DisplayPort 2.1 Power Delivery Coexistence: EPR, Inrush And Connector Heating

SEP 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DisplayPort 2.1 PD Evolution and Objectives

DisplayPort technology has evolved significantly since its inception in 2006, with each iteration bringing substantial improvements in bandwidth, power delivery capabilities, and feature sets. The evolution from DisplayPort 1.0 to the current 2.1 specification represents a strategic response to the increasing demands of modern display technologies, including higher resolutions, refresh rates, and the integration of power delivery systems.

The DisplayPort 2.1 specification, released in 2022, builds upon the foundation established by DisplayPort 2.0, with particular emphasis on enhancing power delivery coexistence mechanisms. This evolution was driven by the growing need for unified connectivity solutions that can simultaneously handle high-bandwidth video transmission and power delivery through a single cable and connector system.

A primary objective of DisplayPort 2.1 is to establish robust compatibility with USB Power Delivery (PD) protocols, particularly focusing on Extended Power Range (EPR) capabilities that enable power delivery beyond the standard 100W limit. This integration aims to simplify connection ecosystems while supporting the increasing power requirements of modern laptops, monitors, and other peripherals.

The technical goals of DisplayPort 2.1's power delivery coexistence framework include managing inrush current effectively to prevent damage to connected devices during hot-plugging scenarios. This represents a critical safety consideration as higher power levels introduce greater risks of electrical stress and potential component failure if not properly controlled.

Another key objective is addressing thermal management challenges associated with high-power delivery through compact connectors. As power levels increase, the potential for connector heating becomes a significant concern that could impact both reliability and user safety. DisplayPort 2.1 aims to implement sophisticated power negotiation protocols that can dynamically adjust power delivery parameters based on thermal conditions.

The specification also seeks to establish clear guidelines for manufacturers regarding connector design, cable requirements, and power management circuitry to ensure consistent implementation across the industry. This standardization is essential for maintaining interoperability between devices from different manufacturers while preserving backward compatibility with existing DisplayPort implementations.

Looking forward, DisplayPort 2.1's power delivery evolution establishes a foundation for future iterations that will likely continue to increase power handling capabilities while maintaining the high-bandwidth data transmission that has made DisplayPort a preferred standard for high-performance display connections. The technology roadmap suggests continued convergence with USB standards, potentially leading toward a unified connector ecosystem that can address both data and power requirements across a wide range of consumer and professional applications.

The DisplayPort 2.1 specification, released in 2022, builds upon the foundation established by DisplayPort 2.0, with particular emphasis on enhancing power delivery coexistence mechanisms. This evolution was driven by the growing need for unified connectivity solutions that can simultaneously handle high-bandwidth video transmission and power delivery through a single cable and connector system.

A primary objective of DisplayPort 2.1 is to establish robust compatibility with USB Power Delivery (PD) protocols, particularly focusing on Extended Power Range (EPR) capabilities that enable power delivery beyond the standard 100W limit. This integration aims to simplify connection ecosystems while supporting the increasing power requirements of modern laptops, monitors, and other peripherals.

The technical goals of DisplayPort 2.1's power delivery coexistence framework include managing inrush current effectively to prevent damage to connected devices during hot-plugging scenarios. This represents a critical safety consideration as higher power levels introduce greater risks of electrical stress and potential component failure if not properly controlled.

Another key objective is addressing thermal management challenges associated with high-power delivery through compact connectors. As power levels increase, the potential for connector heating becomes a significant concern that could impact both reliability and user safety. DisplayPort 2.1 aims to implement sophisticated power negotiation protocols that can dynamically adjust power delivery parameters based on thermal conditions.

The specification also seeks to establish clear guidelines for manufacturers regarding connector design, cable requirements, and power management circuitry to ensure consistent implementation across the industry. This standardization is essential for maintaining interoperability between devices from different manufacturers while preserving backward compatibility with existing DisplayPort implementations.

