PEMFC System Controls: Transients, Load-Following And Degradation Minimization

SEP 15, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PEMFC Technology Evolution and Control Objectives

Proton Exchange Membrane Fuel Cells (PEMFCs) have evolved significantly since their inception in the early 1960s at General Electric. Initially developed for NASA's Gemini space program, these fuel cells have undergone substantial technological advancements over the decades. The evolution trajectory has moved from basic proof-of-concept designs with limited power density and durability to today's sophisticated systems capable of powering vehicles, stationary power units, and portable devices with increasing efficiency and reliability.

The technological progression of PEMFCs has been marked by several key milestones. In the 1980s and 1990s, breakthroughs in membrane technology, particularly the development of Nafion by DuPont, significantly enhanced proton conductivity and operational stability. The early 2000s witnessed substantial improvements in catalyst utilization, reducing platinum loading while maintaining performance, thereby addressing cost constraints that had previously limited commercial viability.

Control systems for PEMFCs have similarly evolved from rudimentary open-loop configurations to sophisticated closed-loop systems incorporating advanced sensors, predictive algorithms, and real-time optimization strategies. This evolution has been driven by the increasing demands for fuel cell systems to operate reliably under dynamic conditions, particularly in automotive applications where load profiles can change rapidly and unpredictably.

The primary control objectives for modern PEMFC systems center around three critical aspects: managing transient responses, enabling effective load-following capabilities, and minimizing degradation mechanisms. Transient management involves controlling the rapid changes in operating conditions that can occur during startup, shutdown, and sudden load variations. These transitions can induce mechanical and thermal stresses that accelerate component degradation if not properly managed.

Load-following capability refers to the system's ability to adjust power output in response to changing demand profiles. This is particularly challenging for fuel cells due to the complex interplay between hydrogen supply, air delivery, water management, and thermal control subsystems. Advanced control strategies must orchestrate these subsystems harmoniously to maintain optimal operating conditions across varying power demands.

Degradation minimization has emerged as perhaps the most crucial control objective as the industry pushes toward the Department of Energy's 2030 durability targets of 8,000 hours for light-duty vehicles and 30,000 hours for heavy-duty applications. Control systems must now incorporate degradation models and mitigation strategies to extend operational lifetimes by avoiding conditions known to accelerate membrane, catalyst, and gas diffusion layer deterioration.

The technological trajectory points toward increasingly integrated control architectures that leverage artificial intelligence, model predictive control, and real-time diagnostics to balance performance, efficiency, and longevity. These advanced control paradigms represent the frontier of PEMFC technology development and will be instrumental in achieving widespread commercial adoption across diverse application domains.

The technological progression of PEMFCs has been marked by several key milestones. In the 1980s and 1990s, breakthroughs in membrane technology, particularly the development of Nafion by DuPont, significantly enhanced proton conductivity and operational stability. The early 2000s witnessed substantial improvements in catalyst utilization, reducing platinum loading while maintaining performance, thereby addressing cost constraints that had previously limited commercial viability.

Control systems for PEMFCs have similarly evolved from rudimentary open-loop configurations to sophisticated closed-loop systems incorporating advanced sensors, predictive algorithms, and real-time optimization strategies. This evolution has been driven by the increasing demands for fuel cell systems to operate reliably under dynamic conditions, particularly in automotive applications where load profiles can change rapidly and unpredictably.

The primary control objectives for modern PEMFC systems center around three critical aspects: managing transient responses, enabling effective load-following capabilities, and minimizing degradation mechanisms. Transient management involves controlling the rapid changes in operating conditions that can occur during startup, shutdown, and sudden load variations. These transitions can induce mechanical and thermal stresses that accelerate component degradation if not properly managed.

Load-following capability refers to the system's ability to adjust power output in response to changing demand profiles. This is particularly challenging for fuel cells due to the complex interplay between hydrogen supply, air delivery, water management, and thermal control subsystems. Advanced control strategies must orchestrate these subsystems harmoniously to maintain optimal operating conditions across varying power demands.

