HDPE's Role in Modernizing Traffic Segmentation

HDPE in Traffic Evolution

High-density polyethylene (HDPE) has played a significant role in the evolution of traffic management systems, particularly in the realm of traffic segmentation. The journey of HDPE in this field began in the mid-20th century when plastic materials started to gain prominence in various industries. Initially, traffic segmentation relied heavily on traditional materials such as concrete and metal, which were often costly, difficult to install, and prone to damage.

The introduction of HDPE in traffic management marked a turning point in the industry. Its lightweight nature, durability, and cost-effectiveness made it an attractive alternative to conventional materials. In the 1970s and 1980s, HDPE began to be used in the production of traffic cones and barriers, offering improved visibility and safety on roads and construction sites.

As technology advanced, so did the applications of HDPE in traffic segmentation. The 1990s saw the development of more sophisticated HDPE products, including modular traffic barriers and channelizers. These innovations allowed for greater flexibility in traffic management, enabling quick and easy reconfiguration of road layouts to accommodate changing traffic patterns or construction needs.

The early 2000s brought about a new era in HDPE traffic segmentation with the introduction of smart technologies. HDPE barriers and delineators began to incorporate reflective materials and even LED lighting, enhancing visibility and safety, especially in low-light conditions. This integration of technology with HDPE products significantly improved the effectiveness of traffic management systems.

In recent years, the focus has shifted towards sustainability and environmental concerns. HDPE's recyclability has become a key factor in its continued use and development in traffic segmentation. Manufacturers have been developing HDPE products with higher recycled content, reducing the environmental impact of traffic management systems while maintaining their performance and durability.

The latest trend in HDPE traffic segmentation involves the integration of IoT (Internet of Things) technologies. Smart HDPE barriers equipped with sensors can now provide real-time data on traffic flow, accidents, and road conditions. This data-driven approach allows for more efficient and responsive traffic management, further cementing HDPE's role in modern traffic systems.

Looking ahead, the evolution of HDPE in traffic segmentation is likely to continue, with a focus on developing even more sustainable, intelligent, and adaptable solutions. As urban environments become increasingly complex, the demand for flexible and efficient traffic management systems will grow, and HDPE is well-positioned to meet these evolving needs.

Market Demand Analysis

The market demand for High-Density Polyethylene (HDPE) in traffic segmentation has been steadily increasing due to its superior properties and the growing need for modernized traffic management systems. As urbanization continues to accelerate globally, the demand for efficient and durable traffic control solutions has become more pressing. HDPE's role in this sector has expanded significantly, driven by its ability to enhance safety, reduce maintenance costs, and improve overall traffic flow.

In the realm of traffic segmentation, HDPE products such as barriers, delineators, and channelizers have gained substantial traction. These products offer several advantages over traditional materials like concrete or metal, including lightweight construction, high visibility, and excellent impact resistance. The flexibility of HDPE allows for easy installation and removal, making it ideal for both permanent and temporary traffic control applications.

The construction industry, a major consumer of traffic segmentation products, has shown a strong preference for HDPE solutions. This trend is particularly evident in road construction and maintenance projects, where the need for quick deployment and minimal disruption to traffic flow is paramount. The durability of HDPE products also aligns well with the industry's focus on long-term cost-effectiveness and sustainability.

Urban planning initiatives across developed and developing nations have further fueled the demand for HDPE traffic segmentation products. As cities strive to create more pedestrian-friendly environments and implement smart traffic management systems, the versatility of HDPE has proven invaluable. Its ability to be molded into various shapes and sizes allows for customized solutions that can adapt to diverse urban landscapes.

The automotive industry's shift towards autonomous vehicles has also contributed to the increased demand for advanced traffic segmentation solutions. HDPE products play a crucial role in creating clearly defined lanes and boundaries, which are essential for the proper functioning of autonomous driving systems. This emerging market segment presents significant growth opportunities for HDPE manufacturers and suppliers.

