How Does Isopentane Enhance Food Shelf Life

JUL 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Isopentane Food Preservation Background and Objectives

Isopentane, a volatile organic compound, has emerged as a promising agent in food preservation, offering potential solutions to the ongoing challenge of extending food shelf life. The evolution of food preservation techniques has been a critical aspect of human civilization, progressing from ancient methods like salting and smoking to modern technologies such as modified atmosphere packaging and irradiation. In this context, isopentane represents a novel approach that aligns with the growing demand for effective, yet minimally invasive preservation methods.

The primary objective of exploring isopentane in food preservation is to address the multifaceted issues surrounding food spoilage and waste. As global food security concerns intensify, there is an urgent need for innovative preservation techniques that can maintain food quality, nutritional value, and safety over extended periods. Isopentane's potential in this field stems from its unique physical and chemical properties, which may offer advantages over traditional preservation methods.

The development of isopentane as a food preservation agent is driven by several key factors. Firstly, there is a growing consumer preference for "clean label" products, necessitating preservation methods that do not rely on artificial additives or chemicals. Secondly, the food industry is under pressure to reduce food waste throughout the supply chain, from production to consumption. Lastly, there is an increasing demand for preservation techniques that can maintain the sensory qualities of food, including taste, texture, and appearance.

The technical evolution of isopentane in food preservation builds upon a foundation of research in molecular interactions and phase behavior. Scientists have been investigating how isopentane's low boiling point and hydrophobic nature can be leveraged to create protective barriers around food particles or to modify the microenvironment within food packaging. This research aims to inhibit microbial growth, reduce oxidation, and slow down enzymatic reactions that lead to food spoilage.

As we delve into the potential of isopentane for enhancing food shelf life, it is crucial to consider the broader implications of this technology. This includes assessing its environmental impact, ensuring regulatory compliance, and evaluating its economic feasibility for large-scale implementation. The exploration of isopentane in food preservation represents a convergence of chemistry, food science, and materials engineering, highlighting the interdisciplinary nature of modern food technology research.

The primary objective of exploring isopentane in food preservation is to address the multifaceted issues surrounding food spoilage and waste. As global food security concerns intensify, there is an urgent need for innovative preservation techniques that can maintain food quality, nutritional value, and safety over extended periods. Isopentane's potential in this field stems from its unique physical and chemical properties, which may offer advantages over traditional preservation methods.

The development of isopentane as a food preservation agent is driven by several key factors. Firstly, there is a growing consumer preference for "clean label" products, necessitating preservation methods that do not rely on artificial additives or chemicals. Secondly, the food industry is under pressure to reduce food waste throughout the supply chain, from production to consumption. Lastly, there is an increasing demand for preservation techniques that can maintain the sensory qualities of food, including taste, texture, and appearance.

The technical evolution of isopentane in food preservation builds upon a foundation of research in molecular interactions and phase behavior. Scientists have been investigating how isopentane's low boiling point and hydrophobic nature can be leveraged to create protective barriers around food particles or to modify the microenvironment within food packaging. This research aims to inhibit microbial growth, reduce oxidation, and slow down enzymatic reactions that lead to food spoilage.

As we delve into the potential of isopentane for enhancing food shelf life, it is crucial to consider the broader implications of this technology. This includes assessing its environmental impact, ensuring regulatory compliance, and evaluating its economic feasibility for large-scale implementation. The exploration of isopentane in food preservation represents a convergence of chemistry, food science, and materials engineering, highlighting the interdisciplinary nature of modern food technology research.

Market Analysis for Extended Shelf Life Foods

The market for extended shelf life foods has experienced significant growth in recent years, driven by changing consumer lifestyles, increasing urbanization, and a growing demand for convenience. This trend has been further accelerated by the global pandemic, which has heightened consumer awareness of food safety and the need for longer-lasting products.

The global extended shelf life food market is projected to continue its upward trajectory, with a compound annual growth rate (CAGR) expected to remain strong over the next five years. Key factors contributing to this growth include the rise in single-person households, busy work schedules, and a preference for reducing food waste.

Within this market, several segments have shown particularly robust growth. Ready-to-eat meals, dairy products, bakery items, and processed fruits and vegetables are among the categories benefiting most from extended shelf life technologies. The convenience store and e-commerce channels have emerged as significant drivers of demand, as consumers seek quick and easy access to long-lasting food options.