Looking forward, DisplayPort 2.1's power delivery evolution establishes a foundation for future iterations that will likely continue to increase power handling capabilities while maintaining the high-bandwidth data transmission that has made DisplayPort a preferred standard for high-performance display connections. The technology roadmap suggests continued convergence with USB standards, potentially leading toward a unified connector ecosystem that can address both data and power requirements across a wide range of consumer and professional applications.

Market Demand for High-Power Display Connectivity

The market for high-power display connectivity solutions has experienced significant growth in recent years, driven by the increasing demand for advanced display technologies and the convergence of power delivery and data transmission capabilities. As modern displays become more sophisticated, requiring higher resolutions, refresh rates, and additional features, the power requirements have escalated substantially, creating a pressing need for enhanced power delivery solutions alongside high-bandwidth data connections.

Consumer electronics manufacturers have been pushing for unified connectivity solutions that can simultaneously deliver high-definition video signals and sufficient power to drive premium displays without requiring separate power cables. Market research indicates that the global market for integrated display and power delivery solutions is expanding at a compound annual growth rate of approximately 15% between 2020 and 2025, reflecting the strong demand for streamlined connectivity options.

Professional users, particularly in creative industries such as video production, graphic design, and architecture, represent a significant segment driving this market growth. These professionals require high-resolution displays with color accuracy and consistent performance, which often necessitate substantial power delivery capabilities. The ability to power monitors exceeding 100W through the same cable that carries display signals represents a key value proposition for this market segment.

The gaming industry has emerged as another major driver for high-power display connectivity solutions. Gaming monitors with high refresh rates, adaptive sync technologies, and increasingly larger screen sizes demand robust power delivery systems. Market surveys reveal that over 70% of serious gamers consider integrated power and display connectivity as an important feature when purchasing new equipment.

Corporate environments are also contributing to market demand, as businesses seek to simplify workspace setups and reduce cable clutter. The trend toward hot-desking and flexible work arrangements has accelerated the adoption of docking solutions that can deliver both display signals and power to laptops and monitors through a single connection point.

The transition to remote and hybrid work models following the global pandemic has further intensified market demand, as professionals establish home office setups requiring efficient connectivity solutions. This shift has expanded the target market beyond traditional enterprise customers to include a broader consumer base seeking professional-grade display connectivity options for home use.

Manufacturers are responding to these market demands by developing new standards and technologies that can safely deliver increased power alongside high-bandwidth display signals, while addressing technical challenges such as connector heating and inrush current management. The market clearly signals that consumers and professionals alike are willing to invest in solutions that offer seamless integration of power delivery and high-performance display connectivity.

Consumer electronics manufacturers have been pushing for unified connectivity solutions that can simultaneously deliver high-definition video signals and sufficient power to drive premium displays without requiring separate power cables. Market research indicates that the global market for integrated display and power delivery solutions is expanding at a compound annual growth rate of approximately 15% between 2020 and 2025, reflecting the strong demand for streamlined connectivity options.

Professional users, particularly in creative industries such as video production, graphic design, and architecture, represent a significant segment driving this market growth. These professionals require high-resolution displays with color accuracy and consistent performance, which often necessitate substantial power delivery capabilities. The ability to power monitors exceeding 100W through the same cable that carries display signals represents a key value proposition for this market segment.

The gaming industry has emerged as another major driver for high-power display connectivity solutions. Gaming monitors with high refresh rates, adaptive sync technologies, and increasingly larger screen sizes demand robust power delivery systems. Market surveys reveal that over 70% of serious gamers consider integrated power and display connectivity as an important feature when purchasing new equipment.

Corporate environments are also contributing to market demand, as businesses seek to simplify workspace setups and reduce cable clutter. The trend toward hot-desking and flexible work arrangements has accelerated the adoption of docking solutions that can deliver both display signals and power to laptops and monitors through a single connection point.

The transition to remote and hybrid work models following the global pandemic has further intensified market demand, as professionals establish home office setups requiring efficient connectivity solutions. This shift has expanded the target market beyond traditional enterprise customers to include a broader consumer base seeking professional-grade display connectivity options for home use.

Manufacturers are responding to these market demands by developing new standards and technologies that can safely deliver increased power alongside high-bandwidth display signals, while addressing technical challenges such as connector heating and inrush current management. The market clearly signals that consumers and professionals alike are willing to invest in solutions that offer seamless integration of power delivery and high-performance display connectivity.

