HDPE Bio-Based Alternatives: Pioneering Sustainable Solutions

HDPE Bio-Based Evolution

The evolution of HDPE bio-based alternatives represents a significant shift in the plastics industry towards more sustainable and environmentally friendly solutions. This journey began in the early 2000s when concerns about petroleum-based plastics' environmental impact gained traction. Initially, research focused on developing bio-based polymers that could mimic HDPE's properties while reducing reliance on fossil fuels.

The first generation of bio-based alternatives to HDPE emerged around 2005, primarily derived from corn and sugarcane. These early materials faced challenges in matching HDPE's performance, particularly in terms of durability and moisture resistance. However, they paved the way for further innovation and research into more advanced bio-based polymers.

By 2010, the second generation of bio-based HDPE alternatives began to surface. These materials incorporated a wider range of feedstocks, including agricultural waste and non-food crops. This diversification helped address concerns about competition with food production and improved the overall sustainability profile of bio-based plastics.

A significant breakthrough came in 2015 with the development of drop-in bio-based HDPE alternatives. These materials were chemically identical to conventional HDPE but produced from renewable resources. This innovation allowed for seamless integration into existing manufacturing processes and recycling streams, overcoming a major hurdle in adoption.

The period from 2015 to 2020 saw rapid advancements in production technologies and feedstock efficiency. Researchers and companies focused on optimizing fermentation processes and developing new catalysts to improve yield and reduce production costs. This era also witnessed the emergence of hybrid materials, combining bio-based components with recycled content to further enhance sustainability.

Most recently, from 2020 onwards, the focus has shifted towards creating fully circular bio-based alternatives to HDPE. This includes developing materials that are not only bio-based but also biodegradable or easily recyclable. Innovations in this area aim to address the entire lifecycle of plastic products, from production to end-of-life management.

Looking ahead, the evolution of HDPE bio-based alternatives is expected to continue along several key trajectories. These include further improvements in material performance, expansion of feedstock sources to include more diverse and sustainable options, and the development of advanced recycling technologies specifically tailored for bio-based plastics. The ultimate goal is to create a new generation of materials that can fully replace conventional HDPE while offering superior environmental benefits and maintaining or exceeding current performance standards.

Market Demand Analysis

The market demand for bio-based alternatives to HDPE (High-Density Polyethylene) has been steadily increasing in recent years, driven by growing environmental concerns and the push for sustainable materials. As consumers and businesses become more environmentally conscious, there is a significant shift towards eco-friendly packaging and product solutions. This trend is particularly evident in industries such as packaging, consumer goods, and automotive, where HDPE is widely used.

The global bio-based plastics market, which includes alternatives to HDPE, has been experiencing robust growth. This growth is fueled by stringent regulations on single-use plastics, increasing corporate sustainability initiatives, and consumer preferences for environmentally friendly products. Major retailers and consumer goods companies have set ambitious targets to incorporate more sustainable packaging materials, creating a substantial demand for bio-based HDPE alternatives.

In the packaging sector, which accounts for a significant portion of HDPE usage, there is a strong push for renewable and compostable materials. Food and beverage companies, in particular, are seeking bio-based alternatives that can match the performance characteristics of traditional HDPE while offering improved environmental profiles. This demand extends to personal care and household product packaging, where brands are differentiating themselves through sustainable packaging choices.

The automotive industry represents another key market for bio-based HDPE alternatives. As automakers strive to reduce vehicle weight and improve fuel efficiency, they are increasingly looking at bio-based plastics as a viable option for various components. The durability and chemical resistance of HDPE make its bio-based alternatives particularly attractive for automotive applications.

Agriculture and horticulture sectors are also showing increased interest in bio-based HDPE alternatives for applications such as mulch films, greenhouse covers, and irrigation systems. The biodegradability of some bio-based alternatives offers significant advantages in these sectors, addressing concerns about plastic accumulation in soil.

Market analysts project continued growth in the demand for bio-based HDPE alternatives. This growth is expected to be driven by advancements in material science, improving the performance and cost-effectiveness of these alternatives. Additionally, the expansion of production capacities for bio-based materials is likely to make them more competitive with traditional HDPE in terms of price and availability.

However, challenges remain in fully realizing the market potential of bio-based HDPE alternatives. These include the need for further improvements in material properties, scaling up production to meet growing demand, and addressing concerns about land use for bio-based feedstocks. Despite these challenges, the overall market trajectory for bio-based HDPE alternatives remains positive, with significant opportunities for innovation and market expansion in the coming years.

Technical Challenges

The development of bio-based alternatives to HDPE faces several significant technical challenges. One of the primary obstacles is achieving comparable mechanical properties to conventional HDPE. Bio-based polymers often exhibit lower tensile strength, impact resistance, and thermal stability, which limits their applicability in high-performance applications.

Another major challenge lies in the scalability of production processes for bio-based HDPE alternatives. Current manufacturing methods for these materials are often less efficient and more costly than those for traditional HDPE. This disparity in production efficiency creates barriers to widespread adoption and market competitiveness.

