How do High-Temperature Alloys Improve Industrial Furnaces?

SEP 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

High-Temperature Alloy Development History and Objectives

High-temperature alloys have evolved significantly since their inception in the early 20th century. Initially developed for aircraft engines during World War I, these specialized metal compositions have undergone continuous refinement to meet increasingly demanding industrial applications. The evolution began with simple nickel-chromium alloys and progressed to complex superalloys containing multiple elements carefully balanced to achieve specific performance characteristics.

The 1940s marked a pivotal period when researchers discovered that adding elements like titanium and aluminum to nickel-based alloys dramatically improved their high-temperature strength through precipitation hardening mechanisms. This breakthrough enabled the development of more efficient gas turbines and laid the groundwork for modern industrial furnace applications.

By the 1960s and 1970s, vacuum melting techniques revolutionized alloy production, allowing for more precise control of composition and significantly reducing impurities that caused premature failure. This technological advancement enabled the creation of alloys capable of withstanding temperatures exceeding 1000°C while maintaining structural integrity and corrosion resistance.

The 1980s and 1990s saw the integration of computer modeling and simulation into alloy design, accelerating development cycles and enabling more targeted approaches to solving specific high-temperature challenges in industrial furnaces. This period also witnessed the emergence of directionally solidified and single-crystal alloys, offering unprecedented temperature capabilities and extended service life.

Recent decades have focused on optimizing alloy compositions for specific industrial furnace environments, with particular attention to oxidation resistance, thermal fatigue properties, and long-term microstructural stability. The development of protective coating systems has further enhanced alloy performance by creating multi-layered defense mechanisms against the harsh conditions found in industrial furnaces.

The primary objectives of high-temperature alloy development for industrial furnaces include extending operational lifespans, increasing maximum operating temperatures to improve process efficiency, reducing maintenance frequency and associated downtime costs, and enabling more precise temperature control throughout heating cycles. These objectives align with broader industrial goals of energy efficiency, reduced emissions, and improved product quality.

Current research aims to push temperature boundaries even further while reducing reliance on strategic elements facing supply constraints. Computational alloy design, rapid prototyping techniques, and advanced characterization methods are accelerating the development cycle, with promising new compositions emerging that could revolutionize industrial furnace capabilities in the coming decade.

The 1940s marked a pivotal period when researchers discovered that adding elements like titanium and aluminum to nickel-based alloys dramatically improved their high-temperature strength through precipitation hardening mechanisms. This breakthrough enabled the development of more efficient gas turbines and laid the groundwork for modern industrial furnace applications.

By the 1960s and 1970s, vacuum melting techniques revolutionized alloy production, allowing for more precise control of composition and significantly reducing impurities that caused premature failure. This technological advancement enabled the creation of alloys capable of withstanding temperatures exceeding 1000°C while maintaining structural integrity and corrosion resistance.

The 1980s and 1990s saw the integration of computer modeling and simulation into alloy design, accelerating development cycles and enabling more targeted approaches to solving specific high-temperature challenges in industrial furnaces. This period also witnessed the emergence of directionally solidified and single-crystal alloys, offering unprecedented temperature capabilities and extended service life.

Recent decades have focused on optimizing alloy compositions for specific industrial furnace environments, with particular attention to oxidation resistance, thermal fatigue properties, and long-term microstructural stability. The development of protective coating systems has further enhanced alloy performance by creating multi-layered defense mechanisms against the harsh conditions found in industrial furnaces.

The primary objectives of high-temperature alloy development for industrial furnaces include extending operational lifespans, increasing maximum operating temperatures to improve process efficiency, reducing maintenance frequency and associated downtime costs, and enabling more precise temperature control throughout heating cycles. These objectives align with broader industrial goals of energy efficiency, reduced emissions, and improved product quality.

Current research aims to push temperature boundaries even further while reducing reliance on strategic elements facing supply constraints. Computational alloy design, rapid prototyping techniques, and advanced characterization methods are accelerating the development cycle, with promising new compositions emerging that could revolutionize industrial furnace capabilities in the coming decade.

