Graphene Oxide: Pushing Limits in Proton Exchange Membranes

Graphene Oxide PEM Evolution and Objectives

Graphene oxide (GO) has emerged as a revolutionary material in the field of proton exchange membranes (PEMs), offering unprecedented potential for enhancing fuel cell performance. The evolution of GO-based PEMs can be traced back to the early 2000s when researchers first began exploring the unique properties of graphene and its derivatives for energy applications.

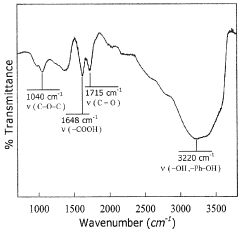

Initially, the focus was on understanding the fundamental characteristics of GO, such as its high surface area, excellent mechanical strength, and tunable oxygen-containing functional groups. These properties made GO an attractive candidate for PEM development, promising improved proton conductivity and reduced fuel crossover compared to traditional materials like Nafion.

As research progressed, scientists discovered that GO's two-dimensional structure could be leveraged to create highly ordered channels for proton transport. This realization led to a surge in studies aimed at optimizing GO's structure and composition for PEM applications. Researchers began experimenting with various synthesis methods, including chemical exfoliation and modified Hummers' method, to produce GO with tailored properties.

The mid-2010s saw a significant breakthrough with the development of GO-based composite membranes. By incorporating GO into polymer matrices, researchers were able to overcome some of the limitations of pure GO membranes, such as brittleness and poor mechanical stability. These composite membranes demonstrated enhanced proton conductivity and improved mechanical properties, paving the way for practical applications in fuel cells.

Recent years have witnessed a shift towards more sophisticated GO-based PEMs, with researchers exploring novel functionalization techniques and hybrid materials. The integration of GO with other nanomaterials, such as metal-organic frameworks and carbon nanotubes, has opened up new avenues for pushing the limits of PEM performance.

The primary objectives in GO-based PEM research now focus on several key areas. First, there is a concerted effort to enhance proton conductivity under various operating conditions, particularly at high temperatures and low humidity. Researchers aim to achieve conductivity values that surpass those of conventional PEMs while maintaining excellent mechanical and chemical stability.

Another crucial objective is to improve the durability and longevity of GO-based PEMs. This involves developing strategies to mitigate degradation mechanisms and enhance the membrane's resistance to chemical and mechanical stresses during fuel cell operation. Additionally, researchers are working on optimizing the water management capabilities of GO-based PEMs to ensure efficient proton transport without compromising fuel cell performance.

As the field continues to evolve, there is a growing emphasis on scalability and cost-effectiveness. The ultimate goal is to develop GO-based PEMs that not only outperform existing technologies but also offer a viable pathway for large-scale production and commercialization in fuel cell applications.

Market Demand Analysis for Advanced PEMs

The market demand for advanced Proton Exchange Membranes (PEMs) has been experiencing significant growth, driven by the increasing focus on clean energy solutions and the rapid development of fuel cell technologies. The global PEM market is projected to expand substantially over the next decade, with a compound annual growth rate (CAGR) exceeding 20% in some regions. This growth is primarily fueled by the automotive sector's shift towards hydrogen fuel cell vehicles, as well as the rising adoption of stationary fuel cell systems for power generation.

In the automotive industry, major manufacturers are investing heavily in fuel cell electric vehicles (FCEVs), creating a robust demand for high-performance PEMs. Countries like Japan, South Korea, and Germany are at the forefront of this transition, with ambitious targets for FCEV adoption. This shift is expected to drive the demand for advanced PEMs that can operate at higher temperatures and pressures, offering improved efficiency and durability.

The stationary power generation sector is another key driver for advanced PEM demand. As countries strive to decarbonize their energy systems, fuel cells are increasingly being considered for both primary and backup power applications. This trend is particularly evident in data centers, telecommunications, and remote off-grid locations, where reliable and clean power sources are crucial.

The aerospace industry is also showing growing interest in fuel cell technologies, particularly for unmanned aerial vehicles (UAVs) and auxiliary power units in commercial aircraft. This emerging market segment is expected to contribute to the overall demand for advanced PEMs in the coming years.

