HDPE Recycling: Strategic Approaches for Better Yields

HDPE Recycling Evolution

The evolution of HDPE recycling has been marked by significant technological advancements and strategic approaches aimed at improving yield and quality. In the early stages, HDPE recycling primarily focused on basic mechanical processes, such as sorting, grinding, and melting. These methods, while effective to some extent, often resulted in downcycled materials with limited applications.

As environmental concerns grew and circular economy principles gained traction, the recycling industry began to invest in more sophisticated technologies. The introduction of advanced sorting systems, including near-infrared (NIR) spectroscopy and X-ray fluorescence, dramatically improved the purity of HDPE streams. This development allowed for higher-quality recycled materials and expanded their potential applications.

The next significant leap came with the adoption of chemical recycling techniques. These processes break down HDPE into its molecular components, effectively "resetting" the plastic and allowing for the production of virgin-quality recycled material. Pyrolysis and solvent-based purification methods emerged as promising technologies in this field, offering the potential to address contamination issues that had previously limited recycling yields.

In parallel with these technological advancements, strategic approaches to HDPE recycling have evolved. The implementation of extended producer responsibility (EPR) programs and design for recyclability initiatives have improved the quality of HDPE waste streams entering recycling facilities. This upstream focus has been crucial in enhancing overall recycling efficiency and yield.

More recently, the integration of artificial intelligence and machine learning into recycling processes has opened new frontiers. These technologies enable more precise sorting, predictive maintenance of recycling equipment, and optimization of process parameters in real-time. The result is a significant increase in both the quantity and quality of recycled HDPE.

The evolution of HDPE recycling has also seen a shift towards closed-loop systems, where manufacturers take responsibility for the entire lifecycle of their products. This approach has led to innovations in product design that facilitate easier recycling and the development of specialized recycling processes tailored to specific HDPE products.

As the field continues to advance, emerging technologies such as enzymatic recycling and advanced catalytic processes promise to further revolutionize HDPE recycling. These methods offer the potential for even higher yields, lower energy consumption, and the ability to recycle previously problematic HDPE products. The ongoing evolution of HDPE recycling reflects a broader trend towards more sustainable and efficient resource utilization in the plastics industry.

Market Demand Analysis

The global market for HDPE recycling has been experiencing significant growth in recent years, driven by increasing environmental awareness, regulatory pressures, and the circular economy concept. The demand for recycled HDPE is on the rise across various industries, including packaging, construction, and automotive sectors.

In the packaging industry, which accounts for a substantial portion of HDPE consumption, there is a growing trend towards using recycled content in bottles, containers, and other packaging materials. Major consumer goods companies have set ambitious targets for incorporating recycled plastics into their packaging, creating a strong pull for high-quality recycled HDPE.

The construction sector is another key market for recycled HDPE, with applications in pipes, lumber, and other building materials. The durability and weather resistance of HDPE make it an attractive option for outdoor applications, and the use of recycled content aligns with green building initiatives.

In the automotive industry, there is an increasing focus on lightweight materials and sustainability, leading to greater interest in recycled HDPE for interior and exterior components. This trend is expected to continue as automakers strive to meet stringent environmental regulations and consumer demands for more eco-friendly vehicles.

The market demand for recycled HDPE is also influenced by government policies and regulations. Many countries have implemented or are considering measures to promote plastic recycling and the use of recycled content in products. These policies, such as minimum recycled content requirements and extended producer responsibility schemes, are expected to further drive demand for recycled HDPE.

Despite the growing demand, the market faces challenges in terms of supply and quality. The collection and sorting of post-consumer HDPE remain inefficient in many regions, leading to a shortage of high-quality feedstock for recycling. Additionally, contamination issues and the degradation of material properties during the recycling process can limit the applications of recycled HDPE.

To address these challenges and meet the increasing market demand, there is a need for strategic approaches to improve HDPE recycling yields. This includes developing more efficient collection and sorting systems, advancing recycling technologies to produce higher quality recycled HDPE, and investing in research and development to expand the range of applications for recycled materials.

The market outlook for recycled HDPE remains positive, with projections indicating continued growth in demand across various sectors. As industries and consumers increasingly prioritize sustainability, the development of innovative recycling solutions and the improvement of recycling yields will be crucial in meeting this growing market demand and realizing the full potential of HDPE recycling in the circular economy.

Technical Challenges

The recycling of High-Density Polyethylene (HDPE) faces several significant technical challenges that hinder the achievement of better yields. One of the primary obstacles is the contamination of HDPE waste streams. HDPE products often contain various additives, labels, and other materials that are difficult to separate during the recycling process. These contaminants can significantly reduce the quality of the recycled HDPE, limiting its potential applications and market value.

Another major challenge is the degradation of HDPE during its lifecycle and recycling process. Exposure to UV radiation, heat, and mechanical stress can cause changes in the polymer structure, leading to a decrease in the material's properties. This degradation makes it challenging to maintain consistent quality in recycled HDPE, especially when aiming for high-value applications that require specific mechanical and chemical properties.

