than their liquid counterparts, they still require careful temperature control. Regulatory bodies are establishing guidelines for thermal management systems, including specifications for heat dissipation mechanisms and temperature monitoring protocols.

The charging and discharging processes of SSBs also require specific safety considerations. Regulations are being formulated to address the unique voltage and current characteristics of SSBs, ensuring that battery management systems (BMS) are designed to prevent overcharging, over-discharging, and other potential hazards specific to solid-state technology.

Manufacturing processes for SSBs are subject to stringent quality control regulations. These include guidelines for material purity, assembly techniques, and testing procedures to ensure the integrity of the solid electrolyte and other components. Regulatory bodies are working closely with industry experts to develop standards that balance safety requirements with manufacturing feasibility.

Transportation and storage regulations for SSBs are also being adapted. While SSBs offer improved safety in these areas compared to traditional batteries, specific protocols are being established for handling, packaging, and shipping to address their unique properties and potential failure modes.

As the technology evolves, safety regulations for SSBs are expected to become more refined. Regulatory bodies are adopting a proactive approach, collaborating with researchers, manufacturers, and industry stakeholders to stay ahead of potential safety issues. This collaborative effort aims to create a robust regulatory framework that fosters innovation while ensuring the highest standards of safety for solid-state battery technology.

One of the primary focuses of SSB safety regulations is addressing the potential risks associated with the solid electrolyte. Unlike traditional lithium-ion batteries with liquid electrolytes, SSBs use solid materials, which can reduce the risk of leakage and thermal runaway. However, new safety concerns arise, such as the formation of dendrites and mechanical stress on the solid electrolyte. Regulatory frameworks are being developed to ensure manufacturers implement appropriate safeguards against these specific risks.

Thermal management is another critical aspect of SSB safety regulations. While SSBs generally have better thermal stability than their liquid counterparts, they still require careful temperature control. Regulatory bodies are establishing guidelines for thermal management systems, including specifications for heat dissipation mechanisms and temperature monitoring protocols.

The charging and discharging processes of SSBs also require specific safety considerations. Regulations are being formulated to address the unique voltage and current characteristics of SSBs, ensuring that battery management systems (BMS) are designed to prevent overcharging, over-discharging, and other potential hazards specific to solid-state technology.

Manufacturing processes for SSBs are subject to stringent quality control regulations. These include guidelines for material purity, assembly techniques, and testing procedures to ensure the integrity of the solid electrolyte and other components. Regulatory bodies are working closely with industry experts to develop standards that balance safety requirements with manufacturing feasibility.

Transportation and storage regulations for SSBs are also being adapted. While SSBs offer improved safety in these areas compared to traditional batteries, specific protocols are being established for handling, packaging, and shipping to address their unique properties and potential failure modes.

As the technology evolves, safety regulations for SSBs are expected to become more refined. Regulatory bodies are adopting a proactive approach, collaborating with researchers, manufacturers, and industry stakeholders to stay ahead of potential safety issues. This collaborative effort aims to create a robust regulatory framework that fosters innovation while ensuring the highest standards of safety for solid-state battery technology.

SSB BMS Integration

The integration of Battery Management Systems (BMS) with Solid-State Batteries (SSBs) presents unique challenges and opportunities in the evolving landscape of energy storage technologies. SSBs offer significant advantages over traditional lithium-ion batteries, including higher energy density, improved safety, and longer lifespan. However, their distinct characteristics necessitate specialized BMS solutions to optimize performance and ensure reliable operation.

One of the primary considerations in SSB BMS integration is the management of temperature. Unlike liquid electrolyte batteries, SSBs operate optimally at elevated temperatures, typically between 60°C and 100°C. The BMS must incorporate advanced thermal management strategies to maintain this temperature range consistently across the battery pack. This may involve the implementation of active heating systems during startup and low-temperature conditions, as well as efficient cooling mechanisms to prevent overheating during high-load scenarios.

