How Decane Enables Strategic Formulation in Chemical Synthesis

JUL 28, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Decane in Synthesis

Decane plays a crucial role in strategic formulation within chemical synthesis, serving as a versatile solvent and reagent in various organic reactions. Its unique properties make it an invaluable tool for chemists seeking to optimize reaction conditions and enhance product yields. As a straight-chain hydrocarbon with ten carbon atoms, decane offers a non-polar environment that facilitates the dissolution of organic compounds and promotes efficient reactivity.

In organic synthesis, decane's low polarity and high boiling point (174°C) make it an excellent choice for reactions requiring elevated temperatures without the risk of solvent evaporation. This characteristic is particularly advantageous in processes such as alkylation, dehydration, and cyclization reactions, where maintaining a consistent reaction medium is essential for achieving desired outcomes.

The strategic use of decane in chemical synthesis extends to its role as a phase-transfer agent in biphasic reaction systems. By creating a distinct organic layer, decane enables the separation of reactants and products, facilitating easier purification and isolation of target compounds. This property is especially valuable in industrial-scale syntheses, where efficient separation processes can significantly impact overall production costs and yields.

Furthermore, decane's inertness towards many reactive species allows it to serve as a diluent in highly exothermic reactions. By moderating reaction rates and heat dissipation, chemists can exercise greater control over reaction kinetics and prevent unwanted side reactions or decomposition of sensitive intermediates. This strategic application of decane contributes to improved safety profiles in chemical processes and enhances the overall efficiency of synthetic routes.

In the realm of catalytic reactions, decane's non-coordinating nature makes it an ideal solvent for maintaining catalyst activity. Unlike more polar solvents that may interact with catalytic sites, decane provides a neutral environment that allows catalysts to function optimally. This property is particularly beneficial in metal-catalyzed transformations, where catalyst performance is critical to achieving high selectivity and yield.

The strategic formulation of reaction mixtures incorporating decane also extends to its use as a co-solvent in multi-component systems. By fine-tuning the ratio of decane to other solvents, chemists can modulate the polarity and solvation properties of the reaction medium, thereby optimizing conditions for specific transformations or influencing the selectivity of competing reaction pathways.

In organic synthesis, decane's low polarity and high boiling point (174°C) make it an excellent choice for reactions requiring elevated temperatures without the risk of solvent evaporation. This characteristic is particularly advantageous in processes such as alkylation, dehydration, and cyclization reactions, where maintaining a consistent reaction medium is essential for achieving desired outcomes.

The strategic use of decane in chemical synthesis extends to its role as a phase-transfer agent in biphasic reaction systems. By creating a distinct organic layer, decane enables the separation of reactants and products, facilitating easier purification and isolation of target compounds. This property is especially valuable in industrial-scale syntheses, where efficient separation processes can significantly impact overall production costs and yields.

Furthermore, decane's inertness towards many reactive species allows it to serve as a diluent in highly exothermic reactions. By moderating reaction rates and heat dissipation, chemists can exercise greater control over reaction kinetics and prevent unwanted side reactions or decomposition of sensitive intermediates. This strategic application of decane contributes to improved safety profiles in chemical processes and enhances the overall efficiency of synthetic routes.

In the realm of catalytic reactions, decane's non-coordinating nature makes it an ideal solvent for maintaining catalyst activity. Unlike more polar solvents that may interact with catalytic sites, decane provides a neutral environment that allows catalysts to function optimally. This property is particularly beneficial in metal-catalyzed transformations, where catalyst performance is critical to achieving high selectivity and yield.

The strategic formulation of reaction mixtures incorporating decane also extends to its use as a co-solvent in multi-component systems. By fine-tuning the ratio of decane to other solvents, chemists can modulate the polarity and solvation properties of the reaction medium, thereby optimizing conditions for specific transformations or influencing the selectivity of competing reaction pathways.

Market Applications

Decane plays a crucial role in strategic formulation within chemical synthesis, offering a wide range of market applications across various industries. In the pharmaceutical sector, decane serves as an essential solvent and reagent in the production of active pharmaceutical ingredients (APIs) and drug intermediates. Its unique properties make it particularly useful in the synthesis of complex organic compounds, enabling more efficient and cost-effective manufacturing processes for medications.

