High-Voltage Battery Management System Design for Energy-Dense Applications

AUG 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

HV BMS Evolution and Objectives

High-Voltage Battery Management Systems (HV BMS) have undergone significant evolution since their inception, driven by the increasing demand for energy-dense applications in electric vehicles and renewable energy storage. The journey of HV BMS began with simple voltage monitoring and basic safety features, gradually progressing to more sophisticated systems capable of managing complex battery packs with hundreds of cells.

In the early stages, HV BMS focused primarily on ensuring safe operation and preventing catastrophic failures. As battery technology advanced, the objectives of BMS expanded to include optimizing battery performance, extending lifespan, and enhancing overall system efficiency. This shift in focus led to the development of more advanced algorithms for state estimation, including State of Charge (SoC), State of Health (SoH), and State of Power (SoP) calculations.

The evolution of HV BMS has been closely tied to advancements in semiconductor technology, enabling more powerful microcontrollers and integrated circuits specifically designed for battery management. This has allowed for increased computational capabilities, improved accuracy in measurements, and the ability to handle higher voltages and currents.

One of the key milestones in HV BMS evolution was the introduction of cell balancing techniques. Initially, passive balancing methods were employed, but as energy efficiency became a critical factor, active balancing solutions gained prominence. These advanced balancing techniques have become essential for maximizing the utilization of battery capacity and ensuring uniform aging across all cells.

The integration of communication protocols and connectivity features marks another significant step in HV BMS development. Modern systems now incorporate CAN, LIN, or even wireless communication capabilities, enabling seamless integration with vehicle control systems and facilitating remote monitoring and diagnostics.

As the automotive industry moves towards higher voltage systems, exceeding 800V in some cases, HV BMS designs have had to adapt to manage these increased voltage levels safely and efficiently. This has led to the development of new isolation technologies and safety mechanisms to protect both the battery system and its users.

Looking forward, the objectives of HV BMS in energy-dense applications are multifaceted. There is a strong focus on improving energy density while maintaining or enhancing safety standards. This includes developing more accurate and reliable methods for predicting battery behavior under various conditions and implementing adaptive control strategies to optimize performance in real-time.

Another key objective is to reduce the overall cost and complexity of HV BMS while increasing functionality. This involves exploring new sensor technologies, improving thermal management strategies, and developing more integrated solutions that combine multiple functions into single components.

In the early stages, HV BMS focused primarily on ensuring safe operation and preventing catastrophic failures. As battery technology advanced, the objectives of BMS expanded to include optimizing battery performance, extending lifespan, and enhancing overall system efficiency. This shift in focus led to the development of more advanced algorithms for state estimation, including State of Charge (SoC), State of Health (SoH), and State of Power (SoP) calculations.

The evolution of HV BMS has been closely tied to advancements in semiconductor technology, enabling more powerful microcontrollers and integrated circuits specifically designed for battery management. This has allowed for increased computational capabilities, improved accuracy in measurements, and the ability to handle higher voltages and currents.

One of the key milestones in HV BMS evolution was the introduction of cell balancing techniques. Initially, passive balancing methods were employed, but as energy efficiency became a critical factor, active balancing solutions gained prominence. These advanced balancing techniques have become essential for maximizing the utilization of battery capacity and ensuring uniform aging across all cells.

The integration of communication protocols and connectivity features marks another significant step in HV BMS development. Modern systems now incorporate CAN, LIN, or even wireless communication capabilities, enabling seamless integration with vehicle control systems and facilitating remote monitoring and diagnostics.

As the automotive industry moves towards higher voltage systems, exceeding 800V in some cases, HV BMS designs have had to adapt to manage these increased voltage levels safely and efficiently. This has led to the development of new isolation technologies and safety mechanisms to protect both the battery system and its users.

Looking forward, the objectives of HV BMS in energy-dense applications are multifaceted. There is a strong focus on improving energy density while maintaining or enhancing safety standards. This includes developing more accurate and reliable methods for predicting battery behavior under various conditions and implementing adaptive control strategies to optimize performance in real-time.

Another key objective is to reduce the overall cost and complexity of HV BMS while increasing functionality. This involves exploring new sensor technologies, improving thermal management strategies, and developing more integrated solutions that combine multiple functions into single components.