Environmental concerns and sustainability goals have further bolstered the market for HDPE traffic segmentation products. The material's recyclability and long lifespan align well with green initiatives adopted by many municipalities and transportation authorities. This eco-friendly aspect has become a key selling point, especially in regions with strict environmental regulations.

The global pandemic has unexpectedly boosted demand for HDPE traffic management solutions. The need for social distancing measures and the rapid setup of temporary facilities has led to increased use of HDPE barriers and delineators in various public spaces. This trend is likely to continue as cities adapt to new public health requirements and flexible urban planning strategies.

HDPE Challenges

High-density polyethylene (HDPE) has emerged as a promising material for modernizing traffic segmentation, yet it faces several significant challenges in its implementation and widespread adoption. One of the primary obstacles is the material's durability under extreme weather conditions and prolonged exposure to UV radiation. While HDPE is known for its strength and resistance to chemicals, its long-term performance in outdoor environments, particularly in areas with high temperature fluctuations or intense sunlight, remains a concern for traffic management authorities.

Another challenge lies in the integration of HDPE traffic segmentation solutions with existing infrastructure. Many urban areas have established traffic management systems that may not be easily compatible with new HDPE-based solutions. This incompatibility can lead to increased costs and logistical difficulties in implementing HDPE traffic segmentation devices on a large scale.

The environmental impact of HDPE production and disposal is also a significant concern. Although HDPE is recyclable, the process of collecting, sorting, and recycling traffic segmentation devices made from this material can be complex and resource-intensive. There is a growing need for more efficient recycling methods and a circular economy approach to mitigate the environmental footprint of HDPE traffic solutions.

Cost considerations present another hurdle for the widespread adoption of HDPE in traffic segmentation. While HDPE may offer long-term cost benefits due to its durability and low maintenance requirements, the initial investment for replacing traditional materials with HDPE can be substantial. This financial barrier may deter some municipalities or transportation departments from embracing HDPE solutions, particularly in regions with limited budgets for infrastructure improvements.

The aesthetic aspect of HDPE traffic segmentation devices is also a challenge, especially in historic or architecturally sensitive urban areas. The plastic appearance of HDPE may not align with the visual character of certain environments, leading to resistance from urban planners and local communities. Developing HDPE solutions that can be customized or designed to blend with various urban landscapes is crucial for overcoming this obstacle.

Lastly, there are technical challenges related to the manufacturing and installation of HDPE traffic segmentation devices. Ensuring consistent quality across large production volumes, developing efficient installation techniques, and creating standardized designs that meet diverse traffic management needs are ongoing challenges for the industry. Addressing these technical hurdles is essential for improving the reliability and effectiveness of HDPE in modernizing traffic segmentation systems.

Current HDPE Solutions

01 Composition and properties of HDPE

High-Density Polyethylene (HDPE) is a thermoplastic polymer with a high strength-to-density ratio. It is characterized by its long linear chains with minimal branching, resulting in higher tensile strength, stiffness, and chemical resistance compared to other polyethylene types. HDPE's properties make it suitable for various applications, including packaging, pipes, and industrial products.- Composition and properties of HDPE: High-Density Polyethylene (HDPE) is a thermoplastic polymer with a high strength-to-density ratio. It is characterized by its long linear chains with minimal branching, resulting in higher tensile strength, stiffness, and chemical resistance compared to other polyethylene types. HDPE's properties make it suitable for various applications in packaging, construction, and automotive industries.

- HDPE blends and composites: HDPE can be blended with other materials or reinforced with fillers to enhance its properties. These blends and composites can improve mechanical strength, thermal stability, or specific functional characteristics. Common additives include other polymers, natural fibers, or inorganic particles, resulting in materials with tailored properties for specific applications.

- HDPE processing techniques: Various processing techniques are used to manufacture HDPE products, including injection molding, extrusion, blow molding, and rotational molding. Each method offers specific advantages and is suited for different product types. Advanced processing techniques can improve the material's performance or enable the production of complex shapes and structures.

