DisplayPort 2.1 Cable/Active Cable Choices: E-Marker Data, Attenuation And Latency

SEP 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DisplayPort 2.1 Evolution and Technical Objectives

DisplayPort technology has evolved significantly since its introduction by VESA in 2006, progressing through multiple iterations to address increasing bandwidth demands for high-resolution displays. The evolution from DisplayPort 1.0 to the current 2.1 specification represents a continuous effort to enhance digital display connectivity while maintaining backward compatibility with previous versions.

DisplayPort 2.1, released in late 2022, builds upon the foundation established by DisplayPort 2.0, which was introduced in 2019. This latest iteration maintains the impressive 80 Gbps maximum bandwidth of its predecessor while implementing critical refinements to cable specifications and signal integrity requirements. The primary technical advancement in DisplayPort 2.1 is the standardization with USB Type-C and USB4 physical layer specifications, creating a more unified ecosystem across different connection types.

The evolution of DisplayPort technology has been driven by several key factors, including the increasing resolution and refresh rates of modern displays, the growing demand for multiple monitor setups, and the need for enhanced features such as HDR content support. The transition from DisplayPort 1.4 to 2.0/2.1 represented a particularly significant leap, with nearly a threefold increase in bandwidth capacity to accommodate 8K and beyond display requirements.

A critical aspect of DisplayPort 2.1's technical objectives centers on cable performance and reliability. The specification introduces more stringent requirements for cable certification, particularly focusing on E-marker data implementation, signal attenuation management, and latency optimization. These elements are essential for ensuring reliable high-bandwidth data transmission across various cable lengths and types.

The E-marker (Electronic Marker) component in DisplayPort 2.1 cables serves as an embedded chip that stores and communicates critical cable specifications, capabilities, and authentication data. This information enables source devices to adjust transmission parameters optimally for each specific cable, ensuring signal integrity across the connection pathway.

Signal attenuation, which increases with cable length and frequency, presents a significant challenge for DisplayPort 2.1's high-bandwidth operation. The technical objectives include developing solutions that can maintain signal quality over practical cable lengths while supporting the full bandwidth potential of the specification. This has led to innovations in both passive cable design and active cable technologies that incorporate signal boosting capabilities.

Latency management represents another key technical objective, as the increased data rates in DisplayPort 2.1 require precise timing control to prevent data corruption and display artifacts. The specification aims to minimize processing delays in both the cable and connected devices, ensuring a seamless visual experience even with the most demanding content.

DisplayPort 2.1, released in late 2022, builds upon the foundation established by DisplayPort 2.0, which was introduced in 2019. This latest iteration maintains the impressive 80 Gbps maximum bandwidth of its predecessor while implementing critical refinements to cable specifications and signal integrity requirements. The primary technical advancement in DisplayPort 2.1 is the standardization with USB Type-C and USB4 physical layer specifications, creating a more unified ecosystem across different connection types.

The evolution of DisplayPort technology has been driven by several key factors, including the increasing resolution and refresh rates of modern displays, the growing demand for multiple monitor setups, and the need for enhanced features such as HDR content support. The transition from DisplayPort 1.4 to 2.0/2.1 represented a particularly significant leap, with nearly a threefold increase in bandwidth capacity to accommodate 8K and beyond display requirements.

A critical aspect of DisplayPort 2.1's technical objectives centers on cable performance and reliability. The specification introduces more stringent requirements for cable certification, particularly focusing on E-marker data implementation, signal attenuation management, and latency optimization. These elements are essential for ensuring reliable high-bandwidth data transmission across various cable lengths and types.

The E-marker (Electronic Marker) component in DisplayPort 2.1 cables serves as an embedded chip that stores and communicates critical cable specifications, capabilities, and authentication data. This information enables source devices to adjust transmission parameters optimally for each specific cable, ensuring signal integrity across the connection pathway.

Signal attenuation, which increases with cable length and frequency, presents a significant challenge for DisplayPort 2.1's high-bandwidth operation. The technical objectives include developing solutions that can maintain signal quality over practical cable lengths while supporting the full bandwidth potential of the specification. This has led to innovations in both passive cable design and active cable technologies that incorporate signal boosting capabilities.