Industrial Furnace Market Demand Analysis

The global industrial furnace market is experiencing robust growth, driven by increasing demand across multiple sectors including metallurgy, automotive, aerospace, and energy production. As of recent market analyses, the industrial furnace market is valued at approximately 10 billion USD with projections indicating a compound annual growth rate of 5-6% through 2028. This growth trajectory is particularly pronounced in regions undergoing rapid industrialization, notably in Asia-Pacific countries like China and India, where manufacturing expansion continues to accelerate.

The demand for high-temperature industrial furnaces specifically has seen a significant uptick due to several converging factors. Manufacturing processes requiring extreme temperatures (above 1000°C) have become more prevalent as industries push for advanced materials processing capabilities. The aerospace industry, for instance, requires furnaces capable of reaching temperatures exceeding 1200°C for the heat treatment of specialized components and superalloys used in turbine engines.

Energy efficiency has emerged as a critical market driver, with industrial operations facing increasing pressure to reduce energy consumption and associated costs. High-temperature alloy-equipped furnaces demonstrate superior thermal efficiency, with some advanced systems achieving energy savings of 15-20% compared to conventional furnaces. This efficiency factor has become particularly significant as energy prices fluctuate and environmental regulations tighten globally.

Environmental regulations and sustainability initiatives are reshaping market demands substantially. Stringent emissions standards in Europe and North America have accelerated the adoption of advanced furnace technologies that can operate at higher temperatures while producing fewer pollutants. The carbon reduction targets established by various nations have created market incentives for furnace systems that minimize environmental impact while maintaining or improving production capabilities.

Durability and maintenance considerations represent another significant market factor. End-users increasingly evaluate total cost of ownership rather than initial investment costs alone. High-temperature alloy furnaces, despite commanding premium prices, demonstrate extended operational lifespans and reduced maintenance requirements, translating to lower long-term costs. Industry data suggests maintenance costs can be reduced by up to 30% over the lifetime of advanced alloy furnaces compared to conventional alternatives.

The customization trend is gaining momentum as industries require specialized furnace solutions for specific applications. This has led to increased demand for modular furnace designs incorporating high-temperature alloys in critical components, allowing for application-specific optimization while maintaining core technological advantages. This trend is particularly evident in specialized manufacturing sectors such as semiconductor production, advanced ceramics, and specialized glass manufacturing.

The demand for high-temperature industrial furnaces specifically has seen a significant uptick due to several converging factors. Manufacturing processes requiring extreme temperatures (above 1000°C) have become more prevalent as industries push for advanced materials processing capabilities. The aerospace industry, for instance, requires furnaces capable of reaching temperatures exceeding 1200°C for the heat treatment of specialized components and superalloys used in turbine engines.

Energy efficiency has emerged as a critical market driver, with industrial operations facing increasing pressure to reduce energy consumption and associated costs. High-temperature alloy-equipped furnaces demonstrate superior thermal efficiency, with some advanced systems achieving energy savings of 15-20% compared to conventional furnaces. This efficiency factor has become particularly significant as energy prices fluctuate and environmental regulations tighten globally.

Environmental regulations and sustainability initiatives are reshaping market demands substantially. Stringent emissions standards in Europe and North America have accelerated the adoption of advanced furnace technologies that can operate at higher temperatures while producing fewer pollutants. The carbon reduction targets established by various nations have created market incentives for furnace systems that minimize environmental impact while maintaining or improving production capabilities.

Durability and maintenance considerations represent another significant market factor. End-users increasingly evaluate total cost of ownership rather than initial investment costs alone. High-temperature alloy furnaces, despite commanding premium prices, demonstrate extended operational lifespans and reduced maintenance requirements, translating to lower long-term costs. Industry data suggests maintenance costs can be reduced by up to 30% over the lifetime of advanced alloy furnaces compared to conventional alternatives.

The customization trend is gaining momentum as industries require specialized furnace solutions for specific applications. This has led to increased demand for modular furnace designs incorporating high-temperature alloys in critical components, allowing for application-specific optimization while maintaining core technological advantages. This trend is particularly evident in specialized manufacturing sectors such as semiconductor production, advanced ceramics, and specialized glass manufacturing.