The petrochemical industry heavily relies on decane as a key component in the production of lubricants, fuels, and specialty chemicals. Its high stability and low reactivity make it an ideal candidate for use in high-performance lubricants, particularly in automotive and industrial applications. Additionally, decane's role in fuel formulations contributes to improved engine performance and reduced emissions, aligning with the growing demand for cleaner energy solutions.

In the field of materials science, decane finds applications in the development of advanced polymers and composites. Its use as a solvent or dispersing agent in polymer synthesis enables the creation of materials with enhanced properties, such as improved strength, durability, and chemical resistance. This has significant implications for industries ranging from aerospace to consumer goods manufacturing.

The personal care and cosmetics industry also benefits from decane's versatility. It serves as a carrier for active ingredients in skincare products, facilitating better absorption and efficacy. Moreover, its low toxicity and skin-friendly properties make it a preferred choice for formulators seeking alternatives to traditional petroleum-based ingredients.

In the realm of nanotechnology, decane plays a crucial role in the synthesis and stabilization of nanoparticles. Its ability to control particle size and shape during synthesis processes is invaluable in the production of nanomaterials for applications in electronics, energy storage, and biomedical devices.

The agricultural sector utilizes decane in the formulation of pesticides and herbicides. Its properties as a solvent and carrier for active ingredients contribute to more effective and targeted delivery of crop protection products, potentially reducing overall chemical usage and environmental impact.

Lastly, the electronics industry employs decane in the production of semiconductors and electronic components. Its use as a cleaning agent and in vapor deposition processes aids in the manufacture of high-purity materials essential for advanced electronic devices.

The petrochemical industry heavily relies on decane as a key component in the production of lubricants, fuels, and specialty chemicals. Its high stability and low reactivity make it an ideal candidate for use in high-performance lubricants, particularly in automotive and industrial applications. Additionally, decane's role in fuel formulations contributes to improved engine performance and reduced emissions, aligning with the growing demand for cleaner energy solutions.

In the field of materials science, decane finds applications in the development of advanced polymers and composites. Its use as a solvent or dispersing agent in polymer synthesis enables the creation of materials with enhanced properties, such as improved strength, durability, and chemical resistance. This has significant implications for industries ranging from aerospace to consumer goods manufacturing.

The personal care and cosmetics industry also benefits from decane's versatility. It serves as a carrier for active ingredients in skincare products, facilitating better absorption and efficacy. Moreover, its low toxicity and skin-friendly properties make it a preferred choice for formulators seeking alternatives to traditional petroleum-based ingredients.

In the realm of nanotechnology, decane plays a crucial role in the synthesis and stabilization of nanoparticles. Its ability to control particle size and shape during synthesis processes is invaluable in the production of nanomaterials for applications in electronics, energy storage, and biomedical devices.

The agricultural sector utilizes decane in the formulation of pesticides and herbicides. Its properties as a solvent and carrier for active ingredients contribute to more effective and targeted delivery of crop protection products, potentially reducing overall chemical usage and environmental impact.

Lastly, the electronics industry employs decane in the production of semiconductors and electronic components. Its use as a cleaning agent and in vapor deposition processes aids in the manufacture of high-purity materials essential for advanced electronic devices.

Technical Challenges

The use of decane in strategic formulation for chemical synthesis faces several significant technical challenges. One of the primary obstacles is the low reactivity of decane due to its stable carbon-carbon single bonds. This inherent stability makes it difficult to functionalize decane directly, limiting its potential as a versatile building block in complex chemical syntheses.

Another challenge lies in the selective activation of specific C-H bonds in decane. Given that decane contains multiple equivalent C-H bonds, achieving site-selective functionalization remains a formidable task. This lack of selectivity often leads to a mixture of products, complicating purification processes and reducing overall yield.

The high boiling point of decane (174°C) presents additional difficulties in handling and separation. This property can make it challenging to remove excess decane from reaction mixtures or to use it as a solvent in reactions that require lower temperatures. Furthermore, the low polarity of decane limits its solubility in many common organic solvents, potentially restricting its applicability in certain reaction conditions.

