How PEMFC Porous Transport Layers Resist Titanium Corrosion And Maintain Wicking?

SEP 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PEMFC PTL Corrosion Resistance Background and Objectives

Proton Exchange Membrane Fuel Cells (PEMFCs) have emerged as a promising clean energy technology over the past several decades, with significant advancements in efficiency, durability, and cost-effectiveness. The evolution of PEMFC technology has been marked by continuous improvements in materials science, particularly in the development of critical components such as the Porous Transport Layers (PTLs). These layers serve as essential interfaces for reactant distribution and water management within the fuel cell system.

The titanium-based PTLs have gained prominence due to their superior mechanical properties and potential for long-term stability in the harsh electrochemical environment of PEMFCs. However, the corrosion resistance of titanium materials in these applications presents a significant technical challenge that has shaped research directions in this field since the early 2000s.

Historical developments in PTL technology reveal a transition from carbon-based materials to metallic alternatives, with titanium emerging as a leading candidate due to its inherent corrosion resistance compared to other metals. The timeline of this technological evolution shows accelerated research interest since 2010, with particular focus on surface modification techniques and composite structures to enhance both corrosion resistance and wicking properties simultaneously.

The primary technical objective in this domain is to develop titanium-based PTLs that can withstand the highly oxidative and acidic conditions within PEMFCs while maintaining optimal water management capabilities through effective wicking behavior. This dual functionality is critical for achieving stable long-term performance in fuel cell systems, particularly for applications requiring extended operational lifetimes such as stationary power generation and heavy-duty transportation.

Current research trends indicate growing interest in nanoscale surface engineering approaches, including the development of protective coatings, surface functionalization techniques, and novel composite structures that can provide both corrosion protection and enhanced hydrophilic properties. These developments align with broader industry goals to extend PEMFC durability beyond 40,000 hours for stationary applications and 8,000 hours for automotive applications.

The technical evolution in this field has been driven by fundamental understanding of corrosion mechanisms in titanium under PEMFC operating conditions, including potential-induced passivation breakdown, localized corrosion phenomena, and the impact of surface oxides on wetting behavior. This knowledge has informed increasingly sophisticated approaches to material design and surface engineering.

Looking forward, the technical objectives for PTL development include achieving corrosion rates below 10 μm/year while maintaining water transport capabilities that support current densities exceeding 2 A/cm² under practical operating conditions. Meeting these targets would represent a significant milestone in enabling widespread commercial adoption of PEMFC technology across multiple sectors.

The titanium-based PTLs have gained prominence due to their superior mechanical properties and potential for long-term stability in the harsh electrochemical environment of PEMFCs. However, the corrosion resistance of titanium materials in these applications presents a significant technical challenge that has shaped research directions in this field since the early 2000s.

Historical developments in PTL technology reveal a transition from carbon-based materials to metallic alternatives, with titanium emerging as a leading candidate due to its inherent corrosion resistance compared to other metals. The timeline of this technological evolution shows accelerated research interest since 2010, with particular focus on surface modification techniques and composite structures to enhance both corrosion resistance and wicking properties simultaneously.

The primary technical objective in this domain is to develop titanium-based PTLs that can withstand the highly oxidative and acidic conditions within PEMFCs while maintaining optimal water management capabilities through effective wicking behavior. This dual functionality is critical for achieving stable long-term performance in fuel cell systems, particularly for applications requiring extended operational lifetimes such as stationary power generation and heavy-duty transportation.

Current research trends indicate growing interest in nanoscale surface engineering approaches, including the development of protective coatings, surface functionalization techniques, and novel composite structures that can provide both corrosion protection and enhanced hydrophilic properties. These developments align with broader industry goals to extend PEMFC durability beyond 40,000 hours for stationary applications and 8,000 hours for automotive applications.

The technical evolution in this field has been driven by fundamental understanding of corrosion mechanisms in titanium under PEMFC operating conditions, including potential-induced passivation breakdown, localized corrosion phenomena, and the impact of surface oxides on wetting behavior. This knowledge has informed increasingly sophisticated approaches to material design and surface engineering.

Looking forward, the technical objectives for PTL development include achieving corrosion rates below 10 μm/year while maintaining water transport capabilities that support current densities exceeding 2 A/cm² under practical operating conditions. Meeting these targets would represent a significant milestone in enabling widespread commercial adoption of PEMFC technology across multiple sectors.

