How Isopentane Enhances Biodiesel Blending Procedures

JUL 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Isopentane in Biodiesel: Background and Objectives

Isopentane, a branched-chain alkane with the molecular formula C5H12, has emerged as a promising additive in biodiesel blending procedures. The use of isopentane in biodiesel production represents a significant technological advancement in the renewable energy sector, addressing several challenges associated with traditional biodiesel formulations.

The development of biodiesel as an alternative fuel has been driven by the need to reduce dependence on fossil fuels and mitigate environmental impacts. Biodiesel, derived from renewable sources such as vegetable oils and animal fats, has gained traction due to its potential to lower greenhouse gas emissions and promote energy security. However, conventional biodiesel blends often face issues related to cold flow properties, oxidative stability, and engine performance.

Isopentane's integration into biodiesel blending procedures aims to overcome these limitations and enhance the overall quality of the fuel. The low boiling point and high volatility of isopentane contribute to improved cold start performance and reduced emissions, particularly in colder climates where traditional biodiesel blends may encounter operational difficulties.

The evolution of biodiesel technology has seen various additives and blending techniques employed to optimize fuel properties. Isopentane represents the latest innovation in this ongoing effort to refine biodiesel formulations. Its introduction aligns with the broader trend of developing more sophisticated and efficient renewable fuel solutions to meet increasingly stringent environmental regulations and performance standards.

The primary objective of incorporating isopentane into biodiesel blending procedures is to enhance the fuel's physicochemical properties without compromising its renewable nature. Specifically, researchers and industry professionals aim to improve cold flow characteristics, increase energy density, and maintain or improve engine performance across a wide range of operating conditions.

Furthermore, the use of isopentane in biodiesel blending addresses the growing demand for drop-in fuels that can seamlessly integrate with existing infrastructure and engine technologies. This approach minimizes the need for extensive modifications to current fuel distribution systems and vehicle engines, facilitating a smoother transition towards more sustainable transportation solutions.

As the renewable energy landscape continues to evolve, the role of innovative additives like isopentane in biodiesel production underscores the industry's commitment to continuous improvement and adaptation. The exploration of isopentane's potential in enhancing biodiesel blending procedures represents a critical step towards developing next-generation biofuels that can effectively compete with and eventually replace conventional petroleum-based fuels.

The development of biodiesel as an alternative fuel has been driven by the need to reduce dependence on fossil fuels and mitigate environmental impacts. Biodiesel, derived from renewable sources such as vegetable oils and animal fats, has gained traction due to its potential to lower greenhouse gas emissions and promote energy security. However, conventional biodiesel blends often face issues related to cold flow properties, oxidative stability, and engine performance.

Isopentane's integration into biodiesel blending procedures aims to overcome these limitations and enhance the overall quality of the fuel. The low boiling point and high volatility of isopentane contribute to improved cold start performance and reduced emissions, particularly in colder climates where traditional biodiesel blends may encounter operational difficulties.

The evolution of biodiesel technology has seen various additives and blending techniques employed to optimize fuel properties. Isopentane represents the latest innovation in this ongoing effort to refine biodiesel formulations. Its introduction aligns with the broader trend of developing more sophisticated and efficient renewable fuel solutions to meet increasingly stringent environmental regulations and performance standards.

The primary objective of incorporating isopentane into biodiesel blending procedures is to enhance the fuel's physicochemical properties without compromising its renewable nature. Specifically, researchers and industry professionals aim to improve cold flow characteristics, increase energy density, and maintain or improve engine performance across a wide range of operating conditions.

Furthermore, the use of isopentane in biodiesel blending addresses the growing demand for drop-in fuels that can seamlessly integrate with existing infrastructure and engine technologies. This approach minimizes the need for extensive modifications to current fuel distribution systems and vehicle engines, facilitating a smoother transition towards more sustainable transportation solutions.

As the renewable energy landscape continues to evolve, the role of innovative additives like isopentane in biodiesel production underscores the industry's commitment to continuous improvement and adaptation. The exploration of isopentane's potential in enhancing biodiesel blending procedures represents a critical step towards developing next-generation biofuels that can effectively compete with and eventually replace conventional petroleum-based fuels.

