High Density Polyethylene: Advances in Injection Molding

HDPE Injection Molding Evolution and Objectives

High Density Polyethylene (HDPE) injection molding has undergone significant evolution since its inception in the 1950s. Initially, the process was limited by rudimentary machinery and a lack of understanding of polymer behavior. Over time, advancements in material science, machine technology, and process control have revolutionized HDPE injection molding, making it a cornerstone of modern manufacturing.

The development of HDPE itself has been crucial to the evolution of injection molding techniques. Early formulations of HDPE were prone to warping and inconsistent shrinkage, which posed challenges in producing high-quality parts. As polymer chemistry advanced, new grades of HDPE with improved flow characteristics, thermal stability, and mechanical properties were introduced, enabling more complex and precise molding operations.

Concurrent with material improvements, injection molding machinery has undergone dramatic transformations. The transition from hydraulic to electric and hybrid systems has significantly enhanced precision, energy efficiency, and cycle times. Modern machines feature sophisticated control systems that allow for real-time adjustments and monitoring of critical parameters such as pressure, temperature, and injection speed.

The integration of computer-aided design (CAD) and computer-aided manufacturing (CAM) technologies has been a game-changer in HDPE injection molding. These tools have enabled designers and engineers to optimize part designs for manufacturability, simulate molding processes, and predict potential defects before production begins. This has led to reduced development times, improved part quality, and decreased waste.

In recent years, the focus has shifted towards sustainability and circular economy principles. The industry is now exploring ways to incorporate recycled HDPE into injection molding processes without compromising part quality or performance. This trend aligns with growing environmental concerns and regulatory pressures to reduce plastic waste and carbon footprint.

The current objectives in HDPE injection molding are multifaceted. There is a push towards even greater precision and repeatability, especially for high-performance applications in industries such as automotive and medical devices. Manufacturers are seeking ways to further reduce cycle times and energy consumption without sacrificing part quality. Additionally, there is a growing interest in developing smart manufacturing systems that leverage Internet of Things (IoT) technologies for predictive maintenance and real-time quality control.

Looking ahead, the industry aims to achieve fully automated and lights-out manufacturing capabilities for HDPE injection molding. This involves the integration of robotics, artificial intelligence, and machine learning to create self-optimizing production systems. Another key objective is the development of more sustainable practices, including the use of bio-based or fully recyclable HDPE formulations and closed-loop recycling systems within manufacturing facilities.

Market Demand Analysis for HDPE Molded Products

The market demand for High Density Polyethylene (HDPE) molded products has been experiencing significant growth, driven by various factors across multiple industries. The automotive sector has emerged as a key consumer of HDPE molded parts, particularly for interior components, fuel tanks, and under-the-hood applications. This demand is fueled by the material's excellent chemical resistance, durability, and lightweight properties, which contribute to improved fuel efficiency and overall vehicle performance.

In the packaging industry, HDPE molded products have gained substantial traction due to their versatility and recyclability. The increasing focus on sustainable packaging solutions has led to a surge in demand for HDPE containers, bottles, and caps across food and beverage, personal care, and household product segments. The material's ability to withstand high temperatures and resist moisture makes it particularly suitable for these applications.

The construction sector has also shown a growing appetite for HDPE molded products. The material's resistance to weathering, UV radiation, and chemicals makes it ideal for outdoor applications such as pipes, fittings, and structural components. As urbanization continues and infrastructure development accelerates globally, the demand for HDPE molded products in construction is expected to rise steadily.

In the healthcare and medical device industry, HDPE molded products have found increasing applications due to their biocompatibility and sterilization capabilities. The material is widely used in pharmaceutical packaging, medical equipment housings, and laboratory consumables. The ongoing global health concerns have further boosted the demand for HDPE molded products in this sector.

The agriculture sector represents another significant market for HDPE molded products. Irrigation systems, storage containers, and greenhouse components made from HDPE are in high demand due to their durability and resistance to agricultural chemicals. As precision agriculture and sustainable farming practices gain momentum, the market for HDPE molded products in this sector is poised for continued growth.

