Field-Testing Methods for Evaluating Battery Management Systems

AUG 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

BMS Field-Testing Background and Objectives

Battery Management Systems (BMS) have become an integral component in the rapidly evolving landscape of electric vehicles and energy storage systems. As the demand for more efficient and reliable energy storage solutions continues to grow, the need for robust field-testing methods to evaluate BMS performance has become increasingly critical. The background of BMS field-testing can be traced back to the early days of rechargeable battery technology, where rudimentary monitoring systems were employed to ensure safe operation and longevity of battery packs.

Over the years, the complexity and sophistication of BMS have increased exponentially, driven by advancements in battery chemistry, power electronics, and digital control systems. This evolution has necessitated the development of more comprehensive and accurate field-testing methodologies to assess BMS performance under real-world conditions. The primary objective of BMS field-testing is to validate the system's ability to monitor, protect, and optimize battery performance across a wide range of operating scenarios and environmental conditions.

Field-testing of BMS encompasses various aspects, including but not limited to, cell balancing efficiency, thermal management, state-of-charge (SOC) and state-of-health (SOH) estimation accuracy, fault detection and mitigation, and overall system reliability. These tests aim to bridge the gap between laboratory simulations and actual operational environments, providing valuable insights into BMS behavior under diverse and often unpredictable circumstances.

The importance of field-testing has been further underscored by the increasing integration of BMS with other vehicle systems and smart grid applications. As BMS evolve to become more interconnected and data-driven, field-testing methods must adapt to evaluate not only the core functionalities but also the system's ability to communicate and interact with external networks and energy management systems.

Recent technological trends have shifted the focus towards developing field-testing methods that can capture and analyze vast amounts of real-time data. This shift has been facilitated by advancements in IoT technologies, cloud computing, and machine learning algorithms, enabling more sophisticated analysis of BMS performance over extended periods and across diverse geographical locations.

The ultimate goal of BMS field-testing is to ensure the safety, reliability, and efficiency of battery systems in real-world applications. By subjecting BMS to rigorous field tests, manufacturers and researchers aim to identify potential weaknesses, optimize system parameters, and validate performance claims. This process is crucial for building consumer confidence in electric vehicles and grid-scale energy storage solutions, as well as for meeting increasingly stringent regulatory requirements.

As we look towards the future, the field of BMS testing is expected to continue evolving, with a growing emphasis on standardization of testing protocols, integration of artificial intelligence for predictive maintenance, and development of non-invasive testing techniques that minimize disruption to normal system operation. These advancements will play a pivotal role in accelerating the widespread adoption of electric vehicles and renewable energy storage systems, contributing to a more sustainable and efficient energy ecosystem.

Over the years, the complexity and sophistication of BMS have increased exponentially, driven by advancements in battery chemistry, power electronics, and digital control systems. This evolution has necessitated the development of more comprehensive and accurate field-testing methodologies to assess BMS performance under real-world conditions. The primary objective of BMS field-testing is to validate the system's ability to monitor, protect, and optimize battery performance across a wide range of operating scenarios and environmental conditions.

Field-testing of BMS encompasses various aspects, including but not limited to, cell balancing efficiency, thermal management, state-of-charge (SOC) and state-of-health (SOH) estimation accuracy, fault detection and mitigation, and overall system reliability. These tests aim to bridge the gap between laboratory simulations and actual operational environments, providing valuable insights into BMS behavior under diverse and often unpredictable circumstances.

The importance of field-testing has been further underscored by the increasing integration of BMS with other vehicle systems and smart grid applications. As BMS evolve to become more interconnected and data-driven, field-testing methods must adapt to evaluate not only the core functionalities but also the system's ability to communicate and interact with external networks and energy management systems.

Recent technological trends have shifted the focus towards developing field-testing methods that can capture and analyze vast amounts of real-time data. This shift has been facilitated by advancements in IoT technologies, cloud computing, and machine learning algorithms, enabling more sophisticated analysis of BMS performance over extended periods and across diverse geographical locations.