Environmental and safety concerns also pose challenges in the widespread use of decane. As a hydrocarbon, decane is flammable and can contribute to air pollution if not handled properly. This necessitates the development of safer handling protocols and more environmentally friendly alternatives.

From a synthetic perspective, incorporating decane into complex molecular structures often requires multi-step processes, which can be time-consuming and economically unfavorable. The development of more efficient, one-pot reactions involving decane remains an ongoing challenge in the field.

The scalability of decane-based processes presents another hurdle. While laboratory-scale reactions may be feasible, translating these processes to industrial scales often encounters issues related to heat transfer, mixing, and reaction kinetics. Overcoming these scale-up challenges is crucial for the practical application of decane in large-scale chemical synthesis.

Lastly, the development of catalytic systems that can effectively activate and functionalize decane under mild conditions remains an active area of research. Current catalytic methods often require harsh conditions or expensive noble metal catalysts, limiting their practical applicability. The design of more efficient, cost-effective, and sustainable catalytic systems for decane activation represents a significant technical challenge in this field.

Another challenge lies in the selective activation of specific C-H bonds in decane. Given that decane contains multiple equivalent C-H bonds, achieving site-selective functionalization remains a formidable task. This lack of selectivity often leads to a mixture of products, complicating purification processes and reducing overall yield.

The high boiling point of decane (174°C) presents additional difficulties in handling and separation. This property can make it challenging to remove excess decane from reaction mixtures or to use it as a solvent in reactions that require lower temperatures. Furthermore, the low polarity of decane limits its solubility in many common organic solvents, potentially restricting its applicability in certain reaction conditions.

Environmental and safety concerns also pose challenges in the widespread use of decane. As a hydrocarbon, decane is flammable and can contribute to air pollution if not handled properly. This necessitates the development of safer handling protocols and more environmentally friendly alternatives.

From a synthetic perspective, incorporating decane into complex molecular structures often requires multi-step processes, which can be time-consuming and economically unfavorable. The development of more efficient, one-pot reactions involving decane remains an ongoing challenge in the field.

The scalability of decane-based processes presents another hurdle. While laboratory-scale reactions may be feasible, translating these processes to industrial scales often encounters issues related to heat transfer, mixing, and reaction kinetics. Overcoming these scale-up challenges is crucial for the practical application of decane in large-scale chemical synthesis.

Lastly, the development of catalytic systems that can effectively activate and functionalize decane under mild conditions remains an active area of research. Current catalytic methods often require harsh conditions or expensive noble metal catalysts, limiting their practical applicability. The design of more efficient, cost-effective, and sustainable catalytic systems for decane activation represents a significant technical challenge in this field.

Current Strategies

01 Strategic planning and management

Decane strategic formulation involves comprehensive planning and management processes to guide organizational decision-making and resource allocation. This approach focuses on long-term goals, market analysis, and competitive positioning to develop effective strategies for business growth and sustainability.- Strategic planning and management: Decane strategic formulation involves comprehensive planning and management processes to achieve long-term organizational goals. This includes analyzing market trends, assessing internal capabilities, and developing actionable strategies to maintain competitive advantage. The process often incorporates risk assessment, resource allocation, and performance monitoring to ensure effective implementation.

- Data-driven decision making: Utilizing data analytics and business intelligence tools to inform strategic decisions is crucial in decane strategic formulation. This approach involves collecting, analyzing, and interpreting large volumes of data to identify patterns, trends, and opportunities. By leveraging data-driven insights, organizations can make more informed decisions and develop more effective strategies.

- Agile strategy implementation: Adopting an agile approach to strategy implementation allows organizations to respond quickly to changing market conditions and customer needs. This involves breaking down long-term goals into smaller, manageable objectives, and continuously iterating and adjusting strategies based on feedback and performance metrics. Agile implementation enables organizations to maintain flexibility while pursuing their strategic objectives.

