HDPE in Construction: Benefits and Limitations

HDPE in Construction: Overview and Objectives

High-Density Polyethylene (HDPE) has emerged as a versatile and innovative material in the construction industry, offering a unique combination of properties that address various challenges faced by traditional building materials. This technical research report aims to provide a comprehensive overview of HDPE's applications in construction and outline the objectives for its further development and implementation.

HDPE, a thermoplastic polymer derived from petroleum, has gained significant traction in construction due to its exceptional durability, chemical resistance, and flexibility. Its evolution from a simple plastic to a crucial construction material reflects the industry's growing demand for sustainable, cost-effective, and high-performance solutions. The primary goal of this research is to explore the benefits and limitations of HDPE in construction applications, paving the way for informed decision-making and strategic planning in the sector.

The construction industry has witnessed a paradigm shift towards materials that offer enhanced longevity, reduced maintenance requirements, and improved environmental sustainability. HDPE aligns well with these trends, presenting opportunities for innovation in various construction elements such as piping systems, geomembranes, and structural components. By examining the current state of HDPE technology and its potential for future advancements, this report seeks to identify key areas for research and development.

One of the primary objectives of this study is to assess the performance of HDPE in different construction applications, comparing it with traditional materials like concrete, steel, and PVC. This comparative analysis will focus on crucial factors such as strength-to-weight ratio, chemical resistance, thermal properties, and long-term durability. Additionally, the report aims to evaluate the economic implications of HDPE adoption, considering both initial costs and life-cycle expenses.

Environmental considerations form a critical aspect of this research. As the construction industry faces increasing pressure to reduce its carbon footprint, the report will investigate HDPE's environmental impact, including its production process, recyclability, and potential for reducing energy consumption in buildings. This analysis will help determine HDPE's role in sustainable construction practices and its alignment with global environmental regulations.

Furthermore, this technical research aims to identify the current limitations and challenges associated with HDPE in construction. These may include concerns about fire resistance, UV stability, and long-term performance under extreme conditions. By understanding these limitations, the report will propose potential research directions and technological innovations to overcome these obstacles, thereby expanding HDPE's applicability in the construction sector.

Lastly, the report will explore emerging trends and future prospects for HDPE in construction. This includes examining ongoing research in HDPE composites, nanotechnology applications, and advanced manufacturing techniques that could enhance HDPE's properties and broaden its use in construction. By providing a forward-looking perspective, this research aims to guide industry stakeholders in leveraging HDPE's potential to address future construction challenges and opportunities.

Market Analysis for HDPE in Construction

The market for High-Density Polyethylene (HDPE) in the construction industry has experienced significant growth in recent years, driven by the material's unique properties and versatility. HDPE's durability, chemical resistance, and flexibility make it an attractive option for various construction applications, including pipes, geomembranes, and structural components.

The global HDPE market in construction is projected to continue its upward trajectory, with a compound annual growth rate (CAGR) expected to remain strong over the next five years. This growth is primarily fueled by increasing infrastructure development, particularly in emerging economies, and the rising demand for sustainable and long-lasting construction materials.

In the piping sector, HDPE has gained substantial market share, particularly in water and wastewater management systems. Its corrosion resistance and ability to withstand high pressure make it an ideal choice for underground pipelines. The material's flexibility also allows for trenchless installation methods, reducing construction time and costs.

The geomembrane segment represents another significant market for HDPE in construction. These impermeable membranes are widely used in landfills, reservoirs, and mining applications due to their excellent chemical resistance and durability. The growing emphasis on environmental protection and waste management is expected to drive further demand in this sector.

HDPE's use in structural applications, such as bridge decks and marine structures, is an emerging trend. While still a relatively small segment, it shows promise due to the material's lightweight nature and resistance to environmental degradation. However, adoption in this area faces challenges related to building codes and long-term performance data.

Regionally, Asia-Pacific dominates the HDPE construction market, with China and India leading in consumption. The rapid urbanization and infrastructure development in these countries are key drivers. North America and Europe follow, with steady growth driven by renovation and replacement of aging infrastructure.