The ultimate goal of BMS field-testing is to ensure the safety, reliability, and efficiency of battery systems in real-world applications. By subjecting BMS to rigorous field tests, manufacturers and researchers aim to identify potential weaknesses, optimize system parameters, and validate performance claims. This process is crucial for building consumer confidence in electric vehicles and grid-scale energy storage solutions, as well as for meeting increasingly stringent regulatory requirements.

As we look towards the future, the field of BMS testing is expected to continue evolving, with a growing emphasis on standardization of testing protocols, integration of artificial intelligence for predictive maintenance, and development of non-invasive testing techniques that minimize disruption to normal system operation. These advancements will play a pivotal role in accelerating the widespread adoption of electric vehicles and renewable energy storage systems, contributing to a more sustainable and efficient energy ecosystem.

Market Demand for BMS Field-Testing Solutions

The market demand for Battery Management System (BMS) field-testing solutions has been steadily increasing due to the rapid growth of the electric vehicle (EV) and renewable energy storage sectors. As these industries expand, the need for reliable and efficient BMS testing methods becomes crucial to ensure the safety, performance, and longevity of battery systems.

In the automotive sector, the global EV market has been experiencing significant growth, with annual sales projected to reach 10 million units by 2025. This surge in EV adoption has created a substantial demand for advanced BMS field-testing solutions. Automotive manufacturers and suppliers require robust testing methods to validate BMS performance under various real-world conditions, including extreme temperatures, high-speed charging, and diverse driving patterns.

The renewable energy storage market, particularly in grid-scale applications, has also been driving the demand for BMS field-testing solutions. As more countries invest in large-scale energy storage projects to support renewable energy integration, the need for reliable BMS testing becomes paramount. The global energy storage market is expected to deploy over 1,000 GWh of new capacity by 2030, further fueling the demand for advanced BMS testing methods.

Industrial and commercial applications represent another significant market segment for BMS field-testing solutions. With the increasing adoption of lithium-ion batteries in material handling equipment, backup power systems, and other industrial applications, there is a growing need for on-site BMS performance evaluation and troubleshooting tools.

The market demand for BMS field-testing solutions is also driven by regulatory requirements and safety concerns. As governments worldwide implement stricter safety standards for battery systems, manufacturers and operators are compelled to invest in comprehensive testing solutions to ensure compliance and minimize the risk of battery-related incidents.

Furthermore, the complexity of modern BMS designs, incorporating advanced features such as predictive maintenance, cell balancing, and thermal management, necessitates more sophisticated field-testing methods. This trend is pushing the market towards integrated testing solutions that can evaluate multiple BMS functions simultaneously and provide real-time data analysis.

The aftermarket and maintenance sectors are emerging as significant drivers of demand for BMS field-testing solutions. As the installed base of EVs and energy storage systems grows, there is an increasing need for diagnostic tools and testing equipment to support maintenance, repair, and performance optimization of existing battery systems throughout their lifecycle.

In conclusion, the market demand for BMS field-testing solutions is robust and multifaceted, driven by the rapid growth of electric vehicles, renewable energy storage, and industrial applications. The need for reliable, efficient, and comprehensive testing methods is expected to continue growing as battery technologies advance and safety requirements become more stringent.

In the automotive sector, the global EV market has been experiencing significant growth, with annual sales projected to reach 10 million units by 2025. This surge in EV adoption has created a substantial demand for advanced BMS field-testing solutions. Automotive manufacturers and suppliers require robust testing methods to validate BMS performance under various real-world conditions, including extreme temperatures, high-speed charging, and diverse driving patterns.

The renewable energy storage market, particularly in grid-scale applications, has also been driving the demand for BMS field-testing solutions. As more countries invest in large-scale energy storage projects to support renewable energy integration, the need for reliable BMS testing becomes paramount. The global energy storage market is expected to deploy over 1,000 GWh of new capacity by 2030, further fueling the demand for advanced BMS testing methods.