Voltage monitoring and balancing in SSB systems require a different approach compared to conventional batteries. The solid electrolyte in SSBs exhibits higher resistance, which can lead to more pronounced voltage gradients across cells. BMS designs must account for these variations and employ sophisticated cell balancing techniques to ensure uniform charge distribution and prevent localized stress on individual cells.

State of charge (SOC) and state of health (SOH) estimation algorithms for SSBs are still in the early stages of development. The unique electrochemical properties of solid electrolytes necessitate the creation of new models and estimation techniques. BMS developers are exploring machine learning and artificial intelligence approaches to improve the accuracy of SOC and SOH predictions, taking into account factors such as temperature, cycling history, and internal resistance changes specific to SSBs.

Safety management is another critical aspect of SSB BMS integration. While SSBs are inherently safer than liquid electrolyte batteries due to their non-flammable nature, they still require robust safety protocols. The BMS must monitor for potential issues such as dendrite formation, which can lead to internal short circuits. Additionally, mechanical stress monitoring becomes crucial, as SSBs are more susceptible to damage from physical deformation.

The integration of SSB BMS also presents opportunities for enhanced data analytics and predictive maintenance. With the potential for longer lifespans, SSB systems can benefit from advanced prognostics and health management algorithms implemented within the BMS. These algorithms can analyze long-term trends in battery performance and predict maintenance needs or potential failures before they occur.

As SSB technology continues to mature, BMS integration efforts are focusing on standardization and scalability. Developing modular BMS architectures that can adapt to various SSB chemistries and form factors will be essential for widespread adoption. This includes creating flexible communication protocols and interfaces that can accommodate the unique requirements of different SSB designs while maintaining compatibility with existing battery management ecosystems.

One of the primary considerations in SSB BMS integration is the management of temperature. Unlike liquid electrolyte batteries, SSBs operate optimally at elevated temperatures, typically between 60°C and 100°C. The BMS must incorporate advanced thermal management strategies to maintain this temperature range consistently across the battery pack. This may involve the implementation of active heating systems during startup and low-temperature conditions, as well as efficient cooling mechanisms to prevent overheating during high-load scenarios.

Voltage monitoring and balancing in SSB systems require a different approach compared to conventional batteries. The solid electrolyte in SSBs exhibits higher resistance, which can lead to more pronounced voltage gradients across cells. BMS designs must account for these variations and employ sophisticated cell balancing techniques to ensure uniform charge distribution and prevent localized stress on individual cells.

State of charge (SOC) and state of health (SOH) estimation algorithms for SSBs are still in the early stages of development. The unique electrochemical properties of solid electrolytes necessitate the creation of new models and estimation techniques. BMS developers are exploring machine learning and artificial intelligence approaches to improve the accuracy of SOC and SOH predictions, taking into account factors such as temperature, cycling history, and internal resistance changes specific to SSBs.

Safety management is another critical aspect of SSB BMS integration. While SSBs are inherently safer than liquid electrolyte batteries due to their non-flammable nature, they still require robust safety protocols. The BMS must monitor for potential issues such as dendrite formation, which can lead to internal short circuits. Additionally, mechanical stress monitoring becomes crucial, as SSBs are more susceptible to damage from physical deformation.

The integration of SSB BMS also presents opportunities for enhanced data analytics and predictive maintenance. With the potential for longer lifespans, SSB systems can benefit from advanced prognostics and health management algorithms implemented within the BMS. These algorithms can analyze long-term trends in battery performance and predict maintenance needs or potential failures before they occur.

As SSB technology continues to mature, BMS integration efforts are focusing on standardization and scalability. Developing modular BMS architectures that can adapt to various SSB chemistries and form factors will be essential for widespread adoption. This includes creating flexible communication protocols and interfaces that can accommodate the unique requirements of different SSB designs while maintaining compatibility with existing battery management ecosystems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!