High Density Polyethylene in Pipe Manufacturing: New Frontiers

HDPE Pipe Evolution

The evolution of High Density Polyethylene (HDPE) pipes represents a significant advancement in the field of pipe manufacturing. Initially introduced in the 1950s, HDPE pipes have undergone substantial improvements in material properties, manufacturing processes, and application scope over the past seven decades.

In the early stages, HDPE pipes were primarily used for low-pressure water distribution and gas transportation. The material's inherent flexibility, corrosion resistance, and lightweight nature made it an attractive alternative to traditional metal pipes. However, limitations in pressure ratings and joint integrity restricted its widespread adoption in more demanding applications.

The 1970s and 1980s saw significant advancements in HDPE resin technology. The introduction of bimodal HDPE resins marked a turning point, offering improved mechanical properties and enhanced long-term performance. This development expanded the use of HDPE pipes into higher pressure applications and larger diameter installations.

The 1990s brought about innovations in pipe extrusion technology, enabling the production of larger diameter pipes with improved dimensional stability. Simultaneously, advancements in joining techniques, such as butt fusion and electrofusion, enhanced the reliability and ease of installation for HDPE pipe systems.

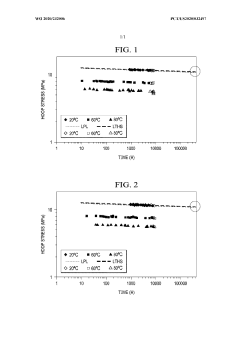

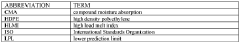

In the early 2000s, the focus shifted towards improving the long-term performance and durability of HDPE pipes. Research into slow crack growth resistance and stress crack resistance led to the development of PE100 grade resins, offering superior strength and longevity. This advancement allowed HDPE pipes to compete effectively with traditional materials in critical infrastructure projects.

Recent years have seen a surge in the development of specialized HDPE pipe formulations. These include pipes with enhanced chemical resistance for industrial applications, pipes with improved thermal properties for geothermal systems, and pipes with reduced environmental impact through the incorporation of recycled materials.

The evolution of HDPE pipes has also been marked by advancements in quality control and testing methodologies. Non-destructive testing techniques, such as ultrasonic inspection and X-ray analysis, have been developed to ensure the integrity of pipe systems, particularly for large-diameter and high-pressure applications.

Looking ahead, the HDPE pipe industry is poised for further innovation. Current research focuses on developing "smart" HDPE pipes with integrated sensors for real-time monitoring of pipe condition and performance. Additionally, efforts are underway to enhance the sustainability of HDPE pipe production through the use of bio-based materials and improved recycling technologies.

Market Demand Analysis

The market demand for High Density Polyethylene (HDPE) in pipe manufacturing has been experiencing significant growth, driven by several key factors. The construction industry's expansion, particularly in developing economies, has led to increased infrastructure development, boosting the demand for HDPE pipes. These pipes are widely used in water supply systems, sewage networks, and gas distribution due to their durability, corrosion resistance, and cost-effectiveness.

In the water management sector, there is a growing need for efficient and reliable piping systems. HDPE pipes offer superior leak resistance and longevity compared to traditional materials, making them an attractive choice for both new installations and replacement of aging infrastructure. This trend is particularly evident in regions facing water scarcity issues, where minimizing water loss through leakage is crucial.

The oil and gas industry has also contributed to the rising demand for HDPE pipes. As exploration and production activities expand into more challenging environments, the need for robust and flexible piping solutions has increased. HDPE pipes' ability to withstand high pressures and harsh chemicals makes them ideal for various applications in this sector.

Environmental concerns and sustainability initiatives have further propelled the market for HDPE pipes. Their recyclability and lower carbon footprint compared to metal pipes align with the growing emphasis on eco-friendly construction practices. Additionally, the increasing adoption of trenchless technology in pipe installation has favored HDPE pipes due to their flexibility and ease of handling.

The agricultural sector presents another significant market for HDPE pipes, particularly in irrigation systems. As global food demand rises and water conservation becomes more critical, efficient irrigation solutions using HDPE pipes are gaining traction. Their resistance to UV radiation and ability to withstand various soil conditions make them well-suited for agricultural applications.