Industrial and commercial applications represent another significant market segment for BMS field-testing solutions. With the increasing adoption of lithium-ion batteries in material handling equipment, backup power systems, and other industrial applications, there is a growing need for on-site BMS performance evaluation and troubleshooting tools.

The market demand for BMS field-testing solutions is also driven by regulatory requirements and safety concerns. As governments worldwide implement stricter safety standards for battery systems, manufacturers and operators are compelled to invest in comprehensive testing solutions to ensure compliance and minimize the risk of battery-related incidents.

Furthermore, the complexity of modern BMS designs, incorporating advanced features such as predictive maintenance, cell balancing, and thermal management, necessitates more sophisticated field-testing methods. This trend is pushing the market towards integrated testing solutions that can evaluate multiple BMS functions simultaneously and provide real-time data analysis.

The aftermarket and maintenance sectors are emerging as significant drivers of demand for BMS field-testing solutions. As the installed base of EVs and energy storage systems grows, there is an increasing need for diagnostic tools and testing equipment to support maintenance, repair, and performance optimization of existing battery systems throughout their lifecycle.

In conclusion, the market demand for BMS field-testing solutions is robust and multifaceted, driven by the rapid growth of electric vehicles, renewable energy storage, and industrial applications. The need for reliable, efficient, and comprehensive testing methods is expected to continue growing as battery technologies advance and safety requirements become more stringent.

Current Challenges in BMS Field-Testing

Field-testing of Battery Management Systems (BMS) presents several significant challenges that researchers and engineers must overcome to ensure accurate and reliable evaluations. One of the primary difficulties is the complex and dynamic nature of battery systems, which require comprehensive testing across various operational conditions and environmental factors.

The variability of real-world scenarios poses a substantial challenge in BMS field-testing. Batteries are subjected to diverse usage patterns, temperature fluctuations, and varying charge-discharge cycles, making it challenging to replicate all possible scenarios in controlled environments. This variability can lead to inconsistencies in test results and may not fully capture the BMS performance under all potential conditions.

Another critical challenge is the long-term nature of battery degradation and BMS performance. Batteries typically have lifespans of several years, making it difficult to conduct comprehensive field tests that accurately predict long-term behavior and BMS effectiveness. Accelerated aging techniques are often employed but may not perfectly simulate real-world degradation patterns.

Data collection and analysis present additional hurdles in BMS field-testing. The sheer volume of data generated during extended testing periods can be overwhelming, requiring sophisticated data management and analysis tools. Moreover, ensuring data integrity and accuracy throughout the testing process is crucial but can be challenging in field conditions.

The integration of BMS with other vehicle systems adds another layer of complexity to field-testing. Interactions between the BMS and other components, such as thermal management systems or power electronics, must be thoroughly evaluated. This system-level testing is often more challenging to conduct in field conditions compared to laboratory settings.

Safety considerations also play a significant role in BMS field-testing challenges. High-voltage battery systems pose inherent risks, necessitating stringent safety protocols that can sometimes limit the extent or nature of tests that can be performed in real-world environments.

Standardization of field-testing methodologies is another ongoing challenge. The lack of universally accepted standards for BMS field-testing can lead to inconsistencies in evaluation methods and results across different organizations or regions, making it difficult to compare and validate findings.

Lastly, the rapid pace of technological advancements in battery and BMS technologies presents a moving target for field-testing protocols. As new battery chemistries, cell designs, and BMS algorithms are developed, testing methodologies must evolve to accurately assess these innovations, requiring continuous updates to testing equipment and procedures.

The variability of real-world scenarios poses a substantial challenge in BMS field-testing. Batteries are subjected to diverse usage patterns, temperature fluctuations, and varying charge-discharge cycles, making it challenging to replicate all possible scenarios in controlled environments. This variability can lead to inconsistencies in test results and may not fully capture the BMS performance under all potential conditions.