Despite its growth, the HDPE market faces challenges. Fluctuations in raw material prices, primarily derived from petroleum, can impact profitability. Additionally, increasing environmental concerns about plastic waste have led to calls for more sustainable alternatives, prompting the industry to invest in recycling technologies and bio-based HDPE options.

The competitive landscape of the HDPE construction market is characterized by a mix of large multinational corporations and regional players. Key market strategies include product innovation, focusing on developing HDPE grades with enhanced properties, and vertical integration to secure raw material supply and control costs.

Current HDPE Applications and Challenges

High-density polyethylene (HDPE) has gained significant traction in the construction industry due to its unique properties and versatility. Currently, HDPE finds extensive applications in various construction sectors, including plumbing, drainage systems, geomembranes, and underground utility protection.

In the plumbing sector, HDPE pipes have become increasingly popular for both potable water distribution and wastewater management. Their corrosion resistance, flexibility, and long service life make them an attractive alternative to traditional materials like copper or PVC. HDPE pipes can withstand high pressure and are less prone to leaks, reducing maintenance costs and improving overall system efficiency.

For drainage applications, HDPE has proven to be an excellent choice for stormwater management and agricultural drainage. The material's smooth inner surface facilitates efficient water flow, while its durability ensures long-term performance even in challenging soil conditions. HDPE drainage pipes are also lightweight, making installation easier and more cost-effective compared to concrete or metal alternatives.

Geomembranes made from HDPE play a crucial role in environmental protection and waste management. These impermeable liners are used in landfills, reservoirs, and contaminated site remediation projects to prevent leachate infiltration and protect groundwater resources. The material's chemical resistance and UV stability contribute to its effectiveness in these applications.

In underground utility protection, HDPE conduits and ducts provide a robust solution for safeguarding electrical cables, telecommunications lines, and other sensitive infrastructure. The material's impact resistance and flexibility help prevent damage from ground movement or external forces, ensuring the longevity of buried utilities.

Despite its numerous advantages, HDPE faces several challenges in the construction industry. One significant limitation is its susceptibility to thermal expansion and contraction, which can lead to dimensional instability in certain applications. This characteristic requires careful consideration during design and installation to prevent potential issues such as buckling or joint separation.

Another challenge is the material's relatively high initial cost compared to some traditional construction materials. While HDPE often proves more cost-effective over its lifecycle due to reduced maintenance and replacement needs, the upfront investment can be a barrier to adoption for budget-conscious projects.

The joining of HDPE components, particularly in large-scale applications, can also present challenges. Specialized equipment and skilled personnel are required for heat fusion welding, which is the preferred method for creating strong, leak-proof connections. This requirement can increase installation complexity and costs, especially in remote or resource-limited areas.

Furthermore, the recycling and end-of-life management of HDPE construction materials pose environmental concerns. While HDPE is theoretically recyclable, the presence of additives and contaminants in construction-grade HDPE can complicate the recycling process, potentially limiting its circularity in the built environment.

HDPE Construction Solutions and Techniques

01 Composition and properties of HDPE

High-Density Polyethylene (HDPE) is a thermoplastic polymer with a high strength-to-density ratio. It is characterized by its long linear chains with minimal branching, resulting in higher tensile strength, stiffness, and chemical resistance compared to other polyethylene types. HDPE's properties make it suitable for various applications, including packaging, pipes, and industrial products.- Composition and manufacturing of HDPE: High-Density Polyethylene (HDPE) is a thermoplastic polymer produced from ethylene monomers. Various methods and catalysts are used to manufacture HDPE with specific properties. The composition can be modified with additives to enhance performance characteristics such as strength, durability, and chemical resistance.

- HDPE blends and composites: HDPE can be blended with other materials or reinforced with fillers to create composites with improved properties. These blends and composites often exhibit enhanced mechanical strength, thermal stability, or specific functional characteristics, making them suitable for a wide range of applications in various industries.

- HDPE recycling and sustainability: Recycling processes for HDPE have been developed to address environmental concerns and promote sustainability. These methods involve collecting, sorting, cleaning, and reprocessing HDPE products to create new materials or products, reducing waste and conserving resources.

