PEMFC Differential Pressure Operation: Safety, Crossover And Venting

SEP 15, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PEMFC Differential Pressure Background and Objectives

Proton Exchange Membrane Fuel Cells (PEMFCs) have emerged as a promising clean energy technology over the past several decades, with significant advancements in efficiency, durability, and cost reduction. The concept of differential pressure operation in PEMFCs represents a critical aspect of fuel cell system design and operation that impacts overall performance, safety, and longevity of these energy conversion devices.

Differential pressure operation refers to the intentional maintenance of pressure differences between the anode and cathode compartments of a PEMFC. Historically, fuel cell systems were designed to operate with balanced pressures to minimize mechanical stress on the membrane electrode assembly (MEA). However, research has demonstrated that controlled differential pressure can offer substantial benefits in certain applications, particularly in automotive and stationary power generation contexts.

The evolution of PEMFC technology has seen a shift from early laboratory demonstrations to commercial deployment across various sectors. Within this progression, pressure management strategies have become increasingly sophisticated, moving from simple balanced pressure systems to advanced differential pressure control mechanisms that adapt to varying load conditions and environmental factors.

The primary objective of investigating differential pressure operation is to optimize the delicate balance between performance enhancement and system safety. Specifically, positive differential pressure (where anode pressure exceeds cathode pressure) can reduce oxygen crossover, thereby minimizing chemical degradation of the membrane and catalyst layers. Conversely, negative differential pressure can improve water management and reduce flooding issues at the cathode.

However, these benefits come with significant challenges related to safety, gas crossover phenomena, and venting requirements. Excessive differential pressure can lead to mechanical failure of the membrane, while insufficient pressure control may result in reactant starvation or undesired crossover effects. Understanding these trade-offs is essential for advancing PEMFC technology toward wider commercial adoption.

This technical research aims to comprehensively examine the fundamental principles, current practices, and future directions of differential pressure operation in PEMFCs. By analyzing the interplay between safety considerations, crossover phenomena, and venting strategies, we seek to identify optimal operational parameters and system design approaches that maximize performance while ensuring reliable and safe operation across diverse applications and operating conditions.

The technological trajectory suggests that advanced pressure control strategies will play an increasingly important role in next-generation fuel cell systems, particularly as the industry moves toward higher power densities, extended durability requirements, and more demanding operational profiles in transportation and energy storage applications.

Differential pressure operation refers to the intentional maintenance of pressure differences between the anode and cathode compartments of a PEMFC. Historically, fuel cell systems were designed to operate with balanced pressures to minimize mechanical stress on the membrane electrode assembly (MEA). However, research has demonstrated that controlled differential pressure can offer substantial benefits in certain applications, particularly in automotive and stationary power generation contexts.

The evolution of PEMFC technology has seen a shift from early laboratory demonstrations to commercial deployment across various sectors. Within this progression, pressure management strategies have become increasingly sophisticated, moving from simple balanced pressure systems to advanced differential pressure control mechanisms that adapt to varying load conditions and environmental factors.

The primary objective of investigating differential pressure operation is to optimize the delicate balance between performance enhancement and system safety. Specifically, positive differential pressure (where anode pressure exceeds cathode pressure) can reduce oxygen crossover, thereby minimizing chemical degradation of the membrane and catalyst layers. Conversely, negative differential pressure can improve water management and reduce flooding issues at the cathode.

However, these benefits come with significant challenges related to safety, gas crossover phenomena, and venting requirements. Excessive differential pressure can lead to mechanical failure of the membrane, while insufficient pressure control may result in reactant starvation or undesired crossover effects. Understanding these trade-offs is essential for advancing PEMFC technology toward wider commercial adoption.

This technical research aims to comprehensively examine the fundamental principles, current practices, and future directions of differential pressure operation in PEMFCs. By analyzing the interplay between safety considerations, crossover phenomena, and venting strategies, we seek to identify optimal operational parameters and system design approaches that maximize performance while ensuring reliable and safe operation across diverse applications and operating conditions.

The technological trajectory suggests that advanced pressure control strategies will play an increasingly important role in next-generation fuel cell systems, particularly as the industry moves toward higher power densities, extended durability requirements, and more demanding operational profiles in transportation and energy storage applications.