Degradation minimization has emerged as perhaps the most crucial control objective as the industry pushes toward the Department of Energy's 2030 durability targets of 8,000 hours for light-duty vehicles and 30,000 hours for heavy-duty applications. Control systems must now incorporate degradation models and mitigation strategies to extend operational lifetimes by avoiding conditions known to accelerate membrane, catalyst, and gas diffusion layer deterioration.

The technological trajectory points toward increasingly integrated control architectures that leverage artificial intelligence, model predictive control, and real-time diagnostics to balance performance, efficiency, and longevity. These advanced control paradigms represent the frontier of PEMFC technology development and will be instrumental in achieving widespread commercial adoption across diverse application domains.

Market Analysis for PEMFC Control Systems

The global market for Proton Exchange Membrane Fuel Cell (PEMFC) control systems is experiencing significant growth, driven by increasing adoption of hydrogen fuel cell technology across multiple sectors. The market size for PEMFC control systems was valued at approximately $2.3 billion in 2022 and is projected to reach $7.8 billion by 2030, representing a compound annual growth rate (CAGR) of 16.5% during the forecast period.

Transportation remains the dominant application segment, accounting for over 45% of the market share. This is primarily due to the accelerating deployment of fuel cell vehicles (FCVs) in commercial fleets, public transportation, and increasingly in passenger vehicles. Major automotive manufacturers including Toyota, Hyundai, and Honda have made substantial investments in PEMFC technology, with particular emphasis on advanced control systems to optimize performance and durability.

The stationary power generation sector represents the second-largest market segment at approximately 30% market share, with applications in backup power systems, distributed generation, and combined heat and power (CHP) systems. This segment is expected to grow at a CAGR of 18.2% through 2030, outpacing the overall market growth rate.

Regionally, Asia Pacific dominates the market with approximately 42% share, led by Japan, South Korea, and China. These countries have implemented supportive government policies and substantial investments in hydrogen infrastructure. North America and Europe follow with 28% and 25% market shares respectively, with both regions showing accelerated adoption rates driven by stringent emission regulations and renewable energy initiatives.

Key market drivers include increasing focus on decarbonization across industries, government subsidies and incentives for clean energy technologies, and declining costs of fuel cell systems. The specific demand for advanced control systems that can effectively manage transients, enable precise load-following, and minimize degradation is growing at a faster rate than the overall PEMFC market, highlighting the critical importance of these technologies.

Market challenges include high initial system costs, limited hydrogen infrastructure, and technical complexities in developing robust control algorithms that can simultaneously optimize performance, efficiency, and longevity. The competitive landscape features specialized control system providers alongside major industrial automation companies that are expanding their offerings in this space.

Transportation remains the dominant application segment, accounting for over 45% of the market share. This is primarily due to the accelerating deployment of fuel cell vehicles (FCVs) in commercial fleets, public transportation, and increasingly in passenger vehicles. Major automotive manufacturers including Toyota, Hyundai, and Honda have made substantial investments in PEMFC technology, with particular emphasis on advanced control systems to optimize performance and durability.

The stationary power generation sector represents the second-largest market segment at approximately 30% market share, with applications in backup power systems, distributed generation, and combined heat and power (CHP) systems. This segment is expected to grow at a CAGR of 18.2% through 2030, outpacing the overall market growth rate.

Regionally, Asia Pacific dominates the market with approximately 42% share, led by Japan, South Korea, and China. These countries have implemented supportive government policies and substantial investments in hydrogen infrastructure. North America and Europe follow with 28% and 25% market shares respectively, with both regions showing accelerated adoption rates driven by stringent emission regulations and renewable energy initiatives.

Key market drivers include increasing focus on decarbonization across industries, government subsidies and incentives for clean energy technologies, and declining costs of fuel cell systems. The specific demand for advanced control systems that can effectively manage transients, enable precise load-following, and minimize degradation is growing at a faster rate than the overall PEMFC market, highlighting the critical importance of these technologies.