Market Demand Analysis for HV BMS

The market demand for High-Voltage Battery Management Systems (HV BMS) in energy-dense applications has been experiencing significant growth, driven by the rapid expansion of electric vehicles (EVs) and renewable energy storage systems. As the automotive industry shifts towards electrification, the need for advanced HV BMS solutions has become paramount to ensure the safety, efficiency, and longevity of high-capacity battery packs.

In the EV sector, the push for longer driving ranges and faster charging capabilities has led to the development of higher voltage battery systems, typically operating at 800V or above. This trend has created a substantial market for HV BMS that can effectively manage these high-voltage systems. The global EV market is projected to grow at a compound annual growth rate (CAGR) of over 20% in the coming years, directly influencing the demand for HV BMS.

The renewable energy sector, particularly in grid-scale energy storage applications, is another key driver for HV BMS demand. As countries worldwide increase their renewable energy capacity, the need for large-scale energy storage solutions grows proportionally. These systems require sophisticated HV BMS to manage the complex charging and discharging cycles of massive battery arrays.

Industrial applications, such as material handling equipment and heavy-duty vehicles, are also contributing to the rising demand for HV BMS. The electrification of forklifts, excavators, and other industrial machinery is gaining momentum, creating new market opportunities for HV BMS manufacturers.

The aerospace industry is emerging as a potential growth area for HV BMS, with electric and hybrid-electric aircraft development accelerating. Although still in its early stages, this sector could represent a significant market for specialized HV BMS solutions in the future.

Consumer electronics and portable power tools are gradually adopting higher voltage systems to improve performance and reduce charging times. This trend, while not as prominent as in the automotive sector, is creating a niche market for compact HV BMS solutions.

Geographically, Asia-Pacific leads the market demand for HV BMS, primarily due to the strong presence of EV manufacturers and battery producers in countries like China, Japan, and South Korea. North America and Europe follow closely, driven by stringent emissions regulations and government incentives promoting EV adoption and renewable energy integration.

The market demand for HV BMS is not only quantitative but also qualitative. There is an increasing emphasis on BMS solutions that offer enhanced safety features, higher precision in cell monitoring and balancing, and advanced diagnostic capabilities. Additionally, the industry is seeking more integrated and cost-effective HV BMS designs to reduce overall system complexity and improve manufacturability.

As the energy-dense applications continue to evolve, the HV BMS market is expected to witness further segmentation, with specialized solutions emerging for different voltage ranges and application-specific requirements. This diversification will likely create new opportunities for both established players and innovative startups in the HV BMS space.

In the EV sector, the push for longer driving ranges and faster charging capabilities has led to the development of higher voltage battery systems, typically operating at 800V or above. This trend has created a substantial market for HV BMS that can effectively manage these high-voltage systems. The global EV market is projected to grow at a compound annual growth rate (CAGR) of over 20% in the coming years, directly influencing the demand for HV BMS.

The renewable energy sector, particularly in grid-scale energy storage applications, is another key driver for HV BMS demand. As countries worldwide increase their renewable energy capacity, the need for large-scale energy storage solutions grows proportionally. These systems require sophisticated HV BMS to manage the complex charging and discharging cycles of massive battery arrays.

Industrial applications, such as material handling equipment and heavy-duty vehicles, are also contributing to the rising demand for HV BMS. The electrification of forklifts, excavators, and other industrial machinery is gaining momentum, creating new market opportunities for HV BMS manufacturers.

The aerospace industry is emerging as a potential growth area for HV BMS, with electric and hybrid-electric aircraft development accelerating. Although still in its early stages, this sector could represent a significant market for specialized HV BMS solutions in the future.

Consumer electronics and portable power tools are gradually adopting higher voltage systems to improve performance and reduce charging times. This trend, while not as prominent as in the automotive sector, is creating a niche market for compact HV BMS solutions.

Geographically, Asia-Pacific leads the market demand for HV BMS, primarily due to the strong presence of EV manufacturers and battery producers in countries like China, Japan, and South Korea. North America and Europe follow closely, driven by stringent emissions regulations and government incentives promoting EV adoption and renewable energy integration.

The market demand for HV BMS is not only quantitative but also qualitative. There is an increasing emphasis on BMS solutions that offer enhanced safety features, higher precision in cell monitoring and balancing, and advanced diagnostic capabilities. Additionally, the industry is seeking more integrated and cost-effective HV BMS designs to reduce overall system complexity and improve manufacturability.