Market Analysis for PEMFC Differential Pressure Applications

The global market for Proton Exchange Membrane Fuel Cells (PEMFC) operating under differential pressure conditions is experiencing significant growth, driven by increasing demand for clean energy solutions across various sectors. The differential pressure operation, which involves maintaining different pressures on the anode and cathode sides, represents a critical aspect of PEMFC technology with substantial market implications.

The automotive sector currently dominates the PEMFC differential pressure applications market, accounting for approximately 45% of the total market share. Major automotive manufacturers have invested heavily in fuel cell electric vehicles (FCEVs) that utilize differential pressure operation to optimize performance and efficiency. Toyota, Hyundai, and Honda lead this segment with commercial FCEV models already in production.

Heavy-duty transportation represents another rapidly expanding market segment, with an annual growth rate exceeding 25%. Bus and truck manufacturers are increasingly adopting PEMFC technology with differential pressure operation to meet stringent emission regulations while maintaining operational requirements for range and refueling time.

Stationary power generation applications constitute about 30% of the current market, with significant growth potential in backup power systems, distributed generation, and combined heat and power (CHP) systems. The ability of differential pressure PEMFCs to provide reliable power with minimal environmental impact makes them particularly attractive for critical infrastructure applications.

Material handling equipment, particularly forklifts and warehouse vehicles, represents a mature market segment where differential pressure PEMFC technology has already achieved commercial success. This segment benefits from the quick refueling capabilities and consistent power output that differential pressure operation provides.

Regionally, Asia Pacific leads the market with Japan, South Korea, and China implementing aggressive hydrogen strategies and substantial investments in fuel cell technology. Europe follows closely, driven by strong regulatory support for decarbonization and significant investments in hydrogen infrastructure. North America represents the third-largest market, with growing adoption in California and other states with zero-emission vehicle mandates.

The market for components specifically designed for differential pressure operation, including pressure regulators, sensors, and safety systems, is projected to grow at a compound annual rate of 22% through 2030. This specialized component market is currently dominated by established industrial gas equipment manufacturers who have adapted their technologies for fuel cell applications.

Emerging applications in portable power, marine propulsion, and aerospace are expected to create new market opportunities for differential pressure PEMFC technology, particularly as safety concerns are addressed through improved venting systems and crossover prevention mechanisms.

The automotive sector currently dominates the PEMFC differential pressure applications market, accounting for approximately 45% of the total market share. Major automotive manufacturers have invested heavily in fuel cell electric vehicles (FCEVs) that utilize differential pressure operation to optimize performance and efficiency. Toyota, Hyundai, and Honda lead this segment with commercial FCEV models already in production.

Heavy-duty transportation represents another rapidly expanding market segment, with an annual growth rate exceeding 25%. Bus and truck manufacturers are increasingly adopting PEMFC technology with differential pressure operation to meet stringent emission regulations while maintaining operational requirements for range and refueling time.

Stationary power generation applications constitute about 30% of the current market, with significant growth potential in backup power systems, distributed generation, and combined heat and power (CHP) systems. The ability of differential pressure PEMFCs to provide reliable power with minimal environmental impact makes them particularly attractive for critical infrastructure applications.

Material handling equipment, particularly forklifts and warehouse vehicles, represents a mature market segment where differential pressure PEMFC technology has already achieved commercial success. This segment benefits from the quick refueling capabilities and consistent power output that differential pressure operation provides.

Regionally, Asia Pacific leads the market with Japan, South Korea, and China implementing aggressive hydrogen strategies and substantial investments in fuel cell technology. Europe follows closely, driven by strong regulatory support for decarbonization and significant investments in hydrogen infrastructure. North America represents the third-largest market, with growing adoption in California and other states with zero-emission vehicle mandates.

The market for components specifically designed for differential pressure operation, including pressure regulators, sensors, and safety systems, is projected to grow at a compound annual rate of 22% through 2030. This specialized component market is currently dominated by established industrial gas equipment manufacturers who have adapted their technologies for fuel cell applications.

Emerging applications in portable power, marine propulsion, and aerospace are expected to create new market opportunities for differential pressure PEMFC technology, particularly as safety concerns are addressed through improved venting systems and crossover prevention mechanisms.