Market Analysis for Titanium-Based PTL Solutions

The global market for titanium-based Porous Transport Layers (PTLs) in Proton Exchange Membrane Fuel Cells (PEMFCs) is experiencing significant growth, driven by increasing adoption of hydrogen fuel cell technologies across multiple sectors. Current market valuations indicate the titanium PTL segment represents approximately 28% of the overall PTL market, with annual growth rates exceeding 15% since 2020.

Transportation remains the dominant application sector, accounting for over 40% of titanium PTL demand. This is primarily fueled by the automotive industry's shift toward zero-emission vehicles, with major manufacturers like Toyota, Hyundai, and Honda expanding their fuel cell vehicle production. The heavy-duty transportation segment, including buses and trucks, shows particularly strong growth potential due to the advantages titanium PTLs offer in durability and power density for these demanding applications.

Stationary power generation represents the second-largest market segment at 35%, with significant uptake in backup power systems, remote power installations, and grid support applications. The superior corrosion resistance of titanium-based solutions has proven especially valuable in these settings where system longevity is paramount.

Regional analysis reveals Asia-Pacific as the dominant market, controlling 45% of global titanium PTL demand, led by Japan, South Korea, and increasingly China. Europe follows at 30%, with Germany, Scandinavia, and the UK showing the strongest adoption rates. North America accounts for 20% of the market, with concentrated growth in California and the Northeast United States.

Key market drivers include increasingly stringent emissions regulations worldwide, substantial government investments in hydrogen infrastructure, and declining production costs as manufacturing scales up. The titanium PTL market benefits particularly from performance advantages in durability and corrosion resistance compared to traditional carbon-based alternatives, justifying their premium pricing in applications where longevity is critical.

Market challenges include high material costs, with titanium commanding a 3-5x price premium over carbon alternatives, and competition from emerging materials such as niobium-doped titanium and titanium-carbon composites that aim to deliver similar performance at lower costs. Supply chain constraints also present challenges, with limited titanium processing capacity creating potential bottlenecks as demand accelerates.

The competitive landscape features specialized materials suppliers like Toray Industries, SGL Carbon, and Freudenberg Group dominating the high-performance PTL segment, while fuel cell manufacturers like Ballard Power Systems and Plug Power are increasingly developing proprietary titanium PTL solutions to optimize their system performance and reduce dependency on external suppliers.

Transportation remains the dominant application sector, accounting for over 40% of titanium PTL demand. This is primarily fueled by the automotive industry's shift toward zero-emission vehicles, with major manufacturers like Toyota, Hyundai, and Honda expanding their fuel cell vehicle production. The heavy-duty transportation segment, including buses and trucks, shows particularly strong growth potential due to the advantages titanium PTLs offer in durability and power density for these demanding applications.

Stationary power generation represents the second-largest market segment at 35%, with significant uptake in backup power systems, remote power installations, and grid support applications. The superior corrosion resistance of titanium-based solutions has proven especially valuable in these settings where system longevity is paramount.

Regional analysis reveals Asia-Pacific as the dominant market, controlling 45% of global titanium PTL demand, led by Japan, South Korea, and increasingly China. Europe follows at 30%, with Germany, Scandinavia, and the UK showing the strongest adoption rates. North America accounts for 20% of the market, with concentrated growth in California and the Northeast United States.

Key market drivers include increasingly stringent emissions regulations worldwide, substantial government investments in hydrogen infrastructure, and declining production costs as manufacturing scales up. The titanium PTL market benefits particularly from performance advantages in durability and corrosion resistance compared to traditional carbon-based alternatives, justifying their premium pricing in applications where longevity is critical.

Market challenges include high material costs, with titanium commanding a 3-5x price premium over carbon alternatives, and competition from emerging materials such as niobium-doped titanium and titanium-carbon composites that aim to deliver similar performance at lower costs. Supply chain constraints also present challenges, with limited titanium processing capacity creating potential bottlenecks as demand accelerates.

The competitive landscape features specialized materials suppliers like Toray Industries, SGL Carbon, and Freudenberg Group dominating the high-performance PTL segment, while fuel cell manufacturers like Ballard Power Systems and Plug Power are increasingly developing proprietary titanium PTL solutions to optimize their system performance and reduce dependency on external suppliers.