Market analysis indicates that the global HDPE pipe market is expected to continue its upward trajectory. Emerging economies in Asia-Pacific and Africa are anticipated to be major growth drivers, with rapid urbanization and government investments in infrastructure development fueling demand. In mature markets like North America and Europe, the focus is shifting towards replacing aging pipeline networks with more durable and efficient HDPE alternatives.

The market is also witnessing a trend towards larger diameter HDPE pipes, expanding their application scope in major infrastructure projects. This development is opening new opportunities for manufacturers to innovate and capture larger market shares. However, the market faces challenges such as fluctuating raw material prices and competition from alternative piping materials, which could impact growth rates in certain segments.

Technical Challenges

The development of High Density Polyethylene (HDPE) in pipe manufacturing faces several technical challenges that require innovative solutions. One of the primary obstacles is achieving optimal balance between mechanical strength and flexibility. HDPE pipes must withstand high pressure and external loads while maintaining sufficient flexibility to adapt to ground movements and installation stresses.

Another significant challenge lies in improving the long-term performance and durability of HDPE pipes. While HDPE is known for its resistance to corrosion and chemical degradation, enhancing its resistance to environmental stress cracking and slow crack growth remains a key focus area. This is particularly crucial for applications in harsh environments or where pipes are subjected to sustained loads.

The manufacturing process itself presents technical hurdles. Ensuring consistent wall thickness and uniform material distribution throughout the pipe length is critical for maintaining structural integrity. Advanced extrusion techniques and precise control of processing parameters are necessary to achieve this consistency, especially for large-diameter pipes.

Joining techniques for HDPE pipes also pose challenges. While heat fusion is a common method, it requires specialized equipment and skilled operators. Developing more efficient and reliable joining methods, particularly for field installations, is an ongoing area of research.

Furthermore, the industry faces challenges in recycling and sustainability. Although HDPE is recyclable, the process of separating and recycling used pipes, especially those with additives or coatings, can be complex. Developing eco-friendly additives and more easily recyclable HDPE formulations without compromising performance is a significant technical challenge.

The incorporation of smart technologies into HDPE pipes presents another frontier. Integrating sensors for real-time monitoring of pipe condition, leak detection, and flow characteristics requires overcoming issues related to material compatibility, long-term reliability of embedded electronics, and data transmission through the pipe material.

Lastly, there is a growing demand for HDPE pipes with enhanced properties for specific applications. This includes developing pipes with improved resistance to high temperatures, increased chemical resistance for industrial applications, and better insulation properties for energy-efficient systems. Meeting these specialized requirements while maintaining the core benefits of HDPE poses significant research and development challenges.

Addressing these technical challenges requires a multidisciplinary approach, combining advances in polymer science, manufacturing technology, and materials engineering. Overcoming these hurdles will be crucial for expanding the applications of HDPE in pipe manufacturing and meeting the evolving needs of various industries.

Current HDPE Solutions

01 Composition and properties of HDPE

High Density Polyethylene (HDPE) is a thermoplastic polymer with a high strength-to-density ratio. It is characterized by its long linear chains with minimal branching, resulting in higher tensile strength and melting point compared to other polyethylene types. HDPE exhibits excellent chemical resistance, low moisture absorption, and good electrical insulation properties.- Composition and properties of HDPE: High Density Polyethylene (HDPE) is a thermoplastic polymer with a high strength-to-density ratio. It is characterized by its long linear chains with minimal branching, resulting in higher tensile strength, stiffness, and chemical resistance compared to other polyethylene types. HDPE's properties make it suitable for various applications in packaging, construction, and automotive industries.

- HDPE blends and composites: HDPE can be blended with other materials or reinforced with fillers to enhance its properties. These blends and composites often aim to improve mechanical strength, thermal stability, or specific functional characteristics. Common additives include other polymers, natural fibers, or inorganic particles, resulting in materials with tailored properties for specific applications.

- HDPE processing techniques: Various processing techniques are employed to manufacture HDPE products, including injection molding, extrusion, and blow molding. These methods allow for the production of a wide range of items, from bottles and containers to pipes and automotive parts. Innovations in processing techniques focus on improving efficiency, reducing cycle times, and enhancing the quality of the final products.