Consumer goods and electronics industries have also contributed to the increasing demand for HDPE molded products. The material's versatility allows for the production of a wide range of household items, toys, and electronic device casings. The growing middle-class population in emerging economies has further fueled this demand, as consumers seek durable and affordable products.

The global push towards circular economy principles has positively impacted the market for HDPE molded products. The material's recyclability and the development of advanced recycling technologies have made HDPE an attractive choice for manufacturers and consumers alike. This trend is expected to drive further innovation in HDPE molding techniques and applications, opening up new market opportunities.

Current Challenges in HDPE Injection Molding

Despite the widespread use of High Density Polyethylene (HDPE) in injection molding, several challenges persist in optimizing the process for this versatile material. One of the primary issues is the control of warpage and shrinkage. HDPE, being a semi-crystalline polymer, undergoes significant volumetric changes during cooling, which can lead to dimensional instability in the final product. This challenge is particularly pronounced in large or complex parts where uneven cooling rates can exacerbate warpage.

Another significant hurdle is achieving consistent melt flow and distribution throughout the mold cavity. HDPE's high melt viscosity can result in incomplete filling, especially in thin-walled sections or intricate geometries. This issue is often compounded by the material's sensitivity to processing temperatures, where even slight variations can significantly affect flow characteristics and part quality.

The management of residual stresses in HDPE molded parts also presents a considerable challenge. These internal stresses, if not properly controlled, can lead to post-molding deformation, reduced mechanical properties, and in severe cases, part failure. The challenge lies in optimizing process parameters such as injection speed, holding pressure, and cooling time to minimize these stresses without compromising cycle times or productivity.

Environmental stress cracking (ESC) resistance is another area of concern in HDPE injection molding. While HDPE generally has good chemical resistance, certain applications expose the material to aggressive chemicals or stress conditions that can induce cracking over time. Improving ESC resistance through material formulation or processing techniques remains an ongoing challenge for manufacturers in sectors such as packaging and automotive.

The pursuit of enhanced surface finish and aesthetics in HDPE molded parts is also a persistent challenge. The material's inherent properties can lead to issues such as flow lines, sink marks, and gloss variations, which are particularly problematic in consumer products where appearance is crucial. Overcoming these surface defects often requires a delicate balance of material selection, mold design, and processing parameters.

Lastly, the drive towards sustainability and circular economy principles presents new challenges in HDPE injection molding. Incorporating recycled HDPE into the production stream without compromising part quality or performance is a complex task. Variations in the properties of recycled material, potential contamination, and maintaining consistent processing conditions are hurdles that need to be addressed to increase the use of recycled HDPE in injection molding applications.

Advanced HDPE Injection Molding Techniques

01 Manufacturing processes for HDPE

Various manufacturing processes are used to produce high-density polyethylene (HDPE), including polymerization techniques and extrusion methods. These processes aim to create HDPE with specific properties such as high strength, durability, and chemical resistance. Different catalysts and reaction conditions can be employed to control the molecular weight and distribution of the polymer chains.- Manufacturing processes for HDPE: Various manufacturing processes are employed to produce high-density polyethylene (HDPE), including polymerization techniques and extrusion methods. These processes aim to achieve specific molecular structures and properties, such as high density and improved mechanical strength.

- HDPE blends and composites: HDPE is often blended with other materials or used in composites to enhance its properties. These blends and composites can improve characteristics such as impact resistance, thermal stability, and processability, making them suitable for a wide range of applications.

- HDPE applications in packaging and containers: HDPE is widely used in packaging and container applications due to its excellent chemical resistance, durability, and barrier properties. It is commonly employed in the production of bottles, containers, and various packaging materials for both industrial and consumer goods.

- Recycling and sustainability of HDPE: Recycling processes and sustainable practices for HDPE are being developed to address environmental concerns. These include methods for collecting, sorting, and reprocessing HDPE materials, as well as the development of bio-based alternatives and additives to improve recyclability.

- HDPE modifications for specific properties: Various modifications and treatments are applied to HDPE to enhance specific properties or functionalities. These can include surface treatments, crosslinking, or the incorporation of additives to improve characteristics such as wear resistance, electrical properties, or UV stability.