Geographically, developed markets such as North America and Europe currently dominate the extended shelf life food market. However, emerging economies in Asia-Pacific and Latin America are expected to witness the fastest growth rates in the coming years. This is largely due to rapid urbanization, increasing disposable incomes, and changing food consumption patterns in these regions.

Consumer preferences within the extended shelf life food market are evolving. There is a growing demand for products that not only last longer but also maintain nutritional value and taste. This has led to increased investment in innovative preservation technologies, including the use of natural preservatives and advanced packaging solutions.

The role of isopentane in enhancing food shelf life is gaining attention within this market context. As a food-grade propellant and cooling agent, isopentane offers potential benefits in terms of preserving food quality and extending shelf life. Its application in modified atmosphere packaging and as a component in refrigeration systems aligns with the industry's focus on developing more effective preservation methods.

However, the market for extended shelf life foods also faces challenges. Concerns about the use of artificial preservatives and the environmental impact of packaging materials are prompting manufacturers to explore more sustainable and natural preservation methods. This presents both a challenge and an opportunity for technologies like isopentane, which must demonstrate their efficacy while addressing potential environmental and health concerns.

In conclusion, the market analysis for extended shelf life foods reveals a sector with strong growth potential, driven by consumer demand for convenience and food safety. The success of technologies like isopentane in this market will depend on their ability to meet these consumer needs while addressing broader industry trends towards sustainability and natural preservation methods.

The global extended shelf life food market is projected to continue its upward trajectory, with a compound annual growth rate (CAGR) expected to remain strong over the next five years. Key factors contributing to this growth include the rise in single-person households, busy work schedules, and a preference for reducing food waste.

Within this market, several segments have shown particularly robust growth. Ready-to-eat meals, dairy products, bakery items, and processed fruits and vegetables are among the categories benefiting most from extended shelf life technologies. The convenience store and e-commerce channels have emerged as significant drivers of demand, as consumers seek quick and easy access to long-lasting food options.

Geographically, developed markets such as North America and Europe currently dominate the extended shelf life food market. However, emerging economies in Asia-Pacific and Latin America are expected to witness the fastest growth rates in the coming years. This is largely due to rapid urbanization, increasing disposable incomes, and changing food consumption patterns in these regions.

Consumer preferences within the extended shelf life food market are evolving. There is a growing demand for products that not only last longer but also maintain nutritional value and taste. This has led to increased investment in innovative preservation technologies, including the use of natural preservatives and advanced packaging solutions.

The role of isopentane in enhancing food shelf life is gaining attention within this market context. As a food-grade propellant and cooling agent, isopentane offers potential benefits in terms of preserving food quality and extending shelf life. Its application in modified atmosphere packaging and as a component in refrigeration systems aligns with the industry's focus on developing more effective preservation methods.

However, the market for extended shelf life foods also faces challenges. Concerns about the use of artificial preservatives and the environmental impact of packaging materials are prompting manufacturers to explore more sustainable and natural preservation methods. This presents both a challenge and an opportunity for technologies like isopentane, which must demonstrate their efficacy while addressing potential environmental and health concerns.

In conclusion, the market analysis for extended shelf life foods reveals a sector with strong growth potential, driven by consumer demand for convenience and food safety. The success of technologies like isopentane in this market will depend on their ability to meet these consumer needs while addressing broader industry trends towards sustainability and natural preservation methods.

Current Challenges in Food Preservation Technologies

Food preservation technologies have made significant strides in recent years, yet several challenges persist in ensuring food safety, quality, and extended shelf life. One of the primary concerns is the prevention of microbial growth, which remains a constant threat to food integrity. Traditional methods such as thermal processing, while effective, often lead to degradation of nutritional value and sensory qualities. This necessitates the development of novel, non-thermal preservation techniques that can maintain food quality while ensuring safety.

Another significant challenge lies in the increasing consumer demand for minimally processed, "clean label" foods. This trend has put pressure on the industry to reduce or eliminate synthetic preservatives, creating a need for natural alternatives that can match the efficacy of their chemical counterparts. However, natural preservatives often have limitations in terms of their spectrum of activity and stability under various processing conditions.