Current Challenges in PEMFC Differential Pressure Management

The management of differential pressure in Proton Exchange Membrane Fuel Cells (PEMFCs) presents significant technical challenges that impact system performance, durability, and safety. Current differential pressure control systems struggle with maintaining optimal pressure gradients across the membrane under varying operational conditions. When anode pressure exceeds cathode pressure beyond critical thresholds, mechanical stress on the membrane increases substantially, potentially leading to irreversible physical damage and premature system failure.

Gas crossover represents another major challenge in differential pressure management. Hydrogen permeation from anode to cathode increases proportionally with differential pressure, creating safety hazards and reducing fuel efficiency. Studies indicate that for every 100 mbar increase in differential pressure, hydrogen crossover rates can increase by 10-15%, significantly impacting long-term operational economics. This crossover phenomenon accelerates membrane degradation through radical formation mechanisms, particularly at the cathode where crossed-over hydrogen reacts with oxygen.

Venting systems, critical for pressure regulation, face reliability issues under real-world conditions. Current automatic purge valves demonstrate inconsistent performance during rapid load changes, with response times often exceeding 500 milliseconds—too slow for preventing dangerous pressure spikes. Additionally, these systems struggle with water accumulation, which can obstruct venting pathways and compromise pressure relief functionality.

Sensor technology limitations further complicate differential pressure management. Available pressure sensors exhibit drift characteristics over time, with accuracy degradation of approximately 2-5% annually under typical PEMFC operating conditions. This degradation necessitates frequent recalibration or replacement, increasing maintenance costs and system downtime.

Temperature fluctuations introduce additional complexity, as they significantly affect gas permeability across the membrane. Current control algorithms inadequately account for the non-linear relationship between temperature and differential pressure behavior, particularly during cold-start conditions or rapid thermal cycling.

Material limitations also present substantial challenges. State-of-the-art membrane materials show accelerated degradation under sustained differential pressure conditions. Research indicates that operating at differential pressures exceeding 300 mbar can reduce membrane lifespan by up to 40% compared to balanced pressure operation. This degradation is particularly pronounced in automotive applications where frequent load changes create dynamic pressure conditions.

Integration of differential pressure management with other subsystems remains problematic. Current control architectures struggle to harmonize pressure management with thermal management and water balance requirements, often resulting in competing operational priorities that compromise overall system efficiency and stability.

Gas crossover represents another major challenge in differential pressure management. Hydrogen permeation from anode to cathode increases proportionally with differential pressure, creating safety hazards and reducing fuel efficiency. Studies indicate that for every 100 mbar increase in differential pressure, hydrogen crossover rates can increase by 10-15%, significantly impacting long-term operational economics. This crossover phenomenon accelerates membrane degradation through radical formation mechanisms, particularly at the cathode where crossed-over hydrogen reacts with oxygen.

Venting systems, critical for pressure regulation, face reliability issues under real-world conditions. Current automatic purge valves demonstrate inconsistent performance during rapid load changes, with response times often exceeding 500 milliseconds—too slow for preventing dangerous pressure spikes. Additionally, these systems struggle with water accumulation, which can obstruct venting pathways and compromise pressure relief functionality.

Sensor technology limitations further complicate differential pressure management. Available pressure sensors exhibit drift characteristics over time, with accuracy degradation of approximately 2-5% annually under typical PEMFC operating conditions. This degradation necessitates frequent recalibration or replacement, increasing maintenance costs and system downtime.

Temperature fluctuations introduce additional complexity, as they significantly affect gas permeability across the membrane. Current control algorithms inadequately account for the non-linear relationship between temperature and differential pressure behavior, particularly during cold-start conditions or rapid thermal cycling.

Material limitations also present substantial challenges. State-of-the-art membrane materials show accelerated degradation under sustained differential pressure conditions. Research indicates that operating at differential pressures exceeding 300 mbar can reduce membrane lifespan by up to 40% compared to balanced pressure operation. This degradation is particularly pronounced in automotive applications where frequent load changes create dynamic pressure conditions.

Integration of differential pressure management with other subsystems remains problematic. Current control architectures struggle to harmonize pressure management with thermal management and water balance requirements, often resulting in competing operational priorities that compromise overall system efficiency and stability.