The variability and inconsistency of bio-based raw materials pose additional challenges. Unlike petroleum-based feedstocks, which are relatively uniform, bio-based sources can vary significantly in composition and quality depending on factors such as growing conditions and harvesting methods. This variability can lead to inconsistencies in the final product, making it difficult to maintain uniform quality standards.

Durability and long-term performance of bio-based HDPE alternatives remain concerns. These materials may be more susceptible to degradation under certain environmental conditions, potentially limiting their use in applications requiring long-term stability or exposure to harsh environments.

The development of effective additives and compatibilizers for bio-based HDPE alternatives presents another technical hurdle. These additives are crucial for enhancing properties such as UV resistance, flame retardancy, and processability, but finding bio-based or environmentally friendly alternatives that perform as well as conventional additives is challenging.

Recycling and end-of-life management of bio-based HDPE alternatives also pose technical difficulties. Many of these materials are not compatible with existing recycling streams for conventional plastics, necessitating the development of new recycling technologies and infrastructure.

Lastly, achieving full biodegradability while maintaining the desired performance characteristics remains a significant challenge. While some bio-based alternatives offer improved biodegradability compared to HDPE, balancing this property with the need for durability and strength during the product's intended lifespan is complex and requires further innovation in material science and polymer engineering.

Current Bio-HDPE Solutions

01 Bio-based polymers as HDPE alternatives

Various bio-based polymers are being developed as alternatives to HDPE. These include polymers derived from renewable resources such as plant-based materials, which offer similar properties to HDPE while reducing reliance on fossil fuels. These bio-based alternatives aim to provide comparable strength, durability, and processability to traditional HDPE.- Bio-based polymers as HDPE alternatives: Various bio-based polymers are being developed as alternatives to HDPE. These include polymers derived from renewable resources such as plant-based materials, which offer similar properties to HDPE while reducing reliance on fossil fuels. These bio-based alternatives aim to provide comparable strength, durability, and processability to traditional HDPE.

- Blends of bio-based materials with HDPE: Research is focused on creating blends that combine bio-based materials with traditional HDPE. These blends aim to maintain the desirable properties of HDPE while incorporating renewable content. The goal is to develop materials that can be processed using existing HDPE manufacturing equipment and techniques, facilitating easier adoption by industry.

- Biodegradable HDPE alternatives: Development of biodegradable alternatives to HDPE is another area of focus. These materials are designed to break down more readily in the environment, addressing concerns about plastic pollution. Research is ongoing to improve the mechanical properties and processability of these biodegradable alternatives to match those of conventional HDPE.

- Recycling and upcycling of HDPE: Innovations in recycling and upcycling technologies for HDPE are being developed as an alternative to virgin HDPE production. These processes aim to improve the quality of recycled HDPE, making it suitable for a wider range of applications and reducing the need for new plastic production from fossil fuels.

- Novel processing techniques for bio-based HDPE alternatives: New processing techniques are being explored to enhance the properties of bio-based HDPE alternatives. These include methods to improve the crystallinity, molecular weight distribution, and overall performance of bio-based polymers. The goal is to create materials that can directly replace HDPE in various applications without compromising on quality or performance.

02 Blends of bio-based materials with HDPE

Researchers are exploring blends of bio-based materials with HDPE to create hybrid materials that combine the benefits of both. These blends can improve the environmental profile of the resulting material while maintaining or enhancing certain performance characteristics. The bio-based components can help reduce the overall carbon footprint of the product.Expand Specific Solutions03 Biodegradable alternatives to HDPE

Development of biodegradable alternatives that can replace HDPE in certain applications is ongoing. These materials are designed to break down more readily in the environment, addressing concerns about plastic pollution. While they may not match all of HDPE's properties, they offer a more environmentally friendly option for specific use cases.Expand Specific Solutions04 Recycling and upcycling of HDPE

Innovative recycling and upcycling techniques are being developed to give HDPE a second life, reducing the need for virgin material production. These processes aim to maintain or improve the properties of recycled HDPE, making it a viable alternative to new HDPE production. Advanced sorting and purification methods are key to this approach.Expand Specific Solutions05 Novel processing techniques for bio-based HDPE alternatives

New processing techniques are being explored to enhance the properties of bio-based HDPE alternatives. These methods aim to improve the mechanical properties, thermal stability, and processability of bio-based materials to make them more competitive with traditional HDPE. Techniques may include novel polymerization methods or post-processing treatments.Expand Specific Solutions

Key Industry Players

The development of HDPE bio-based alternatives is in a nascent stage, with significant growth potential as the market for sustainable plastics expands. The global bio-based plastics market is projected to reach $19.93 billion by 2026, driven by increasing environmental concerns and regulatory pressures. The technology's maturity varies among key players, with companies like Braskem SA and Archer-Daniels-Midland Co. leading in commercial production. Research institutions such as Tianjin University and South China University of Technology are advancing the fundamental science, while industrial players like China Petroleum & Chemical Corp. and Stora Enso Oyj are focusing on scalable production methods. The competitive landscape is diverse, with a mix of established petrochemical companies, dedicated bioplastics firms, and innovative startups all vying for market share in this rapidly evolving sector.