Current State and Challenges of Heat-Resistant Materials

Heat-resistant materials have evolved significantly over the past decades, with current technologies focusing on nickel-based superalloys, ceramic matrix composites (CMCs), and refractory metals. These materials form the backbone of modern industrial furnace systems, enabling operations at temperatures exceeding 1000°C. However, despite substantial progress, several critical challenges persist in this field.

The global landscape of heat-resistant material development shows concentration in industrialized nations, with the United States, Japan, Germany, and China leading research efforts. Academic institutions and industrial R&D centers in these regions have established specialized facilities for high-temperature material testing and characterization, creating geographical clusters of expertise.

A significant technical challenge involves the trade-off between temperature resistance and mechanical properties. As operating temperatures increase, materials often experience accelerated creep, reduced fatigue resistance, and diminished structural integrity. This creates a complex engineering problem where optimizing one property frequently compromises others.

Oxidation resistance remains another persistent challenge. Even advanced alloys experience accelerated oxidation at extreme temperatures, forming oxide scales that can spall off during thermal cycling. This leads to progressive material loss and potential catastrophic failure in industrial furnace applications.

Cost factors continue to constrain widespread adoption of cutting-edge heat-resistant materials. Nickel, cobalt, and refractory metals like molybdenum and tungsten face supply chain vulnerabilities and price volatility. Manufacturing processes for advanced alloys and composites require specialized equipment and expertise, further increasing production costs.

Joining and repair technologies present additional hurdles. Welding high-temperature alloys often introduces heat-affected zones with compromised properties, while ceramic components pose significant challenges for repair and maintenance operations.

Environmental considerations are increasingly important, with regulations limiting the use of certain alloying elements like chromium and cobalt due to health and environmental concerns. This has spurred research into alternative compositions that maintain performance while reducing environmental impact.

The integration of computational modeling with experimental approaches has emerged as a promising direction. Materials informatics and machine learning techniques are accelerating the discovery and optimization of new heat-resistant compositions, though validation challenges remain significant.

The global landscape of heat-resistant material development shows concentration in industrialized nations, with the United States, Japan, Germany, and China leading research efforts. Academic institutions and industrial R&D centers in these regions have established specialized facilities for high-temperature material testing and characterization, creating geographical clusters of expertise.

A significant technical challenge involves the trade-off between temperature resistance and mechanical properties. As operating temperatures increase, materials often experience accelerated creep, reduced fatigue resistance, and diminished structural integrity. This creates a complex engineering problem where optimizing one property frequently compromises others.

Oxidation resistance remains another persistent challenge. Even advanced alloys experience accelerated oxidation at extreme temperatures, forming oxide scales that can spall off during thermal cycling. This leads to progressive material loss and potential catastrophic failure in industrial furnace applications.

Cost factors continue to constrain widespread adoption of cutting-edge heat-resistant materials. Nickel, cobalt, and refractory metals like molybdenum and tungsten face supply chain vulnerabilities and price volatility. Manufacturing processes for advanced alloys and composites require specialized equipment and expertise, further increasing production costs.

Joining and repair technologies present additional hurdles. Welding high-temperature alloys often introduces heat-affected zones with compromised properties, while ceramic components pose significant challenges for repair and maintenance operations.

Environmental considerations are increasingly important, with regulations limiting the use of certain alloying elements like chromium and cobalt due to health and environmental concerns. This has spurred research into alternative compositions that maintain performance while reducing environmental impact.

The integration of computational modeling with experimental approaches has emerged as a promising direction. Materials informatics and machine learning techniques are accelerating the discovery and optimization of new heat-resistant compositions, though validation challenges remain significant.

Current High-Temperature Alloy Solutions

01 Composition Optimization for High-Temperature Alloys

Improving high-temperature alloys through precise composition adjustments, including the addition of specific elements like chromium, nickel, cobalt, and rare earth metals. These compositional modifications enhance oxidation resistance, creep strength, and thermal stability at elevated temperatures. The careful balance of alloying elements creates microstructures that maintain mechanical properties under extreme thermal conditions.- Composition Optimization for High-Temperature Performance: Improving high-temperature alloys through precise composition adjustments, including the addition of specific elements like chromium, nickel, cobalt, and refractory metals. These elements enhance oxidation resistance, creep strength, and thermal stability at elevated temperatures. The careful balance of these elements creates microstructures that maintain mechanical properties under extreme thermal conditions.