Market challenges include high initial system costs, limited hydrogen infrastructure, and technical complexities in developing robust control algorithms that can simultaneously optimize performance, efficiency, and longevity. The competitive landscape features specialized control system providers alongside major industrial automation companies that are expanding their offerings in this space.

Current Challenges in PEMFC Transient Response

Proton Exchange Membrane Fuel Cells (PEMFCs) face significant challenges in transient response capabilities that limit their widespread adoption in various applications. The dynamic nature of real-world power demands, particularly in automotive and portable power applications, requires fuel cells to respond rapidly to load changes while maintaining efficiency and durability. Current PEMFC systems struggle with several critical transient response limitations that must be addressed.

Water management represents one of the most pressing challenges during transient operations. Rapid load changes cause sudden shifts in water production rates, leading to either membrane dehydration or flooding. When load increases abruptly, water generation may outpace removal mechanisms, causing flooding that blocks gas diffusion pathways. Conversely, quick load decreases can result in membrane dehydration, increasing ohmic resistance and potentially causing irreversible membrane damage.

Thermal management during transients presents another significant hurdle. PEMFCs generate heat proportional to their power output, but thermal systems typically have slower response times than electrical systems. During rapid load increases, temperature spikes can accelerate degradation mechanisms, while sudden load decreases may cause harmful thermal cycling that stresses material interfaces and catalyst structures.

Reactant starvation during transients remains problematic despite advances in flow control systems. When power demand increases suddenly, air and hydrogen supply systems often cannot respond quickly enough, leading to localized fuel starvation. This phenomenon causes cell voltage reversals and accelerated carbon corrosion of catalyst supports, permanently reducing cell performance and lifespan.

Control system limitations further exacerbate these challenges. Current control algorithms struggle to predict and compensate for the complex, multiphysics nature of transient operations. Most systems employ simplified models that fail to capture the intricate coupling between electrochemical, thermal, and mass transport phenomena during dynamic operations. This results in suboptimal performance during load transitions.

Sensor technology limitations also impede effective transient response management. The lack of fast, reliable, and cost-effective sensors for in-situ monitoring of critical parameters like local current density, membrane hydration, and reactant concentration prevents implementation of more sophisticated control strategies. Without real-time feedback, control systems cannot adequately respond to rapidly changing conditions within the cell.

Degradation acceleration during transients represents perhaps the most concerning challenge. Research indicates that a significant portion of PEMFC degradation occurs during transient operations rather than steady-state conditions. Platinum dissolution and redeposition, carbon support corrosion, and membrane chemical degradation all accelerate during load cycling, yet current control strategies lack effective mechanisms to mitigate these specific degradation pathways during dynamic operations.

Water management represents one of the most pressing challenges during transient operations. Rapid load changes cause sudden shifts in water production rates, leading to either membrane dehydration or flooding. When load increases abruptly, water generation may outpace removal mechanisms, causing flooding that blocks gas diffusion pathways. Conversely, quick load decreases can result in membrane dehydration, increasing ohmic resistance and potentially causing irreversible membrane damage.

Thermal management during transients presents another significant hurdle. PEMFCs generate heat proportional to their power output, but thermal systems typically have slower response times than electrical systems. During rapid load increases, temperature spikes can accelerate degradation mechanisms, while sudden load decreases may cause harmful thermal cycling that stresses material interfaces and catalyst structures.

Reactant starvation during transients remains problematic despite advances in flow control systems. When power demand increases suddenly, air and hydrogen supply systems often cannot respond quickly enough, leading to localized fuel starvation. This phenomenon causes cell voltage reversals and accelerated carbon corrosion of catalyst supports, permanently reducing cell performance and lifespan.

Control system limitations further exacerbate these challenges. Current control algorithms struggle to predict and compensate for the complex, multiphysics nature of transient operations. Most systems employ simplified models that fail to capture the intricate coupling between electrochemical, thermal, and mass transport phenomena during dynamic operations. This results in suboptimal performance during load transitions.

