HDPE in Ocean Cleanup Initiatives: Opportunities and Uses

HDPE Ocean Cleanup Background and Objectives

High-density polyethylene (HDPE) has emerged as a significant player in ocean cleanup initiatives, addressing the growing concern of plastic pollution in marine environments. The evolution of HDPE's role in this context stems from its unique properties and widespread use in consumer products. As plastic waste accumulation in oceans reached critical levels, researchers and environmental organizations began exploring innovative solutions to mitigate this global issue.

The primary objective of incorporating HDPE in ocean cleanup efforts is to effectively remove plastic waste from marine ecosystems while simultaneously repurposing the collected material. This dual approach aims to reduce the environmental impact of plastic pollution and promote circular economy principles. By targeting HDPE, which constitutes a substantial portion of ocean plastic debris, cleanup initiatives can make significant strides in restoring marine habitats and protecting marine life.

The development of HDPE-focused ocean cleanup technologies has progressed through several key stages. Initially, efforts concentrated on manual collection methods and basic filtration systems. As the scale of the problem became apparent, more sophisticated approaches emerged, including autonomous collection vessels, advanced sorting technologies, and innovative recycling processes specifically designed for ocean-recovered plastics.

Recent technological advancements have led to the creation of large-scale cleanup systems that can efficiently collect and process HDPE waste from various marine environments. These systems often employ a combination of passive drift mechanisms, active propulsion, and advanced sensors to maximize collection efficiency while minimizing environmental impact. The integration of artificial intelligence and machine learning algorithms has further enhanced the ability to identify, track, and retrieve HDPE debris in complex ocean conditions.

The potential applications for recovered HDPE extend beyond mere waste reduction. Researchers and industry partners are exploring innovative ways to upcycle ocean-recovered HDPE into high-value products, creating economic incentives for cleanup efforts. This approach not only addresses the immediate problem of plastic pollution but also contributes to the development of sustainable material cycles and promotes awareness of plastic waste issues.

As the field of ocean cleanup continues to evolve, the focus on HDPE presents both challenges and opportunities. Technical hurdles, such as the degradation of plastics in marine environments and the logistics of large-scale collection efforts, drive ongoing research and development. Simultaneously, the increasing global emphasis on sustainability and circular economy principles creates a favorable environment for the expansion and refinement of HDPE-focused ocean cleanup initiatives.

Market Analysis for Ocean Cleanup Solutions

The ocean cleanup solutions market has been experiencing significant growth in recent years, driven by increasing awareness of marine pollution and its detrimental effects on ecosystems and human health. The global market for ocean cleanup technologies is projected to expand rapidly, with a particular focus on plastic waste removal solutions.

High-density polyethylene (HDPE) plays a crucial role in this market, both as a target for removal and as a material for cleanup equipment. The demand for HDPE-based cleanup solutions is expected to rise due to the material's durability, buoyancy, and recyclability. Companies developing ocean cleanup technologies are increasingly incorporating HDPE into their designs for floating barriers, collection systems, and processing equipment.

The market for ocean cleanup solutions can be segmented into several categories, including plastic collection systems, waste processing technologies, and recycling initiatives. HDPE-focused solutions are particularly prominent in the plastic collection segment, where floating barriers and nets made from recycled HDPE are used to capture and concentrate plastic debris.

Geographically, the market for ocean cleanup solutions is global, with significant activities in regions heavily affected by marine pollution, such as Southeast Asia, the Pacific Islands, and coastal areas of developed countries. North America and Europe are leading in terms of technology development and investment, while emerging economies are increasingly adopting and implementing cleanup solutions.

Key market drivers include government regulations on plastic waste, corporate sustainability initiatives, and growing public concern over ocean health. The implementation of extended producer responsibility (EPR) programs and single-use plastic bans in various countries is creating additional momentum for ocean cleanup efforts and the development of innovative solutions.

The market faces challenges such as the high costs associated with large-scale cleanup operations, the need for continuous technological improvements, and the complexity of operating in marine environments. However, these challenges also present opportunities for innovation and the development of more efficient and cost-effective HDPE-based cleanup technologies.

Collaborations between technology companies, environmental organizations, and governments are becoming more common, fostering a supportive ecosystem for market growth. These partnerships are crucial for scaling up cleanup efforts and developing integrated solutions that address the entire lifecycle of plastic waste, from collection to recycling.