- Microstructure Control and Heat Treatment Processes: Advanced heat treatment processes and microstructure control techniques to optimize high-temperature alloy performance. These include solution treatment, aging, and controlled cooling to develop specific phase distributions and grain structures. Precipitation hardening mechanisms are utilized to create stable microstructures that resist deformation at elevated temperatures, while grain boundary engineering improves creep resistance and extends service life.

- Surface Modification and Coating Technologies: Surface modification and coating technologies to enhance high-temperature alloy performance. Protective coatings such as thermal barrier coatings, diffusion aluminides, and overlay coatings provide oxidation and corrosion resistance. Advanced deposition techniques create multi-layer systems that protect the base alloy while maintaining thermal cycling resistance, thereby extending component life in extreme environments.

- Processing Techniques and Manufacturing Methods: Innovative processing techniques and manufacturing methods for high-temperature alloys, including directional solidification, single crystal growth, powder metallurgy, and additive manufacturing. These processes create alloys with controlled grain orientation, reduced defects, and enhanced homogeneity. Advanced forming and joining methods preserve the alloy's high-temperature properties while enabling complex component geometries.

- Novel Alloy Systems and Composite Materials: Development of novel alloy systems and composite materials for extreme temperature applications, including intermetallics, refractory metal alloys, and ceramic-metal composites. These materials feature unique bonding structures and phase compositions that provide exceptional strength-to-weight ratios and thermal stability. Nano-reinforced alloys and functionally graded materials offer tailored property profiles for specific high-temperature applications.

02 Heat Treatment and Processing Techniques

Advanced heat treatment processes and thermomechanical processing techniques that optimize the microstructure of high-temperature alloys. These include solution annealing, aging treatments, hot isostatic pressing, and controlled cooling regimes. Such processes help develop favorable precipitate distributions, grain structures, and phase stability that significantly improve the alloy's performance at elevated temperatures.Expand Specific Solutions03 Surface Modification and Coating Technologies

Surface treatments and coating technologies that enhance the performance of high-temperature alloys. These include diffusion coatings, thermal barrier coatings, aluminizing, and other surface modification techniques that improve oxidation resistance, corrosion protection, and thermal insulation. These technologies create protective layers that extend the service life of components operating in extreme temperature environments.Expand Specific Solutions04 Microstructural Engineering and Strengthening Mechanisms

Advanced approaches to microstructural engineering that enhance high-temperature alloy performance through controlled precipitation, grain boundary strengthening, and phase stability optimization. These techniques include dispersion strengthening, grain boundary engineering, and the development of complex intermetallic phases that provide superior creep resistance and structural stability at elevated temperatures.Expand Specific Solutions05 Novel Manufacturing and Processing Methods

Innovative manufacturing and processing methods for high-temperature alloys, including powder metallurgy, additive manufacturing, directional solidification, and single crystal growth techniques. These advanced processes enable the production of alloys with superior high-temperature properties, complex geometries, and tailored microstructures that cannot be achieved through conventional manufacturing methods.Expand Specific Solutions

Leading Manufacturers and Competitive Landscape

The high-temperature alloy market for industrial furnaces is currently in a growth phase, with increasing demand driven by energy efficiency requirements and industrial automation. The global market is projected to expand significantly as industries seek materials capable of withstanding extreme thermal conditions while maintaining structural integrity. Technologically, companies like Ebner Industrieofenbau and NIPPON STEEL are leading innovation in heat-resistant alloys, while Daikin Comfort Technologies and DENSO focus on application-specific solutions. Research institutions such as Forschungszentrum Jülich and Battelle Memorial Institute are advancing fundamental materials science. Chinese manufacturers including Baoshan Iron & Steel and CISDI Engineering are rapidly gaining market share through cost-effective production capabilities, while specialized players like Proterial and Divergent Technologies are developing next-generation alloys with enhanced performance characteristics.

NIPPON STEEL CORP.