Technical Challenges in EPR Implementation

The implementation of Extended Power Range (EPR) in DisplayPort 2.1 presents several significant technical challenges that must be addressed to ensure safe and reliable operation. The primary concern revolves around managing the substantially higher power levels that EPR introduces, with capabilities reaching up to 240W compared to the standard 100W limit of Standard Power Range (SPR).

One of the most critical challenges is the thermal management of connectors and cables. When delivering power at EPR levels, the increased current flow generates considerably more heat within the connector interfaces. This thermal load can lead to accelerated degradation of connector materials, reduced connection reliability, and in extreme cases, safety hazards. Engineering solutions must account for this increased thermal stress through improved materials, enhanced heat dissipation designs, and more robust connector architectures.

Inrush current management presents another substantial technical hurdle. When a device initially connects to a power source, there can be a momentary surge of current significantly higher than the steady-state operating current. At EPR power levels, these inrush currents can reach potentially damaging magnitudes. Sophisticated current limiting circuitry must be implemented to prevent damage to both the power source and the receiving device, while still allowing for rapid power negotiation and delivery.

The complexity of power negotiation protocols increases exponentially with EPR implementation. The system must accurately identify EPR-capable cables and devices, negotiate appropriate voltage and current parameters, and maintain continuous monitoring for safety conditions. This requires enhanced communication protocols and more sophisticated power delivery controllers on both ends of the connection.

Safety mechanisms for fault detection and response become more critical at higher power levels. EPR implementations must include advanced overcurrent protection, overvoltage protection, and thermal monitoring systems that can respond within milliseconds to prevent damage or hazardous conditions. These protection circuits must be both highly reliable and nuanced enough to distinguish between normal power fluctuations and genuine fault conditions.

Backward compatibility requirements add another layer of complexity. EPR-capable systems must seamlessly interact with existing SPR devices and infrastructure without compromising functionality or safety. This necessitates intelligent power negotiation that can adapt to the capabilities of connected hardware while preventing inappropriate power delivery to devices not designed for EPR levels.

Manufacturing tolerances and quality control become more stringent with EPR implementation. The reduced margins for error at higher power levels mean that cable quality, connector precision, and electronic component specifications must be tightly controlled to ensure consistent performance and safety across all implementations.

One of the most critical challenges is the thermal management of connectors and cables. When delivering power at EPR levels, the increased current flow generates considerably more heat within the connector interfaces. This thermal load can lead to accelerated degradation of connector materials, reduced connection reliability, and in extreme cases, safety hazards. Engineering solutions must account for this increased thermal stress through improved materials, enhanced heat dissipation designs, and more robust connector architectures.

Inrush current management presents another substantial technical hurdle. When a device initially connects to a power source, there can be a momentary surge of current significantly higher than the steady-state operating current. At EPR power levels, these inrush currents can reach potentially damaging magnitudes. Sophisticated current limiting circuitry must be implemented to prevent damage to both the power source and the receiving device, while still allowing for rapid power negotiation and delivery.

The complexity of power negotiation protocols increases exponentially with EPR implementation. The system must accurately identify EPR-capable cables and devices, negotiate appropriate voltage and current parameters, and maintain continuous monitoring for safety conditions. This requires enhanced communication protocols and more sophisticated power delivery controllers on both ends of the connection.

Safety mechanisms for fault detection and response become more critical at higher power levels. EPR implementations must include advanced overcurrent protection, overvoltage protection, and thermal monitoring systems that can respond within milliseconds to prevent damage or hazardous conditions. These protection circuits must be both highly reliable and nuanced enough to distinguish between normal power fluctuations and genuine fault conditions.

Backward compatibility requirements add another layer of complexity. EPR-capable systems must seamlessly interact with existing SPR devices and infrastructure without compromising functionality or safety. This necessitates intelligent power negotiation that can adapt to the capabilities of connected hardware while preventing inappropriate power delivery to devices not designed for EPR levels.

