How PEMFC Systems Achieve Compliance With Automotive And Stationary Safety Standards?

SEP 15, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PEMFC Safety Standards Background and Objectives

Proton Exchange Membrane Fuel Cells (PEMFCs) have emerged as a promising clean energy technology for both automotive and stationary applications. The evolution of PEMFC technology dates back to the 1960s when it was first developed for NASA's Gemini space program. Since then, significant advancements have been made in terms of efficiency, durability, and cost-effectiveness, positioning PEMFCs as a viable alternative to conventional power sources.

The technological trajectory of PEMFCs has been characterized by continuous improvements in membrane materials, catalyst performance, and system integration. Early systems faced challenges related to high platinum catalyst loading, limited durability, and complex balance-of-plant components. Modern PEMFC systems have overcome many of these limitations through innovations in membrane electrode assembly (MEA) design, reduced platinum loading, and advanced system control strategies.

Safety standards for PEMFC systems have evolved in parallel with the technology itself. Initially, safety considerations were primarily focused on hydrogen handling and storage. However, as applications expanded into automotive and stationary sectors, comprehensive safety frameworks became necessary to address the specific risks associated with each application environment. This evolution reflects the growing recognition of PEMFCs as a mainstream energy technology requiring standardized safety protocols.

The primary objective of PEMFC safety standards is to ensure the safe operation of fuel cell systems across diverse applications while facilitating market adoption through regulatory compliance. These standards aim to address potential hazards such as hydrogen leakage, electrical safety, thermal management, and system integration risks. By establishing clear safety guidelines, these standards provide a framework for manufacturers to design systems that minimize risks to users, property, and the environment.

For automotive applications, PEMFC safety standards focus on crash safety, on-board hydrogen storage, and integration with vehicle electrical systems. Key standards include ISO 23273 for fuel cell vehicles and SAE J2578 for fuel cell system safety. In contrast, stationary applications are governed by standards such as IEC 62282 series, which addresses installation requirements, performance testing, and safety protocols for stationary fuel cell power systems.

The convergence of automotive and stationary safety standards presents both challenges and opportunities for PEMFC system developers. While certain safety principles apply universally, the specific requirements can vary significantly between applications. This necessitates a comprehensive understanding of the regulatory landscape and the technical requirements for achieving compliance across different sectors.

Looking forward, the evolution of PEMFC safety standards is expected to continue as the technology matures and new applications emerge. Future standards development will likely focus on harmonization across regions, addressing emerging technologies such as high-pressure hydrogen storage, and incorporating lessons learned from real-world deployments.

The technological trajectory of PEMFCs has been characterized by continuous improvements in membrane materials, catalyst performance, and system integration. Early systems faced challenges related to high platinum catalyst loading, limited durability, and complex balance-of-plant components. Modern PEMFC systems have overcome many of these limitations through innovations in membrane electrode assembly (MEA) design, reduced platinum loading, and advanced system control strategies.

Safety standards for PEMFC systems have evolved in parallel with the technology itself. Initially, safety considerations were primarily focused on hydrogen handling and storage. However, as applications expanded into automotive and stationary sectors, comprehensive safety frameworks became necessary to address the specific risks associated with each application environment. This evolution reflects the growing recognition of PEMFCs as a mainstream energy technology requiring standardized safety protocols.

The primary objective of PEMFC safety standards is to ensure the safe operation of fuel cell systems across diverse applications while facilitating market adoption through regulatory compliance. These standards aim to address potential hazards such as hydrogen leakage, electrical safety, thermal management, and system integration risks. By establishing clear safety guidelines, these standards provide a framework for manufacturers to design systems that minimize risks to users, property, and the environment.

For automotive applications, PEMFC safety standards focus on crash safety, on-board hydrogen storage, and integration with vehicle electrical systems. Key standards include ISO 23273 for fuel cell vehicles and SAE J2578 for fuel cell system safety. In contrast, stationary applications are governed by standards such as IEC 62282 series, which addresses installation requirements, performance testing, and safety protocols for stationary fuel cell power systems.