As the market matures, there is an increasing focus on creating value from recovered ocean plastics, including HDPE. This trend is driving the development of recycling technologies and the creation of new markets for products made from ocean-recovered plastics, further stimulating growth in the ocean cleanup solutions sector.

HDPE in Marine Environment: Current Status and Challenges

High-density polyethylene (HDPE) has become a significant concern in marine environments due to its widespread use and persistence. The current status of HDPE in oceans is alarming, with an estimated 8 million metric tons of plastic entering the marine ecosystem annually. HDPE, being one of the most common types of plastic, contributes substantially to this pollution.

The challenges associated with HDPE in marine environments are multifaceted. Firstly, the durability that makes HDPE valuable for many applications also renders it resistant to natural degradation. In marine settings, HDPE can persist for hundreds of years, slowly breaking down into smaller particles known as microplastics. These microplastics pose a severe threat to marine life, as they can be ingested by various organisms, leading to malnutrition, internal injuries, and the potential transfer of toxins up the food chain.

Another significant challenge is the difficulty in removing HDPE from marine environments once it has entered the ecosystem. Traditional cleanup methods are often ineffective or impractical on a large scale. The vast expanse of oceans and the dispersion of HDPE across different depths make comprehensive cleanup efforts extremely challenging and resource-intensive.

The impact of HDPE on marine biodiversity is another critical concern. Marine animals often mistake HDPE debris for food, leading to ingestion and entanglement. This not only affects individual organisms but can also disrupt entire ecosystems. Furthermore, HDPE in marine environments can act as a vector for invasive species, facilitating their transport across different marine regions.

The economic implications of HDPE pollution in oceans are substantial. Coastal communities and industries such as fishing and tourism face significant losses due to plastic pollution. The cost of cleanup efforts and the potential long-term impact on marine resources add to the economic burden.

From a global perspective, the distribution of HDPE in marine environments is not uniform. Certain areas, known as gyres, accumulate higher concentrations of plastic due to ocean currents. The Great Pacific Garbage Patch is a prime example of this phenomenon, highlighting the transboundary nature of the problem and the need for international cooperation in addressing it.

Recent research has also revealed the potential for HDPE to absorb and concentrate toxic chemicals present in seawater. This characteristic amplifies the environmental impact of HDPE, as it can lead to the concentration and transfer of harmful substances throughout the marine food web.

Addressing these challenges requires a multifaceted approach, including improved waste management systems, development of biodegradable alternatives, and innovative cleanup technologies. The current status of HDPE in marine environments underscores the urgent need for global action to mitigate its impact and prevent further pollution.

Existing HDPE Applications in Ocean Cleanup Projects

01 Composition and properties of HDPE

High-Density Polyethylene (HDPE) is a thermoplastic polymer with a high strength-to-density ratio. It is characterized by its long linear chains with minimal branching, resulting in higher tensile strength, stiffness, and chemical resistance compared to other polyethylene types. HDPE's properties make it suitable for various applications in packaging, construction, and automotive industries.- HDPE composition and manufacturing: High-Density Polyethylene (HDPE) compositions are developed with specific additives and manufacturing processes to enhance properties such as strength, durability, and processability. These compositions may include various stabilizers, fillers, and other polymers to achieve desired characteristics for different applications.

- HDPE recycling and sustainability: Recycling processes for HDPE are developed to improve sustainability and reduce environmental impact. These methods may involve sorting, cleaning, and reprocessing HDPE materials to create new products or blend with virgin HDPE. Innovations in this area focus on increasing recycling efficiency and maintaining material quality.

- HDPE applications in packaging: HDPE is widely used in packaging applications due to its excellent barrier properties, chemical resistance, and durability. Innovations in this area include the development of HDPE packaging with improved strength, reduced weight, and enhanced recyclability for various industries such as food, beverage, and personal care products.

- HDPE in construction and infrastructure: HDPE materials are utilized in construction and infrastructure projects due to their durability, chemical resistance, and flexibility. Applications include pipes, geomembranes, and structural components. Innovations focus on improving long-term performance, ease of installation, and resistance to environmental factors.

- HDPE blends and composites: HDPE is blended with other materials or reinforced with fillers to create composites with enhanced properties. These blends and composites may offer improved mechanical strength, thermal stability, or specific functional characteristics for specialized applications in various industries.