Sensor technology limitations also impede effective transient response management. The lack of fast, reliable, and cost-effective sensors for in-situ monitoring of critical parameters like local current density, membrane hydration, and reactant concentration prevents implementation of more sophisticated control strategies. Without real-time feedback, control systems cannot adequately respond to rapidly changing conditions within the cell.

Degradation acceleration during transients represents perhaps the most concerning challenge. Research indicates that a significant portion of PEMFC degradation occurs during transient operations rather than steady-state conditions. Platinum dissolution and redeposition, carbon support corrosion, and membrane chemical degradation all accelerate during load cycling, yet current control strategies lack effective mechanisms to mitigate these specific degradation pathways during dynamic operations.

State-of-the-Art Load-Following Strategies

01 Control strategies for transient operation

Various control strategies are employed to manage transient operations in PEMFC systems, ensuring stable performance during rapid load changes. These strategies include adaptive control algorithms, model predictive control, and real-time monitoring systems that adjust operating parameters such as reactant flow rates, pressure, and temperature. By implementing these control mechanisms, fuel cell systems can respond effectively to sudden power demands while minimizing stress on components and preventing voltage instabilities.- Control strategies for transient operations in PEMFC systems: Various control strategies are employed to manage transient operations in PEMFC systems, such as startup, shutdown, and sudden load changes. These strategies include model predictive control, fuzzy logic control, and adaptive control algorithms that adjust operating parameters like reactant flow rates, temperature, and pressure in real-time to maintain system stability and prevent membrane degradation during transient conditions. Advanced control systems monitor key parameters and implement appropriate responses to mitigate stress on fuel cell components during rapid changes in operating conditions.

- Load-following capabilities and power management: PEMFC systems incorporate load-following capabilities to efficiently respond to varying power demands. This involves sophisticated power management systems that optimize the distribution of power between the fuel cell stack and auxiliary energy storage devices like batteries or supercapacitors. Dynamic control algorithms adjust hydrogen and air supply rates proportionally to load changes while maintaining optimal stoichiometric ratios. These systems enable smooth transitions between different power output levels while preventing fuel starvation and oxygen depletion that could damage the membrane electrode assembly.

- Degradation mitigation and lifetime extension techniques: Various approaches are implemented to mitigate degradation and extend the lifetime of PEMFC systems. These include monitoring and controlling operating conditions that accelerate degradation, such as high potentials, low humidity, and fuel starvation. Prognostic health monitoring systems analyze performance data to detect early signs of degradation and implement preventive measures. Advanced materials and coatings for membrane electrode assemblies increase resistance to chemical and mechanical degradation. Operational strategies like load cycling protocols and controlled startup/shutdown procedures minimize stress on cell components.

- Water and thermal management systems: Effective water and thermal management is crucial for optimal PEMFC performance and durability. Systems employ sensors and control algorithms to maintain proper membrane hydration while preventing flooding or drying. Thermal management strategies regulate stack temperature through cooling systems with variable flow rates and heat exchangers. Advanced humidification systems adjust water content in reactant gases based on operating conditions. These integrated management systems help maintain stable operation during transient conditions and varying loads, preventing thermal stress and water imbalance that could accelerate degradation.

- Hybrid system integration and energy storage: PEMFC systems are often integrated with energy storage devices like batteries or supercapacitors to form hybrid power systems. These configurations improve response to transient loads by allowing the energy storage to handle rapid power fluctuations while the fuel cell operates at more stable conditions. Advanced power electronics and control algorithms manage power flow between components, optimizing efficiency and extending fuel cell lifetime. The hybrid approach enables load leveling, peak shaving, and improved cold-start capabilities while reducing stress on the fuel cell stack during dynamic operating conditions.