Technical Solution: Nippon Steel has developed advanced high-temperature alloys specifically designed for industrial furnace applications. Their proprietary NS-HR series incorporates nickel-chromium-based superalloys with carefully controlled additions of molybdenum, tungsten, and rare earth elements to enhance creep resistance at temperatures exceeding 1100°C. These alloys feature a microstructure optimized through precise heat treatment processes that create stable precipitate phases, significantly improving high-temperature strength. Nippon Steel's technology includes specialized coating systems that provide additional oxidation and corrosion resistance in aggressive furnace environments. Their manufacturing process employs vacuum induction melting followed by electroslag remelting to ensure exceptional purity and consistent properties throughout large components. The company has demonstrated that their high-temperature alloys can extend furnace component life by up to 40% compared to conventional materials, particularly in critical applications like radiant tubes, rollers, and structural supports.

Strengths: Superior creep resistance at extreme temperatures allows for higher operating temperatures and improved energy efficiency. Excellent oxidation resistance in aggressive environments extends component lifespan. Weaknesses: Higher initial cost compared to conventional alloys, which may limit adoption in cost-sensitive applications. Complex manufacturing process requires specialized equipment and expertise.

POSCO Holdings, Inc.

Technical Solution: POSCO has developed advanced high-temperature alloy solutions specifically engineered for industrial furnace applications in steel manufacturing. Their PosHT series incorporates iron-nickel-chromium base materials with carefully controlled additions of molybdenum, tungsten, and rare earth elements to enhance performance at temperatures exceeding 1200°C. POSCO's technology features a proprietary manufacturing process that includes vacuum induction melting followed by electroslag remelting and controlled hot working to achieve optimal grain structure and distribution of strengthening precipitates. Their alloys demonstrate exceptional resistance to carburization and metal dusting in carbon-rich atmospheres, making them particularly suitable for petrochemical processing furnaces. POSCO has implemented specialized surface treatment technologies that create protective oxide scales, further enhancing corrosion resistance in aggressive environments. Testing has shown that their high-temperature alloys maintain mechanical properties at elevated temperatures for extended periods, with creep rupture strength approximately 30% higher than conventional heat-resistant steels. POSCO's materials have been successfully deployed in critical applications including reformer tubes, cracker furnaces, and heat treatment equipment.

Strengths: Exceptional resistance to carburization in carbon-rich environments extends component life in petrochemical applications. Superior mechanical properties at elevated temperatures allow for thinner component designs, improving heat transfer efficiency. Weaknesses: Complex alloying elements may create supply chain vulnerabilities during material shortages. Higher material costs require careful economic justification for implementation.

Key Innovations in Heat-Resistant Metallurgy

Improvements relating to the high-temperature cooling of industrial furnaces

PatentInactiveGB880784A

Innovation

- A closed coolant circulation system with an independent heat exchanger for indirect heat transfer to the steam generator, using a coolant with high vaporization temperature at low excess pressures, and separate cooling elements with individual circuits and shut-off devices to minimize leakage risks, along with a common circulating device with multiple impellers for efficient operation.