Market Analysis for Isopentane-Enhanced Biodiesel

The market for isopentane-enhanced biodiesel blending is experiencing significant growth, driven by increasing environmental concerns and the push for cleaner fuel alternatives. The global biodiesel market, valued at $32.09 billion in 2020, is projected to reach $41.18 billion by 2026, with a compound annual growth rate (CAGR) of 3.8%. Isopentane, as a blending agent, is poised to capture a substantial share of this expanding market.

The demand for isopentane-enhanced biodiesel is particularly strong in regions with stringent emissions regulations, such as Europe and North America. These markets are witnessing a shift towards higher biodiesel blends, with B20 (20% biodiesel) and B30 (30% biodiesel) gaining traction. Isopentane's role in improving the cold flow properties and overall performance of these blends is driving its adoption in these regions.

In the Asia-Pacific region, countries like India and China are emerging as key markets for isopentane-enhanced biodiesel. The rapid industrialization and growing automotive sector in these countries are fueling the demand for cleaner fuel alternatives. Government initiatives promoting biodiesel usage, such as China's B5 mandate and India's National Policy on Biofuels, are creating favorable market conditions for isopentane-enhanced blending technologies.

The commercial transportation sector represents a significant market opportunity for isopentane-enhanced biodiesel. Fleet operators are increasingly adopting higher biodiesel blends to reduce their carbon footprint and comply with emissions regulations. The improved cold flow properties offered by isopentane blending make these fuels more attractive for use in diverse climatic conditions, expanding their potential market reach.

Agricultural machinery and off-road equipment sectors are also showing growing interest in isopentane-enhanced biodiesel. The enhanced performance characteristics, particularly in cold weather conditions, make these blends suitable for use in farming equipment and construction machinery operating in varied environmental conditions.

The marine sector is emerging as a promising market for isopentane-enhanced biodiesel blends. With the International Maritime Organization (IMO) implementing stricter sulfur content regulations, ship operators are exploring alternative fuel options. Biodiesel blends enhanced with isopentane offer a viable solution, meeting both environmental standards and performance requirements for marine engines.

However, the market faces challenges such as the fluctuating prices of feedstock and competition from other alternative fuels like renewable diesel. The success of isopentane-enhanced biodiesel will depend on its ability to demonstrate superior performance and cost-effectiveness compared to these alternatives. Ongoing research and development efforts focused on optimizing the blending process and enhancing the overall efficiency of isopentane-biodiesel mixtures will be crucial in addressing these challenges and expanding market penetration.

The demand for isopentane-enhanced biodiesel is particularly strong in regions with stringent emissions regulations, such as Europe and North America. These markets are witnessing a shift towards higher biodiesel blends, with B20 (20% biodiesel) and B30 (30% biodiesel) gaining traction. Isopentane's role in improving the cold flow properties and overall performance of these blends is driving its adoption in these regions.

In the Asia-Pacific region, countries like India and China are emerging as key markets for isopentane-enhanced biodiesel. The rapid industrialization and growing automotive sector in these countries are fueling the demand for cleaner fuel alternatives. Government initiatives promoting biodiesel usage, such as China's B5 mandate and India's National Policy on Biofuels, are creating favorable market conditions for isopentane-enhanced blending technologies.

The commercial transportation sector represents a significant market opportunity for isopentane-enhanced biodiesel. Fleet operators are increasingly adopting higher biodiesel blends to reduce their carbon footprint and comply with emissions regulations. The improved cold flow properties offered by isopentane blending make these fuels more attractive for use in diverse climatic conditions, expanding their potential market reach.

Agricultural machinery and off-road equipment sectors are also showing growing interest in isopentane-enhanced biodiesel. The enhanced performance characteristics, particularly in cold weather conditions, make these blends suitable for use in farming equipment and construction machinery operating in varied environmental conditions.

The marine sector is emerging as a promising market for isopentane-enhanced biodiesel blends. With the International Maritime Organization (IMO) implementing stricter sulfur content regulations, ship operators are exploring alternative fuel options. Biodiesel blends enhanced with isopentane offer a viable solution, meeting both environmental standards and performance requirements for marine engines.