Current Challenges in Titanium PTL Corrosion Protection

Titanium-based Porous Transport Layers (PTLs) in Proton Exchange Membrane Fuel Cells (PEMFCs) face significant corrosion challenges that compromise their long-term performance and durability. The primary issue stems from the harsh electrochemical environment within PEMFCs, where titanium materials are exposed to acidic conditions, high potentials, and elevated temperatures. These conditions accelerate corrosion processes, leading to material degradation and subsequent performance losses.

One major challenge is the formation of passive oxide layers on titanium surfaces. While these naturally occurring TiO2 layers initially provide some corrosion resistance, they gradually thicken over time, increasing electrical resistance and reducing the overall efficiency of the fuel cell. This oxide growth is particularly problematic at the critical interfaces where electron transfer occurs, directly impacting cell performance.

The bipolar operating conditions in PEMFCs present another significant challenge. During startup/shutdown cycles and load fluctuations, titanium PTLs experience potential excursions that can destabilize protective layers and accelerate corrosion rates. This cyclic stress creates localized corrosion sites that progressively expand, compromising the structural integrity of the PTL network.

Maintaining proper wicking properties while implementing corrosion protection measures represents a fundamental technical contradiction. Most corrosion-resistant coatings tend to alter the surface energy and pore structure of the PTL, negatively affecting water management capabilities. This trade-off between corrosion resistance and wicking functionality remains largely unresolved in current designs.

The presence of contaminants and impurities in the fuel cell system further complicates corrosion protection efforts. Even trace amounts of certain ions can initiate or accelerate localized corrosion processes through mechanisms such as pitting or crevice corrosion. These degradation modes are particularly difficult to predict and mitigate in the complex microstructure of porous titanium networks.

Current coating technologies face significant limitations in providing uniform protection throughout the three-dimensional PTL structure. Conventional methods like physical vapor deposition or electroplating struggle to penetrate the intricate pore network, resulting in incomplete coverage and vulnerable areas. The few coating methods that do achieve good penetration often compromise the porosity and gas diffusion properties essential for PTL functionality.

Cost-effective manufacturing of corrosion-resistant titanium PTLs at scale remains an industrial challenge. The specialized treatments and coatings that provide adequate protection significantly increase production costs, limiting widespread commercial adoption. This economic barrier has slowed the development and implementation of more durable titanium PTL solutions in commercial PEMFC systems.

One major challenge is the formation of passive oxide layers on titanium surfaces. While these naturally occurring TiO2 layers initially provide some corrosion resistance, they gradually thicken over time, increasing electrical resistance and reducing the overall efficiency of the fuel cell. This oxide growth is particularly problematic at the critical interfaces where electron transfer occurs, directly impacting cell performance.

The bipolar operating conditions in PEMFCs present another significant challenge. During startup/shutdown cycles and load fluctuations, titanium PTLs experience potential excursions that can destabilize protective layers and accelerate corrosion rates. This cyclic stress creates localized corrosion sites that progressively expand, compromising the structural integrity of the PTL network.

Maintaining proper wicking properties while implementing corrosion protection measures represents a fundamental technical contradiction. Most corrosion-resistant coatings tend to alter the surface energy and pore structure of the PTL, negatively affecting water management capabilities. This trade-off between corrosion resistance and wicking functionality remains largely unresolved in current designs.

The presence of contaminants and impurities in the fuel cell system further complicates corrosion protection efforts. Even trace amounts of certain ions can initiate or accelerate localized corrosion processes through mechanisms such as pitting or crevice corrosion. These degradation modes are particularly difficult to predict and mitigate in the complex microstructure of porous titanium networks.

Current coating technologies face significant limitations in providing uniform protection throughout the three-dimensional PTL structure. Conventional methods like physical vapor deposition or electroplating struggle to penetrate the intricate pore network, resulting in incomplete coverage and vulnerable areas. The few coating methods that do achieve good penetration often compromise the porosity and gas diffusion properties essential for PTL functionality.

Cost-effective manufacturing of corrosion-resistant titanium PTLs at scale remains an industrial challenge. The specialized treatments and coatings that provide adequate protection significantly increase production costs, limiting widespread commercial adoption. This economic barrier has slowed the development and implementation of more durable titanium PTL solutions in commercial PEMFC systems.