Manufacturing tolerances and quality control become more stringent with EPR implementation. The reduced margins for error at higher power levels mean that cable quality, connector precision, and electronic component specifications must be tightly controlled to ensure consistent performance and safety across all implementations.

Current EPR and Inrush Management Solutions

01 Thermal management solutions for DisplayPort connectors

Various thermal management solutions are implemented to address heating issues in DisplayPort 2.1 power delivery connectors. These include heat sinks, thermal pads, and improved airflow designs that help dissipate heat generated during high-power data transmission and power delivery operations. These solutions prevent overheating that could lead to performance degradation or component damage in DisplayPort interfaces.- Thermal management solutions for DisplayPort connectors: Various thermal management solutions are implemented to address heating issues in DisplayPort 2.1 power delivery connectors. These include heat sinks, thermal pads, and improved airflow designs that help dissipate heat generated during high-power data transmission and power delivery operations. These solutions prevent overheating that could lead to performance degradation or component damage in DisplayPort interfaces.

- Power delivery circuit design optimization: Optimized circuit designs for power delivery in DisplayPort 2.1 connectors focus on reducing resistance and improving current distribution. These designs incorporate advanced power management ICs, voltage regulators, and current limiters to prevent excessive heating during operation. Circuit optimizations include improved trace layouts and component selection to handle the increased power requirements of DisplayPort 2.1 while maintaining thermal stability.

- Connector material and structural improvements: Advanced materials and structural improvements in DisplayPort 2.1 connectors address heating concerns through better thermal conductivity and electrical performance. These include gold-plated contacts, thermally conductive plastics, and redesigned pin arrangements that minimize resistance. Structural enhancements also focus on improving the physical connection stability while facilitating better heat dissipation from critical components.

- Power management protocols and algorithms: Sophisticated power management protocols and algorithms are implemented in DisplayPort 2.1 interfaces to dynamically adjust power delivery based on device requirements and thermal conditions. These systems monitor connector temperature and can reduce power consumption during periods of high thermal stress. Intelligent power negotiation between connected devices helps prevent excessive current draw that could lead to connector heating issues.

- Integration with USB Power Delivery standards: DisplayPort 2.1 connectors are designed with compatibility for USB Power Delivery standards, allowing for standardized power management across different interface types. This integration includes shared thermal management considerations and power negotiation protocols that help prevent connector heating. The harmonization of these standards enables more efficient power handling while maintaining safe operating temperatures for both the connector and connected devices.

02 Power delivery optimization in DisplayPort interfaces

Advanced power delivery optimization techniques are employed in DisplayPort 2.1 connectors to minimize heating issues. These include dynamic power management, voltage regulation, and current limiting mechanisms that adjust power delivery based on device requirements and thermal conditions. By optimizing power delivery, these technologies reduce unnecessary heat generation while maintaining reliable performance.Expand Specific Solutions03 Connector design improvements for heat reduction

Innovative connector designs specifically address heating concerns in DisplayPort 2.1 power delivery systems. These designs incorporate improved contact materials with better electrical conductivity, enhanced pin configurations that reduce resistance, and structural modifications that facilitate heat dissipation. The improved physical design of connectors helps minimize heat generation at connection points where power transfer occurs.Expand Specific Solutions04 Integrated circuit solutions for thermal management

Specialized integrated circuits are developed to manage power delivery and associated heating in DisplayPort 2.1 connections. These ICs include temperature monitoring sensors, adaptive power controllers, and protection circuits that can adjust operation parameters or initiate protective measures when excessive heating is detected. The intelligent management of power through these circuits prevents thermal issues while maintaining optimal performance.Expand Specific Solutions05 Signal integrity and power delivery separation techniques

Advanced techniques separate high-speed data signals from power delivery pathways in DisplayPort 2.1 connectors to reduce interference and heating. These include electromagnetic shielding, isolated power planes, and optimized trace routing that minimize crosstalk between power and data lines. By effectively separating these functions, these technologies reduce power losses that contribute to connector heating while maintaining signal integrity.Expand Specific Solutions