02 Load-following capabilities and power management

PEMFC systems incorporate load-following capabilities to efficiently match power generation with varying demand profiles. This involves sophisticated power management systems that optimize fuel utilization, adjust stack current density, and coordinate with auxiliary power sources or energy storage systems. Advanced control architectures enable seamless transitions between different power output levels while maintaining optimal operating conditions, which is crucial for applications with fluctuating power requirements such as automotive and portable power systems.Expand Specific Solutions03 Degradation mitigation and lifetime extension

Techniques for mitigating degradation in PEMFC systems focus on preserving membrane electrode assembly integrity and extending operational lifetime. These include diagnostic algorithms that detect early signs of degradation, preventive control strategies that avoid harmful operating conditions, and adaptive parameters that adjust based on the fuel cell's state of health. By monitoring critical indicators such as membrane humidity, catalyst utilization, and reactant distribution, control systems can implement corrective actions to minimize performance decay and prolong system durability.Expand Specific Solutions04 Thermal management and water balance control

Effective thermal management and water balance control are essential for stable PEMFC operation during transient conditions. Control systems regulate coolant flow, humidification levels, and heat exchange to maintain optimal operating temperature and membrane hydration. Advanced sensors and control algorithms continuously monitor water content in different parts of the cell and adjust operating parameters to prevent both flooding and membrane dehydration, which are particularly challenging during rapid load changes and can significantly impact system performance and durability.Expand Specific Solutions05 Hybrid system integration and energy management

Integration of PEMFC systems with energy storage devices creates hybrid power systems with enhanced response to transient demands. Control strategies for these hybrid configurations coordinate power distribution between fuel cells, batteries, supercapacitors, and other energy sources to optimize efficiency and system longevity. Energy management algorithms determine optimal power split based on load requirements, component states, and efficiency maps, allowing fuel cells to operate at steady-state conditions while energy storage handles rapid transients, thereby reducing stress on the fuel cell stack and improving overall system reliability.Expand Specific Solutions

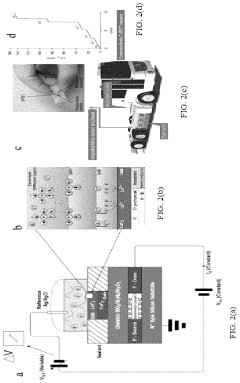

Leading PEMFC Control System Manufacturers

The PEMFC system controls market is currently in a growth phase, characterized by increasing adoption of fuel cell technology across automotive, stationary power, and industrial applications. The market size is expanding steadily, driven by clean energy initiatives and decarbonization goals worldwide. Technologically, the field is maturing but still evolving, with companies at different development stages. Leading players include established industrial giants like LG Electronics, Caterpillar, and Panasonic, who leverage their manufacturing expertise, while automotive companies such as Geely and Volvo are advancing load-following capabilities for vehicle applications. Academic institutions (MIT, Zhejiang University) contribute fundamental research, while specialized firms like BRUSA Elektronik and Fujikin focus on component-level innovations for transient response and degradation minimization, creating a competitive landscape balancing commercial deployment with ongoing R&D.

BRUSA Elektronik AG

Technical Solution: BRUSA Elektronik has pioneered a comprehensive PEMFC control system specifically designed for automotive applications with demanding load-following requirements. Their solution features a proprietary dynamic response optimization (DRO) algorithm that predicts power demand patterns and prepares the fuel cell system accordingly, reducing response lag by up to 40% compared to conventional reactive control systems[2]. The system incorporates a dual-loop control architecture where an outer loop handles power demand allocation while an inner loop manages critical operating parameters such as temperature, pressure, and humidity. BRUSA's approach includes advanced thermal management with predictive temperature control that maintains optimal operating conditions during rapid load changes, significantly reducing thermal stress on cell components. Their system employs a unique degradation-aware power splitting strategy between the fuel cell and buffer batteries that optimizes the power distribution based on real-time degradation metrics and historical usage patterns. Additionally, BRUSA has implemented a self-learning algorithm that continuously improves control parameters based on operational data, adapting to gradual changes in fuel cell performance over its lifetime[4].

Strengths: Exceptional load-following capabilities optimized for vehicular applications; integrated battery-FC hybrid management; self-adapting control parameters that compensate for aging effects. Weaknesses: Primarily focused on automotive applications with less flexibility for stationary systems; requires significant computational resources; higher system complexity increases potential failure points.