Geographically, Asia-Pacific is anticipated to be the fastest-growing market for advanced PEMs, driven by strong government support and investments in hydrogen infrastructure in countries like China, Japan, and South Korea. North America and Europe are also expected to see substantial growth, supported by stringent emissions regulations and increasing adoption of clean energy technologies.

However, the market faces challenges such as high production costs and the need for improved durability and performance of PEMs. These factors are driving research and development efforts towards novel materials and manufacturing processes, with graphene oxide emerging as a promising candidate for next-generation PEMs.

The demand for advanced PEMs is closely tied to the broader hydrogen economy, which is gaining momentum globally. As hydrogen production, storage, and distribution infrastructure expands, it is expected to create a positive feedback loop, further boosting the demand for fuel cell technologies and, consequently, advanced PEMs.

Current Challenges in Graphene Oxide PEM Technology

Despite the promising potential of graphene oxide (GO) in proton exchange membranes (PEMs), several significant challenges hinder its widespread adoption and commercialization. One of the primary obstacles is the difficulty in achieving consistent and uniform dispersion of GO within the polymer matrix. The tendency of GO sheets to aggregate due to strong van der Waals interactions compromises the overall performance and stability of the membrane.

Another critical challenge lies in balancing proton conductivity and mechanical strength. While increasing GO content can enhance proton conductivity, it often leads to a decrease in mechanical stability. This trade-off necessitates careful optimization to achieve a balance between these two crucial properties, which is essential for practical applications in fuel cells and other electrochemical devices.

The long-term stability of GO-based PEMs remains a concern, particularly under the harsh operating conditions typical of fuel cells. Degradation of GO over time can lead to a decrease in membrane performance and durability. This issue is exacerbated by the chemical and thermal instability of GO, which can undergo reduction or decomposition under certain conditions, altering its properties and potentially compromising the membrane's integrity.

Furthermore, the scalability of GO production and membrane fabrication processes presents a significant hurdle. Current methods for synthesizing high-quality GO and incorporating it into polymer matrices are often complex, time-consuming, and not easily scalable to industrial levels. This limitation hampers the transition from laboratory-scale success to commercial viability.

The environmental impact and potential toxicity of GO nanoparticles also pose challenges that need to be addressed. As the use of GO in PEMs increases, concerns about its long-term effects on human health and the environment must be thoroughly investigated and mitigated to ensure sustainable development and widespread acceptance of this technology.

Lastly, the cost-effectiveness of GO-based PEMs compared to traditional alternatives remains a significant barrier to commercialization. While GO offers superior performance in many aspects, the current production costs and complexities in membrane fabrication make it challenging to compete with established technologies on a cost basis. Overcoming this economic hurdle is crucial for the widespread adoption of GO-based PEMs in various applications.

Existing Graphene Oxide PEM Solutions

01 Graphene oxide-based proton exchange membranes

Graphene oxide is used as a key component in developing proton exchange membranes for fuel cells and other electrochemical devices. These membranes exhibit enhanced proton conductivity, mechanical strength, and thermal stability compared to traditional membranes. The incorporation of graphene oxide improves the overall performance and efficiency of proton exchange membrane systems.- Graphene oxide-based proton exchange membranes: Graphene oxide is used as a key component in developing high-performance proton exchange membranes. These membranes exhibit improved proton conductivity, mechanical strength, and chemical stability, making them suitable for fuel cell applications and other electrochemical devices.

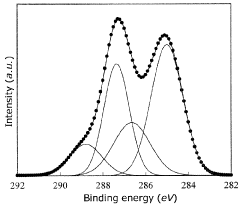

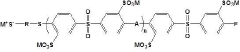

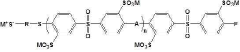

- Functionalization of graphene oxide for enhanced proton conductivity: Various methods are employed to functionalize graphene oxide, such as sulfonation or incorporation of other functional groups, to enhance its proton conductivity. This modification improves the membrane's performance in proton exchange applications.