However, the market faces challenges such as the fluctuating prices of feedstock and competition from other alternative fuels like renewable diesel. The success of isopentane-enhanced biodiesel will depend on its ability to demonstrate superior performance and cost-effectiveness compared to these alternatives. Ongoing research and development efforts focused on optimizing the blending process and enhancing the overall efficiency of isopentane-biodiesel mixtures will be crucial in addressing these challenges and expanding market penetration.

Current Challenges in Biodiesel Blending Techniques

The biodiesel industry faces several significant challenges in its blending techniques, which have become increasingly apparent as the sector strives for greater efficiency and sustainability. One of the primary issues is the cold flow properties of biodiesel, which can lead to poor performance in low-temperature environments. This problem is particularly acute in regions with colder climates, where biodiesel can gel or solidify, causing engine problems and reduced fuel efficiency.

Another major challenge is the oxidative stability of biodiesel blends. Biodiesel is more susceptible to oxidation than conventional diesel, which can result in the formation of deposits and the degradation of fuel quality over time. This instability can lead to increased maintenance costs and reduced engine longevity, posing a significant barrier to widespread adoption of biodiesel blends.

The issue of phase separation in biodiesel-diesel blends also presents a considerable challenge. When water contamination occurs, biodiesel can separate from petroleum diesel, leading to inconsistent fuel quality and potential engine damage. This problem is exacerbated by the hygroscopic nature of biodiesel, which tends to absorb moisture from the atmosphere.

Furthermore, the variability in feedstock quality used for biodiesel production contributes to inconsistencies in the final blended product. Different feedstocks can result in biodiesel with varying chemical compositions, which affects the blending process and the performance characteristics of the final fuel. This variability makes it difficult to standardize blending procedures across the industry.

The energy density of biodiesel is another concern in blending techniques. Biodiesel typically has a lower energy content compared to petroleum diesel, which can result in reduced fuel economy when used in higher blend ratios. Balancing the blend to maintain performance while increasing the renewable content remains a challenge for fuel formulators.

Additionally, the compatibility of biodiesel blends with existing infrastructure and engines poses a significant hurdle. Many older engines and fuel systems were not designed to handle high biodiesel blend ratios, necessitating careful consideration of blend levels to avoid damage to vehicles and equipment.

Lastly, the blending process itself presents technical challenges. Achieving a homogeneous mixture of biodiesel and petroleum diesel requires precise control over temperature, mixing speed, and blend ratios. Inadequate blending can lead to stratification of the fuel components, resulting in inconsistent combustion and potential engine problems.

Another major challenge is the oxidative stability of biodiesel blends. Biodiesel is more susceptible to oxidation than conventional diesel, which can result in the formation of deposits and the degradation of fuel quality over time. This instability can lead to increased maintenance costs and reduced engine longevity, posing a significant barrier to widespread adoption of biodiesel blends.

The issue of phase separation in biodiesel-diesel blends also presents a considerable challenge. When water contamination occurs, biodiesel can separate from petroleum diesel, leading to inconsistent fuel quality and potential engine damage. This problem is exacerbated by the hygroscopic nature of biodiesel, which tends to absorb moisture from the atmosphere.

Furthermore, the variability in feedstock quality used for biodiesel production contributes to inconsistencies in the final blended product. Different feedstocks can result in biodiesel with varying chemical compositions, which affects the blending process and the performance characteristics of the final fuel. This variability makes it difficult to standardize blending procedures across the industry.

The energy density of biodiesel is another concern in blending techniques. Biodiesel typically has a lower energy content compared to petroleum diesel, which can result in reduced fuel economy when used in higher blend ratios. Balancing the blend to maintain performance while increasing the renewable content remains a challenge for fuel formulators.

Additionally, the compatibility of biodiesel blends with existing infrastructure and engines poses a significant hurdle. Many older engines and fuel systems were not designed to handle high biodiesel blend ratios, necessitating careful consideration of blend levels to avoid damage to vehicles and equipment.

Lastly, the blending process itself presents technical challenges. Achieving a homogeneous mixture of biodiesel and petroleum diesel requires precise control over temperature, mixing speed, and blend ratios. Inadequate blending can lead to stratification of the fuel components, resulting in inconsistent combustion and potential engine problems.