As the energy-dense applications continue to evolve, the HV BMS market is expected to witness further segmentation, with specialized solutions emerging for different voltage ranges and application-specific requirements. This diversification will likely create new opportunities for both established players and innovative startups in the HV BMS space.

Current HV BMS Challenges

High-voltage battery management systems (HV BMS) for energy-dense applications face several significant challenges in their design and implementation. One of the primary concerns is the accurate measurement and balancing of cell voltages across large battery packs. As the number of cells in series increases, the precision required for voltage measurements becomes more critical, and the complexity of balancing algorithms grows exponentially.

Thermal management presents another major challenge for HV BMS. High-voltage systems generate substantial heat during operation, which can lead to reduced battery life, decreased performance, and potential safety hazards. Designing effective cooling systems that can maintain optimal temperature ranges across all cells in large battery packs is a complex engineering task.

Safety considerations are paramount in HV BMS design. The high voltages involved pose significant risks of electrical shock and fire. Implementing robust isolation mechanisms, fault detection systems, and emergency shutdown procedures is essential but adds layers of complexity to the overall system architecture.

The integration of advanced diagnostic and prognostic capabilities is becoming increasingly important for HV BMS. Accurately predicting battery state of health, remaining useful life, and potential failure modes requires sophisticated algorithms and extensive data analysis. Developing these capabilities while maintaining system reliability and real-time performance is a significant challenge.

Communication and data management within HV BMS systems present their own set of challenges. High-speed, reliable data transfer between numerous sensors, control units, and external systems is crucial for effective battery management. Ensuring data integrity and minimizing electromagnetic interference in high-voltage environments adds to the complexity of system design.

Scalability and modularity are key considerations in HV BMS design, particularly for energy-dense applications where battery configurations may vary. Creating flexible architectures that can adapt to different battery sizes and chemistries while maintaining optimal performance is a significant engineering challenge.

Regulatory compliance adds another layer of complexity to HV BMS design. Meeting stringent safety standards and certification requirements across different regions and applications necessitates careful consideration of system architecture and component selection.

Finally, cost optimization remains a persistent challenge in HV BMS development. Balancing the need for advanced features and high performance with the pressure to reduce overall system costs requires innovative design approaches and careful component selection.

Thermal management presents another major challenge for HV BMS. High-voltage systems generate substantial heat during operation, which can lead to reduced battery life, decreased performance, and potential safety hazards. Designing effective cooling systems that can maintain optimal temperature ranges across all cells in large battery packs is a complex engineering task.

Safety considerations are paramount in HV BMS design. The high voltages involved pose significant risks of electrical shock and fire. Implementing robust isolation mechanisms, fault detection systems, and emergency shutdown procedures is essential but adds layers of complexity to the overall system architecture.

The integration of advanced diagnostic and prognostic capabilities is becoming increasingly important for HV BMS. Accurately predicting battery state of health, remaining useful life, and potential failure modes requires sophisticated algorithms and extensive data analysis. Developing these capabilities while maintaining system reliability and real-time performance is a significant challenge.

Communication and data management within HV BMS systems present their own set of challenges. High-speed, reliable data transfer between numerous sensors, control units, and external systems is crucial for effective battery management. Ensuring data integrity and minimizing electromagnetic interference in high-voltage environments adds to the complexity of system design.

Scalability and modularity are key considerations in HV BMS design, particularly for energy-dense applications where battery configurations may vary. Creating flexible architectures that can adapt to different battery sizes and chemistries while maintaining optimal performance is a significant engineering challenge.

Regulatory compliance adds another layer of complexity to HV BMS design. Meeting stringent safety standards and certification requirements across different regions and applications necessitates careful consideration of system architecture and component selection.

Finally, cost optimization remains a persistent challenge in HV BMS development. Balancing the need for advanced features and high performance with the pressure to reduce overall system costs requires innovative design approaches and careful component selection.