- HDPE applications in packaging and containers: HDPE is widely used in packaging and container applications due to its excellent chemical resistance, durability, and moisture barrier properties. It is commonly used in the production of bottles, drums, tanks, and various types of packaging materials for food, beverages, chemicals, and other products.

- HDPE in construction and infrastructure: HDPE finds extensive use in construction and infrastructure projects due to its durability, corrosion resistance, and flexibility. It is used in the production of pipes for water supply, sewage systems, and gas distribution, as well as in geomembranes for landfills and other civil engineering applications.

02 HDPE blends and composites

HDPE can be blended with other materials or reinforced with fillers to enhance its properties. These blends and composites can improve mechanical strength, thermal stability, or specific functional characteristics. Common additives include other polymers, natural fibers, or inorganic particles, resulting in materials with tailored properties for specific applications.Expand Specific Solutions03 HDPE processing techniques

Various processing techniques are used to manufacture HDPE products, including injection molding, extrusion, and blow molding. These methods allow for the production of a wide range of HDPE items, from thin films to large containers. Advanced processing techniques can improve the material's performance or enable the creation of complex shapes and structures.Expand Specific Solutions04 Recycling and sustainability of HDPE

HDPE is recyclable and can be reprocessed multiple times without significant loss of properties. Recycling processes for HDPE include mechanical recycling, chemical recycling, and the development of upcycling techniques. Efforts are being made to improve the recyclability of HDPE products and increase the use of recycled HDPE in various applications to promote sustainability.Expand Specific Solutions05 HDPE applications in various industries

HDPE finds applications in numerous industries due to its versatile properties. It is widely used in packaging, construction, automotive, and healthcare sectors. Specific applications include food packaging, water pipes, fuel tanks, medical devices, and consumer goods. Ongoing research focuses on expanding HDPE's use in emerging fields and improving its performance in existing applications.Expand Specific Solutions

Key HDPE Manufacturers and Suppliers

The HDPE construction market is in a growth phase, driven by increasing demand for durable and cost-effective building materials. The global market size is expanding, with projections indicating significant growth in the coming years. Technologically, HDPE in construction is relatively mature, with ongoing innovations focused on enhancing performance and sustainability. Key players like Dow Global Technologies, ExxonMobil Chemical, and Chevron Phillips Chemical are at the forefront of HDPE technology development, while companies such as Borealis AG and Braskem SA are contributing to market expansion through product diversification and regional growth strategies. The competitive landscape is characterized by a mix of established petrochemical giants and specialized HDPE manufacturers, all vying for market share through technological advancements and application-specific solutions.

Dow Global Technologies LLC

Borealis AG

Innovative HDPE Technologies in Building

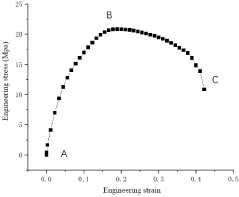

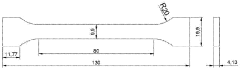

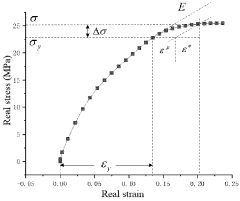

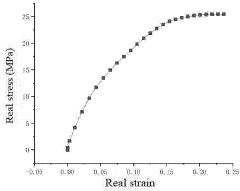

- A hydraulic bulge testing method and system that combines uniaxial tensile testing and hydraulic bulge testing with finite element modeling to obtain mechanical response relations, using Marlow constitutive models and isotropic power law hardening to analyze nonlinear elasticity and ductile damage, and ABAQUS/Explicit for explicit scheme integration to refine grid division and loading conditions.