- Recycling and sustainability of HDPE: HDPE is highly recyclable, making it an environmentally friendly option in many applications. Recycling processes for HDPE involve collection, sorting, cleaning, and reprocessing into new products. Innovations in this area focus on improving recycling efficiency, developing new applications for recycled HDPE, and creating closed-loop systems to minimize waste and environmental impact.

- HDPE applications in specialized fields: HDPE finds applications in various specialized fields due to its unique properties. These include use in medical devices, food packaging, water treatment systems, and geomembranes for environmental protection. Ongoing research focuses on expanding HDPE's use in these areas by modifying its properties or developing new processing techniques to meet specific industry requirements.

02 HDPE production methods

Various methods are employed to produce HDPE, including slurry polymerization, gas-phase polymerization, and solution polymerization. These processes often involve the use of catalysts, such as Ziegler-Natta or metallocene catalysts, to control the polymerization reaction and achieve desired molecular weight distributions and properties.Expand Specific Solutions03 HDPE blends and composites

HDPE is often blended with other materials or reinforced with fillers to enhance its properties. These blends and composites can improve mechanical strength, impact resistance, thermal stability, or introduce specific functionalities. Common additives include other polymers, natural fibers, nanoparticles, and inorganic fillers.Expand Specific Solutions04 Applications of HDPE

HDPE finds widespread use in various industries due to its versatile properties. It is commonly used in packaging, construction, automotive parts, pipes, containers, and household products. HDPE's durability, chemical resistance, and recyclability make it suitable for both single-use and long-term applications.Expand Specific Solutions05 Recycling and sustainability of HDPE

HDPE is highly recyclable, contributing to its sustainability profile. Recycling processes for HDPE include mechanical recycling, chemical recycling, and energy recovery. Efforts are being made to improve the recycling efficiency of HDPE and develop more sustainable production methods to reduce its environmental impact.Expand Specific Solutions

Industry Leaders

The High Density Polyethylene (HDPE) pipe manufacturing industry is in a mature growth stage, with a global market size expected to reach $17.3 billion by 2027. The technology's maturity is evident in the diverse range of players, from established petrochemical giants like SABIC, Dow, and ExxonMobil to specialized pipe manufacturers such as Pipelife Nederland and ZYfire Hose Corp. The competitive landscape is characterized by ongoing innovation in material properties and manufacturing processes. Companies like Borealis AG and Univation Technologies LLC are at the forefront of developing advanced HDPE resins, while others like Chevron Phillips Chemical Co. LP focus on enhancing production efficiency. The industry is seeing increased competition from emerging markets, with Chinese companies like Sinopec and Jiangsu B&Q Pipes Industry Co., Ltd. rapidly gaining market share.

Borealis AG

Dow Global Technologies LLC

Key HDPE Innovations

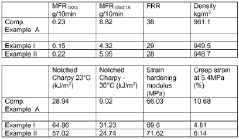

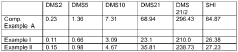

- A multimodal, preferably bimodal, HDPE is produced using a multi-step slurry polymerization process with a Ziegler Natta catalyst system, featuring a specific composition of ethylene homopolymer and hexene copolymer, resulting in enhanced hydrostatic strength, impact resistance, and strain hardening properties.

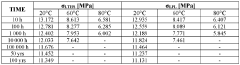

- The development of novel pressure pipe resins comprising high-density polyethylene (HDPE) with optimized base polymers and carbon black masterbatches, which increase the Minimum Required Strength (MRS) and creep performance by adjusting the density and molecular weight of the base polymer and masterbatch, allowing for the creation of lighter, stronger pipes with a PEI 12 rating.

Environmental Impact

The environmental impact of High Density Polyethylene (HDPE) in pipe manufacturing is a critical consideration as the industry explores new frontiers. HDPE pipes have gained popularity due to their durability, flexibility, and resistance to corrosion. However, their production and disposal pose significant environmental challenges that must be addressed.