Another critical challenge is the long-term nature of battery degradation and BMS performance. Batteries typically have lifespans of several years, making it difficult to conduct comprehensive field tests that accurately predict long-term behavior and BMS effectiveness. Accelerated aging techniques are often employed but may not perfectly simulate real-world degradation patterns.

Data collection and analysis present additional hurdles in BMS field-testing. The sheer volume of data generated during extended testing periods can be overwhelming, requiring sophisticated data management and analysis tools. Moreover, ensuring data integrity and accuracy throughout the testing process is crucial but can be challenging in field conditions.

The integration of BMS with other vehicle systems adds another layer of complexity to field-testing. Interactions between the BMS and other components, such as thermal management systems or power electronics, must be thoroughly evaluated. This system-level testing is often more challenging to conduct in field conditions compared to laboratory settings.

Safety considerations also play a significant role in BMS field-testing challenges. High-voltage battery systems pose inherent risks, necessitating stringent safety protocols that can sometimes limit the extent or nature of tests that can be performed in real-world environments.

Standardization of field-testing methodologies is another ongoing challenge. The lack of universally accepted standards for BMS field-testing can lead to inconsistencies in evaluation methods and results across different organizations or regions, making it difficult to compare and validate findings.

Lastly, the rapid pace of technological advancements in battery and BMS technologies presents a moving target for field-testing protocols. As new battery chemistries, cell designs, and BMS algorithms are developed, testing methodologies must evolve to accurately assess these innovations, requiring continuous updates to testing equipment and procedures.

Existing BMS Field-Testing Approaches

01 Battery monitoring and control systems

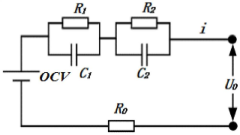

These systems monitor various parameters of batteries, such as voltage, current, temperature, and state of charge. They use this information to optimize battery performance, extend battery life, and ensure safe operation. Advanced algorithms are employed to estimate battery health and predict remaining useful life.- Battery monitoring and control systems: These systems monitor battery parameters such as voltage, current, temperature, and state of charge. They use this data to optimize battery performance, extend battery life, and ensure safe operation. Advanced algorithms are employed to estimate battery health and predict remaining useful life.

- Thermal management in battery systems: Thermal management is crucial for battery performance and safety. These systems regulate battery temperature through cooling or heating mechanisms, preventing overheating and maintaining optimal operating conditions. They may include liquid cooling systems, air cooling, or phase change materials for efficient heat dissipation.

- Cell balancing techniques: Cell balancing ensures uniform charge distribution across all cells in a battery pack. This prevents overcharging of individual cells and extends overall battery life. Various methods are used, including passive balancing with resistors and active balancing with charge redistribution circuits.

- Battery management for electric vehicles: Specialized battery management systems for electric vehicles focus on optimizing range, fast charging capabilities, and integrating with vehicle systems. These systems often include regenerative braking energy recovery and power distribution management for various vehicle components.

- Smart grid integration and energy storage management: Battery management systems for grid-scale energy storage facilitate integration with smart grids. They manage charge and discharge cycles based on grid demand, optimize energy storage efficiency, and provide grid stabilization services. These systems often incorporate predictive analytics for demand forecasting and energy arbitrage.

02 Thermal management in battery systems

Thermal management is crucial for battery performance and safety. These systems regulate battery temperature through cooling or heating mechanisms, preventing overheating and maintaining optimal operating conditions. They may include sensors, cooling circuits, and control algorithms to manage heat distribution across battery packs.Expand Specific Solutions03 Battery balancing techniques

Battery balancing ensures that all cells in a battery pack maintain similar charge levels, improving overall performance and longevity. Various balancing methods are employed, including passive and active balancing techniques, to equalize charge across cells and prevent overcharging or undercharging of individual cells.Expand Specific Solutions04 State of charge and state of health estimation