- Stakeholder engagement and collaboration: Effective decane strategic formulation requires engaging and collaborating with various stakeholders, including employees, customers, partners, and shareholders. This involves creating communication channels, fostering open dialogue, and aligning diverse interests to support the organization's strategic goals. Stakeholder engagement helps ensure buy-in and support for strategic initiatives.

- Risk management and compliance: Incorporating risk management and compliance considerations into the strategic formulation process is essential for long-term success. This involves identifying potential risks, developing mitigation strategies, and ensuring adherence to relevant regulations and industry standards. By proactively addressing risks and compliance issues, organizations can protect their interests and maintain sustainable growth.

02 Risk assessment and mitigation

The strategic formulation process incorporates risk assessment and mitigation strategies to identify potential threats and opportunities. This includes analyzing market trends, regulatory environments, and internal capabilities to develop robust contingency plans and adaptive strategies.Expand Specific Solutions03 Technology integration and innovation

Decane strategic formulation emphasizes the integration of advanced technologies and innovative approaches to enhance operational efficiency and competitive advantage. This may include leveraging artificial intelligence, data analytics, and digital transformation initiatives to drive strategic decision-making and business model innovation.Expand Specific Solutions04 Stakeholder engagement and collaboration

The strategic formulation process involves engaging various stakeholders, including employees, customers, partners, and investors, to ensure alignment and buy-in. This collaborative approach helps in developing comprehensive strategies that address diverse perspectives and foster organizational commitment.Expand Specific Solutions05 Performance measurement and adaptation

Decane strategic formulation incorporates robust performance measurement systems and adaptive mechanisms to monitor strategy implementation and effectiveness. This enables organizations to track progress, identify areas for improvement, and make data-driven adjustments to their strategic plans in response to changing market conditions.Expand Specific Solutions

Industry Leaders

The development of decane-enabled strategic formulation in chemical synthesis is in its growth phase, with increasing market size and technological advancements. The global market for this technology is expanding, driven by the demand for more efficient and sustainable chemical processes. Major players like BASF, DuPont, and Saudi Aramco are investing heavily in research and development, indicating a high level of competition and technological maturity. Smaller companies and research institutions, such as King Abdullah University of Science & Technology and Global Bioenergies, are also contributing to innovation in this field. The technology's maturity is evidenced by its application across various industries, including petrochemicals, pharmaceuticals, and materials science, suggesting a robust and evolving competitive landscape.

BASF Corp.

Technical Solution: BASF Corp. has developed an innovative approach to utilizing decane in strategic formulation for chemical synthesis. Their method involves the use of decane as a solvent and reactant in various organic synthesis processes. BASF has implemented a catalytic system that allows for the selective functionalization of decane, enabling the production of valuable chemical intermediates [1]. This approach leverages decane's stability and versatility, allowing for more efficient and environmentally friendly synthesis routes. BASF's technology also incorporates advanced process control systems to optimize reaction conditions, resulting in higher yields and reduced waste [3]. The company has successfully applied this method in the production of specialty chemicals and performance materials, demonstrating its scalability and industrial relevance [5].

Strengths: Improved efficiency in chemical synthesis, reduced environmental impact, and versatility in producing various chemical intermediates. Weaknesses: Potential limitations in reaction scope and the need for specialized catalysts and equipment.

DuPont de Nemours, Inc.

Technical Solution: DuPont has developed a proprietary technology that utilizes decane as a key component in their strategic formulation for chemical synthesis. Their approach focuses on the use of decane as a platform molecule for the production of high-value chemicals. DuPont's method involves a combination of catalytic and biocatalytic processes to selectively functionalize decane, allowing for the synthesis of a wide range of products [2]. The company has implemented advanced reactor designs that enhance mass transfer and reaction kinetics, leading to improved yields and selectivity [4]. DuPont's technology also incorporates in-line analytics and machine learning algorithms to optimize reaction conditions in real-time, ensuring consistent product quality and maximizing resource efficiency [6]. This innovative approach has been successfully applied in the production of specialty polymers and advanced materials.

Strengths: High selectivity and yield in product formation, adaptability to various chemical syntheses, and integration of advanced process control. Weaknesses: Potential high initial investment costs and complexity in scaling up for certain applications.