Latency management represents another key technical objective, as the increased data rates in DisplayPort 2.1 require precise timing control to prevent data corruption and display artifacts. The specification aims to minimize processing delays in both the cable and connected devices, ensuring a seamless visual experience even with the most demanding content.

Market Analysis for High-Speed Display Connectivity

The high-speed display connectivity market is experiencing robust growth driven by increasing demand for higher resolution displays, faster refresh rates, and enhanced visual experiences across multiple sectors. The global market for high-speed display interfaces, including DisplayPort, HDMI, and USB-C with alt mode, is projected to reach $2.3 billion by 2026, growing at a CAGR of 8.7% from 2021.

DisplayPort technology, particularly the latest 2.1 standard, is gaining significant traction in professional and high-end consumer segments. Market research indicates that DisplayPort-enabled devices are expected to grow at a faster rate than the overall display connectivity market, with an estimated CAGR of 11.2% through 2025, primarily due to its superior bandwidth capabilities and feature set.

The demand for high-performance cables supporting DisplayPort 2.1 specifications is being driven by several key market segments. The professional graphics and video production industry represents approximately 28% of the high-speed cable market, where uncompromised visual fidelity and color accuracy are essential requirements. Gaming enthusiasts constitute another 23% of the market, with their need for high refresh rates and low latency connections.

Enterprise and commercial applications account for roughly 32% of the market, where multi-monitor setups and high-resolution displays are becoming standard for productivity enhancement. The remaining market share is distributed among medical imaging, digital signage, and other specialized applications requiring superior display performance.

Regional analysis shows North America leading the market with 38% share, followed by Asia-Pacific at 34%, Europe at 22%, and the rest of the world at 6%. China has emerged as the largest manufacturing hub for DisplayPort cables, while South Korea and Taiwan dominate the active cable component production.

The pricing structure for DisplayPort 2.1 cables varies significantly based on cable type, with passive cables ranging from $15-45 and active cables commanding premium prices between $60-120 depending on length and feature set. The market for active cables specifically is growing at 14.3% annually, outpacing passive cables due to increasing demand for longer cable runs and guaranteed performance at maximum bandwidth.

Consumer purchasing behavior indicates a growing awareness of cable quality importance, with 67% of professional users willing to pay premium prices for certified cables that guarantee full DisplayPort 2.1 performance specifications, particularly regarding attenuation characteristics and latency performance.

DisplayPort technology, particularly the latest 2.1 standard, is gaining significant traction in professional and high-end consumer segments. Market research indicates that DisplayPort-enabled devices are expected to grow at a faster rate than the overall display connectivity market, with an estimated CAGR of 11.2% through 2025, primarily due to its superior bandwidth capabilities and feature set.

The demand for high-performance cables supporting DisplayPort 2.1 specifications is being driven by several key market segments. The professional graphics and video production industry represents approximately 28% of the high-speed cable market, where uncompromised visual fidelity and color accuracy are essential requirements. Gaming enthusiasts constitute another 23% of the market, with their need for high refresh rates and low latency connections.

Enterprise and commercial applications account for roughly 32% of the market, where multi-monitor setups and high-resolution displays are becoming standard for productivity enhancement. The remaining market share is distributed among medical imaging, digital signage, and other specialized applications requiring superior display performance.

Regional analysis shows North America leading the market with 38% share, followed by Asia-Pacific at 34%, Europe at 22%, and the rest of the world at 6%. China has emerged as the largest manufacturing hub for DisplayPort cables, while South Korea and Taiwan dominate the active cable component production.

The pricing structure for DisplayPort 2.1 cables varies significantly based on cable type, with passive cables ranging from $15-45 and active cables commanding premium prices between $60-120 depending on length and feature set. The market for active cables specifically is growing at 14.3% annually, outpacing passive cables due to increasing demand for longer cable runs and guaranteed performance at maximum bandwidth.

Consumer purchasing behavior indicates a growing awareness of cable quality importance, with 67% of professional users willing to pay premium prices for certified cables that guarantee full DisplayPort 2.1 performance specifications, particularly regarding attenuation characteristics and latency performance.