The convergence of automotive and stationary safety standards presents both challenges and opportunities for PEMFC system developers. While certain safety principles apply universally, the specific requirements can vary significantly between applications. This necessitates a comprehensive understanding of the regulatory landscape and the technical requirements for achieving compliance across different sectors.

Looking forward, the evolution of PEMFC safety standards is expected to continue as the technology matures and new applications emerge. Future standards development will likely focus on harmonization across regions, addressing emerging technologies such as high-pressure hydrogen storage, and incorporating lessons learned from real-world deployments.

Market Requirements for PEMFC Safety Compliance

The market for Proton Exchange Membrane Fuel Cell (PEMFC) systems is increasingly demanding robust safety compliance frameworks that meet both automotive and stationary application standards. Primary market drivers include the growing adoption of hydrogen as a clean energy carrier and the expansion of fuel cell applications across various sectors. Automotive manufacturers require PEMFC systems that comply with regulations such as UN GTR No. 13, ISO 23273, and SAE J2578, which address hydrogen storage, fuel system integrity, and electrical safety in fuel cell vehicles.

Consumer safety expectations represent a critical market requirement, with end-users demanding assurance that hydrogen-powered vehicles and stationary systems pose no greater risk than conventional technologies. This has led to stringent requirements for leak detection systems, pressure relief devices, and automatic shutdown mechanisms that must function reliably under all operating conditions.

Insurance providers and financial institutions have established specific requirements for PEMFC systems, including comprehensive risk assessment documentation and compliance with recognized safety standards before offering coverage or financing. These requirements directly influence market adoption rates and commercial viability of fuel cell technologies.

Regional variations in safety regulations present significant challenges for global PEMFC manufacturers. The European market emphasizes compliance with the ATEX directive and the Machinery Directive, while North American markets focus on NFPA 2 and CSA standards. Asian markets, particularly Japan and South Korea, have developed their own hydrogen safety frameworks that manufacturers must navigate.

The stationary power generation sector demands PEMFC systems that comply with IEC 62282 standards, with particular emphasis on installation requirements, protection against environmental conditions, and integration with existing building safety systems. These requirements become more complex in residential applications where proximity to occupants necessitates additional safety measures.

Market analysis indicates growing pressure for harmonized global standards to reduce compliance costs and accelerate market entry. Industry stakeholders are actively participating in international standardization efforts through organizations like ISO and IEC to develop unified approaches to hydrogen safety.

Emerging market requirements include enhanced cybersecurity measures for networked fuel cell systems, particularly for critical infrastructure applications. As PEMFC systems become more integrated with smart grid technologies, protection against unauthorized access and control has become a priority for utility companies and industrial customers.

The market increasingly values transparent safety certification processes, with third-party validation becoming a competitive advantage for PEMFC manufacturers. This trend is driving investment in comprehensive testing programs and safety demonstration projects to build consumer and regulatory confidence in hydrogen technologies.

Consumer safety expectations represent a critical market requirement, with end-users demanding assurance that hydrogen-powered vehicles and stationary systems pose no greater risk than conventional technologies. This has led to stringent requirements for leak detection systems, pressure relief devices, and automatic shutdown mechanisms that must function reliably under all operating conditions.

Insurance providers and financial institutions have established specific requirements for PEMFC systems, including comprehensive risk assessment documentation and compliance with recognized safety standards before offering coverage or financing. These requirements directly influence market adoption rates and commercial viability of fuel cell technologies.

Regional variations in safety regulations present significant challenges for global PEMFC manufacturers. The European market emphasizes compliance with the ATEX directive and the Machinery Directive, while North American markets focus on NFPA 2 and CSA standards. Asian markets, particularly Japan and South Korea, have developed their own hydrogen safety frameworks that manufacturers must navigate.

The stationary power generation sector demands PEMFC systems that comply with IEC 62282 standards, with particular emphasis on installation requirements, protection against environmental conditions, and integration with existing building safety systems. These requirements become more complex in residential applications where proximity to occupants necessitates additional safety measures.