State-of-the-Art HV BMS Solutions

01 Voltage monitoring and management

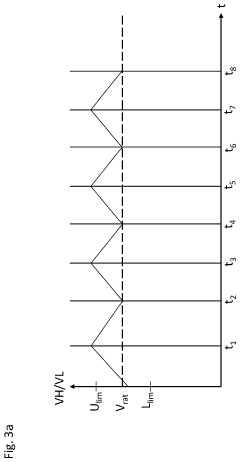

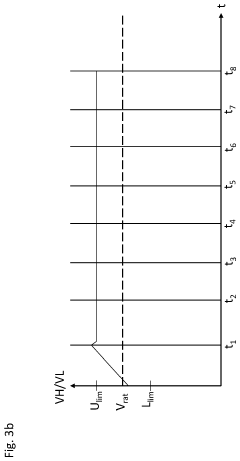

Battery Management Systems (BMS) employ sophisticated voltage monitoring techniques to ensure optimal battery performance and safety. These systems continuously measure individual cell voltages and overall battery pack voltage, allowing for real-time adjustments and protection against over-voltage or under-voltage conditions. Advanced algorithms are used to balance cell voltages, extending battery life and improving overall efficiency.- Voltage monitoring and management: Battery Management Systems (BMS) employ sophisticated voltage monitoring techniques to ensure optimal battery performance and safety. These systems continuously measure individual cell voltages and overall battery pack voltage, allowing for real-time adjustments and protection against over-voltage or under-voltage conditions. Advanced algorithms are used to balance cell voltages, extending battery life and improving overall efficiency.

- State of charge estimation: BMS utilize voltage measurements to accurately estimate the state of charge (SOC) of batteries. This involves complex calculations that consider factors such as voltage curves, temperature, and current flow. Precise SOC estimation is crucial for optimizing battery usage, predicting remaining range in electric vehicles, and preventing deep discharge or overcharging scenarios.

- Thermal management and voltage correlation: The relationship between battery temperature and voltage is carefully managed in BMS. Voltage measurements are used in conjunction with temperature sensors to detect and mitigate thermal runaway risks. The system adjusts charging and discharging rates based on voltage and temperature data to maintain optimal operating conditions and prevent battery degradation.

- Voltage-based fault detection and diagnostics: BMS employ voltage analysis for early detection of battery faults and performance issues. Abnormal voltage behaviors are used to identify potential cell failures, internal short circuits, or capacity degradation. This proactive approach allows for timely maintenance interventions and helps prevent catastrophic battery failures in various applications.

- Voltage-based charging control: Charging processes in BMS are precisely controlled using voltage measurements. The system monitors cell and pack voltages to determine optimal charging rates and cut-off points. Advanced charging algorithms, such as constant current-constant voltage (CC-CV) methods, are implemented to maximize charging efficiency while preserving battery health and longevity.

02 State of charge estimation

BMS utilize voltage measurements to accurately estimate the state of charge (SOC) of batteries. This involves complex calculations that consider factors such as voltage curves, temperature, and current flow. Precise SOC estimation is crucial for optimizing battery usage, predicting remaining range in electric vehicles, and preventing deep discharge or overcharging scenarios.Expand Specific Solutions03 Thermal management and voltage correlation

The relationship between battery temperature and voltage is carefully managed in BMS. Voltage measurements are used in conjunction with temperature sensors to detect and mitigate thermal issues. This integrated approach helps prevent thermal runaway, ensures safe charging and discharging processes, and maintains optimal battery performance across various environmental conditions.Expand Specific Solutions04 Voltage-based fault detection and diagnostics

BMS employ voltage analysis for early detection of battery faults and degradation. Abnormal voltage behaviors are used to identify issues such as cell deterioration, internal short circuits, or connection problems. This proactive approach allows for timely maintenance, enhances safety, and helps in predicting battery end-of-life, crucial for applications like electric vehicles and grid energy storage.Expand Specific Solutions05 Adaptive voltage control for charging

Advanced BMS implement adaptive voltage control strategies for optimized charging. These systems adjust charging voltage profiles based on battery condition, age, and environmental factors. By dynamically controlling charge voltage, BMS can maximize charging efficiency, reduce charging times, and extend battery lifespan while maintaining safety and preventing overcharging.Expand Specific Solutions

Key HV BMS Industry Players

The high-voltage battery management system (BMS) market for energy-dense applications is in a growth phase, driven by increasing demand for electric vehicles and energy storage solutions. The market size is expanding rapidly, with major automotive and technology players investing heavily in research and development. Technologically, the field is advancing quickly, with companies like Robert Bosch, BYD Semiconductor, and CATL leading innovation. Established automakers such as BMW, Porsche, and Hyundai are integrating advanced BMS into their electric vehicle lineups, while specialized firms like Enedym and LS Mtron are developing cutting-edge solutions. The competitive landscape is diverse, featuring traditional automotive suppliers, tech giants, and emerging startups, all vying for market share in this critical component of electrification.