DisplayPort 2.1 Cable Technology Challenges

DisplayPort 2.1 technology represents a significant advancement in digital display connectivity, supporting ultra-high bandwidth requirements for modern visual applications. However, the implementation of this standard faces several critical technical challenges that must be addressed to ensure optimal performance and reliability.

The primary challenge lies in signal integrity maintenance across the cable length. As DisplayPort 2.1 supports data rates up to 80 Gbps using UHBR (Ultra High Bit Rate) specifications, signal degradation becomes increasingly problematic. Attenuation, which increases proportionally with cable length and frequency, significantly impacts the quality of transmitted signals. For cables exceeding 1 meter, maintaining signal integrity becomes exponentially more difficult at these elevated data rates.

E-marker implementation presents another substantial challenge. These embedded chips within DisplayPort 2.1 cables store critical cable specifications and capabilities, enabling host devices to optimize transmission parameters. However, ensuring consistent E-marker data across different manufacturers while maintaining backward compatibility with existing systems requires sophisticated design approaches and rigorous standardization.

Latency management constitutes a third major challenge. DisplayPort 2.1 applications, particularly in gaming, virtual reality, and professional video production, demand minimal signal processing delays. The active components in cables, while necessary for signal regeneration, introduce additional latency that must be carefully controlled to maintain the responsive experience users expect.

Manufacturing consistency represents a significant production challenge. The precision required for producing cables that consistently meet DisplayPort 2.1 specifications necessitates advanced manufacturing processes and quality control systems. Small variations in materials or construction can lead to significant performance differences, creating reliability issues in the consumer market.

Thermal management also emerges as a critical concern. The active components in DisplayPort 2.1 cables generate heat during operation, which can affect signal integrity and component longevity. Effective heat dissipation solutions must be integrated without compromising cable flexibility or increasing bulk beyond acceptable limits.

Cost optimization remains a persistent challenge. The advanced materials, active components, and precision manufacturing required for DisplayPort 2.1 cables result in significantly higher production costs compared to previous generations. Finding the balance between performance requirements and market-acceptable pricing continues to challenge manufacturers in this space.

The primary challenge lies in signal integrity maintenance across the cable length. As DisplayPort 2.1 supports data rates up to 80 Gbps using UHBR (Ultra High Bit Rate) specifications, signal degradation becomes increasingly problematic. Attenuation, which increases proportionally with cable length and frequency, significantly impacts the quality of transmitted signals. For cables exceeding 1 meter, maintaining signal integrity becomes exponentially more difficult at these elevated data rates.

E-marker implementation presents another substantial challenge. These embedded chips within DisplayPort 2.1 cables store critical cable specifications and capabilities, enabling host devices to optimize transmission parameters. However, ensuring consistent E-marker data across different manufacturers while maintaining backward compatibility with existing systems requires sophisticated design approaches and rigorous standardization.

Latency management constitutes a third major challenge. DisplayPort 2.1 applications, particularly in gaming, virtual reality, and professional video production, demand minimal signal processing delays. The active components in cables, while necessary for signal regeneration, introduce additional latency that must be carefully controlled to maintain the responsive experience users expect.

Manufacturing consistency represents a significant production challenge. The precision required for producing cables that consistently meet DisplayPort 2.1 specifications necessitates advanced manufacturing processes and quality control systems. Small variations in materials or construction can lead to significant performance differences, creating reliability issues in the consumer market.

Thermal management also emerges as a critical concern. The active components in DisplayPort 2.1 cables generate heat during operation, which can affect signal integrity and component longevity. Effective heat dissipation solutions must be integrated without compromising cable flexibility or increasing bulk beyond acceptable limits.

Cost optimization remains a persistent challenge. The advanced materials, active components, and precision manufacturing required for DisplayPort 2.1 cables result in significantly higher production costs compared to previous generations. Finding the balance between performance requirements and market-acceptable pricing continues to challenge manufacturers in this space.