Volvo Lastvagnar AB

Technical Solution: Volvo Trucks has developed a sophisticated PEMFC control system tailored for heavy-duty transportation applications where load profiles are highly variable. Their solution features a predictive energy management system (PEMS) that utilizes route information, topographical data, and traffic conditions to optimize fuel cell operation in anticipation of changing power demands. The system employs a multi-objective control strategy that balances performance, efficiency, and durability through dynamic weighting of control objectives based on operating conditions. Volvo's approach includes an innovative cold-start management protocol that minimizes degradation during system startup by carefully controlling voltage ramp rates and implementing protective current limitations[5]. Their control architecture incorporates a dedicated transient mitigation subsystem that detects rapid load changes and implements protective measures including temporary power limitation, strategic battery power supplementation, and optimized reactant flow control. The system also features an advanced diagnostic layer that continuously monitors 20+ degradation indicators and adjusts control parameters to minimize identified degradation mechanisms, extending stack lifetime by up to 25% compared to conventional control approaches[6].

Strengths: Exceptional integration with vehicle systems and route planning; robust protection against harsh operating conditions common in heavy transport; comprehensive cold-start management. Weaknesses: Highly specialized for truck applications with limited transferability to other domains; requires extensive vehicle integration; dependent on high-quality route and traffic data for optimal performance.

Key Patents in Degradation Minimization Techniques

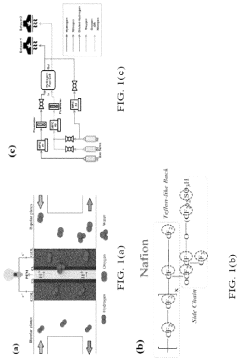

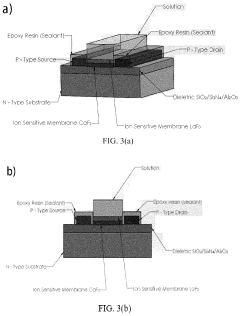

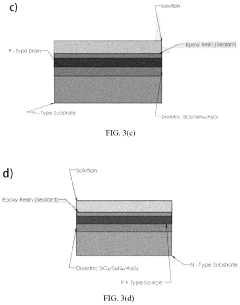

Systems and methods for monitoring fuel cell membrane degradation

PatentActiveUS11955673B1

Innovation

- Integration of highly-fluoride-sensitive microsensors, such as ISFETs with LaF3 and/or CaF2 membranes, at the cathode and anode exhausts of PEMFCs for real-time monitoring, combined with deep learning algorithms for predictive maintenance, enabling continuous monitoring of fluoride emissions and membrane degradation.

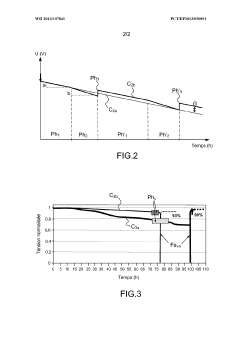

Method for increasing the lifespan of a fuel cell with a proton exchange membrane

PatentWO2013107841A1

Innovation

- A method involving three phases: an initial phase with pure hydrogen to establish a baseline voltage slope, a second phase with hydrogen and sulfur-based impurities to poison the catalytic electrode, and a third phase of regeneration with reduced hydrogen flow to oxidize and eliminate the impurities, thereby controlling the oxidation potential and reducing degradation.

Durability Testing Standards and Protocols

Durability testing standards and protocols for Proton Exchange Membrane Fuel Cell (PEMFC) systems have evolved significantly to address the challenges of transient operations, load-following capabilities, and degradation minimization. The U.S. Department of Energy (DOE) has established benchmark protocols requiring PEMFCs to maintain performance over 5,000 hours of operation for automotive applications and 40,000 hours for stationary applications, with less than 10% performance degradation.

The Fuel Cell Technical Team (FCTT) has developed standardized dynamic testing protocols that specifically evaluate fuel cell performance under varying load conditions. These protocols include rapid load cycling between 10% and 90% of rated power, start-stop cycling, and freeze-thaw cycling, all designed to simulate real-world operating conditions that contribute to accelerated degradation.