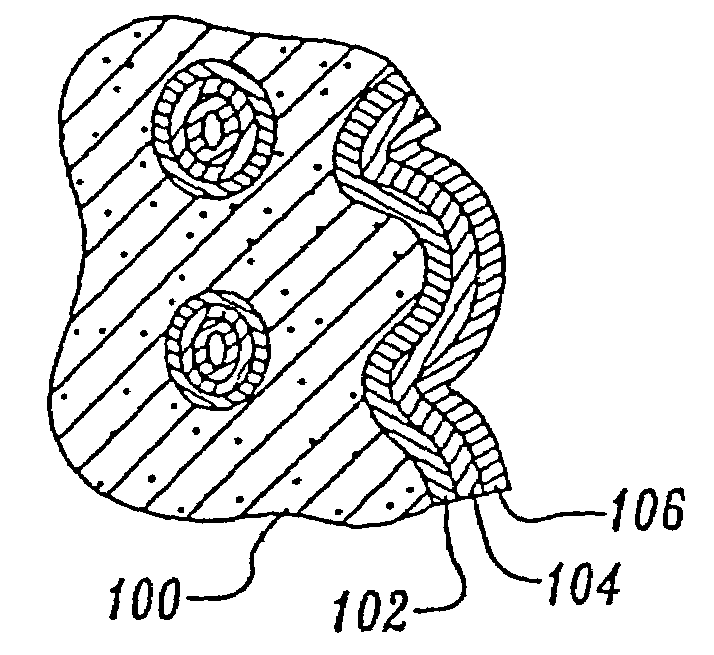

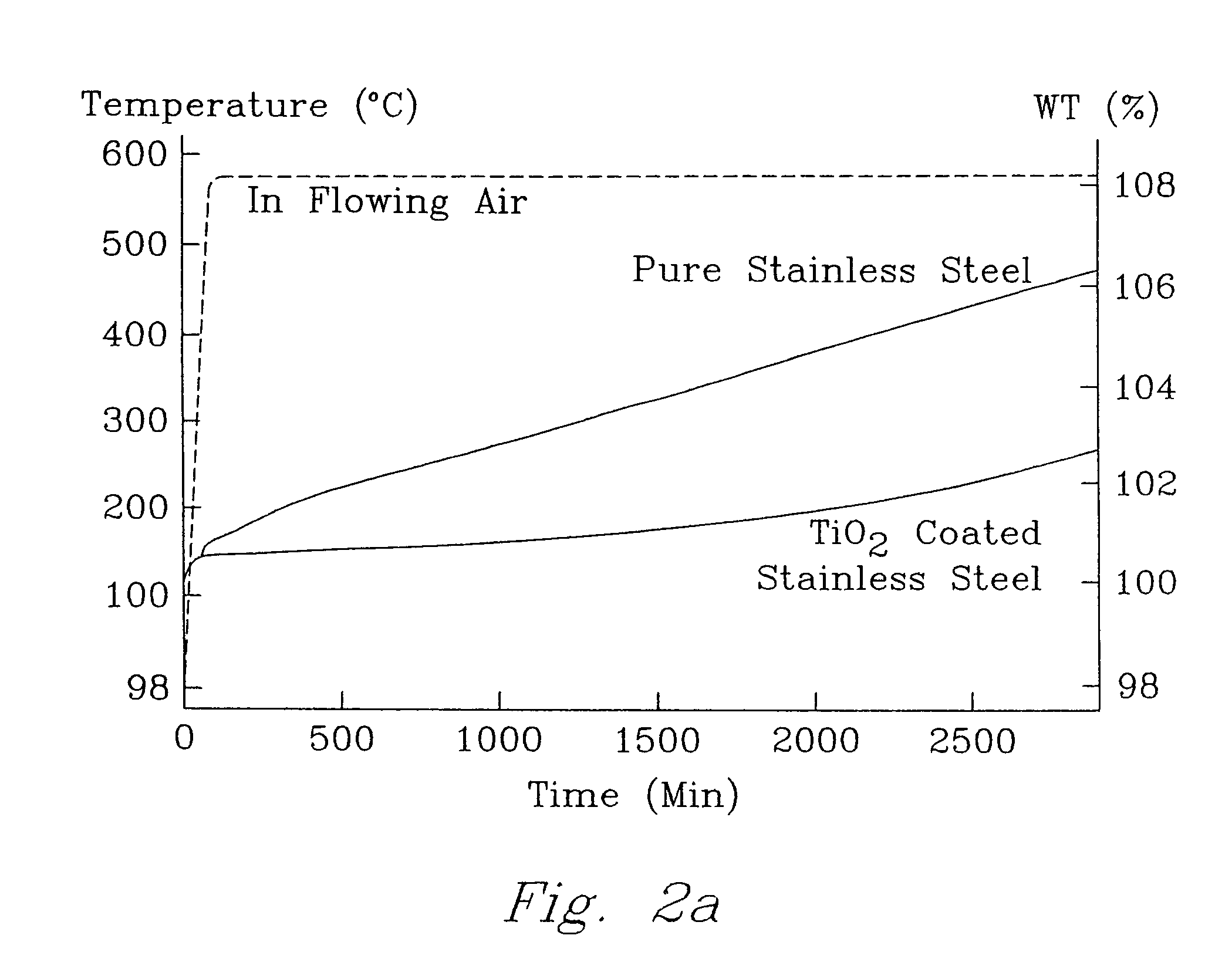

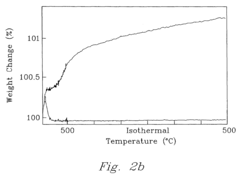

Catalyst, method of making, and reactions using the catalyst

PatentInactiveUS7498001B2

Innovation

- A catalyst with a porous support, a buffer layer with a tailored thermal expansion coefficient, and an interfacial layer, where the buffer layer is vapor-deposited to enhance adhesion and oxidation resistance, reducing thermal stress and side reactions.