Accurate estimation of a battery's state of charge (SOC) and state of health (SOH) is essential for effective battery management. Advanced algorithms, including machine learning techniques, are used to analyze battery data and provide real-time estimates of SOC and SOH, enabling better decision-making for battery usage and maintenance.Expand Specific Solutions05 Integration with energy management systems

Battery management systems are increasingly integrated with broader energy management systems, particularly in applications like electric vehicles and renewable energy storage. This integration allows for optimized energy flow, improved grid interaction, and more efficient use of battery resources in complex energy ecosystems.Expand Specific Solutions

Key Players in BMS Testing Industry

The field of battery management system (BMS) evaluation is currently in a growth phase, with increasing market size driven by the rapid expansion of electric vehicle and energy storage sectors. The global BMS market is expected to reach significant value in the coming years, reflecting the technology's critical role in optimizing battery performance and longevity. Technologically, BMS field-testing methods are evolving, with companies like LG Energy Solution, Samsung SDI, and Contemporary Amperex Technology leading innovation. These firms, along with others such as BYD and Bosch, are investing heavily in R&D to enhance BMS capabilities, focusing on improving accuracy, reliability, and real-time monitoring features. The competitive landscape is characterized by a mix of established electronics giants and specialized battery technology firms, all vying for market share in this increasingly important sector.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has developed advanced field-testing methods for evaluating Battery Management Systems (BMS). Their approach includes real-time monitoring and analysis of battery pack performance in various environmental conditions. They utilize a combination of hardware-in-the-loop (HIL) simulation and on-road testing to validate BMS functionality[1]. Their method incorporates machine learning algorithms to predict battery degradation and optimize charging strategies based on field data[3]. LG's testing protocol also includes stress testing under extreme temperatures and rapid charge/discharge cycles to ensure BMS reliability[5].

Strengths: Comprehensive testing approach combining simulation and real-world data. Advanced predictive algorithms for battery health. Weaknesses: May require significant resources and time for extensive field testing.

Robert Bosch GmbH

Technical Solution: Bosch has implemented a multi-faceted approach to field-testing Battery Management Systems. Their methodology includes a network of sensors for continuous monitoring of battery parameters during real-world usage. They employ a cloud-based data analytics platform that processes terabytes of field data to identify patterns and anomalies in BMS performance[2]. Bosch's testing protocol incorporates accelerated aging tests combined with long-term field trials to validate BMS algorithms for state-of-charge and state-of-health estimation[4]. They also utilize electromagnetic compatibility (EMC) testing in various environments to ensure BMS reliability in different vehicle types and operating conditions[6].

Strengths: Robust data analytics capabilities. Comprehensive EMC testing for various environments. Weaknesses: High dependency on cloud infrastructure for data processing and analysis.

Innovative BMS Field-Testing Techniques

Systems and method for testing battery management systems

PatentActiveUS11480626B1

Innovation

- A control-hardware-in-the-loop testbed with a simulation bench, including a battery cell simulator, temperature simulator, and programmable power supply, is used to simulate and analyze battery performance, allowing for constrained cycling and improved voltage balancing, thereby extending the life of second-life batteries.

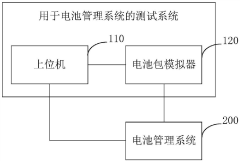

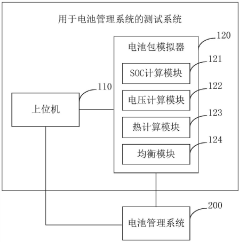

Test system and test method for battery management system

PatentActiveCN112394288A

Innovation

- Provide a test system including a host computer and a battery pack simulator, which simulates the status parameters of each single cell in the battery pack through current excitation signals and pre-configured battery pack parameters, and adjusts them according to the action instructions of the battery management system. Enable dynamic and complex testing of battery management systems.

Safety and Reliability Standards for BMS Testing

Safety and reliability standards play a crucial role in the field-testing of Battery Management Systems (BMS). These standards ensure that BMS testing procedures are consistent, comprehensive, and aligned with industry best practices. The primary focus of these standards is to guarantee the safe operation of battery systems and to maintain their reliability over extended periods.