- Composite membranes incorporating graphene oxide: Graphene oxide is combined with other materials, such as polymers or inorganic compounds, to create composite membranes. These composites often demonstrate synergistic effects, resulting in improved proton conductivity, mechanical properties, and durability compared to single-component membranes.

- Graphene oxide-based proton exchange membranes for fuel cells: Graphene oxide-based proton exchange membranes are specifically designed and optimized for use in fuel cell applications. These membranes aim to enhance fuel cell efficiency, power density, and overall performance by improving proton transport and reducing fuel crossover.

- Fabrication methods for graphene oxide proton exchange membranes: Various fabrication techniques are developed to produce graphene oxide-based proton exchange membranes with desired properties. These methods include solution casting, layer-by-layer assembly, in-situ polymerization, and other novel approaches to optimize membrane structure and performance.

02 Functionalization of graphene oxide for proton exchange

Various methods are employed to functionalize graphene oxide, enhancing its proton exchange capabilities. These include surface modification, doping with heteroatoms, and incorporation of functional groups. Functionalization improves proton conductivity, water retention, and overall membrane performance in fuel cell applications.Expand Specific Solutions03 Composite membranes incorporating graphene oxide

Composite membranes are developed by combining graphene oxide with other materials such as polymers, inorganic compounds, or other nanomaterials. These composites synergistically enhance proton conductivity, mechanical properties, and durability of the membranes. The resulting hybrid structures offer improved performance in various electrochemical applications.Expand Specific Solutions04 Graphene oxide-based proton exchange membrane fabrication techniques

Various fabrication techniques are developed to produce graphene oxide-based proton exchange membranes. These include solution casting, layer-by-layer assembly, in-situ polymerization, and electrospinning. The fabrication methods aim to optimize membrane structure, thickness, and uniformity for enhanced proton exchange properties.Expand Specific Solutions05 Applications of graphene oxide in proton exchange devices

Graphene oxide-based proton exchange membranes find applications in various devices and systems. These include fuel cells, water electrolysis, sensors, and energy storage devices. The unique properties of graphene oxide contribute to improved device performance, efficiency, and durability in these applications.Expand Specific Solutions

Key Players in Graphene Oxide PEM Research

The graphene oxide-based proton exchange membrane technology is in a rapidly evolving phase, with significant market potential in the fuel cell and energy storage sectors. The global market for these membranes is expanding, driven by the increasing demand for clean energy solutions. Technologically, the field is advancing quickly, with various research institutions and companies making notable progress. Key players like Shanghai Institute of Applied Physics, University of Florida, and Korea Research Institute of Chemical Technology are at the forefront of innovation. Companies such as GM Global Technology Operations LLC and Toyota Motor Corp. are also investing in this technology, indicating its growing commercial viability. The involvement of diverse organizations, from academic institutions to major automotive manufacturers, suggests a competitive and collaborative landscape with promising future developments.

Toyota Motor Corp.

Via Separations, Inc.

Breakthrough Innovations in Graphene Oxide PEMs

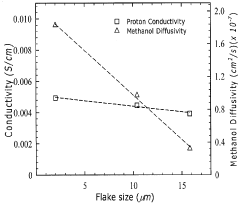

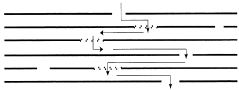

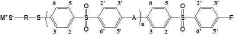

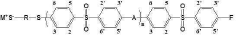

- Development of graphene oxide (GO) and sulfonated graphene oxide (SGO) PEMs in the form of laminates with large platelets (>10 μm) that suppress methanol crossover while maintaining proton conductivity, using larger platelets to enhance stability and reduce methanol diffusivity.

- A polymer compound with sulfonic acid groups is introduced to graphene oxide, forming sulfonated graphene oxide, which is then used as a filler in cation exchange membranes, enhancing compatibility and conductivity.