Current Anti-Corrosion and Wicking Enhancement Techniques

01 Corrosion-resistant coatings for porous transport layers

Various coating materials can be applied to porous transport layers (PTLs) in PEMFCs to enhance corrosion resistance while maintaining necessary porosity. These coatings include carbon-based materials, metal oxides, and polymer composites that form protective barriers against chemical degradation. The coatings are designed to be thin enough to preserve gas diffusion properties while providing effective protection against corrosive environments in fuel cell operation.- Corrosion-resistant coatings for porous transport layers: Various coating materials can be applied to porous transport layers (PTLs) in proton exchange membrane fuel cells (PEMFCs) to enhance corrosion resistance while maintaining porosity. These coatings include carbon-based materials, metal oxides, and polymer composites that form protective barriers against chemical degradation in the harsh fuel cell environment. The coatings are designed to be thin enough to preserve the gas diffusion properties of the PTL while providing effective protection against corrosion.

- Advanced material compositions for PTL durability: Specialized material compositions can significantly improve the durability of porous transport layers in PEMFCs. These include carbon-based materials with enhanced graphitization, metal-doped carbon structures, and composite materials that combine hydrophobic and hydrophilic properties. These advanced materials are engineered to resist electrochemical corrosion while maintaining essential wicking properties for effective water management within the fuel cell system.

- Surface treatment techniques for wicking maintenance: Various surface treatment methods can be applied to porous transport layers to maintain optimal wicking properties while enhancing corrosion resistance. These techniques include plasma treatment, chemical functionalization, and controlled oxidation processes that modify the surface energy of the PTL materials. By carefully balancing hydrophobic and hydrophilic properties, these treatments help maintain efficient water transport while protecting against degradation in the corrosive fuel cell environment.

- Microporous structure optimization for dual functionality: The microporous structure of PTLs can be optimized to simultaneously enhance corrosion resistance and maintain wicking properties. This involves controlling pore size distribution, tortuosity, and interconnectivity through advanced manufacturing techniques. Gradient porosity structures and hierarchical pore networks can be designed to facilitate efficient water management while providing structural stability against corrosive conditions, extending the operational lifetime of the fuel cell system.

- Hybrid PTL systems with functional additives: Hybrid porous transport layer systems incorporate functional additives that enhance both corrosion resistance and wicking maintenance. These additives include hydrophobic agents like PTFE, corrosion inhibitors, and nanomaterials that modify the surface properties of the PTL. The strategic distribution of these additives throughout the PTL structure creates a multifunctional material that can withstand corrosive conditions while maintaining optimal water management capabilities essential for PEMFC performance and durability.

02 Advanced material compositions for PTL durability

Specialized material compositions have been developed for porous transport layers that inherently resist corrosion. These include carbon-based materials with modified surface properties, metal alloys with enhanced stability, and composite structures that combine hydrophobic and hydrophilic components. These materials are engineered to maintain structural integrity and wicking properties under the harsh operating conditions of fuel cells, including exposure to acidic environments and potential cycling.Expand Specific Solutions03 Wicking maintenance through microstructure optimization

The microstructure of porous transport layers can be optimized to maintain wicking properties while enhancing corrosion resistance. This includes controlling pore size distribution, creating gradient porosity structures, and implementing specific surface treatments. These approaches ensure efficient water management within the fuel cell by balancing hydrophobic and hydrophilic properties, preventing both flooding and dry-out conditions that can compromise performance and durability.Expand Specific Solutions04 Hybrid PTL designs with functional layers

Hybrid designs for porous transport layers incorporate multiple functional layers, each serving specific purposes related to corrosion resistance and wicking maintenance. These designs may include a corrosion-resistant base layer, a middle layer optimized for gas diffusion, and a surface layer engineered for water management. The layered approach allows for targeted optimization of different properties without compromising overall performance, resulting in PTLs that maintain functionality over extended operational periods.Expand Specific Solutions05 Treatment processes for enhanced PTL performance

Various treatment processes can be applied to porous transport layers to simultaneously enhance corrosion resistance and maintain wicking properties. These include thermal treatments, chemical surface modifications, plasma processing, and electrochemical treatments. Such processes can alter surface energy, create protective oxide layers, or introduce functional groups that improve durability while preserving the transport properties essential for efficient fuel cell operation.Expand Specific Solutions