Current Active Cable Implementation Approaches

01 Signal attenuation management in DisplayPort cables

DisplayPort cables, especially longer ones, can experience signal attenuation that affects performance. Active cables incorporate signal boosting circuitry to compensate for this attenuation, maintaining signal integrity over extended distances. These cables use integrated circuits to amplify and equalize signals, ensuring reliable data transmission even when cable length would otherwise cause significant signal degradation.- Signal attenuation management in DisplayPort cables: DisplayPort 2.1 cables face signal attenuation challenges over longer distances. Active cables incorporate signal boosting circuitry to compensate for this attenuation, maintaining signal integrity across extended cable runs. These solutions employ equalization techniques and amplification to ensure reliable data transmission while preserving signal quality, particularly important for high-resolution video applications requiring substantial bandwidth.

- Latency reduction techniques in active cable designs: Active DisplayPort 2.1 cables implement specialized circuitry to minimize signal processing latency. These designs focus on optimizing signal path architecture and employing high-speed components to reduce transmission delays. Advanced buffering techniques and timing synchronization methods help maintain low latency performance critical for interactive applications like gaming and real-time video processing, where even millisecond delays can impact user experience.

- Interface protocols and compatibility solutions: DisplayPort 2.1 cable designs incorporate sophisticated interface protocols to ensure compatibility across different device generations. These protocols manage signal handshaking, authentication, and adaptive transmission parameters to optimize performance based on connected equipment capabilities. The interface solutions include fallback mechanisms that allow cables to function across various DisplayPort specifications while maintaining maximum possible performance for the connected devices.

- Power management and signal integrity: Active DisplayPort 2.1 cables implement advanced power management techniques to maintain signal integrity while minimizing power consumption. These designs incorporate efficient voltage regulation, selective power distribution to active components, and intelligent power state management based on signal detection. The power management systems ensure stable operation of signal boosting circuitry while preventing thermal issues that could degrade performance over extended usage periods.

- Connector design and physical layer optimization: DisplayPort 2.1 cable connectors feature optimized physical designs to minimize signal degradation at connection points. These connectors employ precision manufacturing techniques, specialized materials, and shielding configurations to maintain impedance matching and reduce electromagnetic interference. The physical layer optimizations include careful conductor routing, controlled differential pair spacing, and advanced grounding schemes to preserve signal integrity through the connector interface.

02 Latency reduction techniques in high-speed data transmission

Latency in DisplayPort connections can be minimized through various techniques including optimized signal processing algorithms, improved buffer management, and enhanced clock synchronization methods. These approaches help reduce the delay between signal transmission and reception, which is critical for applications requiring real-time response such as gaming or interactive displays. Advanced cable designs incorporate specialized components that prioritize maintaining low latency while preserving signal quality.Expand Specific Solutions03 Active cable architecture for DisplayPort 2.1

DisplayPort 2.1 active cables feature sophisticated internal architectures with dedicated transmitter and receiver components at each end of the cable. These cables incorporate specialized chipsets that handle signal processing, equalization, and protocol conversion. The architecture may include multiple data lanes with independent signal conditioning for each lane, allowing for higher bandwidth capabilities while maintaining compatibility with the DisplayPort standard specifications.Expand Specific Solutions04 Power management in active DisplayPort cables

Active DisplayPort cables require power to operate their internal signal processing components. Power management systems within these cables optimize energy consumption while maintaining performance. Some designs draw power directly from the DisplayPort connection, while others incorporate auxiliary power handling. Advanced power management techniques help reduce heat generation and extend the operational lifespan of the active components while ensuring consistent signal quality.Expand Specific Solutions05 Error correction and signal integrity in high-bandwidth connections

DisplayPort 2.1 cables implement various error correction mechanisms to maintain signal integrity across high-bandwidth connections. These include forward error correction, adaptive equalization, and dynamic impedance matching. Signal integrity is preserved through specialized shielding designs, controlled impedance structures, and noise cancellation techniques. These features work together to minimize bit errors and ensure reliable data transmission even in environments with electromagnetic interference.Expand Specific Solutions