02 HDPE blends and composites

HDPE can be blended with other materials or used as a matrix for composites to enhance its properties or create new materials with specific characteristics. These blends and composites may include other polymers, fillers, or reinforcing agents to improve mechanical strength, thermal stability, or other desired properties. The resulting materials find applications in various industries.Expand Specific Solutions03 HDPE applications in packaging and containers

High-density polyethylene is widely used in packaging and container applications due to its excellent barrier properties, chemical resistance, and durability. HDPE is utilized in the production of bottles, containers, and packaging materials for various products, including food, beverages, and chemicals. The material's properties make it suitable for both rigid and flexible packaging solutions.Expand Specific Solutions04 Recycling and sustainability of HDPE

Recycling processes and sustainable practices for HDPE are being developed and implemented to address environmental concerns. These include methods for collecting, sorting, and reprocessing HDPE products, as well as the development of bio-based or biodegradable alternatives. Efforts are also being made to improve the recyclability of HDPE products and increase the use of recycled HDPE in new applications.Expand Specific Solutions05 HDPE modifications for enhanced properties

Various modifications and treatments can be applied to HDPE to enhance its properties or impart new functionalities. These modifications may include crosslinking, surface treatments, or the incorporation of additives to improve characteristics such as impact resistance, weatherability, or flame retardancy. Such modifications expand the range of applications for HDPE in different industries.Expand Specific Solutions

Key Players in HDPE Injection Molding Industry

The High Density Polyethylene (HDPE) injection molding industry is in a mature growth stage, with a global market size expected to reach $85 billion by 2027. Technological advancements are driving competition among key players like Dow Global Technologies, Borealis AG, and SABIC Global Technologies BV. These companies are focusing on improving HDPE properties and processing efficiency. The technology maturity varies, with established firms like Basell Polyolefine GmbH and Total Research Corp leading in innovation, while emerging players such as Ningbo University and Shanghai Research Institute of Chemical Industry Co. Ltd. are contributing to regional advancements. The competitive landscape is characterized by a mix of multinational corporations and specialized research institutions, all striving to enhance HDPE injection molding techniques for various applications.

Dow Global Technologies LLC

Borealis AG

Innovative HDPE Molding Patents and Research

- A polyethylene composition with a specific density range, incorporating carbon black and/or UV stabilizers, and having a tailored molecular weight distribution, melt flow rates, and branching structure to reduce warpage and lower injection pressures, achieved through a combination of ethylene copolymers and specific catalyst systems.

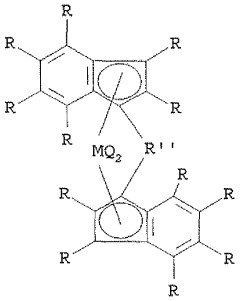

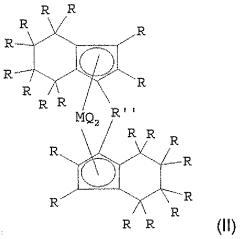

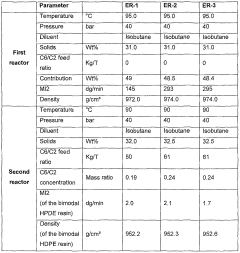

- A bimodal high density polyethylene (HDPE) resin is developed using a metallocene-containing catalyst system with bridged bisindenyl or bridged bis-tetrahydroindenyl metallocene, produced in two reactors connected in series, resulting in a resin with specific molecular weight distribution and melt index ratios, enhancing processability and maintaining or improving other critical properties.

Sustainability in HDPE Injection Molding

Sustainability in HDPE injection molding has become a critical focus in recent years, driven by increasing environmental concerns and regulatory pressures. The industry is actively pursuing strategies to reduce the environmental impact of HDPE production and processing while maintaining the material's desirable properties.

One of the primary sustainability initiatives in HDPE injection molding is the incorporation of recycled content. Manufacturers are developing technologies to effectively blend post-consumer and post-industrial HDPE into new products without compromising quality. This approach not only reduces waste but also decreases the demand for virgin materials, thereby conserving resources and energy.

Energy efficiency improvements in the injection molding process represent another key area of sustainability advancement. Modern machinery incorporates features such as servo-driven hydraulics, advanced heating and cooling systems, and precise process controls to minimize energy consumption. These innovations not only reduce the carbon footprint of production but also offer cost savings to manufacturers.