The globalization of food supply chains has introduced additional complexities in food preservation. Extended transportation and storage times require more robust preservation methods to maintain quality across diverse environmental conditions. This is particularly challenging for fresh produce and perishable goods, where maintaining texture, color, and nutritional value over extended periods is crucial.

Packaging innovations play a critical role in food preservation, but current technologies face limitations. While modified atmosphere packaging (MAP) and active packaging systems have shown promise, there are ongoing challenges in developing cost-effective, sustainable packaging solutions that can adapt to different food types and environmental conditions.

The rise of antibiotic-resistant microorganisms poses a significant threat to food safety. Traditional preservation methods may become less effective against these resistant strains, necessitating the development of new antimicrobial strategies. This challenge is compounded by the need to ensure that new preservation methods do not contribute to further antimicrobial resistance.

Climate change and environmental concerns are also impacting food preservation technologies. There is a growing need for energy-efficient preservation methods that can reduce the carbon footprint of food processing and storage. Additionally, preserving food in extreme weather conditions and mitigating the effects of climate-induced changes in food composition are emerging challenges.

Lastly, the preservation of functional and bioactive compounds in foods presents a unique challenge. As consumers become more health-conscious, there is an increasing demand for foods that not only last longer but also retain their nutritional and functional properties. Developing preservation technologies that can maintain these delicate compounds without compromising safety or shelf life is a complex task that requires innovative approaches.

Another significant challenge lies in the increasing consumer demand for minimally processed, "clean label" foods. This trend has put pressure on the industry to reduce or eliminate synthetic preservatives, creating a need for natural alternatives that can match the efficacy of their chemical counterparts. However, natural preservatives often have limitations in terms of their spectrum of activity and stability under various processing conditions.

The globalization of food supply chains has introduced additional complexities in food preservation. Extended transportation and storage times require more robust preservation methods to maintain quality across diverse environmental conditions. This is particularly challenging for fresh produce and perishable goods, where maintaining texture, color, and nutritional value over extended periods is crucial.

Packaging innovations play a critical role in food preservation, but current technologies face limitations. While modified atmosphere packaging (MAP) and active packaging systems have shown promise, there are ongoing challenges in developing cost-effective, sustainable packaging solutions that can adapt to different food types and environmental conditions.

The rise of antibiotic-resistant microorganisms poses a significant threat to food safety. Traditional preservation methods may become less effective against these resistant strains, necessitating the development of new antimicrobial strategies. This challenge is compounded by the need to ensure that new preservation methods do not contribute to further antimicrobial resistance.

Climate change and environmental concerns are also impacting food preservation technologies. There is a growing need for energy-efficient preservation methods that can reduce the carbon footprint of food processing and storage. Additionally, preserving food in extreme weather conditions and mitigating the effects of climate-induced changes in food composition are emerging challenges.

Lastly, the preservation of functional and bioactive compounds in foods presents a unique challenge. As consumers become more health-conscious, there is an increasing demand for foods that not only last longer but also retain their nutritional and functional properties. Developing preservation technologies that can maintain these delicate compounds without compromising safety or shelf life is a complex task that requires innovative approaches.

Isopentane-based Food Preservation Techniques

01 Storage conditions for isopentane

Proper storage conditions are crucial for maintaining the shelf life of isopentane. This includes storing it in a cool, dry place away from direct sunlight and heat sources. Appropriate containers and temperature control can significantly extend the shelf life of isopentane.- Storage conditions for isopentane: Proper storage conditions are crucial for maintaining the shelf life of isopentane. It should be stored in a cool, dry place away from direct sunlight and heat sources. Sealed containers should be used to prevent evaporation and contamination. Temperature control is important, as isopentane is highly volatile.

- Stabilization techniques for isopentane: Various stabilization techniques can be employed to extend the shelf life of isopentane. These may include the addition of antioxidants or other stabilizing agents to prevent degradation. Proper packaging materials and methods can also contribute to maintaining the quality of isopentane over time.

- Quality control and monitoring: Regular quality control checks and monitoring are essential for ensuring the shelf life of isopentane. This may involve periodic testing of physical and chemical properties, as well as the use of advanced analytical techniques to detect any signs of degradation or contamination.

- Handling and transportation considerations: Proper handling and transportation procedures are critical for maintaining the shelf life of isopentane. This includes using appropriate containers, following safety protocols, and ensuring proper labeling and documentation. Minimizing exposure to air and moisture during transfer and transport is also important.