Stora Enso Oyj

Braskem SA

Innovative Bio-Feedstocks

- A coextrusion process involving an inner layer blend of 10-25 wt-% LDPE with 75-90 wt-% of higher melt viscosity polyethylene (LLDPE or HDPE) and an outer layer of over 90 wt-% HDPE, enhancing adhesion and heat-sealability, with the option of additional layers for improved barriers, is used to create a multilayer structure for packaging materials.

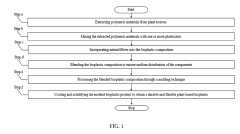

- A method involving the extraction of polymeric materials from renewable plant sources, mixing with plasticizers, incorporation of natural fibers, and processing through standard molding techniques to produce biodegradable and compostable bioplastics with enhanced mechanical properties and thermal stability.

Environmental Impact

The environmental impact of HDPE bio-based alternatives is a critical consideration in the pursuit of sustainable solutions. These alternatives offer significant potential for reducing the carbon footprint associated with traditional petroleum-based HDPE production. Bio-based materials, derived from renewable resources such as plant-based feedstocks, contribute to a circular economy by utilizing carbon that is already part of the natural carbon cycle.

One of the primary environmental benefits of HDPE bio-based alternatives is the reduction in greenhouse gas emissions. Studies have shown that the production of bio-based plastics can result in up to 80% lower carbon dioxide emissions compared to their fossil-fuel counterparts. This reduction is attributed to the carbon sequestration that occurs during the growth of the biomass used as feedstock.

Additionally, the use of renewable resources in the production of bio-based HDPE alternatives helps to conserve finite fossil fuel reserves. This shift towards renewable feedstocks promotes a more sustainable resource management approach, aligning with global efforts to reduce dependence on non-renewable energy sources.

However, it is essential to consider the entire life cycle of these bio-based alternatives when assessing their environmental impact. Land use changes, water consumption, and potential competition with food crops are factors that must be carefully evaluated. Sustainable agricultural practices and efficient use of biomass resources are crucial to maximizing the environmental benefits of these alternatives.

The end-of-life management of bio-based HDPE alternatives also plays a significant role in their overall environmental impact. Many of these materials are designed to be biodegradable or compostable, potentially reducing the accumulation of plastic waste in landfills and oceans. However, proper waste management infrastructure and consumer education are necessary to ensure these materials are disposed of correctly and their environmental benefits are fully realized.

Furthermore, the development of bio-based HDPE alternatives contributes to the advancement of green chemistry principles. These innovations often involve more environmentally friendly production processes, utilizing less toxic chemicals and reducing the overall environmental burden of plastic manufacturing.

As the technology for producing bio-based HDPE alternatives continues to evolve, improvements in energy efficiency and resource utilization are expected. This ongoing development promises to further enhance the environmental benefits of these sustainable solutions, paving the way for a more eco-friendly future in plastic production and use.

Regulatory Framework

The regulatory framework surrounding HDPE bio-based alternatives plays a crucial role in shaping the development, adoption, and market penetration of these sustainable solutions. Governments worldwide are increasingly implementing policies and regulations to promote the use of bio-based materials and reduce reliance on fossil fuel-derived plastics.

In the European Union, the Circular Economy Action Plan and the European Green Deal have set ambitious targets for reducing plastic waste and promoting bio-based alternatives. The EU Plastics Strategy aims to make all plastic packaging recyclable or reusable by 2030, creating a strong incentive for the development of bio-based HDPE alternatives. Additionally, the EU's Single-Use Plastics Directive has banned certain single-use plastic items, further driving the demand for sustainable alternatives.

In the United States, the Sustainable Chemistry Research and Development Act of 2019 aims to support the development of sustainable chemistry, including bio-based materials. Several states have also implemented their own regulations, such as California's Plastic Pollution Prevention and Packaging Producer Responsibility Act, which mandates the use of recyclable or compostable packaging materials.

Many countries have introduced extended producer responsibility (EPR) schemes, which require manufacturers to take responsibility for the entire lifecycle of their products, including disposal. These regulations incentivize the use of bio-based materials that can be more easily recycled or composted.

Certification systems and standards play a vital role in the regulatory landscape. The International Sustainability and Carbon Certification (ISCC) and the Roundtable on Sustainable Biomaterials (RSB) provide frameworks for assessing the sustainability of bio-based materials. These certifications help ensure that bio-based HDPE alternatives meet specific environmental and social criteria.

Tax incentives and subsidies are also being implemented in various jurisdictions to encourage the production and use of bio-based materials. For example, some countries offer tax credits for companies that invest in research and development of sustainable materials or provide subsidies for the production of bio-based plastics.

However, the regulatory landscape is not without challenges. The lack of harmonized global standards for bio-based materials can create confusion and hinder international trade. Additionally, some regulations may inadvertently favor certain types of bio-based materials over others, potentially limiting innovation in the field.

As the industry continues to evolve, it is likely that regulatory frameworks will adapt to address emerging challenges and opportunities in the development of HDPE bio-based alternatives. Stakeholders in this field must stay informed about regulatory changes and actively engage with policymakers to ensure that regulations support innovation while maintaining environmental and safety standards.