- Recycling and sustainability of HDPE: HDPE is highly recyclable, making it an environmentally friendly option. Recycling processes for HDPE involve collection, sorting, cleaning, and reprocessing into new products. Innovations in recycling technologies aim to improve the quality of recycled HDPE and expand its applications, contributing to circular economy initiatives and reducing plastic waste.

- Novel applications of HDPE: HDPE finds applications in various innovative fields beyond traditional uses. These include advanced packaging solutions, medical devices, 3D printing filaments, and construction materials. Research focuses on expanding HDPE's functionality through surface modifications, nanocomposites, or smart material development, opening up new possibilities in diverse industries.

02 HDPE blends and composites

HDPE can be blended with other materials or reinforced with additives to enhance its properties. These blends and composites can improve characteristics such as impact resistance, thermal stability, or specific mechanical properties. The resulting materials find applications in areas where standard HDPE may not meet all requirements.Expand Specific Solutions03 HDPE processing techniques

Various processing techniques are used to manufacture HDPE products, including injection molding, extrusion, and blow molding. Each method offers specific advantages and is suited to different product types. Innovations in processing techniques aim to improve efficiency, reduce costs, and enhance the quality of HDPE products.Expand Specific Solutions04 Recycling and sustainability of HDPE

HDPE is recyclable and efforts are being made to improve its recycling processes and increase the use of recycled HDPE in new products. This focus on sustainability aims to reduce environmental impact and promote circular economy principles in the plastics industry.Expand Specific Solutions05 HDPE applications in specific industries

HDPE finds applications in various industries due to its versatile properties. It is used in packaging, construction, automotive, and medical industries, among others. Ongoing research focuses on expanding HDPE's applications and tailoring its properties for specific industry needs.Expand Specific Solutions

Key Industry Players

The HDPE market for traffic segmentation is in a growth phase, driven by increasing urbanization and infrastructure development. The market size is expanding, with a projected CAGR of 5-7% over the next five years. Technologically, HDPE solutions for traffic management are reaching maturity, with companies like Dow Global Technologies LLC and ExxonMobil Chemical Patents, Inc. leading innovation. Emerging players such as Borealis AG and Basell Polyolefine GmbH are also contributing to advancements in material properties and manufacturing processes. The competitive landscape is characterized by a mix of established petrochemical giants and specialized polymer manufacturers, with increasing focus on sustainable and high-performance HDPE solutions for modern traffic management systems.

Dow Global Technologies LLC

Equistar Chemicals LP

HDPE Innovations

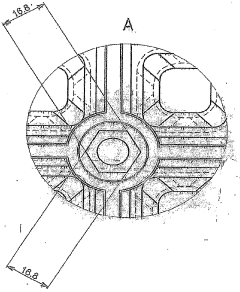

- A high-density polyethylene (HDPE) coating system comprising modular assemblies and polypropylene plates, with a honeycomb framework structure and pyramid-shaped squares for anti-slip functionality, allowing for adaptable and reliable load distribution and circulation on diverse terrains without soil deformation or environmental harm.

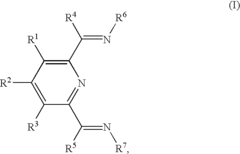

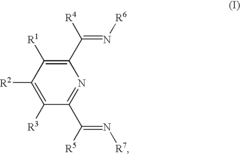

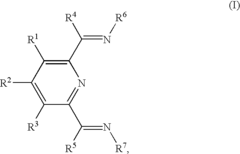

- HDPE is produced using polymerization catalysts comprising iron or cobalt complexes of specific compounds, such as those with aryl and substituted aryl groups, which significantly reduce water vapor and oxygen transmission rates, making them suitable for improved packaging.

Safety Regulations

Safety regulations play a crucial role in the implementation of HDPE (High-Density Polyethylene) for modernizing traffic segmentation. As this material gains prominence in road safety applications, it is essential to understand and adhere to the evolving regulatory landscape.