Market analysis indicates growing pressure for harmonized global standards to reduce compliance costs and accelerate market entry. Industry stakeholders are actively participating in international standardization efforts through organizations like ISO and IEC to develop unified approaches to hydrogen safety.

Emerging market requirements include enhanced cybersecurity measures for networked fuel cell systems, particularly for critical infrastructure applications. As PEMFC systems become more integrated with smart grid technologies, protection against unauthorized access and control has become a priority for utility companies and industrial customers.

The market increasingly values transparent safety certification processes, with third-party validation becoming a competitive advantage for PEMFC manufacturers. This trend is driving investment in comprehensive testing programs and safety demonstration projects to build consumer and regulatory confidence in hydrogen technologies.

Current Safety Challenges in PEMFC Systems

Proton Exchange Membrane Fuel Cell (PEMFC) systems face significant safety challenges that must be addressed to ensure compliance with automotive and stationary applications standards. Hydrogen, the primary fuel for PEMFCs, presents inherent risks due to its wide flammability range (4-75% in air) and low ignition energy (0.02mJ), making leak detection and management critical safety concerns. Current PEMFC systems struggle with reliable hydrogen sensors that can operate effectively across varying environmental conditions while maintaining accuracy throughout the system's lifecycle.

Thermal management represents another major challenge, as PEMFCs generate substantial heat during operation. Inadequate cooling systems can lead to hotspots, membrane degradation, and in extreme cases, thermal runaway. The balance between efficient heat dissipation and system compactness remains difficult, particularly in automotive applications where space constraints are significant.

Electrical safety issues persist in high-voltage PEMFC stacks, especially in automotive applications where systems typically operate at 400-800V. Insulation failures, ground faults, and electrical arcing pose serious risks that current monitoring systems sometimes fail to detect quickly enough. The integration of electrical safety components often adds complexity, weight, and cost to PEMFC systems.

Material compatibility challenges exist throughout PEMFC systems, as hydrogen embrittlement can compromise structural integrity of metal components over time. Current materials selection must balance mechanical properties, hydrogen compatibility, and cost-effectiveness, which often leads to suboptimal compromises in system design and longevity.

Water management presents dual safety concerns: insufficient hydration can damage membranes and reduce performance, while excess water accumulation can freeze in cold conditions, potentially damaging system components. Current water management strategies struggle to maintain optimal balance across varying operational conditions and load profiles.

End-of-life considerations remain inadequately addressed in many PEMFC designs. The safe decommissioning, recycling, or disposal of fuel cell components containing precious metals and potentially hazardous materials lacks standardized protocols across the industry.

System integration challenges persist when combining PEMFC with other power sources in hybrid configurations. The complex interaction between batteries, supercapacitors, and fuel cells creates potential safety vulnerabilities at system interfaces that current control architectures struggle to fully mitigate.

Regulatory compliance frameworks vary significantly across regions and applications, creating a fragmented landscape of safety requirements that manufacturers must navigate. The lack of globally harmonized standards increases compliance complexity and potentially creates safety gaps in international deployments.

Thermal management represents another major challenge, as PEMFCs generate substantial heat during operation. Inadequate cooling systems can lead to hotspots, membrane degradation, and in extreme cases, thermal runaway. The balance between efficient heat dissipation and system compactness remains difficult, particularly in automotive applications where space constraints are significant.

Electrical safety issues persist in high-voltage PEMFC stacks, especially in automotive applications where systems typically operate at 400-800V. Insulation failures, ground faults, and electrical arcing pose serious risks that current monitoring systems sometimes fail to detect quickly enough. The integration of electrical safety components often adds complexity, weight, and cost to PEMFC systems.

Material compatibility challenges exist throughout PEMFC systems, as hydrogen embrittlement can compromise structural integrity of metal components over time. Current materials selection must balance mechanical properties, hydrogen compatibility, and cost-effectiveness, which often leads to suboptimal compromises in system design and longevity.

Water management presents dual safety concerns: insufficient hydration can damage membranes and reduce performance, while excess water accumulation can freeze in cold conditions, potentially damaging system components. Current water management strategies struggle to maintain optimal balance across varying operational conditions and load profiles.