Environmental Impact of Graphene Oxide PEMs

The environmental impact of Graphene Oxide Proton Exchange Membranes (GO PEMs) is a critical consideration in their development and implementation. These advanced materials offer promising solutions for clean energy technologies, particularly in fuel cells and water purification systems. However, their potential environmental effects must be carefully evaluated throughout their lifecycle.

During the production phase of GO PEMs, the synthesis of graphene oxide involves chemical processes that may generate hazardous waste. The use of strong oxidizing agents and acids in the Hummers method, a common technique for GO production, raises concerns about proper waste management and potential environmental contamination. Efforts to develop greener synthesis methods are ongoing, aiming to reduce the environmental footprint of GO production.

The application of GO PEMs in fuel cells contributes to the advancement of clean energy technologies, potentially reducing greenhouse gas emissions associated with traditional power generation. By enhancing the efficiency of fuel cells, GO PEMs indirectly support the transition to more sustainable energy sources, thus positively impacting air quality and climate change mitigation efforts.

In water treatment applications, GO PEMs demonstrate excellent filtration capabilities, effectively removing contaminants and improving water quality. This technology could play a crucial role in addressing global water scarcity issues and reducing the environmental impact of water pollution. However, the long-term effects of nanomaterial release into aquatic ecosystems during the filtration process require further investigation.

The durability and lifespan of GO PEMs are important factors in assessing their overall environmental impact. Longer-lasting membranes reduce the frequency of replacement, minimizing waste generation and resource consumption. Research into improving the stability and resistance of GO PEMs to degradation is essential for enhancing their environmental sustainability.

End-of-life considerations for GO PEMs present both challenges and opportunities. The potential for recycling and recovering graphene oxide from used membranes could significantly reduce waste and conserve resources. However, the development of efficient recycling processes for these complex materials is still in its early stages and requires further research and innovation.

The potential bioaccumulation and ecotoxicity of graphene-based materials in the environment remain areas of concern. While initial studies suggest low acute toxicity, the long-term effects of GO nanoparticles on ecosystems and human health are not fully understood. Continued research into the environmental fate and behavior of GO is crucial for ensuring the safe and sustainable use of GO PEMs.

Scalability and Manufacturing Considerations

The scalability and manufacturing considerations for graphene oxide-based proton exchange membranes (PEMs) are crucial factors in determining their commercial viability and widespread adoption. As research progresses, the focus is shifting from laboratory-scale production to industrial-scale manufacturing processes.

One of the primary challenges in scaling up graphene oxide PEM production is maintaining consistent quality and performance across large batches. The synthesis of graphene oxide itself requires careful control of oxidation conditions, and any variations can lead to inconsistencies in the final membrane properties. Developing robust and reproducible manufacturing protocols is essential to ensure uniform membrane thickness, porosity, and proton conductivity.

Another critical aspect is the cost-effectiveness of large-scale production. While graphene oxide offers superior performance compared to traditional PEM materials, its manufacturing process is currently more expensive. Researchers and industry partners are exploring ways to optimize the production chain, from raw material sourcing to final membrane fabrication, to reduce overall costs and make graphene oxide PEMs economically competitive.

The environmental impact of manufacturing graphene oxide PEMs at scale is also a significant consideration. The production process often involves the use of strong oxidizing agents and acids, which can pose environmental risks if not properly managed. Developing greener synthesis methods and implementing efficient waste treatment systems are crucial for sustainable large-scale manufacturing.

Integration of graphene oxide PEMs into existing fuel cell production lines presents another challenge. Manufacturers need to adapt their assembly processes and equipment to accommodate the unique properties of graphene oxide membranes. This may require significant investment in new machinery and training for personnel.

Durability and long-term stability of graphene oxide PEMs under real-world operating conditions are critical factors that need to be addressed for successful commercialization. Accelerated aging tests and extensive field trials are necessary to validate the performance and longevity of these membranes in various applications, from portable electronics to automotive fuel cells.

As the technology matures, standardization of graphene oxide PEM manufacturing processes and quality control measures will become increasingly important. Establishing industry-wide standards will facilitate consistency across different manufacturers and ensure that graphene oxide PEMs meet the rigorous requirements of various applications.