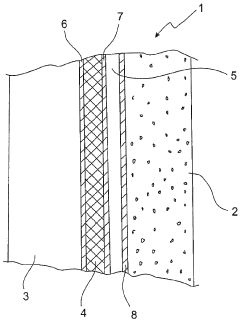

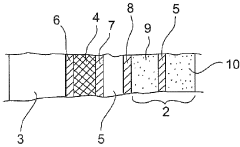

- A multilayer composite material is developed, comprising a self-supporting rigid external layer of fiber composite material, a cracking-resistant intermediate layer, and an adhesion promoter layer, where the intermediate layer absorbs fracture energy to prevent crack propagation, allowing for a lightweight and fracture-resistant structure with reduced material thickness.

Environmental Impact of HDPE in Construction

The environmental impact of HDPE in construction is a complex issue that requires careful consideration of both positive and negative aspects. HDPE's durability and long lifespan contribute to reduced material replacement frequency, potentially lowering the overall environmental footprint of construction projects. The material's resistance to corrosion and chemical degradation means fewer repairs and less frequent replacements, which can lead to reduced resource consumption and waste generation over time.

HDPE's lightweight nature compared to traditional materials like concrete or metal can result in lower transportation emissions during the construction phase. This characteristic also allows for easier handling and installation, potentially reducing on-site energy consumption and associated emissions. Furthermore, HDPE's thermal insulation properties can contribute to improved energy efficiency in buildings, leading to reduced heating and cooling demands and consequently lower operational carbon emissions.

However, the production of HDPE is energy-intensive and relies heavily on fossil fuel resources. The manufacturing process generates significant greenhouse gas emissions and can contribute to air and water pollution if not properly managed. While HDPE is recyclable, the actual recycling rates in the construction industry remain low due to challenges in collection, sorting, and processing of construction waste.

The end-of-life management of HDPE in construction applications presents additional environmental concerns. When not properly disposed of or recycled, HDPE can persist in the environment for hundreds of years, contributing to plastic pollution in ecosystems. Incineration of HDPE waste, while sometimes used as an alternative to landfilling, can release harmful emissions if not conducted under controlled conditions.

Despite these challenges, ongoing research and technological advancements are focusing on improving the environmental profile of HDPE in construction. Efforts to increase the use of recycled content in HDPE products, develop bio-based alternatives, and enhance end-of-life recycling processes are promising steps towards mitigating the material's environmental impact. Additionally, the implementation of life cycle assessment methodologies in construction planning can help optimize the use of HDPE and other materials to minimize overall environmental impacts throughout a building's lifespan.

HDPE Recycling and Circular Economy

The integration of HDPE recycling into the construction industry aligns with the principles of circular economy, offering significant environmental and economic benefits. HDPE's durability and recyclability make it an ideal candidate for closed-loop systems within the construction sector.

Recycling HDPE from construction waste presents a viable solution to reduce landfill burden and conserve natural resources. The process typically involves collecting, sorting, cleaning, and reprocessing HDPE materials from construction sites. Advanced sorting technologies, such as near-infrared spectroscopy, enable efficient separation of HDPE from other plastics and contaminants.

The recycled HDPE can be reincorporated into various construction applications, including pipes, conduits, and geomembranes. This circular approach not only reduces the demand for virgin HDPE but also lowers the carbon footprint associated with material production. Studies have shown that recycled HDPE can maintain up to 95% of its original properties, ensuring its suitability for high-performance construction applications.

Implementing HDPE recycling in construction contributes to the circular economy by creating new value chains and job opportunities in waste management and recycling sectors. It also supports the achievement of sustainability goals set by governments and construction companies, aligning with green building certifications such as LEED and BREEAM.

However, challenges remain in establishing effective collection and recycling systems for construction HDPE waste. Contamination from other materials and the need for consistent quality in recycled HDPE are key issues that require ongoing research and development. Additionally, the construction industry must overcome barriers related to perception and acceptance of recycled materials.

To fully realize the potential of HDPE recycling in construction, collaboration between material scientists, construction companies, and policymakers is essential. Developing standardized practices for HDPE recycling in construction and incentivizing the use of recycled materials can accelerate the transition towards a more circular construction economy.

As the construction industry continues to embrace sustainable practices, the role of HDPE recycling is expected to grow. Innovations in recycling technologies and the development of new applications for recycled HDPE in construction will further enhance its circular economy potential, contributing to a more sustainable built environment.