International standards organizations, including ISO (International Organization for Standardization) and IEC (International Electrotechnical Commission), have established comprehensive testing frameworks. ISO 14687 specifies hydrogen fuel quality requirements, while IEC 62282-2 outlines test methods for performance characteristics of fuel cell modules. These standards ensure consistency in durability evaluation across different research institutions and manufacturers.

The European Joint Research Centre (JRC) has implemented harmonized testing protocols focusing on load transients, which involve rapid changes between different power outputs. Their methodology includes controlled ramp rates, step changes, and frequency response tests to evaluate how control systems manage these transitions while minimizing degradation.

Accelerated stress tests (ASTs) have become increasingly important in durability assessment, allowing researchers to simulate years of degradation in weeks or months. These tests typically involve extreme operating conditions such as high current density cycling, high-potential holds, and humidity cycling. The U.S. DOE's Fuel Cell Technologies Office has standardized AST protocols that specifically target membrane, catalyst, and gas diffusion layer degradation mechanisms.

Recent advancements in durability testing include the integration of real-time diagnostic tools such as electrochemical impedance spectroscopy (EIS) and segmented cell analysis. These techniques enable researchers to monitor degradation processes during dynamic operation, providing valuable insights into the relationship between control strategies and component degradation.

Machine learning approaches are increasingly being incorporated into testing protocols to predict long-term degradation based on short-term test data. These methods analyze patterns in voltage decay, impedance changes, and other performance metrics to develop more accurate lifetime predictions and optimize control strategies for durability.

The Fuel Cell Technical Team (FCTT) has developed standardized dynamic testing protocols that specifically evaluate fuel cell performance under varying load conditions. These protocols include rapid load cycling between 10% and 90% of rated power, start-stop cycling, and freeze-thaw cycling, all designed to simulate real-world operating conditions that contribute to accelerated degradation.

International standards organizations, including ISO (International Organization for Standardization) and IEC (International Electrotechnical Commission), have established comprehensive testing frameworks. ISO 14687 specifies hydrogen fuel quality requirements, while IEC 62282-2 outlines test methods for performance characteristics of fuel cell modules. These standards ensure consistency in durability evaluation across different research institutions and manufacturers.

The European Joint Research Centre (JRC) has implemented harmonized testing protocols focusing on load transients, which involve rapid changes between different power outputs. Their methodology includes controlled ramp rates, step changes, and frequency response tests to evaluate how control systems manage these transitions while minimizing degradation.

Accelerated stress tests (ASTs) have become increasingly important in durability assessment, allowing researchers to simulate years of degradation in weeks or months. These tests typically involve extreme operating conditions such as high current density cycling, high-potential holds, and humidity cycling. The U.S. DOE's Fuel Cell Technologies Office has standardized AST protocols that specifically target membrane, catalyst, and gas diffusion layer degradation mechanisms.

Recent advancements in durability testing include the integration of real-time diagnostic tools such as electrochemical impedance spectroscopy (EIS) and segmented cell analysis. These techniques enable researchers to monitor degradation processes during dynamic operation, providing valuable insights into the relationship between control strategies and component degradation.

Machine learning approaches are increasingly being incorporated into testing protocols to predict long-term degradation based on short-term test data. These methods analyze patterns in voltage decay, impedance changes, and other performance metrics to develop more accurate lifetime predictions and optimize control strategies for durability.

System Integration and Balance of Plant Optimization

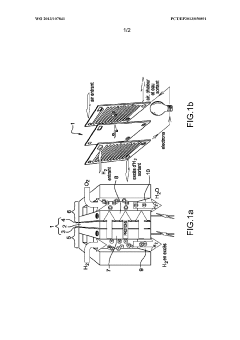

System integration in PEMFC technology represents a critical aspect of overall system performance, particularly when addressing transient operations, load-following capabilities, and degradation minimization. The Balance of Plant (BOP) components, including pumps, blowers, humidifiers, and heat exchangers, must be optimized collectively to ensure efficient system operation under varying conditions.