Existing Solutions for PEMFC Differential Pressure Operation

01 Differential pressure control systems in PEMFC

Control systems that manage differential pressure between the anode and cathode in proton exchange membrane fuel cells are essential for optimal performance and durability. These systems typically include pressure sensors, controllers, and actuators that work together to maintain appropriate pressure differentials across the membrane. Proper differential pressure control prevents membrane damage, reduces gas crossover, and improves overall system efficiency.- Differential pressure control systems in PEMFC: Control systems for managing differential pressure in proton exchange membrane fuel cells are essential for optimal performance. These systems monitor and adjust pressure differences between the anode and cathode to prevent membrane damage and ensure efficient operation. Advanced control algorithms and feedback mechanisms help maintain appropriate pressure levels during various operating conditions, including startup, shutdown, and load changes.

- Pressure monitoring and sensing technologies: Various sensing technologies are employed to accurately measure differential pressure in PEMFCs. These include pressure transducers, differential pressure sensors, and integrated monitoring systems that provide real-time data on pressure conditions across the membrane. Advanced sensors can detect subtle pressure changes and trigger appropriate responses to maintain optimal operating conditions, preventing membrane degradation and improving overall system reliability.

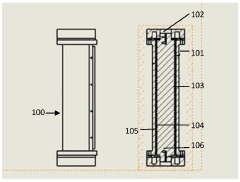

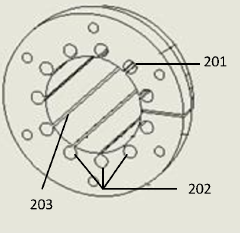

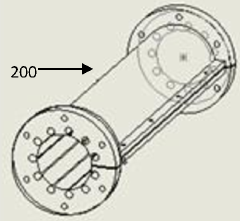

- Membrane design for pressure management: Specialized membrane designs help manage differential pressure challenges in PEMFCs. These membranes incorporate structural features that enhance mechanical stability under varying pressure conditions. Reinforced membranes with improved mechanical properties can withstand higher differential pressures without deformation or damage. Some designs include composite structures with support layers that distribute pressure more evenly across the membrane surface.

- Flow field and channel designs for pressure distribution: Innovative flow field and channel designs help optimize pressure distribution across the fuel cell membrane. These designs include serpentine channels, interdigitated flow fields, and parallel channel configurations that minimize pressure drops while ensuring uniform reactant distribution. Properly designed flow fields can reduce pressure gradients, prevent localized pressure points, and improve overall cell performance by enhancing mass transport and water management.

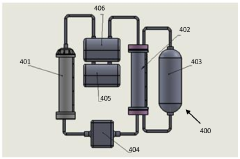

- System integration and balance of plant components: Balance of plant components play a crucial role in managing differential pressure in PEMFC systems. These include pressure regulators, blowers, compressors, and valves that work together to maintain appropriate pressure levels throughout the system. Integrated approaches consider the entire fuel cell system, including humidification systems, reactant supply, and exhaust management, to ensure optimal pressure conditions across all operating modes and prevent pressure-related failures.

02 Pressure monitoring and measurement techniques

Various techniques and devices are employed to monitor and measure differential pressure in PEMFCs. These include specialized pressure sensors, transducers, and monitoring systems that provide real-time data on pressure conditions across the membrane. Advanced monitoring techniques help detect potential issues early, allowing for preventive maintenance and optimization of operating conditions to extend fuel cell life and maintain performance.Expand Specific Solutions03 Differential pressure management during startup and shutdown

Managing differential pressure during transient operations such as startup and shutdown is critical for PEMFC durability. Specialized control strategies and hardware components are implemented to prevent excessive pressure differentials that could damage the membrane during these phases. These systems often include purge valves, bypass channels, and dedicated control algorithms that ensure safe pressure transitions when the fuel cell is not in steady-state operation.Expand Specific Solutions04 Structural design for pressure distribution

The physical design and structure of fuel cell components significantly impact differential pressure distribution. Innovations in flow field designs, membrane support structures, and gasket configurations help achieve more uniform pressure distribution across the active area. These structural improvements minimize localized pressure points that could lead to membrane degradation while optimizing reactant distribution for improved performance and efficiency.Expand Specific Solutions05 Pressure regulation for water management

Differential pressure regulation plays a crucial role in water management within PEMFCs. By controlling the pressure differential between anode and cathode, water transport across the membrane can be optimized to prevent both flooding and drying out. Advanced pressure regulation systems incorporate humidity sensors and adaptive control algorithms that adjust pressure differentials based on operating conditions to maintain optimal membrane hydration levels.Expand Specific Solutions