02 HDPE blends and composites

HDPE can be blended with other materials or reinforced with fillers to enhance its properties. These blends and composites can improve mechanical strength, thermal stability, or specific functional characteristics. Examples include HDPE blended with other polymers, reinforced with natural fibers, or combined with nanoparticles to create materials with tailored properties for specific applications.Expand Specific Solutions03 HDPE processing techniques

Various processing techniques are used to manufacture HDPE products, including injection molding, extrusion, blow molding, and rotational molding. Each technique offers specific advantages for different product types and applications. Innovations in processing methods focus on improving efficiency, reducing cycle times, and enhancing the quality of the final products.Expand Specific Solutions04 Recycling and sustainability of HDPE

HDPE is highly recyclable, making it an environmentally friendly option for many applications. Recycling processes for HDPE involve collection, sorting, cleaning, and reprocessing into new products. Innovations in this area focus on improving recycling efficiency, developing new recycling technologies, and finding novel applications for recycled HDPE to promote circular economy principles.Expand Specific Solutions05 HDPE applications in various industries

HDPE finds applications in numerous industries due to its versatile properties. It is widely used in packaging for bottles, containers, and films. In construction, HDPE is used for pipes, geomembranes, and insulation. The automotive industry utilizes HDPE for fuel tanks and interior components. Other applications include medical devices, toys, and household products, showcasing the material's adaptability and wide-ranging utility.Expand Specific Solutions

Key Players in HDPE-based Ocean Cleanup Initiatives

The HDPE ocean cleanup technology sector is in its early growth stage, with increasing market potential driven by global environmental concerns. The market size is expanding as more organizations and governments invest in ocean pollution solutions. Technologically, HDPE applications in ocean cleanup are evolving, with varying levels of maturity across different approaches. Companies like Dow Global Technologies LLC, ExxonMobil Chemical Patents, Inc., and Chevron Phillips Chemical Co. LP are leading in HDPE material development, while organizations such as The Ocean Cleanup and universities like Ocean University of China are advancing innovative cleanup methods. The competitive landscape is diverse, including chemical manufacturers, environmental technology firms, and research institutions, each contributing to the sector's rapid advancement.

Equistar Chemicals LP

Dow Global Technologies LLC

Innovative HDPE Technologies for Marine Waste Management

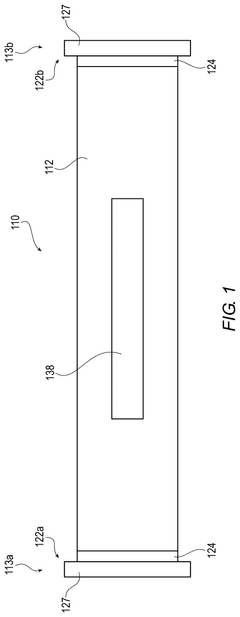

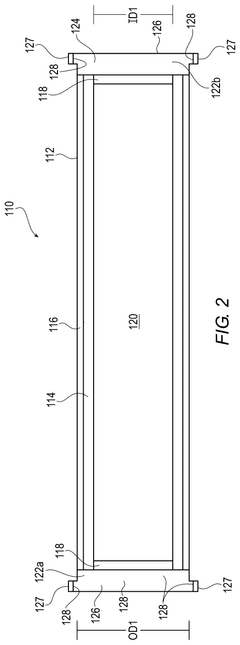

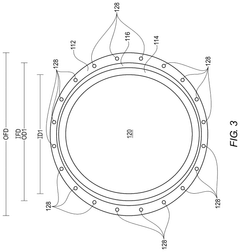

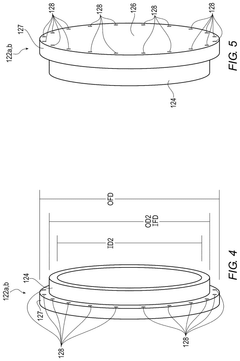

- A marine boom system featuring a High-Density Polyethylene (HDPE) design with a coextruded inner and outer layer, where the inner layer includes carbon black for strength and the outer layer has ultraviolet stabilizers, along with a thicker inner layer and thinner outer layer for improved durability and stability, and additional features like end caps, lug plates, and a strap system for enhanced functionality.

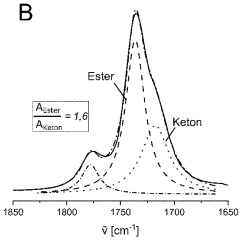

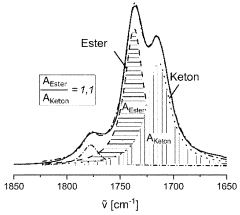

- A process involving the oxidative cleavage of polyethylene-containing mixtures with an oxygen-containing reaction gas at temperatures above the melting point of HDPE, using atmospheric oxygen and specific catalysts to produce a water-insoluble mixture of long-chain alkyldicarboxylic acids, allowing for the recycling of HDPE waste into valuable chemicals without complete combustion.