Key Industry Players in DisplayPort Ecosystem

DisplayPort 2.1 Power Delivery Coexistence technology is currently in an early growth phase, with the market expanding as USB-C and DisplayPort integration becomes more prevalent in consumer electronics. The global market for this technology is projected to reach significant scale as manufacturers adopt the EPR (Extended Power Range) capabilities in premium devices. From a technical maturity perspective, companies like Samsung Electronics, Apple, and NXP Semiconductors are leading development with advanced power management solutions addressing inrush current challenges and connector heating issues. Delta Electronics and Monolithic Power Systems are making notable contributions in thermal management solutions, while BOE and LG Display are integrating these technologies into their display products. The ecosystem is evolving rapidly as manufacturers work to balance increased power delivery requirements with thermal constraints in increasingly compact device designs.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung Electronics has engineered a DisplayPort 2.1 Power Delivery solution focused on their high-performance monitors and mobile devices. Their approach centers on a dual-channel power architecture that physically separates DisplayPort signaling paths from high-current power delivery channels to minimize interference. Samsung's implementation includes custom power management ICs that support EPR modes up to 240W while maintaining signal integrity for DisplayPort's high bandwidth requirements. For connector heating management, Samsung employs advanced composite materials with superior thermal conductivity and has developed a distributed heat dissipation system that prevents hotspot formation at connection points. Their solution also features adaptive power negotiation that dynamically adjusts power profiles based on connected device capabilities and real-time thermal monitoring, allowing for optimal performance without compromising safety or display quality.

Strengths: Excellent thermal management through advanced materials; strong integration with Samsung's display technologies; robust power negotiation capabilities. Weaknesses: Solution optimized primarily for Samsung's own ecosystem; requires specialized components that increase manufacturing complexity; higher implementation cost compared to standard solutions.

Renesas Electronics Corp.

Technical Solution: Renesas has developed an integrated semiconductor solution for DisplayPort 2.1 Power Delivery coexistence that addresses EPR, inrush current, and thermal challenges. Their approach centers on highly integrated power management ICs that combine DisplayPort signal conditioning with USB-PD 3.1 controllers supporting EPR modes. Renesas' solution features advanced inrush current management through adaptive gate driving technology that controls power MOSFET switching characteristics based on real-time load conditions. Their ICs incorporate thermal monitoring with multiple sensing points and implement dynamic frequency adjustment to spread heat generation across larger surface areas. For connector heating issues, Renesas has developed companion protection ICs that work alongside their main controllers to monitor connector temperatures and automatically adjust power profiles to prevent overheating. Their solution also includes proprietary firmware that enables fine-grained power negotiation between source and sink devices, allowing for optimal power delivery while maintaining DisplayPort signal integrity across various cable lengths and qualities.

Strengths: Highly integrated semiconductor solution reducing component count; sophisticated power management algorithms; extensive compatibility testing with major OEMs. Weaknesses: Requires specific Renesas components for full functionality; more complex implementation compared to discrete solutions; higher initial engineering investment for device manufacturers.

Critical Patents in Connector Thermal Management

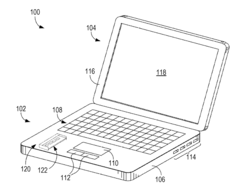

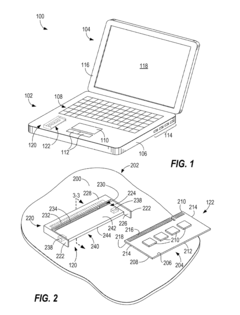

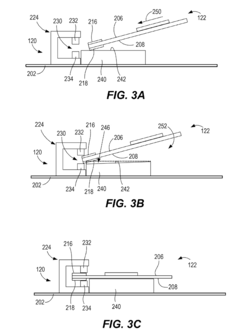

Electrostatic Discharge Protection Structures for Liquid Crystal Displays

PatentActiveUS20150323843A1

Innovation

- Incorporating electrostatic discharge protection structures, including a conductive housing, transparent conductive coatings like indium tin oxide, and conductive materials like conductive tape and elastomeric gaskets to electrically couple the display layers to the housing, providing a ground path for discharge.