The development of bio-based HDPE alternatives is gaining traction as a sustainable solution. Researchers are exploring the use of renewable feedstocks, such as sugarcane or corn, to produce HDPE with properties comparable to petroleum-based versions. While still in the early stages, this approach holds promise for reducing reliance on fossil fuels and decreasing overall carbon emissions.

Lightweighting initiatives are also contributing to sustainability in HDPE injection molding. By optimizing part design and leveraging advanced simulation tools, manufacturers can reduce material usage without sacrificing performance. This not only conserves resources but also leads to reduced energy consumption in transportation and handling throughout the product lifecycle.

Closed-loop manufacturing systems are being implemented to enhance sustainability in HDPE production. These systems aim to minimize waste by reprocessing scrap material and optimizing resource utilization. Additionally, water conservation efforts, such as closed-loop cooling systems and water recycling, are becoming more prevalent in injection molding facilities.

The industry is also focusing on end-of-life considerations for HDPE products. Design for recyclability is becoming a key principle, with manufacturers considering the entire lifecycle of their products. This includes using compatible additives and avoiding composite materials that may hinder recycling efforts.

As sustainability continues to drive innovation in HDPE injection molding, collaboration across the value chain is essential. Material suppliers, equipment manufacturers, and end-users are working together to develop holistic solutions that address environmental concerns while meeting performance requirements. This collaborative approach is key to advancing sustainability in the HDPE injection molding industry and ensuring its long-term viability.

Quality Control in HDPE Molded Products

Quality control is a critical aspect of High Density Polyethylene (HDPE) injection molding processes, ensuring the production of consistent, high-quality products that meet industry standards and customer specifications. The implementation of robust quality control measures begins with the careful selection and testing of raw materials. HDPE resins must be thoroughly evaluated for molecular weight distribution, melt flow index, and contamination levels to ensure optimal processing characteristics and final product properties.

During the injection molding process, real-time monitoring and control of key parameters are essential. Advanced sensor technologies and data analytics systems are employed to track and adjust variables such as melt temperature, injection pressure, holding time, and cooling rate. These parameters directly influence the dimensional accuracy, surface finish, and mechanical properties of the molded parts. Automated process control systems, utilizing statistical process control (SPC) techniques, help maintain tight tolerances and reduce variability in production runs.

Post-molding quality checks are equally important in ensuring the integrity of HDPE products. Non-destructive testing methods, such as ultrasonic inspection and X-ray analysis, are used to detect internal defects or voids that may compromise product performance. Dimensional measurements, often performed using coordinate measuring machines (CMMs) or 3D scanning technologies, verify that parts meet specified tolerances. Surface quality assessments, including gloss measurements and visual inspections, ensure aesthetic consistency and identify potential cosmetic defects.

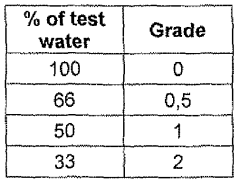

Mechanical testing plays a crucial role in validating the performance characteristics of HDPE molded products. Tensile strength, impact resistance, and flexural modulus are commonly evaluated to ensure compliance with industry standards and application-specific requirements. Environmental stress cracking resistance (ESCR) tests are particularly important for HDPE products exposed to harsh chemicals or prolonged environmental stresses.

Traceability and documentation are integral components of quality control in HDPE injection molding. Advanced manufacturing execution systems (MES) and enterprise resource planning (ERP) software facilitate the tracking of raw materials, process parameters, and quality data throughout the production lifecycle. This comprehensive approach enables rapid identification and resolution of quality issues, as well as continuous improvement of manufacturing processes.

Emerging technologies are enhancing quality control capabilities in HDPE injection molding. Machine learning algorithms are being applied to predict and prevent quality defects based on historical process data. In-mold sensors and real-time monitoring systems provide immediate feedback on part quality, allowing for on-the-fly adjustments to maintain optimal production conditions. Additionally, augmented reality (AR) tools are being utilized for quality inspections, providing operators with visual guidance and reducing the likelihood of human error in defect detection.