Environmental Impact Assessment of HDPE in Marine Ecosystems

The environmental impact of High-Density Polyethylene (HDPE) in marine ecosystems is a critical concern in ocean cleanup initiatives. HDPE, widely used in various applications due to its durability and versatility, poses significant challenges when it enters marine environments.

In marine ecosystems, HDPE can persist for hundreds of years, slowly breaking down into smaller particles known as microplastics. These microplastics can be ingested by marine organisms, leading to physical harm and potential toxicity. Studies have shown that microplastics can accumulate in the food chain, potentially affecting larger predators and even human consumers of seafood.

The presence of HDPE in oceans also impacts marine habitats. Large pieces of HDPE debris can entangle marine life, causing injury or death. Additionally, floating HDPE can transport invasive species across long distances, disrupting local ecosystems and biodiversity.

HDPE pollution in marine environments can also have indirect effects on ecosystem functioning. For instance, plastic debris can alter light penetration in water columns, affecting photosynthesis rates of marine plants and algae. This can lead to changes in primary productivity, which forms the base of marine food webs.

From a chemical perspective, HDPE can act as a vector for other pollutants. Persistent organic pollutants (POPs) and other hydrophobic contaminants can adsorb onto the surface of HDPE particles, potentially increasing their bioavailability to marine organisms.

The impact of HDPE on marine sediments is another area of concern. As HDPE particles settle on the ocean floor, they can alter the physical and chemical properties of sediments, potentially affecting benthic communities and biogeochemical processes.

Efforts to assess the environmental impact of HDPE in marine ecosystems face several challenges. The wide distribution and varying sizes of HDPE particles make quantification difficult. Moreover, the long-term effects of HDPE pollution on marine ecosystems are still not fully understood, necessitating ongoing research and monitoring.

In conclusion, the environmental impact of HDPE in marine ecosystems is multifaceted and far-reaching. It affects marine life at various trophic levels, alters habitats, and potentially disrupts ecosystem functions. Understanding these impacts is crucial for developing effective strategies for ocean cleanup and pollution prevention.

Regulatory Framework for Ocean Cleanup Materials

The regulatory framework for ocean cleanup materials plays a crucial role in ensuring the safety, effectiveness, and environmental sustainability of cleanup initiatives. As HDPE (High-Density Polyethylene) becomes increasingly prevalent in ocean cleanup efforts, it is essential to understand the existing regulations and guidelines governing its use.

At the international level, the United Nations Convention on the Law of the Sea (UNCLOS) provides the overarching legal framework for marine activities, including ocean cleanup. While it does not specifically address materials like HDPE, it establishes general principles for the protection and preservation of the marine environment. The International Maritime Organization (IMO) has also developed guidelines for the removal of shipwrecks and debris, which may indirectly influence the use of HDPE in cleanup operations.

Regional agreements and conventions further shape the regulatory landscape. For instance, the OSPAR Convention for the Protection of the Marine Environment of the North-East Atlantic has established specific measures for the prevention and elimination of marine pollution, which could impact the use of HDPE in cleanup initiatives within its jurisdiction.

At the national level, regulations vary significantly between countries. In the United States, the Environmental Protection Agency (EPA) and the National Oceanic and Atmospheric Administration (NOAA) play key roles in regulating ocean cleanup materials. The Marine Debris Research, Prevention, and Reduction Act provides a framework for addressing marine debris, including the use of materials like HDPE in cleanup efforts.

The European Union has implemented the Marine Strategy Framework Directive, which requires member states to achieve or maintain good environmental status in their marine waters. This directive indirectly influences the selection and use of materials in ocean cleanup initiatives, potentially affecting the adoption of HDPE-based solutions.

Specific regulations regarding the use of HDPE in ocean cleanup are still evolving. Many jurisdictions require environmental impact assessments before deploying large-scale cleanup systems. These assessments typically evaluate the potential effects of the materials used, including HDPE, on marine ecosystems and biodiversity.

As the use of HDPE in ocean cleanup initiatives grows, there is an increasing focus on developing standards and best practices. Organizations such as ASTM International and the International Organization for Standardization (ISO) are working on creating guidelines for the testing and evaluation of materials used in marine environments, which could significantly impact the future use of HDPE in cleanup efforts.