Connector With Electrostatic Discharge Protection

PatentInactiveUS20110237095A1

Innovation

- A connector with an ESD dissipative element is integrated, allowing component modules to make contact with the element before connecting to the connector, thereby dissipating ESD charges to a ground point instead of through the connector and electronic components, preventing potential damage.

Thermal Safety Standards and Compliance

Thermal safety standards play a critical role in the implementation of DisplayPort 2.1 with Power Delivery coexistence, particularly when dealing with Extended Power Range (EPR) capabilities. These standards are designed to ensure that connectors, cables, and devices remain within safe operating temperatures even under high power transfer conditions.

The International Electrotechnical Commission (IEC) has established IEC 62368-1 as the primary safety standard applicable to audio/video and information technology equipment. This standard specifically addresses thermal hazards and requires that accessible parts of equipment not exceed temperature limits that could cause harm to users or damage to the equipment itself.

For DisplayPort 2.1 with EPR capabilities, Underwriters Laboratories (UL) standards UL 62368-1 and UL 1642 provide additional safety requirements for power delivery systems and lithium batteries respectively. These standards mandate specific temperature thresholds that must not be exceeded during normal operation, abnormal operation, and single fault conditions.

The USB Implementers Forum (USB-IF) has also developed compliance standards specifically for USB Power Delivery, which apply to DisplayPort implementations using USB Type-C connectors. These standards include thermal management requirements that address inrush current limitations and connector heating concerns. Compliance testing includes thermal cycling tests and sustained operation tests under maximum rated power conditions.

European standards such as EN 60950-1 and its successor EN 62368-1 incorporate additional requirements for equipment safety, including thermal considerations. These standards are harmonized with the EU's Low Voltage Directive (LVD) and are mandatory for products sold in the European market.

Compliance testing for thermal safety involves sophisticated thermal imaging and temperature measurement techniques. Products must undergo rigorous testing to ensure that under worst-case scenarios—including maximum power delivery, high ambient temperatures, and restricted airflow conditions—all components remain below specified temperature thresholds. For DisplayPort 2.1 with EPR, these tests are particularly stringent due to the higher power levels involved.

Manufacturers must implement thermal protection mechanisms such as temperature sensors, automatic power reduction circuits, and thermal shutdown capabilities to ensure compliance with these standards. Documentation of compliance testing results is typically required as part of product certification processes, and regular audits may be conducted to ensure ongoing compliance.

As power delivery capabilities continue to increase, thermal safety standards are evolving to address new challenges. Future revisions are expected to include more specific requirements for high-power USB-C implementations, including those that combine DisplayPort functionality with Extended Power Range delivery.

The International Electrotechnical Commission (IEC) has established IEC 62368-1 as the primary safety standard applicable to audio/video and information technology equipment. This standard specifically addresses thermal hazards and requires that accessible parts of equipment not exceed temperature limits that could cause harm to users or damage to the equipment itself.

For DisplayPort 2.1 with EPR capabilities, Underwriters Laboratories (UL) standards UL 62368-1 and UL 1642 provide additional safety requirements for power delivery systems and lithium batteries respectively. These standards mandate specific temperature thresholds that must not be exceeded during normal operation, abnormal operation, and single fault conditions.

The USB Implementers Forum (USB-IF) has also developed compliance standards specifically for USB Power Delivery, which apply to DisplayPort implementations using USB Type-C connectors. These standards include thermal management requirements that address inrush current limitations and connector heating concerns. Compliance testing includes thermal cycling tests and sustained operation tests under maximum rated power conditions.

European standards such as EN 60950-1 and its successor EN 62368-1 incorporate additional requirements for equipment safety, including thermal considerations. These standards are harmonized with the EU's Low Voltage Directive (LVD) and are mandatory for products sold in the European market.

Compliance testing for thermal safety involves sophisticated thermal imaging and temperature measurement techniques. Products must undergo rigorous testing to ensure that under worst-case scenarios—including maximum power delivery, high ambient temperatures, and restricted airflow conditions—all components remain below specified temperature thresholds. For DisplayPort 2.1 with EPR, these tests are particularly stringent due to the higher power levels involved.