End-of-life considerations remain inadequately addressed in many PEMFC designs. The safe decommissioning, recycling, or disposal of fuel cell components containing precious metals and potentially hazardous materials lacks standardized protocols across the industry.

System integration challenges persist when combining PEMFC with other power sources in hybrid configurations. The complex interaction between batteries, supercapacitors, and fuel cells creates potential safety vulnerabilities at system interfaces that current control architectures struggle to fully mitigate.

Regulatory compliance frameworks vary significantly across regions and applications, creating a fragmented landscape of safety requirements that manufacturers must navigate. The lack of globally harmonized standards increases compliance complexity and potentially creates safety gaps in international deployments.

Existing PEMFC Safety Compliance Strategies

01 Regulatory compliance frameworks for PEMFC systems

Proton Exchange Membrane Fuel Cell (PEMFC) systems require specific regulatory compliance frameworks to ensure they meet safety, performance, and environmental standards. These frameworks include certification processes, testing protocols, and documentation requirements that manufacturers must adhere to before commercialization. Compliance systems often incorporate automated monitoring and reporting tools to track adherence to various national and international standards specific to hydrogen fuel cell technologies.- Regulatory compliance frameworks for PEMFC systems: Proton Exchange Membrane Fuel Cell (PEMFC) systems must adhere to specific regulatory frameworks to ensure safety and performance standards. These frameworks include certification processes, testing protocols, and documentation requirements that manufacturers must follow. Compliance systems may include automated monitoring tools that track adherence to relevant standards and regulations, helping organizations maintain proper certification status for their fuel cell technologies.

- Safety standards and certification for PEMFC technology: Safety standards for PEMFC systems encompass electrical safety, hydrogen handling protocols, and operational parameters. Certification processes involve rigorous testing of components and integrated systems to verify compliance with international standards. These standards address potential hazards such as hydrogen leakage, electrical faults, and thermal management issues. Certification bodies evaluate PEMFC systems against these standards to ensure they meet minimum safety requirements before market approval.

- Environmental compliance and sustainability metrics for fuel cell systems: Environmental compliance for PEMFC systems involves meeting emissions standards, lifecycle assessment requirements, and sustainability metrics. These systems must demonstrate reduced environmental impact compared to conventional power sources, including carbon footprint calculations and end-of-life recycling protocols. Compliance documentation includes environmental performance data, materials declarations, and evidence of sustainable manufacturing practices that align with global environmental regulations.

- Digital compliance management systems for PEMFC technology: Digital platforms and software solutions are being developed to manage compliance requirements for PEMFC systems. These technologies utilize blockchain, artificial intelligence, and cloud computing to track regulatory adherence, manage certification documentation, and provide real-time compliance monitoring. Such systems can automatically update when regulations change, maintain secure records of compliance testing, and generate necessary documentation for audits and inspections.

- International harmonization of PEMFC compliance standards: Efforts to harmonize international standards for PEMFC systems aim to reduce market barriers and streamline compliance processes across different regions. These initiatives involve collaboration between standards organizations, industry stakeholders, and regulatory bodies to develop consistent testing methodologies, safety requirements, and performance metrics. Harmonized standards facilitate global trade of fuel cell technologies while maintaining appropriate safety and performance levels across diverse regulatory environments.

02 Security and data protection in PEMFC control systems

As PEMFC systems become increasingly connected and digitized, security and data protection have emerged as critical compliance concerns. These systems require robust cybersecurity measures to protect operational data, prevent unauthorized access, and ensure system integrity. Compliance solutions include encryption protocols, secure authentication mechanisms, and regular security audits to protect against vulnerabilities in the digital infrastructure controlling fuel cell operations and monitoring systems.Expand Specific Solutions03 Environmental and emissions compliance for fuel cell systems

PEMFC systems must comply with environmental regulations regarding emissions, waste management, and lifecycle sustainability. Compliance solutions track and document the environmental impact of fuel cell operations, including hydrogen production methods, carbon footprint calculations, and end-of-life disposal protocols. These systems help manufacturers demonstrate adherence to zero-emission standards and qualify for environmental certifications and incentives in various markets.Expand Specific Solutions04 Blockchain-based compliance verification for PEMFC supply chains