Key Innovations

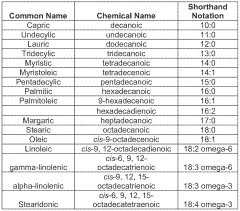

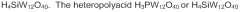

Process for making linear long-chain alkanes from renewable feedstocks using catalysts comprising heteropolyacids

PatentWO2014159490A1

Innovation

- A hydrodeoxygenation process using a catalyst composition comprising a metal catalyst and a heteropolyacid or heteropolyacid salt, operated at temperatures between 240 °C to 280 °C and hydrogen gas pressures of at least 300 psi, which effectively converts C10-18 oxygenates to linear alkanes without significant carbon loss, thereby reducing the formation of unwanted by-products.

process for the production of decancarboxylic acids

PatentInactiveBR112012001274A2

Innovation

- A three-stage process involving hydroformylation of a hydrocarbon mixture containing linear C4 olefins, followed by aldol condensation of C5 aldehydes, selective hydrogenation, and uncatalyzed oxidation of decanal mixture using oxygen-containing gases to produce decanecarboxylic acids, specifically targeting a high yield of 2-propylheptanoic acid.

Green Chemistry

Green chemistry principles are increasingly important in the strategic formulation of chemical synthesis processes, and decane plays a significant role in this context. As a versatile hydrocarbon, decane offers several advantages that align with green chemistry objectives, making it a valuable component in sustainable chemical synthesis strategies.

Decane's low toxicity and biodegradability make it an environmentally friendly alternative to many traditional solvents. Its use in chemical synthesis processes can significantly reduce the environmental impact of reactions, aligning with the principles of green chemistry that emphasize the design of safer chemicals and the reduction of hazardous waste.

In terms of atom economy, decane's simple structure allows for efficient use in reactions, minimizing waste production. This aligns with the green chemistry principle of maximizing the incorporation of all materials used in the process into the final product. Decane's stability also contributes to its effectiveness in various reaction conditions, potentially reducing the need for additional stabilizing agents or complex reaction setups.

The use of decane in chemical synthesis can also lead to improved energy efficiency. Its relatively low boiling point compared to many other hydrocarbons allows for easier separation and purification processes, potentially reducing the energy requirements for these steps. This aspect addresses the green chemistry principle of designing energy-efficient chemical processes.

Furthermore, decane's role in enabling strategic formulation extends to its potential as a renewable resource. While traditionally derived from petroleum, there is growing research into bio-based production methods for decane, which could further enhance its green chemistry credentials. This aligns with the principle of using renewable feedstocks in chemical processes.

In the context of reaction media, decane's non-polar nature makes it an excellent solvent for certain types of reactions, particularly those involving hydrophobic compounds. This property can be strategically leveraged to design more efficient and selective reactions, potentially reducing the need for harsh reaction conditions or excessive use of reagents.

The strategic use of decane in chemical synthesis also supports the development of safer reaction processes. Its low reactivity and stability under various conditions can contribute to safer handling and storage of reaction mixtures, addressing the green chemistry principle of designing inherently safer chemical processes.

Decane's low toxicity and biodegradability make it an environmentally friendly alternative to many traditional solvents. Its use in chemical synthesis processes can significantly reduce the environmental impact of reactions, aligning with the principles of green chemistry that emphasize the design of safer chemicals and the reduction of hazardous waste.

In terms of atom economy, decane's simple structure allows for efficient use in reactions, minimizing waste production. This aligns with the green chemistry principle of maximizing the incorporation of all materials used in the process into the final product. Decane's stability also contributes to its effectiveness in various reaction conditions, potentially reducing the need for additional stabilizing agents or complex reaction setups.

The use of decane in chemical synthesis can also lead to improved energy efficiency. Its relatively low boiling point compared to many other hydrocarbons allows for easier separation and purification processes, potentially reducing the energy requirements for these steps. This aspect addresses the green chemistry principle of designing energy-efficient chemical processes.