Leading Companies in PEMFC Technology and Pressure Management

The PEMFC differential pressure operation market is currently in a growth phase, with increasing adoption across automotive, stationary power, and industrial applications. The market size is expanding rapidly, projected to reach significant value as hydrogen technologies gain traction globally. From a technical maturity perspective, the landscape shows varied development levels. Industry leaders like Zhejiang University and Industrial Technology Research Institute are advancing fundamental research, while established corporations including Panasonic Holdings, Lam Research, and PetroChina are commercializing solutions addressing safety concerns, crossover mitigation, and venting systems. Companies like Furukawa Battery and Baker Hughes Pressure Control LP contribute specialized pressure management expertise. The competitive environment features collaboration between academic institutions and industrial players, with increasing focus on improving reliability and safety parameters for widespread PEMFC adoption.

Zhejiang University

Technical Solution: Zhejiang University has developed a comprehensive research program on PEMFC differential pressure operation focusing on fundamental mechanisms and practical applications. Their approach combines theoretical modeling with experimental validation to optimize pressure differentials for various operating conditions. The university's research team has created advanced computational fluid dynamics models that accurately predict crossover phenomena under different pressure scenarios, enabling precise pressure management strategies. Their technology incorporates a novel membrane support structure that enhances mechanical stability under higher differential pressures, allowing for more aggressive pressure optimization without compromising safety. Zhejiang University researchers have demonstrated that controlled cathode overpressure of 0.2-0.3 bar can reduce hydrogen crossover by up to 45% while maintaining membrane integrity. Their venting system design incorporates passive pressure regulation elements that respond to pressure differentials without requiring active control, enhancing reliability in remote or resource-constrained applications. The university has also developed specialized testing protocols for evaluating membrane durability under various differential pressure conditions, contributing valuable data to the field regarding long-term reliability considerations.

Strengths: Strong theoretical foundation with comprehensive modeling capabilities; innovative membrane support structures enhancing mechanical stability; passive pressure regulation systems reducing control complexity. Weaknesses: Some technologies still in research phase rather than commercial deployment; passive systems may have slower response to rapid transients; limited large-scale validation compared to commercial entities.

Furukawa Battery Co., Ltd.

Technical Solution: Furukawa Battery has developed a specialized differential pressure control system for PEMFCs that focuses on safety and reliability in automotive and industrial applications. Their approach centers on a dynamic pressure regulation system that continuously adjusts the pressure differential between anode and cathode based on operating conditions. The technology incorporates high-precision pressure transducers with response times under 10 milliseconds, enabling rapid detection of pressure anomalies. Furukawa's system employs a dual-path venting architecture that separates normal operational venting from emergency pressure relief, enhancing both efficiency and safety. Their research has shown that maintaining precise differential pressures can extend membrane life by up to 30% while reducing crossover-related efficiency losses. The system includes adaptive algorithms that learn from operating patterns to optimize pressure differentials for specific use cases, whether prioritizing efficiency, power density, or longevity. Additionally, Furukawa has developed specialized membrane formulations that can withstand higher differential pressures without compromising gas permeation properties, allowing for more aggressive pressure optimization strategies.

Strengths: Highly responsive pressure control system with automotive-grade reliability; dual-path venting architecture enhancing safety; adaptive control algorithms for application-specific optimization. Weaknesses: Higher system complexity requiring more components than conventional approaches; potential challenges in miniaturization for space-constrained applications; higher initial cost compared to simpler pressure management systems.

Critical Patents in PEMFC Pressure Safety and Crossover Prevention

Proton exchange membrane fuel cell

PatentInactiveIN202041009757A

Innovation

- A cylindrical fuel cell design with a single-layer Membrane Electrode Assembly (MEA) surrounding a blade screw, eliminating bipolar and compression plates, and incorporating hydrophobic chambers for efficient proton transfer and water management, along with sensors and actuators for automation and temperature control.

A method for manufacturing a passive direct methanol fuel cell and a passive direct methanol fuel cell

PatentInactiveEP2774200A1

Innovation

- A method involving the fabrication of a membrane electrode assembly with current collector meshes attached to a proton exchange membrane by ultrasonic welding and catalyst coating applied using screen printing or spraying, optimizing the structure for reduced impedance and enhanced performance.