The heterogeneity of HDPE waste streams also poses a significant technical hurdle. Different HDPE products have varying molecular weights, densities, and additive compositions, making it difficult to achieve a uniform recycled product. This variability can lead to inconsistencies in the recycled material's performance, which is particularly problematic for industries requiring strict quality standards.

Furthermore, the sorting and identification of HDPE from mixed plastic waste streams remain a technical challenge. While advances have been made in automated sorting technologies, such as near-infrared (NIR) spectroscopy, the accuracy and efficiency of these systems still have room for improvement. Misidentification of plastics can lead to contamination of the HDPE recycling stream, reducing the overall quality of the recycled material.

The presence of multi-layer and multi-material packaging that includes HDPE also presents a significant recycling challenge. These composite materials are designed for specific performance characteristics but are notoriously difficult to separate and recycle effectively. The inability to efficiently process these complex structures often results in their diversion to landfills or incineration, reducing the overall recycling yield of HDPE.

Additionally, the removal of odors and residual contents from HDPE containers, particularly those used for household chemicals or personal care products, presents another technical obstacle. Ineffective cleaning processes can lead to contamination of the recycled material, affecting its quality and potential applications.

Lastly, the energy-intensive nature of the HDPE recycling process poses both environmental and economic challenges. Improving the energy efficiency of recycling technologies while maintaining or enhancing the quality of the recycled HDPE is a critical area that requires further technological innovation and optimization.

Current Recycling Methods

01 Mechanical recycling processes for HDPE

Mechanical recycling processes for HDPE involve sorting, grinding, washing, and extrusion steps to convert waste HDPE into reusable pellets or flakes. These processes can improve the quality and yield of recycled HDPE by removing contaminants and optimizing the processing conditions.- Mechanical recycling processes for HDPE: Mechanical recycling processes are commonly used for HDPE recycling. These methods involve sorting, grinding, washing, and melting the plastic to produce recycled HDPE pellets. The process can include steps such as size reduction, contaminant removal, and extrusion to improve the quality and yield of the recycled material.

- Chemical recycling techniques for HDPE: Chemical recycling methods are used to break down HDPE into its chemical components. These techniques include pyrolysis, depolymerization, and solvent-based processes. Chemical recycling can produce higher quality recycled materials and allow for the removal of additives and contaminants, potentially increasing the overall yield of usable recycled material.

- Improving HDPE recycling yields through advanced sorting: Advanced sorting technologies are employed to improve the purity of HDPE waste streams, leading to higher recycling yields. These technologies may include optical sorting, near-infrared spectroscopy, and artificial intelligence-based systems to accurately identify and separate HDPE from other plastics and contaminants.

- Enhancing HDPE recycling yields with additives and compatibilizers: The use of additives and compatibilizers can improve the properties and processability of recycled HDPE, leading to higher yields of usable material. These additives can help maintain the mechanical properties of recycled HDPE, improve its compatibility with virgin materials, and extend its useful life in new applications.

- Closed-loop recycling systems for HDPE: Closed-loop recycling systems are being developed to maximize HDPE recycling yields. These systems aim to recycle HDPE back into the same or similar products, reducing the need for downcycling. This approach often involves collaboration between manufacturers, recyclers, and consumers to ensure proper collection, sorting, and processing of HDPE waste.

02 Chemical recycling methods for HDPE

Chemical recycling methods break down HDPE into its constituent monomers or other valuable chemicals. These processes can include pyrolysis, depolymerization, or solvent-based techniques, which can potentially yield higher-quality recycled materials and allow for the production of new plastics or other chemical products.Expand Specific Solutions03 Additives and compatibilizers for improving recycled HDPE properties

The use of additives and compatibilizers can enhance the properties of recycled HDPE, improving its mechanical strength, processability, and overall quality. These additives can help increase the yield of usable recycled material by making it more suitable for various applications.Expand Specific Solutions04 Sorting and separation technologies for HDPE recycling

Advanced sorting and separation technologies, such as optical sorting, flotation, and spectroscopic methods, can improve the purity of HDPE waste streams. These technologies help increase recycling yields by reducing contamination and improving the quality of the input material for recycling processes.Expand Specific Solutions05 Energy-efficient and sustainable HDPE recycling methods

Development of energy-efficient and sustainable HDPE recycling methods focuses on reducing energy consumption, minimizing waste, and improving overall process efficiency. These methods can include optimized grinding techniques, advanced washing processes, and innovative extrusion technologies to maximize recycling yields while reducing environmental impact.Expand Specific Solutions

Key Industry Players

The HDPE recycling industry is in a growth phase, driven by increasing environmental concerns and regulatory pressures. The market size is expanding rapidly, with a projected CAGR of 5.8% from 2021 to 2028. Technologically, HDPE recycling is moderately mature, but innovations are ongoing. Companies like Dow Global Technologies, SABIC, and LG Chem are leading in developing advanced recycling processes. Equistar Chemicals and Borealis AG are focusing on improving yield and quality of recycled HDPE. Academic institutions such as the University of North Carolina at Charlotte and Cornell University are contributing to research in this field. The competitive landscape is diverse, with both established petrochemical companies and specialized recycling firms vying for market share.

SABIC Global Technologies BV

Procter & Gamble Co.