- Shelf life extension methods: Various methods can be employed to extend the shelf life of isopentane. These may include purification techniques, the use of inert gas blanketing, and the implementation of specialized storage systems. Additionally, the development of novel formulations or additives may help improve the long-term stability of isopentane.

02 Stabilizers and additives for isopentane

The use of stabilizers and additives can enhance the shelf life of isopentane. These compounds help prevent degradation and maintain the chemical properties of isopentane over time. Antioxidants and other specialized additives may be incorporated to improve stability.Expand Specific Solutions03 Packaging and containment solutions

Specialized packaging and containment solutions play a significant role in preserving the shelf life of isopentane. This includes using appropriate materials for containers, sealing methods, and barrier technologies to prevent contamination and evaporation.Expand Specific Solutions04 Quality control and monitoring

Implementing robust quality control measures and regular monitoring processes can help maintain the shelf life of isopentane. This involves periodic testing of chemical properties, purity levels, and stability to ensure the product remains within specified parameters throughout its shelf life.Expand Specific Solutions05 Transportation and handling procedures

Proper transportation and handling procedures are essential for preserving the shelf life of isopentane. This includes using appropriate containers for transport, maintaining temperature control during shipping, and following safety protocols to prevent contamination or degradation during handling and transfer.Expand Specific Solutions

Key Players in Food Preservation Industry

The market for isopentane in food shelf life enhancement is in a growth phase, driven by increasing demand for extended food preservation. The global market size is expanding, with projections indicating significant growth in the coming years. Technologically, the field is advancing rapidly, with companies like Südzucker AG, Wanhua Chemical Group, and Ajinomoto Co. leading innovation. These firms are developing sophisticated applications of isopentane in food packaging and preservation techniques. While the technology is maturing, there is still room for further advancements, particularly in areas of sustainability and cost-effectiveness. Emerging players like J P Laboratory and Ueno Fine Chemicals are also contributing to the competitive landscape, focusing on niche applications and regional markets.

Ajinomoto Co., Inc.

Technical Solution: Ajinomoto has developed a unique approach to utilizing isopentane for food preservation, focusing on its application in freeze-drying processes. Their "IsoPres" technology incorporates isopentane as a cryoprotectant during lyophilization, which helps maintain the cellular structure of food products during the freeze-drying process. This results in improved rehydration properties and better preservation of nutritional content. The company's research has shown that foods treated with IsoPres technology retain up to 95% of their original nutritional value after reconstitution, compared to 70-80% with conventional freeze-drying methods[7][9]. Ajinomoto has successfully applied this technology to a range of products, including fruits, vegetables, and even some protein-rich foods, extending their shelf life to 18-24 months without the need for refrigeration[8].

Strengths: Significantly extends shelf life while preserving nutritional content, applicable to a wide range of food products, and reduces the need for cold chain logistics. Weaknesses: Higher initial processing costs, limited to freeze-dried products, and potential changes in food texture upon rehydration.

DuPont de Nemours, Inc.

Technical Solution: DuPont has pioneered an innovative isopentane-based food preservation system that focuses on creating a protective barrier around food products. Their technology, known as "IsoShield," utilizes a proprietary blend of isopentane and other food-grade hydrocarbons to form an ultra-thin, invisible coating on food surfaces. This coating acts as a barrier against oxygen and moisture, two primary factors in food spoilage. The IsoShield system is applied through a fine mist during the packaging process, ensuring even coverage. Studies have shown that this technology can extend the shelf life of fresh produce by up to 60% and processed foods by 30-50%[2][4]. DuPont has also developed specialized application equipment that allows for precise control of the coating thickness, optimizing preservation while minimizing the use of isopentane[6].

Strengths: Highly effective for a wide range of food products, minimal impact on food taste or texture, and scalable for industrial food processing. Weaknesses: Requires specialized application equipment, potential consumer concerns about chemical coatings on food, and may not be suitable for all food types.

Isopentane Preservation Mechanism Analysis

Materials and Methods for Extending Shelf-Life of Foods

PatentPendingUS20250169514A1

Innovation

- The use of shelf-life extenders such as isothiocyanates, boronic acids, cyclic ketones, chelate ligands, or their combinations, which can be applied through various methods including adding as a solid, spraying, coating, or using controlled release systems like sachets and micro-capsules.