Robert Bosch GmbH

Technical Solution: Bosch has developed a sophisticated High-Voltage Battery Management System for energy-dense applications, leveraging their expertise in automotive electronics. Their BMS employs a modular architecture that can be scaled to accommodate various battery sizes and configurations[9]. The system features high-precision voltage and current sensing, with accuracy levels reaching 0.1% for voltage measurements[10]. Bosch's BMS incorporates advanced algorithms for cell balancing, using both passive and semi-active methods to optimize battery pack performance and longevity[11]. The system also includes integrated diagnostics and prognostics capabilities, allowing for early detection of potential issues and predictive maintenance scheduling[12]. Additionally, Bosch has implemented robust cybersecurity measures in their BMS, including encrypted communications and secure over-the-air update mechanisms[13].

Strengths: Scalable modular architecture, high-precision sensing, advanced cell balancing, and strong cybersecurity features. Weaknesses: May have higher initial costs due to premium components and extensive feature set.

Hyundai Motor Co., Ltd.

Technical Solution: Hyundai has developed an innovative High-Voltage Battery Management System for their electric vehicle lineup, focusing on energy-dense applications. Their BMS utilizes a hybrid architecture, combining centralized control with distributed sensing modules for optimal performance and reliability[14]. The system incorporates advanced machine learning algorithms for accurate state-of-charge and state-of-health estimation, adapting to battery aging and varying environmental conditions[15]. Hyundai's BMS features a sophisticated thermal management system that integrates with the vehicle's overall thermal architecture, optimizing battery performance across a wide range of operating conditions[16]. The company has also implemented a unique cell balancing strategy that combines passive and active methods, maximizing energy efficiency and battery lifespan[17]. Additionally, Hyundai's BMS includes vehicle-to-grid (V2G) capabilities, allowing for bidirectional power flow and integration with smart grid systems[18].

Strengths: Hybrid architecture for balanced performance and reliability, advanced machine learning algorithms, sophisticated thermal management, and V2G capabilities. Weaknesses: Complexity of the hybrid architecture may lead to higher manufacturing and maintenance costs.

Core HV BMS Innovations

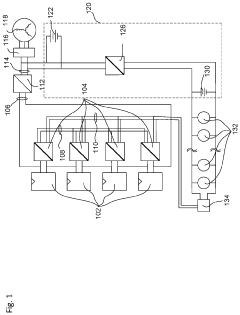

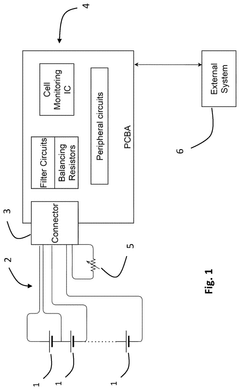

Bidirectional converter for a battery management system

PatentActiveUS20240042896A1

Innovation

- A battery management system that includes a bidirectional converter capable of monitoring and controlling the voltage ratio between high and low voltage batteries within a predetermined range, ensuring optimal operation by generating power flow between the batteries when the voltage ratio exceeds or falls below this range, thereby maintaining efficient ZVS and ZCS without the need for complex frequency adjustments.

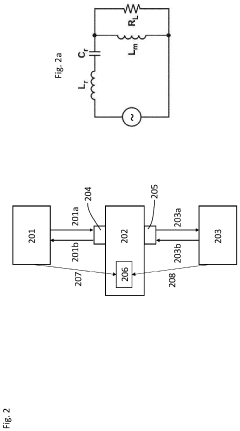

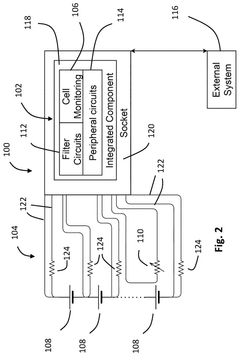

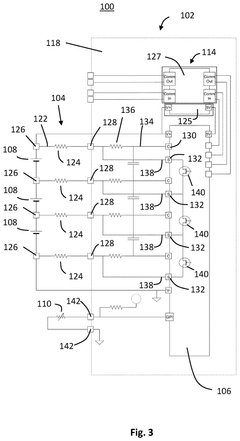

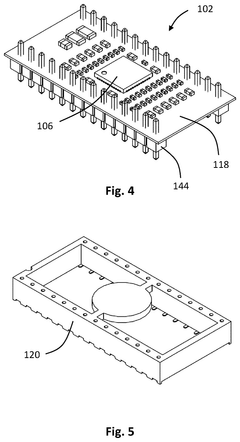

Battery Management System, Battery Pack and Method for Controlling Discharge of at Least One Battery Cell

PatentPendingUS20250087769A1

Innovation

- The battery management system incorporates a control circuit mounted on a small component carrier with a connector circuit that includes a balancing resistor, allowing for a compact design and improved thermal management by placing the balancing resistor outside the control circuit.