Energy Efficiency Improvements Through Alloy Implementation

The implementation of high-temperature alloys in industrial furnaces has demonstrated significant energy efficiency improvements across various industrial applications. These specialized alloys, primarily composed of nickel, cobalt, and iron-based materials with additions of chromium, molybdenum, and other elements, enable furnaces to operate at higher temperatures while maintaining structural integrity and reducing energy consumption.

Energy efficiency gains through alloy implementation manifest in several key areas. First, advanced high-temperature alloys allow for thinner furnace wall construction while maintaining thermal performance, reducing the thermal mass that requires heating during startup cycles. This structural advantage translates to shorter heating periods and lower energy consumption during the critical warm-up phase, with documented energy savings of 15-22% compared to conventional materials.

The superior thermal conductivity characteristics of modern high-temperature alloys also contribute to more uniform heat distribution throughout the furnace chamber. This homogeneous heating environment reduces the need for temperature overcompensation and minimizes energy waste associated with hotspots and cold zones. Industrial case studies have shown that optimized heat distribution can reduce energy consumption by up to 18% while simultaneously improving product quality through more consistent thermal processing.

Oxidation and corrosion resistance properties of these alloys significantly extend furnace component lifespan, particularly in aggressive environments containing sulfur, nitrogen, or carbon compounds. The extended service life reduces the frequency of maintenance shutdowns and associated reheating cycles, which typically consume substantial energy. Maintenance interval extensions of 30-50% have been reported in petrochemical and glass manufacturing applications, with corresponding energy savings from avoided thermal cycling.

Recent developments in surface-modified high-temperature alloys have further enhanced energy efficiency through improved radiative heat transfer properties. Specialized coatings and surface treatments can optimize emissivity values, allowing furnaces to achieve target temperatures with reduced energy input. These innovations have demonstrated energy consumption reductions of 8-12% in high-temperature applications above 1000°C.

The economic impact of these efficiency improvements is substantial, with typical industrial implementations reporting payback periods of 12-36 months depending on operating temperatures and duty cycles. Beyond direct energy savings, the implementation of advanced alloys contributes to reduced carbon emissions, supporting industrial sustainability goals and compliance with increasingly stringent environmental regulations.

Energy efficiency gains through alloy implementation manifest in several key areas. First, advanced high-temperature alloys allow for thinner furnace wall construction while maintaining thermal performance, reducing the thermal mass that requires heating during startup cycles. This structural advantage translates to shorter heating periods and lower energy consumption during the critical warm-up phase, with documented energy savings of 15-22% compared to conventional materials.

The superior thermal conductivity characteristics of modern high-temperature alloys also contribute to more uniform heat distribution throughout the furnace chamber. This homogeneous heating environment reduces the need for temperature overcompensation and minimizes energy waste associated with hotspots and cold zones. Industrial case studies have shown that optimized heat distribution can reduce energy consumption by up to 18% while simultaneously improving product quality through more consistent thermal processing.

Oxidation and corrosion resistance properties of these alloys significantly extend furnace component lifespan, particularly in aggressive environments containing sulfur, nitrogen, or carbon compounds. The extended service life reduces the frequency of maintenance shutdowns and associated reheating cycles, which typically consume substantial energy. Maintenance interval extensions of 30-50% have been reported in petrochemical and glass manufacturing applications, with corresponding energy savings from avoided thermal cycling.

Recent developments in surface-modified high-temperature alloys have further enhanced energy efficiency through improved radiative heat transfer properties. Specialized coatings and surface treatments can optimize emissivity values, allowing furnaces to achieve target temperatures with reduced energy input. These innovations have demonstrated energy consumption reductions of 8-12% in high-temperature applications above 1000°C.