The manufacturing process of HDPE pipes requires substantial energy consumption, contributing to greenhouse gas emissions. The production of HDPE resin involves the use of fossil fuels, primarily natural gas and petroleum, which are non-renewable resources. This reliance on fossil fuels raises concerns about the long-term sustainability of HDPE pipe production.

Despite these challenges, HDPE pipes offer several environmental benefits during their lifecycle. Their lightweight nature reduces transportation costs and associated emissions compared to traditional materials like concrete or metal. Additionally, HDPE pipes have a longer lifespan, reducing the need for frequent replacements and minimizing waste generation.

The recyclability of HDPE pipes is a significant advantage from an environmental perspective. At the end of their useful life, HDPE pipes can be recycled and repurposed into new products, reducing the demand for virgin materials. However, the recycling process itself requires energy and may produce emissions, necessitating careful management.

Water conservation is another area where HDPE pipes contribute positively to environmental sustainability. Their resistance to leaks and corrosion helps prevent water loss in distribution systems, conserving this vital resource. This is particularly crucial in regions facing water scarcity or aging infrastructure.

The disposal of HDPE pipes that are not recycled presents environmental concerns. When improperly disposed of, these pipes can persist in landfills for hundreds of years, contributing to long-term environmental degradation. Efforts to improve end-of-life management and increase recycling rates are essential to mitigate this issue.

As the industry explores new frontiers in HDPE pipe manufacturing, there is a growing focus on developing more environmentally friendly production methods. Research into bio-based alternatives and the use of recycled materials in pipe production shows promise in reducing the environmental footprint of HDPE pipes.

Advancements in manufacturing technologies are also contributing to improved environmental performance. More efficient production processes, such as the use of renewable energy sources and closed-loop systems, are being implemented to reduce energy consumption and minimize waste generation.

In conclusion, while HDPE pipes offer several environmental advantages, their production and disposal still present significant challenges. The industry's ongoing efforts to address these issues through innovation and sustainable practices will be crucial in shaping the environmental impact of HDPE pipes in the future.

Regulatory Framework

The regulatory framework surrounding High Density Polyethylene (HDPE) in pipe manufacturing is a complex and evolving landscape that significantly impacts the industry's operations and future developments. At the international level, organizations such as the International Organization for Standardization (ISO) and the American Society for Testing and Materials (ASTM) have established comprehensive standards for HDPE pipes, covering aspects like material properties, performance requirements, and testing methods.

In the United States, the regulatory environment is shaped by federal agencies and industry associations. The Environmental Protection Agency (EPA) plays a crucial role in setting standards for drinking water systems, which directly affects HDPE pipe usage in water distribution networks. The American Water Works Association (AWWA) and the Plastics Pipe Institute (PPI) provide additional guidelines and specifications that are widely adopted by the industry.

European regulations, particularly those set by the European Committee for Standardization (CEN), have a significant influence on HDPE pipe manufacturing globally. The EU's Construction Products Regulation (CPR) mandates CE marking for plastic piping systems used in buildings, ensuring compliance with harmonized standards across member states.

Emerging markets, such as China and India, are developing their own regulatory frameworks for HDPE pipes, often adapting international standards to suit local conditions. These evolving regulations are creating new opportunities and challenges for manufacturers operating in these regions.

Environmental regulations are increasingly shaping the HDPE pipe industry. Many jurisdictions are implementing stricter rules on the recyclability and environmental impact of plastic products, including pipes. This has led to a growing emphasis on sustainable manufacturing practices and the development of more environmentally friendly HDPE formulations.

Safety regulations, particularly those related to gas distribution systems, are another critical aspect of the regulatory framework. Standards set by organizations like the Gas Technology Institute (GTI) in the US and similar bodies in other countries dictate the performance and safety requirements for HDPE pipes used in natural gas networks.

As the industry explores new frontiers in HDPE pipe manufacturing, regulatory bodies are adapting to address emerging technologies and applications. For instance, the use of nanotechnology in HDPE pipe production is prompting regulators to develop new guidelines for assessing the safety and performance of these advanced materials.

The regulatory landscape also extends to the entire lifecycle of HDPE pipes, from raw material sourcing to end-of-life management. This holistic approach is driving innovations in recycling technologies and circular economy practices within the industry.