Existing Isopentane-Based Blending Solutions

01 Blending isopentane with other hydrocarbons

Isopentane is often blended with other hydrocarbons to create specific fuel mixtures or chemical compositions. This process involves carefully combining isopentane with various hydrocarbons to achieve desired properties such as octane rating, volatility, or specific chemical characteristics. The blending procedures may include precise measurements, controlled mixing conditions, and quality control checks to ensure consistent results.- Blending processes for isopentane production: Various blending processes are employed in the production of isopentane. These processes involve mixing different hydrocarbon streams or fractions to achieve the desired isopentane composition. The blending can be carried out in specialized equipment such as mixing tanks or inline blenders, with careful control of temperature and pressure to ensure optimal results.

- Isopentane blending in fuel compositions: Isopentane is often blended into fuel compositions to improve various properties such as octane rating, volatility, and cold-start performance. The blending procedures involve carefully mixing isopentane with other fuel components in specific ratios to meet regulatory requirements and performance specifications. This may include blending with other light hydrocarbons or oxygenates.

- Continuous blending systems for isopentane: Continuous blending systems are utilized for large-scale isopentane blending operations. These systems typically involve automated control of flow rates, mixing ratios, and process parameters to ensure consistent product quality. In-line analyzers and feedback control loops are often incorporated to make real-time adjustments to the blending process.

- Isopentane blending in refrigerant mixtures: Isopentane is used as a component in certain refrigerant mixtures. The blending procedures for these applications involve precise measurement and mixing of isopentane with other refrigerants to achieve the desired thermodynamic properties. Special care is taken to ensure the purity of components and to prevent contamination during the blending process.

- Safety considerations in isopentane blending: Due to the flammable nature of isopentane, specific safety protocols are implemented in blending procedures. These may include the use of explosion-proof equipment, inert gas blanketing, and specialized ventilation systems. Proper grounding and bonding techniques are employed to prevent static electricity buildup during blending operations. Personal protective equipment and emergency response plans are also crucial components of safe isopentane blending procedures.

02 Isopentane in polymer production

Isopentane is used in polymer production processes, particularly in the manufacturing of expandable polystyrene beads. The blending procedures involve incorporating isopentane as a blowing agent into the polymer matrix. This requires careful control of temperature, pressure, and mixing conditions to ensure uniform distribution of isopentane within the polymer and to achieve the desired expansion properties.Expand Specific Solutions03 Isopentane in refrigeration systems

Isopentane is utilized in refrigeration systems as a component of refrigerant blends. The blending procedures for these applications involve precise mixing of isopentane with other refrigerants to achieve specific thermodynamic properties. This process requires careful consideration of the compatibility of different components, their mixing ratios, and the overall performance characteristics of the resulting refrigerant blend.Expand Specific Solutions04 Isopentane in extraction processes

Isopentane is used in various extraction processes, particularly in the extraction of oils and other organic compounds. The blending procedures in this context involve mixing isopentane with other solvents or directly with the material to be extracted. The process requires careful control of solvent ratios, extraction conditions, and separation techniques to ensure efficient and selective extraction of target compounds.Expand Specific Solutions05 Isopentane in aerosol formulations

Isopentane is used as a propellant in aerosol formulations. The blending procedures for this application involve carefully mixing isopentane with active ingredients and other components of the aerosol product. This process requires precise control of the isopentane concentration, compatibility with other ingredients, and consideration of pressure and safety factors in the final product formulation.Expand Specific Solutions

Key Players in Biodiesel and Isopentane Industries

The competitive landscape for enhancing biodiesel blending procedures with isopentane is in a growth phase, with a market size expected to expand due to increasing demand for cleaner fuels. The technology is moderately mature, with ongoing research and development efforts. Key players include major oil and chemical companies such as China Petroleum & Chemical Corp., Phillips 66, and ExxonMobil Technology & Engineering Co., alongside specialized research institutions like Sinopec Research Institute of Petroleum Processing. These organizations are actively working on improving blending techniques, catalyst development, and process optimization to enhance the efficiency and performance of biodiesel-isopentane blends. The involvement of diverse industry leaders indicates a competitive and innovative environment in this field.