Blockchain technology is being implemented to ensure compliance throughout the PEMFC supply chain, from raw materials to finished systems. These solutions provide immutable records of component sourcing, manufacturing processes, and quality control measures. The distributed ledger approach enables transparent verification of compliance with industry standards and regulations while facilitating traceability of components and materials used in fuel cell production.Expand Specific Solutions05 Automated compliance monitoring and reporting systems

Advanced automated systems are being developed to continuously monitor PEMFC operations and automatically generate compliance reports. These systems integrate sensors, data analytics, and artificial intelligence to track performance parameters, detect anomalies, and ensure adherence to operational standards. The automated approach reduces human error in compliance documentation while providing real-time alerts when systems deviate from regulatory requirements or performance specifications.Expand Specific Solutions

Leading PEMFC Safety Solution Providers

The PEMFC safety standards compliance landscape is currently in a growth phase, with the market expanding as fuel cell technology matures for both automotive and stationary applications. The global market is projected to reach significant scale as regulatory frameworks evolve across regions. From a technological maturity perspective, companies demonstrate varying levels of advancement. Established players like Samsung SDI, NEC Corp, and Geely Holding Group have developed comprehensive safety compliance systems, while research institutions such as Dalian Institute of Chemical Physics, Beijing Institute of Technology, and Zhejiang University are driving fundamental innovations in safety protocols. Sunrise Power and CRRC Industrial Institute are emerging as key players in standardization efforts, particularly in the Chinese market. The industry is transitioning from early adoption to mainstream implementation, with safety certification becoming a critical competitive differentiator.

Sunrise Power Co., Ltd.

Technical Solution: Sunrise Power has developed a comprehensive safety compliance framework for their PEMFC systems that addresses both automotive and stationary applications. Their approach integrates multi-level safety mechanisms including hydrogen leak detection systems with ppb-level sensitivity, advanced thermal management solutions to prevent overheating, and intelligent control systems that can predict and prevent potential failure modes. The company implements a three-tier safety architecture: preventive measures (robust sealing, high-quality materials resistant to hydrogen embrittlement), detection systems (multiple sensor arrays for hydrogen, temperature, pressure, and voltage monitoring), and mitigation strategies (automatic shutdown protocols, pressure relief devices, and isolation mechanisms). Their systems undergo rigorous testing according to GB/T 24549 for automotive applications and IEC 62282 standards for stationary installations, with additional compliance with ISO 26262 for functional safety in automotive settings. Sunrise Power's PEMFC systems feature redundant safety controls and fail-safe mechanisms that ensure continued safe operation even when primary systems fail.

Strengths: Industry-leading hydrogen leak detection sensitivity and comprehensive multi-layered safety architecture provide exceptional reliability. Their systems maintain compliance across multiple international standards simultaneously. Weaknesses: The complex safety systems add cost and weight to their PEMFC solutions, potentially limiting market competitiveness in price-sensitive applications. The redundant safety mechanisms also increase maintenance complexity.

Zhejiang Geely Holding Group Co., Ltd.

Technical Solution: Zhejiang Geely has developed a comprehensive automotive-focused PEMFC safety compliance system that integrates seamlessly with their vehicle platforms. Their approach centers on a proprietary Vehicle Safety Domain Controller (VSDC) that monitors and manages all hydrogen-related safety systems. This controller implements a multi-layered safety architecture compliant with both ISO 26262 (functional safety) and ISO 21434 (cybersecurity) standards. Geely's system features distributed hydrogen sensors throughout the vehicle with redundant communication pathways to ensure detection reliability. Their PEMFC systems incorporate advanced thermal runaway prevention through a patented cooling system that maintains optimal temperature distribution across the stack. For crash safety compliance (UN R134), Geely has engineered specialized high-pressure hydrogen storage tanks with multiple impact protection layers and automatic isolation valves that activate within milliseconds of crash detection. Their compliance testing includes extreme condition simulations such as vehicle rollover, side impact with hydrogen system components, and post-crash hydrogen containment verification. Geely has also developed specialized manufacturing quality control processes to ensure consistent safety performance across production vehicles, with each fuel cell system undergoing automated leak testing and performance verification before installation.