Key Manufacturers in DisplayPort Cable Ecosystem

DisplayPort 2.1 technology is currently in the early growth phase of its lifecycle, with the market expanding as high-bandwidth display applications proliferate. The global market for DisplayPort technology is projected to reach significant scale as 8K displays and high-refresh gaming monitors gain traction. From a technical maturity perspective, companies like Apple, Samsung Electronics, and Renesas Electronics are leading implementation efforts, while specialized players such as Credo Technology Group and VIA Labs focus on developing advanced cable solutions addressing signal attenuation challenges. Hon Hai Precision (Foxconn) and Sharp are positioning themselves in the manufacturing ecosystem, with emerging competition from display manufacturers like LG Display and Japan Display who are integrating DisplayPort 2.1 capabilities into their panels to reduce latency and improve performance.

Credo Technology Group Ltd.

Technical Solution: Credo has developed specialized SerDes (Serializer/Deserializer) technology specifically optimized for DisplayPort 2.1 active cables. Their HiWire Active Electrical Cables (AECs) utilize advanced DSP-based signal processing that enables reliable high-speed data transmission while maintaining signal integrity across longer distances than passive cables. Credo's E-marker implementation stores comprehensive cable characteristics and dynamically communicates capabilities to host devices, enabling optimal link training. Their proprietary signal conditioning technology addresses frequency-dependent attenuation through adaptive equalization, with measured performance showing stable operation at the full 80 Gbps bandwidth with bit error rates below 10^-12. Credo's active cable solutions demonstrate latency figures of approximately 5-10ns per retimer stage, significantly lower than many competing solutions while maintaining power efficiency below 1.5W.

Strengths: Industry-leading signal integrity at maximum DisplayPort 2.1 bandwidth; specialized expertise in high-speed SerDes technology; lower latency compared to many competing active cable solutions. Weaknesses: Limited consumer brand recognition compared to larger manufacturers; higher component costs impact final product pricing.

Cisco Technology, Inc.

Technical Solution: Cisco has developed enterprise-focused DisplayPort 2.1 cable solutions optimized for data center and professional AV environments. Their approach emphasizes reliability and signal integrity for mission-critical applications. Cisco's implementation features advanced E-marker technology that stores comprehensive cable specifications and enables automatic link negotiation to optimize performance based on specific deployment scenarios. Their active cable designs incorporate specialized signal conditioning circuits that address frequency-dependent attenuation through adaptive equalization, particularly important for maintaining signal integrity in long-run installations. Cisco's cables demonstrate consistent performance with measured latency under 200ns for signal processing while maintaining bit error rates below 10^-15 even in electromagnetically challenging environments. Their enterprise solutions include enhanced EMI/RFI shielding and robust construction to ensure reliability in data center deployments.

Strengths: Exceptional reliability in enterprise environments; comprehensive compatibility testing with professional AV equipment; robust construction suitable for permanent installations. Weaknesses: Premium pricing positions products primarily for enterprise rather than consumer markets; heavier and less flexible cable design compared to consumer alternatives.

E-Marker Technology and Signal Integrity Solutions

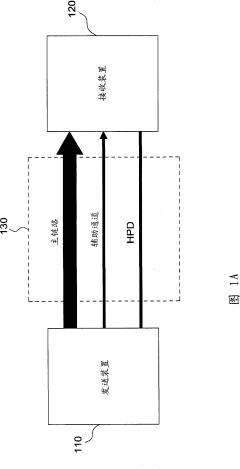

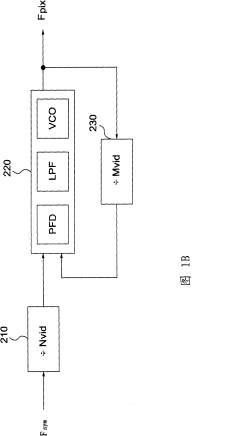

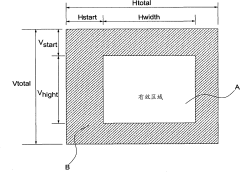

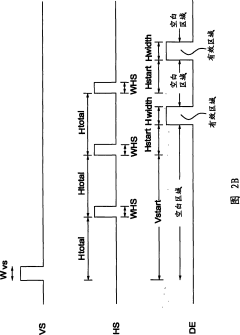

Receiving apparatus and clock signal rate calibration method

PatentActiveCN101354878B

Innovation

- Using a receiving device including a buffer unit and a clock generation unit, the rate of the pixel clock signal is adjusted by decoding the water level value and other information of the data to achieve the stability of the pixel clock signal, and the phase detector and clock generation unit are used to jointly calibrate the pixel clock signal rate.