Innovative Technologies

- A thermofusion process involving crushing, washing, drying, and boiling HDPE waste in a preheated furnace, followed by pressing and extraction, to produce laminated or block-shaped products with specific characteristics such as durability, texturability, and chemical resistance.

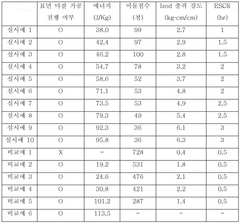

- A method involving shredding and surface friction processing of waste silicon cartridges, followed by wet specific gravity separation to recover high-density polyethylene, with controlled energy application to minimize foreign matter and enhance material properties, specifically applying energy in the range of 35 J/kg to 100 J/kg during surface friction processing.

Environmental Regulations

Environmental regulations play a crucial role in shaping the landscape of HDPE recycling and influencing strategic approaches for better yields. These regulations are designed to address the environmental impacts of plastic waste and promote sustainable practices in the recycling industry.

In recent years, many countries have implemented stringent regulations to reduce plastic pollution and encourage recycling. The European Union, for instance, has set ambitious targets for plastic recycling under its Circular Economy Action Plan. By 2030, the EU aims to recycle 55% of plastic packaging waste, which includes HDPE products. This regulatory framework has spurred innovation in recycling technologies and processes to achieve higher yields.

In the United States, regulations vary by state, but there is a growing trend towards extended producer responsibility (EPR) laws. These laws require manufacturers to take responsibility for the entire lifecycle of their products, including disposal and recycling. California's Rigid Plastic Packaging Container (RPPC) law mandates that certain plastic containers must be made from at least 25% post-consumer recycled material, driving demand for high-quality recycled HDPE.

China's National Sword policy, implemented in 2018, has had a significant global impact on the recycling industry. The policy banned the import of most plastic waste, forcing many countries to develop domestic recycling capabilities and improve the quality of their recyclable materials. This shift has led to increased investment in advanced sorting and processing technologies to produce higher-quality recycled HDPE.

Environmental regulations also address the quality and safety of recycled HDPE. The Food and Drug Administration (FDA) in the United States has established guidelines for the use of recycled plastics in food-contact applications. These regulations ensure that recycled HDPE meets stringent safety standards, opening up new markets for recycled materials in food packaging and other high-value applications.

Emerging regulations are focusing on the concept of a circular economy, promoting the use of recycled materials in new products. The UK Plastic Packaging Tax, introduced in April 2022, imposes a tax on plastic packaging that does not contain at least 30% recycled plastic. This type of regulation creates economic incentives for manufacturers to incorporate recycled HDPE into their products, driving demand and encouraging investment in recycling technologies.

As environmental concerns continue to grow, it is likely that regulations will become more stringent, pushing for higher recycling rates and better quality of recycled materials. This regulatory landscape presents both challenges and opportunities for the HDPE recycling industry, driving innovation and shaping strategic approaches to achieve better yields and contribute to a more sustainable future.

Economic Feasibility Study

The economic feasibility of HDPE recycling is a critical factor in determining the viability of strategic approaches for better yields. A comprehensive analysis reveals that the financial aspects of HDPE recycling are influenced by various interconnected factors, including market demand, processing costs, and revenue potential.

Market demand for recycled HDPE has shown a steady increase in recent years, driven by growing environmental awareness and regulatory pressures on plastic waste reduction. This trend has created a favorable economic environment for HDPE recycling initiatives. However, the market price for recycled HDPE can be volatile, affected by fluctuations in virgin plastic prices and overall economic conditions.

Processing costs represent a significant portion of the economic equation in HDPE recycling. These costs encompass collection, sorting, cleaning, and reprocessing stages. Technological advancements in sorting and processing equipment have led to improved efficiency and reduced operational costs. Nevertheless, the initial capital investment for state-of-the-art recycling facilities remains substantial, necessitating careful financial planning and potentially long payback periods.

Revenue generation from recycled HDPE products is a key driver of economic feasibility. The quality of recycled HDPE directly impacts its market value and potential applications. High-quality recycled HDPE can command premium prices, especially in industries where material purity is crucial. Developing innovative end-use applications for recycled HDPE can open new revenue streams and enhance overall economic viability.

Government incentives and policies play a crucial role in shaping the economic landscape of HDPE recycling. Tax breaks, grants, and subsidies for recycling initiatives can significantly improve the financial attractiveness of HDPE recycling projects. Additionally, extended producer responsibility (EPR) schemes and plastic taxes in some regions create economic incentives for increased recycling rates.

The scale of operations is another critical factor affecting economic feasibility. Larger-scale recycling facilities can benefit from economies of scale, reducing per-unit processing costs. However, this must be balanced against transportation costs and the availability of consistent HDPE waste streams.

In conclusion, the economic feasibility of HDPE recycling for better yields is promising but complex. While market demand and potential revenues are encouraging, careful consideration of processing costs, technological investments, and regulatory environments is essential. Successful implementation of strategic approaches for better yields in HDPE recycling requires a holistic view of these economic factors, coupled with innovative solutions to maximize efficiency and value creation throughout the recycling process.