Furthermore, decane's role in enabling strategic formulation extends to its potential as a renewable resource. While traditionally derived from petroleum, there is growing research into bio-based production methods for decane, which could further enhance its green chemistry credentials. This aligns with the principle of using renewable feedstocks in chemical processes.

In the context of reaction media, decane's non-polar nature makes it an excellent solvent for certain types of reactions, particularly those involving hydrophobic compounds. This property can be strategically leveraged to design more efficient and selective reactions, potentially reducing the need for harsh reaction conditions or excessive use of reagents.

The strategic use of decane in chemical synthesis also supports the development of safer reaction processes. Its low reactivity and stability under various conditions can contribute to safer handling and storage of reaction mixtures, addressing the green chemistry principle of designing inherently safer chemical processes.

Safety Protocols

When working with decane in chemical synthesis, implementing robust safety protocols is paramount to ensure the well-being of laboratory personnel and the integrity of the research environment. Decane, being a highly flammable hydrocarbon, requires specific handling procedures and precautionary measures.

Proper personal protective equipment (PPE) is essential when handling decane. This includes wearing chemical-resistant gloves, safety goggles, and a lab coat. In cases where there is a risk of inhalation, a suitable respirator should be used. All personnel working with decane must be trained in its proper handling and the associated safety measures.

Storage of decane demands particular attention. It should be kept in a cool, well-ventilated area, away from sources of ignition and oxidizing agents. Containers should be tightly sealed and properly labeled. Due to its low flash point, decane should be stored in flammable storage cabinets that meet regulatory standards.

Handling decane requires a fume hood to prevent the accumulation of vapors. All operations involving decane should be conducted in areas with adequate ventilation. Open flames and other ignition sources must be strictly prohibited in areas where decane is used or stored.

Spill response protocols are crucial. Small spills can be contained using inert absorbent materials, while larger spills may require professional hazardous material handling. Proper disposal methods for decane and contaminated materials must be followed, adhering to local environmental regulations.

Fire safety is a critical aspect of decane handling. Appropriate fire extinguishers, such as dry chemical or carbon dioxide types, should be readily available. Automatic fire suppression systems in storage and handling areas provide an additional layer of safety.

Regular safety audits and equipment checks are necessary to maintain a safe working environment. This includes inspecting storage containers for leaks, ensuring proper functioning of fume hoods, and verifying the integrity of electrical equipment in areas where decane is used.

Emergency response plans should be in place and regularly updated. All personnel must be familiar with evacuation procedures, the location of safety equipment, and emergency contact information. Regular drills can help ensure preparedness in case of accidents or spills.

Proper personal protective equipment (PPE) is essential when handling decane. This includes wearing chemical-resistant gloves, safety goggles, and a lab coat. In cases where there is a risk of inhalation, a suitable respirator should be used. All personnel working with decane must be trained in its proper handling and the associated safety measures.

Storage of decane demands particular attention. It should be kept in a cool, well-ventilated area, away from sources of ignition and oxidizing agents. Containers should be tightly sealed and properly labeled. Due to its low flash point, decane should be stored in flammable storage cabinets that meet regulatory standards.

Handling decane requires a fume hood to prevent the accumulation of vapors. All operations involving decane should be conducted in areas with adequate ventilation. Open flames and other ignition sources must be strictly prohibited in areas where decane is used or stored.

Spill response protocols are crucial. Small spills can be contained using inert absorbent materials, while larger spills may require professional hazardous material handling. Proper disposal methods for decane and contaminated materials must be followed, adhering to local environmental regulations.

Fire safety is a critical aspect of decane handling. Appropriate fire extinguishers, such as dry chemical or carbon dioxide types, should be readily available. Automatic fire suppression systems in storage and handling areas provide an additional layer of safety.

Regular safety audits and equipment checks are necessary to maintain a safe working environment. This includes inspecting storage containers for leaks, ensuring proper functioning of fume hoods, and verifying the integrity of electrical equipment in areas where decane is used.

Emergency response plans should be in place and regularly updated. All personnel must be familiar with evacuation procedures, the location of safety equipment, and emergency contact information. Regular drills can help ensure preparedness in case of accidents or spills.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!