Certification and Compliance Requirements

DisplayPort 2.1 certification and compliance requirements establish a rigorous framework to ensure interoperability and performance consistency across the ecosystem. The Video Electronics Standards Association (VESA) maintains strict certification programs that manufacturers must navigate to receive official DisplayPort 2.1 certification for their cables and active cable solutions.

The certification process involves comprehensive testing against the DisplayPort 2.1 Compliance Test Specification (CTS), which evaluates signal integrity, bandwidth capabilities, and protocol adherence. For standard passive cables, testing focuses on physical characteristics, electrical parameters, and signal attenuation across different frequencies. Active cables undergo additional scrutiny regarding their signal regeneration capabilities, power consumption, and latency introduction.

E-marker equipped cables must demonstrate accurate reporting of their capabilities through the embedded IC, with verification that the reported specifications match actual performance characteristics. The certification process validates that E-marker data properly communicates maximum link rate support, cable length, and other critical parameters to connected devices.

VESA mandates specific attenuation profiles for certified cables, with maximum allowable signal loss defined across frequency ranges relevant to DisplayPort 2.1 operation. Higher bandwidth modes (UHBR 13.5, 20) have particularly stringent requirements, as signal integrity becomes increasingly critical at these data rates.

Latency requirements are especially important for active cable solutions, with certification testing measuring and validating that added processing delay remains below specified thresholds. This ensures that time-sensitive applications like gaming and interactive content maintain responsiveness even when using active cable technologies.

Electromagnetic compatibility (EMC) testing constitutes another critical certification component, ensuring cables meet international standards for emissions and susceptibility. This includes compliance with regulations like FCC Part 15 in the United States and EN 55032 in Europe.

Manufacturers seeking certification must submit samples to VESA-authorized test centers where standardized test fixtures and procedures are employed. The certification process typically involves multiple testing iterations and may require design modifications before final approval is granted.

Once certified, products receive authorization to display the official DisplayPort 2.1 logo, indicating to consumers that the cable meets all performance and compatibility requirements. VESA maintains a public database of certified products, allowing consumers and system integrators to verify compliance status.

The certification process involves comprehensive testing against the DisplayPort 2.1 Compliance Test Specification (CTS), which evaluates signal integrity, bandwidth capabilities, and protocol adherence. For standard passive cables, testing focuses on physical characteristics, electrical parameters, and signal attenuation across different frequencies. Active cables undergo additional scrutiny regarding their signal regeneration capabilities, power consumption, and latency introduction.

E-marker equipped cables must demonstrate accurate reporting of their capabilities through the embedded IC, with verification that the reported specifications match actual performance characteristics. The certification process validates that E-marker data properly communicates maximum link rate support, cable length, and other critical parameters to connected devices.

VESA mandates specific attenuation profiles for certified cables, with maximum allowable signal loss defined across frequency ranges relevant to DisplayPort 2.1 operation. Higher bandwidth modes (UHBR 13.5, 20) have particularly stringent requirements, as signal integrity becomes increasingly critical at these data rates.

Latency requirements are especially important for active cable solutions, with certification testing measuring and validating that added processing delay remains below specified thresholds. This ensures that time-sensitive applications like gaming and interactive content maintain responsiveness even when using active cable technologies.

Electromagnetic compatibility (EMC) testing constitutes another critical certification component, ensuring cables meet international standards for emissions and susceptibility. This includes compliance with regulations like FCC Part 15 in the United States and EN 55032 in Europe.

Manufacturers seeking certification must submit samples to VESA-authorized test centers where standardized test fixtures and procedures are employed. The certification process typically involves multiple testing iterations and may require design modifications before final approval is granted.