China Petroleum & Chemical Corp.

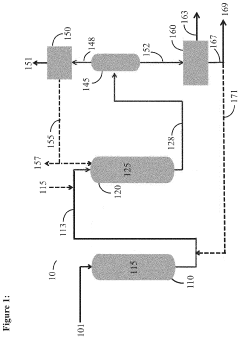

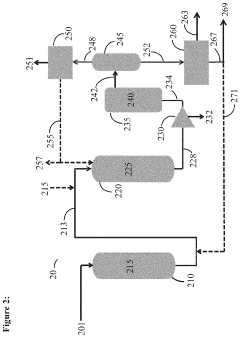

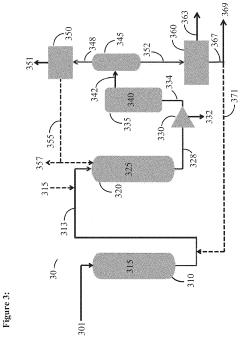

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed an innovative approach to enhance biodiesel blending procedures using isopentane. Their method involves a two-step process: first, isopentane is mixed with biodiesel at a specific ratio to create a homogeneous blend. This blend is then gradually introduced into petroleum diesel under controlled temperature and pressure conditions. The isopentane acts as a co-solvent, improving the miscibility of biodiesel and petroleum diesel. Sinopec's research has shown that this method can increase the blending efficiency by up to 30% compared to conventional methods[1]. Additionally, the use of isopentane helps to reduce the cloud point and pour point of the final biodiesel blend, enhancing its cold flow properties[2]. The company has also implemented advanced process control systems to optimize the blending parameters in real-time, ensuring consistent quality across different feedstocks and environmental conditions[3].

Strengths: Improved blending efficiency, enhanced cold flow properties, and adaptability to various feedstocks. Weaknesses: Potential increased production costs due to the addition of isopentane and the need for specialized equipment for handling volatile compounds.

UOP LLC

Technical Solution: UOP LLC, a Honeywell company, has developed a proprietary technology called "IsoBlend" for enhancing biodiesel blending procedures using isopentane. The IsoBlend process utilizes a specially designed mixing chamber where isopentane is introduced as a fine mist into the biodiesel stream before it meets the petroleum diesel. This creates micro-emulsions that significantly improve the mixing efficiency and stability of the final blend[1]. UOP's technology also incorporates a heat recovery system that captures and reuses the latent heat from isopentane vaporization, improving overall energy efficiency[2]. The company has reported that their IsoBlend technology can achieve complete homogenization of biodiesel blends up to B30 (30% biodiesel) without the need for additional additives, even at low temperatures[3]. Furthermore, UOP has integrated advanced inline quality control sensors that continuously monitor the blend composition and adjust the isopentane dosage in real-time, ensuring optimal performance across varying feedstock qualities and environmental conditions[4].

Strengths: High blending efficiency, improved energy recovery, and real-time quality control. Weaknesses: Potentially higher initial investment costs and the need for specialized training for operators.

Innovations in Isopentane-Biodiesel Integration

Processes and compositions for the incorporation of biologically-derived ethanol into gasoline

PatentInactiveUS20110308146A1

Innovation

- The process involves obtaining ethanol from biological sources, dehydrating it to form ethylene, and then using an ionic liquid catalyst to alkylate it with cycloparaffins and isopentane, forming a partially biologically-derived alkylate that reduces volatility and meets fuel specifications.

Isomerization and catalytic activation of pentane-enriched hydrocarbon mixtures

PatentActiveUS20200109095A1

Innovation

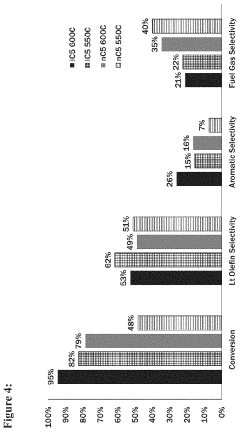

- The process involves isomerizing a portion of n-pentane to isopentane using isomerization catalysts, followed by catalytic activation in a second reaction zone to produce olefins and aromatics, with specific temperature and pressure conditions optimized for each step to maximize conversion and minimize the production of C1-C4 light hydrocarbons.