Safety Standards and Certification Requirements for PEMFC Systems

The safety standards and certification requirements for PEMFC systems have evolved significantly to address the unique challenges posed by differential pressure operation. International standards such as ISO 22734 (Hydrogen generators using water electrolysis), IEC 62282 (Fuel cell technologies), and SAE J2578 (Recommended practice for general fuel cell vehicle safety) establish comprehensive frameworks for ensuring operational safety in PEMFC systems.

These standards specifically address differential pressure management, recognizing its critical role in preventing membrane damage and dangerous gas crossover situations. For instance, ISO 22734 mandates specific pressure monitoring and control systems that can detect abnormal pressure differentials and trigger appropriate safety responses. Similarly, IEC 62282-3-100 outlines safety provisions for stationary fuel cell power systems, including requirements for pressure relief devices and venting systems.

Certification processes typically require manufacturers to demonstrate compliance through rigorous testing protocols. These include pressure cycling tests, where systems must maintain integrity under repeated pressure fluctuations, and fault condition simulations to verify appropriate system responses to pressure anomalies. Notably, certification bodies like UL (Underwriters Laboratories) in North America and TÜV in Europe have developed specialized testing procedures for PEMFC systems that evaluate differential pressure management capabilities.

Regional variations in safety requirements present significant challenges for global manufacturers. For example, European regulations under the ATEX Directive impose additional requirements for explosion protection that directly impact differential pressure management strategies. Meanwhile, North American standards emphasize different aspects of safety, such as more stringent venting requirements for indoor installations.

Recent regulatory developments have increasingly focused on the integration of advanced monitoring systems. Modern safety standards now often require real-time differential pressure monitoring with automated shutdown capabilities when pressure differentials exceed safe thresholds. This trend reflects growing recognition of the relationship between pressure management and overall system safety.

For PEMFC applications in transportation, additional standards apply. UN GTR No. 13 (Global Technical Regulation for hydrogen and fuel cell vehicles) includes specific provisions for pressure management in automotive fuel cell systems, addressing the unique challenges of mobile applications where rapid pressure changes may occur during operation.

Compliance with these evolving standards requires manufacturers to implement sophisticated pressure control architectures, redundant safety systems, and comprehensive testing regimes throughout the product development lifecycle. The certification landscape continues to evolve as the technology matures and deployment expands across diverse applications.

These standards specifically address differential pressure management, recognizing its critical role in preventing membrane damage and dangerous gas crossover situations. For instance, ISO 22734 mandates specific pressure monitoring and control systems that can detect abnormal pressure differentials and trigger appropriate safety responses. Similarly, IEC 62282-3-100 outlines safety provisions for stationary fuel cell power systems, including requirements for pressure relief devices and venting systems.

Certification processes typically require manufacturers to demonstrate compliance through rigorous testing protocols. These include pressure cycling tests, where systems must maintain integrity under repeated pressure fluctuations, and fault condition simulations to verify appropriate system responses to pressure anomalies. Notably, certification bodies like UL (Underwriters Laboratories) in North America and TÜV in Europe have developed specialized testing procedures for PEMFC systems that evaluate differential pressure management capabilities.

Regional variations in safety requirements present significant challenges for global manufacturers. For example, European regulations under the ATEX Directive impose additional requirements for explosion protection that directly impact differential pressure management strategies. Meanwhile, North American standards emphasize different aspects of safety, such as more stringent venting requirements for indoor installations.

Recent regulatory developments have increasingly focused on the integration of advanced monitoring systems. Modern safety standards now often require real-time differential pressure monitoring with automated shutdown capabilities when pressure differentials exceed safe thresholds. This trend reflects growing recognition of the relationship between pressure management and overall system safety.

For PEMFC applications in transportation, additional standards apply. UN GTR No. 13 (Global Technical Regulation for hydrogen and fuel cell vehicles) includes specific provisions for pressure management in automotive fuel cell systems, addressing the unique challenges of mobile applications where rapid pressure changes may occur during operation.

Compliance with these evolving standards requires manufacturers to implement sophisticated pressure control architectures, redundant safety systems, and comprehensive testing regimes throughout the product development lifecycle. The certification landscape continues to evolve as the technology matures and deployment expands across diverse applications.