Manufacturers must implement thermal protection mechanisms such as temperature sensors, automatic power reduction circuits, and thermal shutdown capabilities to ensure compliance with these standards. Documentation of compliance testing results is typically required as part of product certification processes, and regular audits may be conducted to ensure ongoing compliance.

As power delivery capabilities continue to increase, thermal safety standards are evolving to address new challenges. Future revisions are expected to include more specific requirements for high-power USB-C implementations, including those that combine DisplayPort functionality with Extended Power Range delivery.

Power Efficiency Optimization Strategies

Power efficiency optimization in DisplayPort 2.1 with Power Delivery coexistence requires strategic approaches to manage energy consumption while maintaining performance. The implementation of dynamic power states represents a significant advancement, allowing devices to adjust power consumption based on actual bandwidth requirements rather than operating at maximum power continuously.

Advanced power management protocols enable precise control over when and how devices transition between different power states. These protocols incorporate sophisticated algorithms that analyze usage patterns and adjust power allocation accordingly, resulting in substantial energy savings during periods of reduced activity while ensuring immediate responsiveness when needed.

Thermal management techniques play a crucial role in optimizing power efficiency, particularly when addressing connector heating concerns during Extended Power Range (EPR) operation. Implementing thermal sensors and feedback loops allows systems to monitor temperature variations and adjust power delivery parameters in real-time, preventing thermal throttling while maintaining optimal performance.

Voltage regulation optimization represents another key strategy, with adaptive voltage scaling techniques allowing for fine-tuned power delivery based on actual processing demands. This approach significantly reduces power waste compared to fixed voltage systems, particularly beneficial when managing the coexistence of DisplayPort signaling and power delivery through the same connector.

Intelligent inrush current management systems incorporate predictive algorithms that anticipate power demand fluctuations, gradually ramping up power delivery to prevent sudden current spikes. This not only protects connector integrity but also improves overall system efficiency by eliminating energy waste associated with traditional over-provisioning approaches.

Energy-aware link training protocols optimize the power-performance balance during the critical connection establishment phase. By implementing variable power states during link training, systems can allocate only the necessary resources for each stage of the process, reducing overall energy consumption without compromising connection reliability or speed.

Selective feature activation frameworks enable systems to power only the specific DisplayPort features required for current operations. This granular approach to power management ensures that energy is directed exclusively to active components, with unused features placed in ultra-low power states until needed, significantly reducing baseline power consumption in typical usage scenarios.

Advanced power management protocols enable precise control over when and how devices transition between different power states. These protocols incorporate sophisticated algorithms that analyze usage patterns and adjust power allocation accordingly, resulting in substantial energy savings during periods of reduced activity while ensuring immediate responsiveness when needed.

Thermal management techniques play a crucial role in optimizing power efficiency, particularly when addressing connector heating concerns during Extended Power Range (EPR) operation. Implementing thermal sensors and feedback loops allows systems to monitor temperature variations and adjust power delivery parameters in real-time, preventing thermal throttling while maintaining optimal performance.

Voltage regulation optimization represents another key strategy, with adaptive voltage scaling techniques allowing for fine-tuned power delivery based on actual processing demands. This approach significantly reduces power waste compared to fixed voltage systems, particularly beneficial when managing the coexistence of DisplayPort signaling and power delivery through the same connector.

Intelligent inrush current management systems incorporate predictive algorithms that anticipate power demand fluctuations, gradually ramping up power delivery to prevent sudden current spikes. This not only protects connector integrity but also improves overall system efficiency by eliminating energy waste associated with traditional over-provisioning approaches.

Energy-aware link training protocols optimize the power-performance balance during the critical connection establishment phase. By implementing variable power states during link training, systems can allocate only the necessary resources for each stage of the process, reducing overall energy consumption without compromising connection reliability or speed.

Selective feature activation frameworks enable systems to power only the specific DisplayPort features required for current operations. This granular approach to power management ensures that energy is directed exclusively to active components, with unused features placed in ultra-low power states until needed, significantly reducing baseline power consumption in typical usage scenarios.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!