One of the key safety standards for BMS testing is IEC 62619, which outlines safety requirements for lithium-ion batteries in industrial applications. This standard provides guidelines for testing BMS functionality, including overcharge protection, over-discharge protection, and thermal management. It also specifies requirements for cell balancing and state-of-charge estimation, which are critical for maintaining battery health and longevity.

UL 1642 is another important standard that addresses the safety of lithium batteries. While primarily focused on cell-level safety, it includes provisions for BMS testing, particularly in areas related to protection against abnormal charging conditions and short circuits. This standard is often used in conjunction with UL 2054, which covers household and commercial battery systems.

For automotive applications, ISO 26262 is a key standard that addresses functional safety in electrical and electronic systems. It provides a framework for assessing and mitigating potential hazards in BMS, ensuring that safety-critical functions are robust and reliable. This standard is particularly relevant for electric and hybrid vehicle BMS testing.

Reliability standards for BMS testing often draw from broader reliability engineering practices. IEC 61508, a standard for functional safety of electrical/electronic/programmable electronic safety-related systems, provides guidance on reliability assessment methods that can be applied to BMS testing. This includes techniques such as Failure Mode and Effects Analysis (FMEA) and Fault Tree Analysis (FTA).

The SAE J2464 standard specifically addresses electric and hybrid vehicle rechargeable energy storage systems. It includes test procedures for evaluating BMS performance under various environmental and operational conditions, providing a comprehensive approach to assessing BMS reliability in automotive applications.

In addition to these standards, many organizations develop their own internal testing protocols that build upon these industry standards. These protocols often include accelerated life testing, environmental stress screening, and long-term durability tests to ensure BMS reliability under a wide range of operating conditions.

As the field of battery technology continues to evolve, these standards are regularly updated to address new challenges and incorporate emerging best practices. Compliance with these safety and reliability standards is essential for BMS manufacturers to ensure their products meet the rigorous demands of various applications, from consumer electronics to large-scale energy storage systems.

One of the key safety standards for BMS testing is IEC 62619, which outlines safety requirements for lithium-ion batteries in industrial applications. This standard provides guidelines for testing BMS functionality, including overcharge protection, over-discharge protection, and thermal management. It also specifies requirements for cell balancing and state-of-charge estimation, which are critical for maintaining battery health and longevity.

UL 1642 is another important standard that addresses the safety of lithium batteries. While primarily focused on cell-level safety, it includes provisions for BMS testing, particularly in areas related to protection against abnormal charging conditions and short circuits. This standard is often used in conjunction with UL 2054, which covers household and commercial battery systems.

For automotive applications, ISO 26262 is a key standard that addresses functional safety in electrical and electronic systems. It provides a framework for assessing and mitigating potential hazards in BMS, ensuring that safety-critical functions are robust and reliable. This standard is particularly relevant for electric and hybrid vehicle BMS testing.

Reliability standards for BMS testing often draw from broader reliability engineering practices. IEC 61508, a standard for functional safety of electrical/electronic/programmable electronic safety-related systems, provides guidance on reliability assessment methods that can be applied to BMS testing. This includes techniques such as Failure Mode and Effects Analysis (FMEA) and Fault Tree Analysis (FTA).

The SAE J2464 standard specifically addresses electric and hybrid vehicle rechargeable energy storage systems. It includes test procedures for evaluating BMS performance under various environmental and operational conditions, providing a comprehensive approach to assessing BMS reliability in automotive applications.

In addition to these standards, many organizations develop their own internal testing protocols that build upon these industry standards. These protocols often include accelerated life testing, environmental stress screening, and long-term durability tests to ensure BMS reliability under a wide range of operating conditions.

As the field of battery technology continues to evolve, these standards are regularly updated to address new challenges and incorporate emerging best practices. Compliance with these safety and reliability standards is essential for BMS manufacturers to ensure their products meet the rigorous demands of various applications, from consumer electronics to large-scale energy storage systems.