Leading Manufacturers and Research Institutions in PEMFC PTL Technology

The PEMFC porous transport layer (PTL) titanium corrosion resistance market is in a growth phase, with increasing adoption in hydrogen fuel cell applications. The market is projected to expand significantly as clean energy transitions accelerate, particularly in automotive and stationary power sectors. Leading automotive manufacturers like Hyundai, Kia, and Audi are investing heavily in this technology, while specialized materials companies such as Toho Titanium, MAGNETO special anodes, and Shanghai Zhizhen New Energy are developing advanced corrosion-resistant solutions. Research institutions including KAIST, CNRS, and Virginia Tech are collaborating with industry players to improve titanium PTL durability and wicking properties. The technology is approaching commercial maturity, with companies like Johnson Matthey Fuel Cells and Solvay Specialty Polymers offering increasingly reliable solutions for long-term PEMFC operation.

Robert Bosch GmbH

Technical Solution: Robert Bosch has engineered an innovative titanium-based porous transport layer (PTL) system for PEMFCs featuring a gradient microstructure design. Their approach utilizes a multi-layer titanium mesh with decreasing pore sizes from the flow field to the catalyst layer, optimizing both mechanical support and mass transport. Bosch's proprietary surface treatment process creates a controlled oxide layer that balances corrosion protection with electrical conductivity. The company has developed a unique hydrophobic-hydrophilic patterning technique that strategically modifies surface properties across the PTL to direct water movement and prevent flooding while maintaining efficient gas diffusion. Their manufacturing process incorporates precision laser perforation and sintering of titanium powders with controlled particle size distribution to achieve the desired porosity and mechanical strength. Bosch's PTLs also feature specialized conductive coatings at the bipolar plate interface to minimize contact resistance while providing additional corrosion protection. The technology includes integrated temperature and humidity sensors within the PTL structure to enable real-time monitoring and adaptive control of water management during operation.

Strengths: Excellent mechanical durability and dimensional stability; sophisticated water management through controlled wettability patterns; integrated sensing capabilities for system optimization. Weaknesses: Complex manufacturing process increases production costs; potential for performance variability across large-scale production; requires precise assembly to maintain designed gradient structures.

GM Global Technology Operations LLC

Technical Solution: GM has developed a comprehensive titanium PTL solution for PEMFCs focused on automotive applications, emphasizing durability and performance under dynamic operating conditions. Their technology employs a titanium fiber-based structure with engineered porosity gradients that optimize reactant distribution while providing robust mechanical support. GM's approach includes a proprietary multi-stage surface treatment process that creates a stable, conductive passivation layer on titanium surfaces, significantly enhancing corrosion resistance without compromising electrical performance. The company has pioneered an advanced wicking structure design that incorporates micro-channels within the titanium matrix, facilitating controlled water transport through capillary action while maintaining gas permeability. Their manufacturing process utilizes high-precision fiber sintering techniques combined with post-processing treatments to optimize surface energy characteristics. GM's PTLs feature specialized interface materials at the catalyst layer boundary that promote efficient proton transport while preventing titanium ion migration into the membrane. The technology also incorporates freeze-thaw resistant features through strategic pore size distribution and hydrophobic/hydrophilic domain engineering, critical for automotive cold-start reliability.

Strengths: Exceptional freeze-thaw cycle durability; optimized for automotive duty cycles with rapid load changes; excellent mass production scalability. Weaknesses: Higher initial material costs compared to traditional carbon-based PTLs; requires specialized manufacturing equipment; performance optimization focused primarily on automotive operating conditions.

Key Patents and Research on Titanium PTL Corrosion Resistance

A method for manufacturing a passive direct methanol fuel cell and a passive direct methanol fuel cell

PatentInactiveEP2774200A1

Innovation

- A method involving the fabrication of a membrane electrode assembly with current collector meshes attached to a proton exchange membrane by ultrasonic welding and catalyst coating applied using screen printing or spraying, optimizing the structure for reduced impedance and enhanced performance.

Carbon Supported Electrodes

PatentPendingUS20250030008A1

Innovation

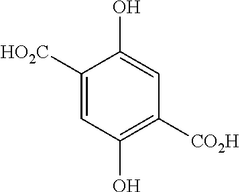

- Incorporating a reversible organic inhibitor within the membrane electrode assembly, specifically in the catalyst layer, microporous layer, or carbon substrate, to act as a sacrificial material that oxidizes preferentially to carbon, thereby mitigating corrosion and membrane degradation.