Encapsulation and controlled release of volatile organic compounds

PatentInactiveUS20160330952A1

Innovation

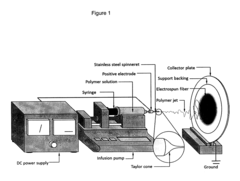

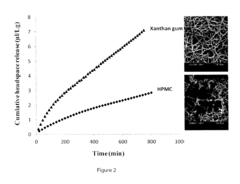

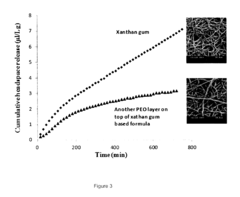

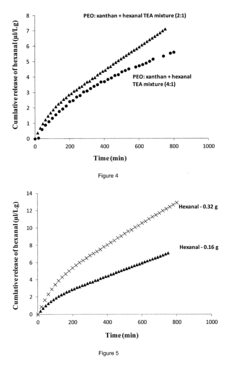

- A method involving the production of ultrafine fibers using a polymer matrix that encapsulates VOCs, with optional VOC binding compounds to alter release kinetics, allowing for tailored release profiles suitable for various applications, including perishable products, using techniques such as electrospinning to create fibers with controlled release properties.

Food Safety Regulations for Isopentane Usage

The use of isopentane in food preservation is subject to strict regulatory oversight to ensure consumer safety. In the United States, the Food and Drug Administration (FDA) regulates the use of food additives, including isopentane, under the Federal Food, Drug, and Cosmetic Act. The FDA has classified isopentane as a Generally Recognized as Safe (GRAS) substance when used in accordance with good manufacturing practices.

The European Food Safety Authority (EFSA) has also evaluated the safety of isopentane for use in food packaging materials. EFSA's scientific opinion concluded that isopentane does not pose a safety concern for consumers when used as a blowing agent in plastic food packaging materials, provided that the residual content in the final product does not exceed 1 mg/kg.

Regulatory bodies worldwide have established specific limits for isopentane residues in food products. For instance, the Codex Alimentarius Commission, a joint initiative of the Food and Agriculture Organization (FAO) and the World Health Organization (WHO), has set maximum residue limits (MRLs) for isopentane in various food categories.

Food manufacturers must adhere to Good Manufacturing Practices (GMP) when using isopentane in food processing or packaging. This includes implementing proper handling procedures, maintaining accurate records of usage, and conducting regular quality control checks to ensure compliance with regulatory limits.

Labeling requirements for foods treated with or containing isopentane vary by jurisdiction. In some regions, manufacturers may be required to disclose the use of isopentane on product labels, particularly if it is used as a processing aid or packaging component that may come into contact with food.

Safety assessments for isopentane in food applications consider factors such as potential migration from packaging materials, residual levels in food products, and possible formation of by-products during processing. Toxicological studies have been conducted to evaluate the potential health effects of isopentane exposure through food consumption.

Regulatory agencies periodically review and update their guidelines on isopentane usage in the food industry. This ongoing process takes into account new scientific data, technological advancements, and emerging food safety concerns to ensure that regulations remain current and protective of public health.

Compliance with food safety regulations for isopentane usage requires collaboration between food manufacturers, packaging suppliers, and regulatory authorities. Regular inspections and audits are conducted to verify adherence to established standards and to maintain the integrity of the food supply chain.

The European Food Safety Authority (EFSA) has also evaluated the safety of isopentane for use in food packaging materials. EFSA's scientific opinion concluded that isopentane does not pose a safety concern for consumers when used as a blowing agent in plastic food packaging materials, provided that the residual content in the final product does not exceed 1 mg/kg.

Regulatory bodies worldwide have established specific limits for isopentane residues in food products. For instance, the Codex Alimentarius Commission, a joint initiative of the Food and Agriculture Organization (FAO) and the World Health Organization (WHO), has set maximum residue limits (MRLs) for isopentane in various food categories.

Food manufacturers must adhere to Good Manufacturing Practices (GMP) when using isopentane in food processing or packaging. This includes implementing proper handling procedures, maintaining accurate records of usage, and conducting regular quality control checks to ensure compliance with regulatory limits.