Environmental Impact of BMS Field-Testing

Field-testing methods for evaluating Battery Management Systems (BMS) have significant environmental implications that must be carefully considered. The process of testing BMS in real-world conditions often involves the use of large-scale battery systems, which can have both direct and indirect environmental impacts.

One of the primary environmental concerns is the energy consumption associated with BMS field-testing. These tests typically require extensive charging and discharging cycles, which can lead to substantial electricity usage. This increased energy demand may contribute to higher greenhouse gas emissions, particularly if the electricity is sourced from non-renewable energy sources.

The disposal of batteries used in field-testing also presents environmental challenges. As BMS evaluations often involve pushing batteries to their limits, some cells may degrade faster than in normal use. This accelerated degradation can result in a higher volume of battery waste, which requires proper recycling or disposal to prevent environmental contamination.

Field-testing of BMS may also impact local ecosystems, especially when conducted in sensitive areas. The installation of testing equipment and the presence of personnel can disrupt wildlife habitats and vegetation. Additionally, the electromagnetic emissions from large battery systems and associated testing equipment may affect local fauna, particularly in long-term testing scenarios.

Water usage is another environmental factor to consider. Cooling systems for large battery arrays used in BMS field-testing can consume significant amounts of water, potentially straining local water resources in arid regions or during drought conditions.

The transportation of battery systems and testing equipment to field locations contributes to the carbon footprint of BMS evaluation. This includes not only the emissions from vehicles used for transport but also the potential for accidental spills or leaks of battery materials during transit, which could harm soil and water systems.

On a positive note, effective BMS field-testing can lead to improvements in battery efficiency and lifespan, which may ultimately reduce the environmental impact of battery production and disposal. By optimizing battery performance and longevity, these tests can contribute to a more sustainable energy storage ecosystem in the long term.

To mitigate the environmental impact of BMS field-testing, researchers and companies are increasingly adopting eco-friendly practices. These include using renewable energy sources to power test sites, implementing closed-loop cooling systems to reduce water consumption, and developing more efficient testing protocols to minimize the number of batteries required for evaluation.

One of the primary environmental concerns is the energy consumption associated with BMS field-testing. These tests typically require extensive charging and discharging cycles, which can lead to substantial electricity usage. This increased energy demand may contribute to higher greenhouse gas emissions, particularly if the electricity is sourced from non-renewable energy sources.

The disposal of batteries used in field-testing also presents environmental challenges. As BMS evaluations often involve pushing batteries to their limits, some cells may degrade faster than in normal use. This accelerated degradation can result in a higher volume of battery waste, which requires proper recycling or disposal to prevent environmental contamination.

Field-testing of BMS may also impact local ecosystems, especially when conducted in sensitive areas. The installation of testing equipment and the presence of personnel can disrupt wildlife habitats and vegetation. Additionally, the electromagnetic emissions from large battery systems and associated testing equipment may affect local fauna, particularly in long-term testing scenarios.

Water usage is another environmental factor to consider. Cooling systems for large battery arrays used in BMS field-testing can consume significant amounts of water, potentially straining local water resources in arid regions or during drought conditions.

The transportation of battery systems and testing equipment to field locations contributes to the carbon footprint of BMS evaluation. This includes not only the emissions from vehicles used for transport but also the potential for accidental spills or leaks of battery materials during transit, which could harm soil and water systems.

On a positive note, effective BMS field-testing can lead to improvements in battery efficiency and lifespan, which may ultimately reduce the environmental impact of battery production and disposal. By optimizing battery performance and longevity, these tests can contribute to a more sustainable energy storage ecosystem in the long term.

To mitigate the environmental impact of BMS field-testing, researchers and companies are increasingly adopting eco-friendly practices. These include using renewable energy sources to power test sites, implementing closed-loop cooling systems to reduce water consumption, and developing more efficient testing protocols to minimize the number of batteries required for evaluation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!