The primary focus of safety regulations concerning HDPE in traffic segmentation is to ensure the material's performance under various conditions and its ability to withstand impacts. Regulatory bodies, such as the Federal Highway Administration (FHWA) in the United States, have established stringent guidelines for the use of HDPE in road safety applications. These regulations typically cover aspects such as material composition, durability, visibility, and crash-worthiness.

One key area of regulatory concern is the impact resistance of HDPE traffic barriers. Standards have been developed to test the material's ability to absorb and dissipate energy during collisions, minimizing the risk of injury to vehicle occupants. These tests often simulate various impact scenarios, including different vehicle types and speeds, to ensure comprehensive safety coverage.

Visibility is another critical aspect addressed by safety regulations. HDPE traffic segmentation devices must meet specific reflectivity and color requirements to ensure they are easily visible to drivers under various lighting and weather conditions. This includes standards for retroreflective materials and color consistency, which are essential for maintaining clear and recognizable traffic patterns.

Environmental considerations also factor into safety regulations for HDPE traffic segmentation. Regulations often stipulate requirements for the material's resistance to UV radiation, extreme temperatures, and chemical exposure. This ensures that HDPE devices maintain their structural integrity and performance over time, even in challenging environmental conditions.

As the use of HDPE in traffic segmentation continues to evolve, safety regulations are adapting to keep pace with technological advancements. For instance, there is growing interest in incorporating smart technologies into HDPE traffic devices, such as sensors for real-time traffic monitoring. Regulatory bodies are working to develop guidelines that address the integration of these technologies while maintaining the core safety functions of the devices.

Compliance with safety regulations is not only a legal requirement but also a critical factor in the widespread adoption of HDPE for traffic segmentation. Manufacturers and road authorities must work closely to ensure that HDPE products meet or exceed all relevant safety standards. This collaboration often involves rigorous testing and certification processes, as well as ongoing monitoring and evaluation of installed devices.

Environmental Impact

The environmental impact of High-Density Polyethylene (HDPE) in modernizing traffic segmentation is a critical aspect to consider. HDPE, a versatile and durable plastic material, offers several environmental benefits when used in traffic management systems. Its long lifespan significantly reduces the need for frequent replacements, thereby minimizing waste generation and resource consumption associated with manufacturing and installation processes.

HDPE's resistance to weathering and chemical degradation ensures that it maintains its structural integrity over extended periods, even in harsh environmental conditions. This durability translates to reduced maintenance requirements, which in turn lowers the carbon footprint associated with repair and replacement activities. Additionally, the lightweight nature of HDPE compared to traditional materials like concrete or metal results in reduced transportation emissions during installation and maintenance.

From a lifecycle perspective, HDPE traffic segmentation products have a lower environmental impact compared to their counterparts. The production of HDPE requires less energy than many alternative materials, and its recyclability at the end of its useful life further enhances its environmental credentials. Many HDPE traffic management products can be recycled into new products, contributing to a circular economy and reducing the demand for virgin materials.

However, it is important to acknowledge the potential negative environmental impacts associated with HDPE use. The production of HDPE relies on fossil fuel resources, contributing to greenhouse gas emissions. There are also concerns about microplastic pollution if HDPE products are not properly managed at the end of their lifecycle. To mitigate these issues, efforts are being made to increase the use of recycled HDPE in traffic segmentation products and improve end-of-life collection and recycling systems.

In the context of traffic management, HDPE's role in modernizing segmentation can lead to improved traffic flow and reduced congestion. This indirect environmental benefit results from decreased vehicle idling times and more efficient transportation systems, potentially leading to lower overall emissions from vehicular traffic. The flexibility in design offered by HDPE also allows for the creation of more effective traffic management solutions that can adapt to changing urban landscapes and transportation needs.

As cities and transportation authorities increasingly prioritize sustainable infrastructure, the use of HDPE in traffic segmentation aligns with broader environmental goals. Its ability to be molded into various shapes and sizes enables the creation of innovative designs that can integrate with smart city initiatives, potentially supporting the implementation of more environmentally friendly transportation systems.