Strengths: Exceptional integration of fuel cell safety systems with overall vehicle safety architecture provides comprehensive protection. Their compliance with both automotive safety and cybersecurity standards creates a robust defense against both physical and digital threats. Weaknesses: Their automotive-focused approach may limit applicability to stationary applications without significant modifications. The complex integration with vehicle systems creates potential dependencies that could affect maintenance and serviceability in the field.

Critical Safety Technologies for PEMFC Systems

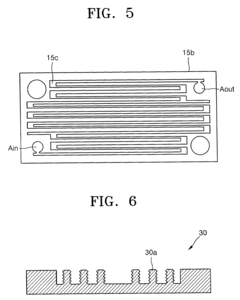

Proton exchange membrane fuel cell

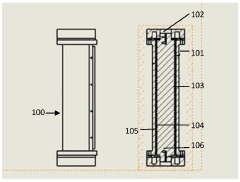

PatentInactiveIN202041009757A

Innovation

- A cylindrical fuel cell design with a single-layer Membrane Electrode Assembly (MEA) surrounding a blade screw, eliminating bipolar and compression plates, and incorporating hydrophobic chambers for efficient proton transfer and water management, along with sensors and actuators for automation and temperature control.

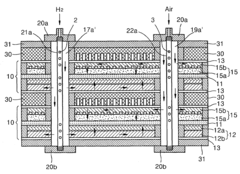

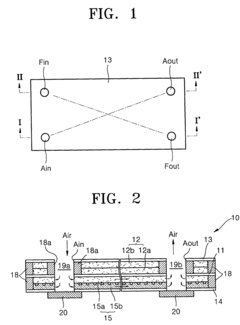

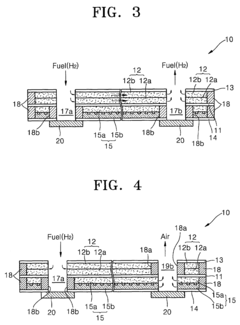

Proton exchange membrane fuel cell stack

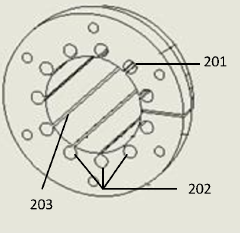

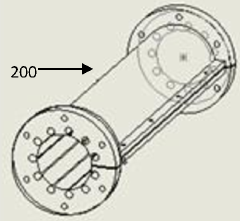

PatentInactiveUS7335436B2

Innovation

- A PEMFC stack design featuring catalyzed membranes with parallel and orthogonal flow fields, bipolar plates, and external sealing layers to facilitate easy assembly and disassembly, along with conductive cooling members for improved heat dissipation and fuel conversion efficiency.

Certification Processes for PEMFC Applications

Certification processes for PEMFC (Proton Exchange Membrane Fuel Cell) applications represent a critical pathway for manufacturers seeking to commercialize their systems in both automotive and stationary markets. These processes involve rigorous testing and validation against established standards to ensure safety, reliability, and performance compliance.

For automotive PEMFC applications, manufacturers must navigate a complex certification landscape that includes regional and international standards. Key automotive standards include ISO 26262 for functional safety, UN GTR No. 13 for hydrogen fuel cell vehicles, and SAE J2578 for fuel cell vehicle safety. The certification process typically begins with design validation testing, followed by prototype evaluation, and culminates in production validation testing.

Stationary PEMFC systems follow a different certification path, primarily governed by standards such as IEC 62282 series for fuel cell technologies, ANSI/CSA FC 1 for stationary fuel cell power systems, and local building codes. These standards address installation requirements, electrical connections, ventilation systems, and emergency shutdown procedures specific to fixed installations.

Both application domains require manufacturers to engage with Nationally Recognized Testing Laboratories (NRTLs) or Technical Service Providers (TSPs) that are authorized to conduct compliance testing. These third-party organizations perform independent verification of safety features, emissions testing, electrical safety, and electromagnetic compatibility assessments.