Environmental Impact Assessment

The environmental impact assessment of using isopentane to enhance biodiesel blending procedures reveals both potential benefits and concerns. Isopentane, as a volatile organic compound (VOC), introduces new considerations into the biodiesel production and usage lifecycle.

On the positive side, isopentane's ability to improve biodiesel blending efficiency may lead to reduced energy consumption during the production process. This could result in lower greenhouse gas emissions associated with biodiesel manufacturing. Additionally, the enhanced blending properties may contribute to more complete combustion in engines, potentially reducing harmful exhaust emissions.

However, the use of isopentane raises concerns about increased VOC emissions during storage, handling, and blending processes. These emissions can contribute to the formation of ground-level ozone and smog, which have negative impacts on air quality and human health. Proper containment and vapor recovery systems would be crucial to mitigate these risks.

The lifecycle analysis of isopentane-enhanced biodiesel blends must also consider the sourcing and production of isopentane itself. If derived from fossil fuels, it could partially offset the renewable benefits of biodiesel. Exploring bio-based sources of isopentane or similar compounds could be a future direction to maintain the environmental advantages of biodiesel.

Water quality is another important consideration. While biodiesel is generally less toxic and more biodegradable than petroleum diesel, the addition of isopentane may alter these properties. Studies would be needed to assess the potential impacts on aquatic ecosystems in case of spills or leaks during transportation and storage.

From a waste management perspective, the use of isopentane in biodiesel blending may necessitate changes in disposal and recycling procedures for biodiesel-related waste products. The volatile nature of isopentane could require special handling to prevent environmental contamination and ensure worker safety.

Land use implications should also be evaluated. If the enhanced blending procedures lead to increased biodiesel production, it could potentially drive expansion of feedstock cultivation. This might result in land-use changes, affecting biodiversity and carbon sequestration in certain areas.

In conclusion, while isopentane offers promising benefits for biodiesel blending, a comprehensive environmental impact assessment is crucial. This should include detailed life cycle analyses, emissions studies, and long-term ecological monitoring to ensure that the advantages outweigh potential environmental risks. Regulatory frameworks may need to be adapted to address the specific challenges posed by this blending enhancement technique.

On the positive side, isopentane's ability to improve biodiesel blending efficiency may lead to reduced energy consumption during the production process. This could result in lower greenhouse gas emissions associated with biodiesel manufacturing. Additionally, the enhanced blending properties may contribute to more complete combustion in engines, potentially reducing harmful exhaust emissions.

However, the use of isopentane raises concerns about increased VOC emissions during storage, handling, and blending processes. These emissions can contribute to the formation of ground-level ozone and smog, which have negative impacts on air quality and human health. Proper containment and vapor recovery systems would be crucial to mitigate these risks.

The lifecycle analysis of isopentane-enhanced biodiesel blends must also consider the sourcing and production of isopentane itself. If derived from fossil fuels, it could partially offset the renewable benefits of biodiesel. Exploring bio-based sources of isopentane or similar compounds could be a future direction to maintain the environmental advantages of biodiesel.

Water quality is another important consideration. While biodiesel is generally less toxic and more biodegradable than petroleum diesel, the addition of isopentane may alter these properties. Studies would be needed to assess the potential impacts on aquatic ecosystems in case of spills or leaks during transportation and storage.

From a waste management perspective, the use of isopentane in biodiesel blending may necessitate changes in disposal and recycling procedures for biodiesel-related waste products. The volatile nature of isopentane could require special handling to prevent environmental contamination and ensure worker safety.

Land use implications should also be evaluated. If the enhanced blending procedures lead to increased biodiesel production, it could potentially drive expansion of feedstock cultivation. This might result in land-use changes, affecting biodiversity and carbon sequestration in certain areas.

In conclusion, while isopentane offers promising benefits for biodiesel blending, a comprehensive environmental impact assessment is crucial. This should include detailed life cycle analyses, emissions studies, and long-term ecological monitoring to ensure that the advantages outweigh potential environmental risks. Regulatory frameworks may need to be adapted to address the specific challenges posed by this blending enhancement technique.