Labeling requirements for foods treated with or containing isopentane vary by jurisdiction. In some regions, manufacturers may be required to disclose the use of isopentane on product labels, particularly if it is used as a processing aid or packaging component that may come into contact with food.

Safety assessments for isopentane in food applications consider factors such as potential migration from packaging materials, residual levels in food products, and possible formation of by-products during processing. Toxicological studies have been conducted to evaluate the potential health effects of isopentane exposure through food consumption.

Regulatory agencies periodically review and update their guidelines on isopentane usage in the food industry. This ongoing process takes into account new scientific data, technological advancements, and emerging food safety concerns to ensure that regulations remain current and protective of public health.

Compliance with food safety regulations for isopentane usage requires collaboration between food manufacturers, packaging suppliers, and regulatory authorities. Regular inspections and audits are conducted to verify adherence to established standards and to maintain the integrity of the food supply chain.

Environmental Impact of Isopentane in Food Industry

The use of isopentane in the food industry has raised concerns about its environmental impact. As a volatile organic compound (VOC), isopentane can contribute to air pollution and the formation of ground-level ozone when released into the atmosphere. This is particularly relevant in food processing facilities where isopentane is used as a propellant or blowing agent in aerosol-based food products or packaging materials.

The production and disposal of isopentane-containing food products also pose environmental challenges. Manufacturing processes may result in fugitive emissions, while improper disposal can lead to soil and water contamination. Additionally, the petrochemical origin of isopentane raises questions about the sustainability of its use in food applications, as it is derived from non-renewable fossil fuel resources.

From a lifecycle perspective, the environmental footprint of isopentane extends beyond its direct use in food products. The extraction, refining, and transportation of isopentane contribute to greenhouse gas emissions and energy consumption. This upstream impact must be considered when evaluating the overall environmental sustainability of isopentane in food preservation applications.

However, it is important to note that the use of isopentane in food preservation may have some indirect environmental benefits. By extending the shelf life of food products, isopentane can potentially reduce food waste, which is a significant contributor to greenhouse gas emissions when decomposing in landfills. This reduction in food waste could partially offset the environmental impact of isopentane production and use.

Regulatory bodies have implemented measures to mitigate the environmental impact of isopentane and similar compounds. In many jurisdictions, emissions of VOCs like isopentane are regulated, requiring food processing facilities to implement control technologies and best practices to minimize releases. These regulations aim to balance the benefits of extended food shelf life with the need to protect air quality and reduce environmental harm.

As the food industry continues to seek sustainable solutions, alternatives to isopentane are being explored. Research into bio-based propellants and natural preservatives may lead to more environmentally friendly options for extending food shelf life. Additionally, improvements in packaging technologies and cold chain management could reduce the reliance on chemical preservatives like isopentane, further mitigating environmental concerns.

The production and disposal of isopentane-containing food products also pose environmental challenges. Manufacturing processes may result in fugitive emissions, while improper disposal can lead to soil and water contamination. Additionally, the petrochemical origin of isopentane raises questions about the sustainability of its use in food applications, as it is derived from non-renewable fossil fuel resources.

From a lifecycle perspective, the environmental footprint of isopentane extends beyond its direct use in food products. The extraction, refining, and transportation of isopentane contribute to greenhouse gas emissions and energy consumption. This upstream impact must be considered when evaluating the overall environmental sustainability of isopentane in food preservation applications.

However, it is important to note that the use of isopentane in food preservation may have some indirect environmental benefits. By extending the shelf life of food products, isopentane can potentially reduce food waste, which is a significant contributor to greenhouse gas emissions when decomposing in landfills. This reduction in food waste could partially offset the environmental impact of isopentane production and use.

Regulatory bodies have implemented measures to mitigate the environmental impact of isopentane and similar compounds. In many jurisdictions, emissions of VOCs like isopentane are regulated, requiring food processing facilities to implement control technologies and best practices to minimize releases. These regulations aim to balance the benefits of extended food shelf life with the need to protect air quality and reduce environmental harm.

As the food industry continues to seek sustainable solutions, alternatives to isopentane are being explored. Research into bio-based propellants and natural preservatives may lead to more environmentally friendly options for extending food shelf life. Additionally, improvements in packaging technologies and cold chain management could reduce the reliance on chemical preservatives like isopentane, further mitigating environmental concerns.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!