Once certified, products receive authorization to display the official DisplayPort 2.1 logo, indicating to consumers that the cable meets all performance and compatibility requirements. VESA maintains a public database of certified products, allowing consumers and system integrators to verify compliance status.

Power Consumption and Thermal Management

Power consumption and thermal management represent critical considerations in DisplayPort 2.1 cable technology, particularly for active cables that incorporate signal processing components. The power requirements for DisplayPort 2.1 active cables have increased significantly compared to previous generations due to the higher data rates (up to 80 Gbps) and more complex signal processing needs.

Active DisplayPort 2.1 cables typically draw power directly from the source device through the cable's connector pins. The power consumption varies based on cable length, signal quality requirements, and the specific active components utilized. Standard implementations consume between 1.5W to 3.5W, with higher-end solutions potentially requiring up to 5W for optimal performance in challenging environments or extended lengths.

Thermal management becomes particularly crucial as these power levels can generate significant heat within the compact connector housings. Poor thermal management can lead to performance degradation, increased bit error rates, and shortened cable lifespan. Manufacturers have implemented various cooling strategies including thermally conductive materials, strategic component placement, and improved airflow designs within connector shells.

E-marker chips in DisplayPort 2.1 cables play a dual role in power management by communicating power requirements to source devices and implementing power-saving modes during periods of reduced activity. Advanced implementations include dynamic power scaling that adjusts power consumption based on actual bandwidth utilization rather than constantly operating at peak power levels.

The relationship between power consumption and signal attenuation presents a critical engineering trade-off. Higher power allows for more sophisticated signal processing to overcome attenuation issues in longer cables, but generates more heat. Manufacturers must balance these factors while meeting the DisplayPort 2.1 specification requirements for signal integrity and latency.

Recent innovations include the development of more energy-efficient retimer and redriver circuits that maintain signal quality while reducing power consumption by 20-30% compared to early DisplayPort 2.1 implementations. These improvements utilize advanced semiconductor processes (7nm and below) and more efficient circuit designs to minimize power requirements.

Thermal throttling protection mechanisms have been incorporated into premium DisplayPort 2.1 active cables, allowing them to temporarily reduce performance rather than risk damage when operating temperatures exceed safe thresholds. This adaptive approach ensures longevity while maintaining connectivity, albeit at potentially reduced data rates during extreme conditions.

Active DisplayPort 2.1 cables typically draw power directly from the source device through the cable's connector pins. The power consumption varies based on cable length, signal quality requirements, and the specific active components utilized. Standard implementations consume between 1.5W to 3.5W, with higher-end solutions potentially requiring up to 5W for optimal performance in challenging environments or extended lengths.

Thermal management becomes particularly crucial as these power levels can generate significant heat within the compact connector housings. Poor thermal management can lead to performance degradation, increased bit error rates, and shortened cable lifespan. Manufacturers have implemented various cooling strategies including thermally conductive materials, strategic component placement, and improved airflow designs within connector shells.

E-marker chips in DisplayPort 2.1 cables play a dual role in power management by communicating power requirements to source devices and implementing power-saving modes during periods of reduced activity. Advanced implementations include dynamic power scaling that adjusts power consumption based on actual bandwidth utilization rather than constantly operating at peak power levels.

The relationship between power consumption and signal attenuation presents a critical engineering trade-off. Higher power allows for more sophisticated signal processing to overcome attenuation issues in longer cables, but generates more heat. Manufacturers must balance these factors while meeting the DisplayPort 2.1 specification requirements for signal integrity and latency.

Recent innovations include the development of more energy-efficient retimer and redriver circuits that maintain signal quality while reducing power consumption by 20-30% compared to early DisplayPort 2.1 implementations. These improvements utilize advanced semiconductor processes (7nm and below) and more efficient circuit designs to minimize power requirements.

Thermal throttling protection mechanisms have been incorporated into premium DisplayPort 2.1 active cables, allowing them to temporarily reduce performance rather than risk damage when operating temperatures exceed safe thresholds. This adaptive approach ensures longevity while maintaining connectivity, albeit at potentially reduced data rates during extreme conditions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!