Safety Standards for HV BMS

Safety standards for High-Voltage Battery Management Systems (HV BMS) are critical in ensuring the safe operation of energy-dense applications. These standards encompass a wide range of requirements and guidelines that manufacturers and designers must adhere to when developing HV BMS for electric vehicles, energy storage systems, and other high-power applications.

One of the primary safety standards for HV BMS is ISO 26262, which focuses on functional safety in road vehicles. This standard provides a framework for assessing and mitigating potential hazards associated with electrical and electronic systems in automobiles. It emphasizes the importance of systematic risk analysis and the implementation of safety measures throughout the entire development process of HV BMS.

Another crucial standard is IEC 61508, which addresses functional safety for electrical, electronic, and programmable electronic safety-related systems. This standard is particularly relevant for HV BMS in industrial and energy storage applications. It outlines the requirements for safety integrity levels (SIL) and provides guidance on how to achieve and maintain these levels throughout the system lifecycle.

UL 2054 and UL 1642 are standards specifically focused on battery safety. These standards cover requirements for lithium-ion batteries and cells, including those used in high-voltage applications. They address issues such as thermal runaway, short circuit protection, and overcharge prevention, which are essential considerations in HV BMS design.

The SAE J2464 standard is tailored for electric and hybrid vehicle rechargeable energy storage systems. It provides test procedures for evaluating the safety and abuse tolerance of batteries, which directly impacts the design requirements for HV BMS. This standard helps ensure that battery systems can withstand various environmental and operational stresses.

IEC 62619 is another important standard that focuses on safety requirements for lithium-ion batteries in industrial applications. It covers aspects such as electrical safety, thermal management, and mechanical integrity, all of which are crucial for HV BMS design in energy-dense applications.

Compliance with these safety standards requires HV BMS designers to implement robust monitoring and control systems. This includes accurate voltage and current measurement, cell balancing mechanisms, and sophisticated algorithms for state estimation and fault detection. Additionally, thermal management systems must be integrated to prevent overheating and ensure safe operation under various environmental conditions.

Furthermore, these standards often necessitate the implementation of redundancy in critical safety functions. This may involve using multiple sensors, independent processing units, and fail-safe mechanisms to ensure system reliability and prevent single points of failure.

As the field of high-voltage energy storage continues to evolve, safety standards for HV BMS are regularly updated to address new challenges and technologies. Designers and manufacturers must stay informed about these changes and adapt their systems accordingly to maintain compliance and ensure the highest levels of safety in energy-dense applications.

One of the primary safety standards for HV BMS is ISO 26262, which focuses on functional safety in road vehicles. This standard provides a framework for assessing and mitigating potential hazards associated with electrical and electronic systems in automobiles. It emphasizes the importance of systematic risk analysis and the implementation of safety measures throughout the entire development process of HV BMS.

Another crucial standard is IEC 61508, which addresses functional safety for electrical, electronic, and programmable electronic safety-related systems. This standard is particularly relevant for HV BMS in industrial and energy storage applications. It outlines the requirements for safety integrity levels (SIL) and provides guidance on how to achieve and maintain these levels throughout the system lifecycle.

UL 2054 and UL 1642 are standards specifically focused on battery safety. These standards cover requirements for lithium-ion batteries and cells, including those used in high-voltage applications. They address issues such as thermal runaway, short circuit protection, and overcharge prevention, which are essential considerations in HV BMS design.

The SAE J2464 standard is tailored for electric and hybrid vehicle rechargeable energy storage systems. It provides test procedures for evaluating the safety and abuse tolerance of batteries, which directly impacts the design requirements for HV BMS. This standard helps ensure that battery systems can withstand various environmental and operational stresses.

IEC 62619 is another important standard that focuses on safety requirements for lithium-ion batteries in industrial applications. It covers aspects such as electrical safety, thermal management, and mechanical integrity, all of which are crucial for HV BMS design in energy-dense applications.