Environmental Impact and Sustainability of PTL Materials

The environmental impact and sustainability of Porous Transport Layer (PTL) materials in Proton Exchange Membrane Fuel Cells (PEMFCs) represent critical considerations in the broader context of clean energy technologies. Titanium-based PTLs, while offering superior corrosion resistance compared to traditional carbon-based materials, present their own environmental challenges throughout their lifecycle.

The extraction and processing of titanium for PTL manufacturing involves energy-intensive processes that generate significant carbon emissions. Mining operations for titanium ore cause habitat disruption, soil erosion, and potential water contamination. However, when compared to the environmental footprint of conventional energy technologies, the lifetime environmental benefits of titanium PTLs in fuel cells generally outweigh these initial impacts.

Titanium's exceptional durability and corrosion resistance contribute positively to sustainability by extending PEMFC operational lifespans. This longevity reduces replacement frequency and associated material consumption, ultimately decreasing waste generation. Furthermore, titanium's complete recyclability presents opportunities for closed-loop material systems, though current recycling infrastructure for fuel cell components remains underdeveloped.

Water management capabilities of titanium PTLs also contribute to environmental sustainability. Effective wicking properties ensure optimal water distribution within the fuel cell, maximizing efficiency and reducing energy waste. This improved efficiency translates to greater hydrogen utilization and reduced overall environmental impact per unit of energy produced.

Recent innovations in titanium PTL manufacturing have focused on reducing environmental impacts through process optimization. Advanced coating technologies that enhance corrosion resistance and wicking properties often utilize nanomaterials, which raise concerns regarding potential environmental release and unknown ecological effects. Ongoing research aims to develop more environmentally benign coating alternatives that maintain performance characteristics.

Life Cycle Assessment (LCA) studies indicate that while titanium PTLs have higher embodied energy than carbon alternatives, their superior durability and performance characteristics result in lower lifetime environmental impacts. The hydrogen economy's growth depends partly on minimizing these environmental footprints, driving research toward more sustainable PTL materials and manufacturing processes.

Regulatory frameworks increasingly emphasize end-of-life management for fuel cell components. Designing titanium PTLs for easier disassembly and material recovery will become essential as PEMFC deployment scales. Industry initiatives exploring bio-inspired surface treatments may further enhance sustainability by reducing dependence on environmentally problematic chemical processes currently used in titanium PTL production.

The extraction and processing of titanium for PTL manufacturing involves energy-intensive processes that generate significant carbon emissions. Mining operations for titanium ore cause habitat disruption, soil erosion, and potential water contamination. However, when compared to the environmental footprint of conventional energy technologies, the lifetime environmental benefits of titanium PTLs in fuel cells generally outweigh these initial impacts.

Titanium's exceptional durability and corrosion resistance contribute positively to sustainability by extending PEMFC operational lifespans. This longevity reduces replacement frequency and associated material consumption, ultimately decreasing waste generation. Furthermore, titanium's complete recyclability presents opportunities for closed-loop material systems, though current recycling infrastructure for fuel cell components remains underdeveloped.

Water management capabilities of titanium PTLs also contribute to environmental sustainability. Effective wicking properties ensure optimal water distribution within the fuel cell, maximizing efficiency and reducing energy waste. This improved efficiency translates to greater hydrogen utilization and reduced overall environmental impact per unit of energy produced.

Recent innovations in titanium PTL manufacturing have focused on reducing environmental impacts through process optimization. Advanced coating technologies that enhance corrosion resistance and wicking properties often utilize nanomaterials, which raise concerns regarding potential environmental release and unknown ecological effects. Ongoing research aims to develop more environmentally benign coating alternatives that maintain performance characteristics.

Life Cycle Assessment (LCA) studies indicate that while titanium PTLs have higher embodied energy than carbon alternatives, their superior durability and performance characteristics result in lower lifetime environmental impacts. The hydrogen economy's growth depends partly on minimizing these environmental footprints, driving research toward more sustainable PTL materials and manufacturing processes.

Regulatory frameworks increasingly emphasize end-of-life management for fuel cell components. Designing titanium PTLs for easier disassembly and material recovery will become essential as PEMFC deployment scales. Industry initiatives exploring bio-inspired surface treatments may further enhance sustainability by reducing dependence on environmentally problematic chemical processes currently used in titanium PTL production.