Effective integration strategies focus on minimizing parasitic power consumption while maintaining optimal operating conditions for the fuel cell stack. Research indicates that BOP components typically consume between 10-30% of the gross power output from PEMFC systems, highlighting the importance of optimization. Advanced control architectures that coordinate multiple subsystems have demonstrated up to 15% improvement in overall system efficiency compared to conventional segregated control approaches.

Thermal management integration presents particular challenges in transient operations. Studies show that temperature fluctuations during load changes can accelerate degradation rates by 20-40% if not properly managed. Integrated cooling systems with predictive control algorithms have successfully reduced these thermal transients by anticipating load changes and preemptively adjusting coolant flow rates.

Water management optimization across the entire system represents another critical integration challenge. Recent developments in integrated humidification systems have reduced water consumption by up to 25% while maintaining optimal membrane hydration. These systems incorporate water recovery from cathode exhaust and intelligent redistribution based on operating conditions.

Air delivery subsystems require careful integration with power management controls to respond appropriately to transient demands. Advanced compressor and blower technologies with variable speed drives have demonstrated response times under 500ms, enabling more effective load-following capabilities while reducing unnecessary oxygen starvation events that accelerate catalyst degradation.

Modular design approaches have gained prominence, allowing for more flexible system architecture and easier maintenance. These designs incorporate standardized interfaces between components and subsystems, facilitating both initial integration and subsequent upgrades. Data from field deployments indicates that modular systems achieve 15-20% lower maintenance costs over their operational lifetime.

Integration of diagnostic and prognostic systems across all BOP components enables condition-based maintenance strategies that can extend system lifetime by 30-40%. These integrated monitoring systems track performance degradation patterns across multiple subsystems, identifying potential failures before they impact system performance.

AI-enhanced control systems that optimize the entire BOP as a unified system rather than individual components have demonstrated significant improvements in transient response and degradation minimization. Machine learning algorithms continuously adapt operating parameters based on historical performance data and current conditions, achieving up to 25% reduction in degradation rates during variable load operations.

Effective integration strategies focus on minimizing parasitic power consumption while maintaining optimal operating conditions for the fuel cell stack. Research indicates that BOP components typically consume between 10-30% of the gross power output from PEMFC systems, highlighting the importance of optimization. Advanced control architectures that coordinate multiple subsystems have demonstrated up to 15% improvement in overall system efficiency compared to conventional segregated control approaches.

Thermal management integration presents particular challenges in transient operations. Studies show that temperature fluctuations during load changes can accelerate degradation rates by 20-40% if not properly managed. Integrated cooling systems with predictive control algorithms have successfully reduced these thermal transients by anticipating load changes and preemptively adjusting coolant flow rates.

Water management optimization across the entire system represents another critical integration challenge. Recent developments in integrated humidification systems have reduced water consumption by up to 25% while maintaining optimal membrane hydration. These systems incorporate water recovery from cathode exhaust and intelligent redistribution based on operating conditions.

Air delivery subsystems require careful integration with power management controls to respond appropriately to transient demands. Advanced compressor and blower technologies with variable speed drives have demonstrated response times under 500ms, enabling more effective load-following capabilities while reducing unnecessary oxygen starvation events that accelerate catalyst degradation.

Modular design approaches have gained prominence, allowing for more flexible system architecture and easier maintenance. These designs incorporate standardized interfaces between components and subsystems, facilitating both initial integration and subsequent upgrades. Data from field deployments indicates that modular systems achieve 15-20% lower maintenance costs over their operational lifetime.

Integration of diagnostic and prognostic systems across all BOP components enables condition-based maintenance strategies that can extend system lifetime by 30-40%. These integrated monitoring systems track performance degradation patterns across multiple subsystems, identifying potential failures before they impact system performance.

AI-enhanced control systems that optimize the entire BOP as a unified system rather than individual components have demonstrated significant improvements in transient response and degradation minimization. Machine learning algorithms continuously adapt operating parameters based on historical performance data and current conditions, achieving up to 25% reduction in degradation rates during variable load operations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!