Environmental Impact and Sustainability of PEMFC Venting Strategies

The environmental implications of PEMFC venting strategies represent a critical consideration in the broader adoption of fuel cell technologies. When hydrogen and oxygen crossover occurs during differential pressure operation, the subsequent venting releases these gases into the atmosphere. While hydrogen itself is not a direct pollutant, its indirect effects as a greenhouse gas through atmospheric interactions cannot be overlooked. Current research indicates that hydrogen has a Global Warming Potential (GWP) significantly lower than carbon dioxide, but its atmospheric lifetime and interaction with other gases warrant careful monitoring.

Venting strategies must balance operational safety with environmental responsibility. Traditional venting approaches that simply release gases to the atmosphere contribute to resource inefficiency and potential environmental impact. The sustainability challenge lies in developing closed-loop systems that can capture, purify, and recycle vented gases, particularly hydrogen, which represents both an energy carrier and a valuable resource.

Advanced PEMFC systems are increasingly incorporating hydrogen recovery systems that can capture vented hydrogen for reuse, significantly reducing the environmental footprint of differential pressure operations. These recovery technologies typically employ pressure swing adsorption or membrane separation techniques to isolate hydrogen from other vented components. The energy requirements for such recovery systems must be factored into the overall efficiency calculations of the fuel cell system.

Life cycle assessment (LCA) studies of PEMFC systems with various venting strategies reveal that environmentally optimized venting can reduce the carbon footprint by 15-20% compared to conventional approaches. This improvement stems primarily from reduced hydrogen losses and decreased need for hydrogen production, which itself carries significant environmental impacts depending on the production method employed.

Water management in venting systems presents another environmental consideration. Water vapor released during venting represents both a resource loss and a potential local environmental factor. In cold climates, this can contribute to icing issues, while in all environments it represents a loss of water that must be replenished in the system.

Regulatory frameworks are evolving to address the environmental aspects of fuel cell venting. The European Union's hydrogen strategy specifically addresses venting practices, while California's Air Resources Board has implemented guidelines for hydrogen emissions from fuel cell vehicles. These regulations increasingly push manufacturers toward closed-loop systems that minimize or eliminate venting to the atmosphere.

Future sustainable venting strategies will likely incorporate smart predictive systems that can anticipate crossover events before they occur, thereby reducing the need for emergency venting and its associated environmental impacts. Such systems would represent a significant advancement in both the operational efficiency and environmental performance of PEMFC technology.

Venting strategies must balance operational safety with environmental responsibility. Traditional venting approaches that simply release gases to the atmosphere contribute to resource inefficiency and potential environmental impact. The sustainability challenge lies in developing closed-loop systems that can capture, purify, and recycle vented gases, particularly hydrogen, which represents both an energy carrier and a valuable resource.

Advanced PEMFC systems are increasingly incorporating hydrogen recovery systems that can capture vented hydrogen for reuse, significantly reducing the environmental footprint of differential pressure operations. These recovery technologies typically employ pressure swing adsorption or membrane separation techniques to isolate hydrogen from other vented components. The energy requirements for such recovery systems must be factored into the overall efficiency calculations of the fuel cell system.

Life cycle assessment (LCA) studies of PEMFC systems with various venting strategies reveal that environmentally optimized venting can reduce the carbon footprint by 15-20% compared to conventional approaches. This improvement stems primarily from reduced hydrogen losses and decreased need for hydrogen production, which itself carries significant environmental impacts depending on the production method employed.

Water management in venting systems presents another environmental consideration. Water vapor released during venting represents both a resource loss and a potential local environmental factor. In cold climates, this can contribute to icing issues, while in all environments it represents a loss of water that must be replenished in the system.

Regulatory frameworks are evolving to address the environmental aspects of fuel cell venting. The European Union's hydrogen strategy specifically addresses venting practices, while California's Air Resources Board has implemented guidelines for hydrogen emissions from fuel cell vehicles. These regulations increasingly push manufacturers toward closed-loop systems that minimize or eliminate venting to the atmosphere.

Future sustainable venting strategies will likely incorporate smart predictive systems that can anticipate crossover events before they occur, thereby reducing the need for emergency venting and its associated environmental impacts. Such systems would represent a significant advancement in both the operational efficiency and environmental performance of PEMFC technology.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!