Durability Testing Standards and Performance Metrics for PTLs

Durability testing standards for Proton Exchange Membrane Fuel Cell (PEMFC) Porous Transport Layers (PTLs) are critical for evaluating their long-term performance, particularly regarding titanium corrosion resistance and wicking properties. The U.S. Department of Energy (DOE) has established benchmark protocols requiring PTLs to maintain functionality for at least 5,000 hours under automotive applications and 40,000 hours for stationary applications, with less than 10% performance degradation.

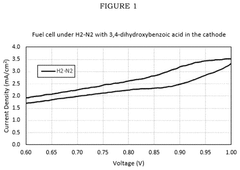

Standard accelerated stress tests (ASTs) for titanium-based PTLs include potential cycling between 0.6-0.95V for 5,000-10,000 cycles, simulating start-stop conditions that accelerate corrosion processes. These tests are typically conducted at elevated temperatures (80-90°C) with high relative humidity (80-100%) to replicate harsh operating environments. The Japanese Automobile Research Institute (JARI) and European Joint Research Centre (JRC) have developed complementary protocols focusing on load cycling and thermal cycling aspects.

Performance metrics for PTL durability assessment encompass multiple parameters. Corrosion resistance is quantified through weight loss measurements (<5% after full testing cycle), surface oxide layer thickness (<100nm after 5,000 hours), and titanium ion leaching rates (<10ppb/hour). Electrochemical impedance spectroscopy (EIS) provides insights into interfacial resistance changes, with acceptable increases limited to 20% over the testing period.

Wicking property retention is evaluated through ex-situ and in-situ methods. Contact angle measurements must remain below 110° throughout the testing period, while capillary pressure characteristics should maintain at least 85% of initial values. Dynamic water breakthrough pressure tests assess the PTL's ability to manage water under varying operational conditions, with breakthrough pressure reduction limited to 15%.

Mechanical integrity metrics include compression set resistance (<20% permanent deformation), interfacial contact resistance stability (<15% increase), and dimensional stability under thermal cycling (±2% maximum dimensional change). Surface morphology changes are monitored using scanning electron microscopy (SEM) and atomic force microscopy (AFM), with roughness factor changes limited to ±30%.

International standardization efforts through organizations like IEC (International Electrotechnical Commission) and ISO (International Organization for Standardization) are working to harmonize these testing protocols. The IEC 62282-8 series specifically addresses component testing methodologies for fuel cells, including PTL materials, while ASTM International provides complementary standards for material characterization under simulated fuel cell conditions.

Standard accelerated stress tests (ASTs) for titanium-based PTLs include potential cycling between 0.6-0.95V for 5,000-10,000 cycles, simulating start-stop conditions that accelerate corrosion processes. These tests are typically conducted at elevated temperatures (80-90°C) with high relative humidity (80-100%) to replicate harsh operating environments. The Japanese Automobile Research Institute (JARI) and European Joint Research Centre (JRC) have developed complementary protocols focusing on load cycling and thermal cycling aspects.

Performance metrics for PTL durability assessment encompass multiple parameters. Corrosion resistance is quantified through weight loss measurements (<5% after full testing cycle), surface oxide layer thickness (<100nm after 5,000 hours), and titanium ion leaching rates (<10ppb/hour). Electrochemical impedance spectroscopy (EIS) provides insights into interfacial resistance changes, with acceptable increases limited to 20% over the testing period.

Wicking property retention is evaluated through ex-situ and in-situ methods. Contact angle measurements must remain below 110° throughout the testing period, while capillary pressure characteristics should maintain at least 85% of initial values. Dynamic water breakthrough pressure tests assess the PTL's ability to manage water under varying operational conditions, with breakthrough pressure reduction limited to 15%.

Mechanical integrity metrics include compression set resistance (<20% permanent deformation), interfacial contact resistance stability (<15% increase), and dimensional stability under thermal cycling (±2% maximum dimensional change). Surface morphology changes are monitored using scanning electron microscopy (SEM) and atomic force microscopy (AFM), with roughness factor changes limited to ±30%.

International standardization efforts through organizations like IEC (International Electrotechnical Commission) and ISO (International Organization for Standardization) are working to harmonize these testing protocols. The IEC 62282-8 series specifically addresses component testing methodologies for fuel cells, including PTL materials, while ASTM International provides complementary standards for material characterization under simulated fuel cell conditions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!