Compliance with these safety standards requires HV BMS designers to implement robust monitoring and control systems. This includes accurate voltage and current measurement, cell balancing mechanisms, and sophisticated algorithms for state estimation and fault detection. Additionally, thermal management systems must be integrated to prevent overheating and ensure safe operation under various environmental conditions.

Furthermore, these standards often necessitate the implementation of redundancy in critical safety functions. This may involve using multiple sensors, independent processing units, and fail-safe mechanisms to ensure system reliability and prevent single points of failure.

As the field of high-voltage energy storage continues to evolve, safety standards for HV BMS are regularly updated to address new challenges and technologies. Designers and manufacturers must stay informed about these changes and adapt their systems accordingly to maintain compliance and ensure the highest levels of safety in energy-dense applications.

Thermal Management in HV BMS

Thermal management is a critical aspect of high-voltage battery management systems (HV BMS) in energy-dense applications. As battery technologies advance and energy densities increase, the challenge of managing heat generation and dissipation becomes more pronounced. Effective thermal management is essential for maintaining optimal battery performance, ensuring safety, and extending the overall lifespan of the battery pack.

In HV BMS, thermal management strategies typically involve a combination of active and passive cooling methods. Passive cooling relies on natural convection and conduction to dissipate heat, often utilizing heat sinks and carefully designed airflow paths. Active cooling systems, on the other hand, employ forced air or liquid cooling to more aggressively regulate battery temperature.

One of the primary challenges in thermal management for HV BMS is the uneven heat distribution within the battery pack. Cells at the center of the pack tend to experience higher temperatures than those at the periphery, leading to potential thermal imbalances. To address this issue, advanced thermal management systems incorporate sophisticated temperature sensing and control mechanisms to ensure uniform heat distribution across the entire battery pack.

The choice of cooling method depends on various factors, including the specific application, environmental conditions, and power requirements. Liquid cooling systems, while more complex and costly, offer superior heat dissipation capabilities and are often preferred in high-performance applications such as electric vehicles. These systems circulate a coolant through channels or plates in direct contact with the battery cells, efficiently removing heat and maintaining optimal operating temperatures.

Another important consideration in thermal management for HV BMS is the integration of thermal runaway prevention and mitigation strategies. This involves implementing robust temperature monitoring systems, incorporating thermal fuses or other safety devices, and designing the battery pack to contain and isolate potential thermal events.

As energy densities continue to increase, the importance of advanced thermal management techniques in HV BMS cannot be overstated. Emerging technologies, such as phase change materials and advanced thermal interface materials, are being explored to enhance heat dissipation and temperature control. Additionally, the development of more accurate thermal modeling and simulation tools is enabling designers to optimize thermal management systems with greater precision, leading to improved overall battery performance and safety in energy-dense applications.

In HV BMS, thermal management strategies typically involve a combination of active and passive cooling methods. Passive cooling relies on natural convection and conduction to dissipate heat, often utilizing heat sinks and carefully designed airflow paths. Active cooling systems, on the other hand, employ forced air or liquid cooling to more aggressively regulate battery temperature.

One of the primary challenges in thermal management for HV BMS is the uneven heat distribution within the battery pack. Cells at the center of the pack tend to experience higher temperatures than those at the periphery, leading to potential thermal imbalances. To address this issue, advanced thermal management systems incorporate sophisticated temperature sensing and control mechanisms to ensure uniform heat distribution across the entire battery pack.

The choice of cooling method depends on various factors, including the specific application, environmental conditions, and power requirements. Liquid cooling systems, while more complex and costly, offer superior heat dissipation capabilities and are often preferred in high-performance applications such as electric vehicles. These systems circulate a coolant through channels or plates in direct contact with the battery cells, efficiently removing heat and maintaining optimal operating temperatures.

Another important consideration in thermal management for HV BMS is the integration of thermal runaway prevention and mitigation strategies. This involves implementing robust temperature monitoring systems, incorporating thermal fuses or other safety devices, and designing the battery pack to contain and isolate potential thermal events.

As energy densities continue to increase, the importance of advanced thermal management techniques in HV BMS cannot be overstated. Emerging technologies, such as phase change materials and advanced thermal interface materials, are being explored to enhance heat dissipation and temperature control. Additionally, the development of more accurate thermal modeling and simulation tools is enabling designers to optimize thermal management systems with greater precision, leading to improved overall battery performance and safety in energy-dense applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!