The economic impact of these efficiency improvements is substantial, with typical industrial implementations reporting payback periods of 12-36 months depending on operating temperatures and duty cycles. Beyond direct energy savings, the implementation of advanced alloys contributes to reduced carbon emissions, supporting industrial sustainability goals and compliance with increasingly stringent environmental regulations.

Environmental Impact and Sustainability Considerations

The adoption of high-temperature alloys in industrial furnaces carries significant environmental implications that merit careful consideration. These specialized materials contribute to sustainability through multiple pathways, primarily through enhanced energy efficiency. By enabling furnaces to operate at higher temperatures with improved thermal stability, these alloys reduce the energy consumption required per unit of production, thereby decreasing the carbon footprint associated with industrial heating processes.

The extended service life of high-temperature alloy components represents another crucial environmental benefit. Traditional furnace materials often require frequent replacement due to thermal fatigue, corrosion, and mechanical failure. High-temperature alloys, with their superior durability, significantly reduce the resource consumption associated with manufacturing replacement parts and minimize waste generation from discarded components.

Emissions reduction constitutes a third environmental advantage. Industrial furnaces utilizing high-temperature alloys can achieve more complete combustion processes, resulting in lower emissions of carbon monoxide, nitrogen oxides, and unburned hydrocarbons. This improvement in combustion efficiency directly translates to cleaner air quality and reduced environmental impact from industrial operations.

From a life cycle assessment perspective, the environmental benefits of high-temperature alloys extend beyond operational improvements. While the initial production of these alloys may require more energy and resources than conventional materials, their extended service life and operational efficiencies typically result in a net positive environmental impact over the complete life cycle.

The recyclability of high-temperature alloys further enhances their sustainability profile. Many of these alloys contain valuable elements such as nickel, chromium, and cobalt that can be effectively recovered and reused, reducing the demand for virgin material extraction and associated environmental disruption.

Future sustainability improvements in this field are focusing on developing alloys with reduced critical material content while maintaining performance characteristics. Research into alternative compositions that minimize reliance on rare or environmentally problematic elements represents an important frontier in sustainable materials science for industrial furnace applications.

Regulatory frameworks worldwide are increasingly recognizing these environmental benefits, with some jurisdictions offering incentives for industrial facilities that adopt more efficient furnace technologies incorporating advanced alloys, further accelerating the transition toward more sustainable industrial heating solutions.

The extended service life of high-temperature alloy components represents another crucial environmental benefit. Traditional furnace materials often require frequent replacement due to thermal fatigue, corrosion, and mechanical failure. High-temperature alloys, with their superior durability, significantly reduce the resource consumption associated with manufacturing replacement parts and minimize waste generation from discarded components.

Emissions reduction constitutes a third environmental advantage. Industrial furnaces utilizing high-temperature alloys can achieve more complete combustion processes, resulting in lower emissions of carbon monoxide, nitrogen oxides, and unburned hydrocarbons. This improvement in combustion efficiency directly translates to cleaner air quality and reduced environmental impact from industrial operations.

From a life cycle assessment perspective, the environmental benefits of high-temperature alloys extend beyond operational improvements. While the initial production of these alloys may require more energy and resources than conventional materials, their extended service life and operational efficiencies typically result in a net positive environmental impact over the complete life cycle.

The recyclability of high-temperature alloys further enhances their sustainability profile. Many of these alloys contain valuable elements such as nickel, chromium, and cobalt that can be effectively recovered and reused, reducing the demand for virgin material extraction and associated environmental disruption.

Future sustainability improvements in this field are focusing on developing alloys with reduced critical material content while maintaining performance characteristics. Research into alternative compositions that minimize reliance on rare or environmentally problematic elements represents an important frontier in sustainable materials science for industrial furnace applications.

Regulatory frameworks worldwide are increasingly recognizing these environmental benefits, with some jurisdictions offering incentives for industrial facilities that adopt more efficient furnace technologies incorporating advanced alloys, further accelerating the transition toward more sustainable industrial heating solutions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!