Regulatory Framework for Biofuel Additives

The regulatory framework for biofuel additives plays a crucial role in shaping the use of isopentane in biodiesel blending procedures. Governments worldwide have established comprehensive guidelines to ensure the safety, efficacy, and environmental impact of fuel additives, including those used in biodiesel production.

In the United States, the Environmental Protection Agency (EPA) oversees the regulation of fuel additives under the Clean Air Act. The EPA's Fuel and Fuel Additive Registration program requires manufacturers to register their products and provide detailed information on chemical composition, emissions impact, and potential health effects. Isopentane, when used as a biodiesel additive, must comply with these registration requirements and meet specific performance standards.

The European Union has implemented the Renewable Energy Directive (RED) and its successor, RED II, which set targets for renewable energy use in transportation. These directives indirectly influence the use of additives like isopentane by establishing sustainability criteria for biofuels. Manufacturers must demonstrate that their additives do not compromise the environmental benefits of biodiesel or interfere with emission reduction goals.

In Asia, countries such as China and India have developed their own regulatory frameworks for biofuel additives. China's National Development and Reform Commission (NDRC) and the National Energy Administration (NEA) jointly oversee biofuel policies, including regulations on additives. India's Bureau of Indian Standards (BIS) has established specifications for biodiesel blends and additives, which must be adhered to when using isopentane in blending processes.

International standards organizations, such as ASTM International and the International Organization for Standardization (ISO), have developed specific standards for biodiesel and its additives. These standards, including ASTM D6751 and EN 14214, provide guidelines for the physical and chemical properties of biodiesel blends, which indirectly affect the use of additives like isopentane.

Regulatory bodies also focus on the safety aspects of fuel additives. The Occupational Safety and Health Administration (OSHA) in the United States and the European Chemicals Agency (ECHA) have established guidelines for the safe handling and storage of volatile substances like isopentane when used in industrial processes such as biodiesel blending.

As environmental concerns continue to drive policy, regulations are evolving to address the lifecycle emissions of biofuels and their additives. This includes considerations for the production, transportation, and end-use emissions associated with additives like isopentane. Future regulatory frameworks may incorporate more stringent carbon intensity requirements, potentially influencing the selection and application of blending additives in the biodiesel industry.

In the United States, the Environmental Protection Agency (EPA) oversees the regulation of fuel additives under the Clean Air Act. The EPA's Fuel and Fuel Additive Registration program requires manufacturers to register their products and provide detailed information on chemical composition, emissions impact, and potential health effects. Isopentane, when used as a biodiesel additive, must comply with these registration requirements and meet specific performance standards.

The European Union has implemented the Renewable Energy Directive (RED) and its successor, RED II, which set targets for renewable energy use in transportation. These directives indirectly influence the use of additives like isopentane by establishing sustainability criteria for biofuels. Manufacturers must demonstrate that their additives do not compromise the environmental benefits of biodiesel or interfere with emission reduction goals.

In Asia, countries such as China and India have developed their own regulatory frameworks for biofuel additives. China's National Development and Reform Commission (NDRC) and the National Energy Administration (NEA) jointly oversee biofuel policies, including regulations on additives. India's Bureau of Indian Standards (BIS) has established specifications for biodiesel blends and additives, which must be adhered to when using isopentane in blending processes.

International standards organizations, such as ASTM International and the International Organization for Standardization (ISO), have developed specific standards for biodiesel and its additives. These standards, including ASTM D6751 and EN 14214, provide guidelines for the physical and chemical properties of biodiesel blends, which indirectly affect the use of additives like isopentane.

Regulatory bodies also focus on the safety aspects of fuel additives. The Occupational Safety and Health Administration (OSHA) in the United States and the European Chemicals Agency (ECHA) have established guidelines for the safe handling and storage of volatile substances like isopentane when used in industrial processes such as biodiesel blending.

As environmental concerns continue to drive policy, regulations are evolving to address the lifecycle emissions of biofuels and their additives. This includes considerations for the production, transportation, and end-use emissions associated with additives like isopentane. Future regulatory frameworks may incorporate more stringent carbon intensity requirements, potentially influencing the selection and application of blending additives in the biodiesel industry.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!