Documentation requirements form a substantial component of the certification process. Manufacturers must prepare comprehensive technical files including risk assessments, FMEA (Failure Mode and Effects Analysis), test reports, material compatibility analyses, and maintenance procedures. This documentation serves as evidence of compliance and becomes part of the product's certification history.

The timeline for certification varies significantly based on product complexity and application domain. Automotive applications typically require 12-24 months for complete certification due to extensive road testing requirements and integration validation. Stationary applications may require 6-18 months, depending on system size and installation environment complexity.

Cost considerations for certification are substantial, with expenses covering laboratory testing, documentation preparation, potential design modifications, and certification body fees. Many manufacturers incorporate certification planning into early design phases to minimize costly late-stage modifications and streamline the overall process.

Post-certification activities include periodic audits, compliance monitoring, and recertification when significant system modifications occur. Manufacturers must maintain robust quality management systems to ensure ongoing compliance with safety standards throughout the product lifecycle.

For automotive PEMFC applications, manufacturers must navigate a complex certification landscape that includes regional and international standards. Key automotive standards include ISO 26262 for functional safety, UN GTR No. 13 for hydrogen fuel cell vehicles, and SAE J2578 for fuel cell vehicle safety. The certification process typically begins with design validation testing, followed by prototype evaluation, and culminates in production validation testing.

Stationary PEMFC systems follow a different certification path, primarily governed by standards such as IEC 62282 series for fuel cell technologies, ANSI/CSA FC 1 for stationary fuel cell power systems, and local building codes. These standards address installation requirements, electrical connections, ventilation systems, and emergency shutdown procedures specific to fixed installations.

Both application domains require manufacturers to engage with Nationally Recognized Testing Laboratories (NRTLs) or Technical Service Providers (TSPs) that are authorized to conduct compliance testing. These third-party organizations perform independent verification of safety features, emissions testing, electrical safety, and electromagnetic compatibility assessments.

Documentation requirements form a substantial component of the certification process. Manufacturers must prepare comprehensive technical files including risk assessments, FMEA (Failure Mode and Effects Analysis), test reports, material compatibility analyses, and maintenance procedures. This documentation serves as evidence of compliance and becomes part of the product's certification history.

The timeline for certification varies significantly based on product complexity and application domain. Automotive applications typically require 12-24 months for complete certification due to extensive road testing requirements and integration validation. Stationary applications may require 6-18 months, depending on system size and installation environment complexity.

Cost considerations for certification are substantial, with expenses covering laboratory testing, documentation preparation, potential design modifications, and certification body fees. Many manufacturers incorporate certification planning into early design phases to minimize costly late-stage modifications and streamline the overall process.

Post-certification activities include periodic audits, compliance monitoring, and recertification when significant system modifications occur. Manufacturers must maintain robust quality management systems to ensure ongoing compliance with safety standards throughout the product lifecycle.

Risk Assessment Methodologies for PEMFC Deployment

Risk assessment methodologies for PEMFC (Proton Exchange Membrane Fuel Cell) deployment require systematic approaches to identify, evaluate, and mitigate potential hazards associated with hydrogen fuel cell systems in both automotive and stationary applications. These methodologies typically follow established frameworks such as ISO 31000 for risk management, with specific adaptations for hydrogen technologies.

The HAZOP (Hazard and Operability Study) methodology has emerged as a cornerstone approach for PEMFC risk assessment. This process-based technique systematically examines each component and operational parameter of the fuel cell system to identify potential deviations and their consequences. For automotive applications, HAZOP studies particularly focus on crash scenarios, thermal management failures, and hydrogen leakage during refueling operations.

Failure Mode and Effects Analysis (FMEA) represents another critical methodology widely adopted by automotive manufacturers integrating PEMFC technology. This bottom-up approach evaluates individual component failures and their system-wide impacts, assigning Risk Priority Numbers (RPNs) based on severity, occurrence probability, and detection difficulty. The automotive industry typically requires RPNs below specific thresholds before PEMFC systems can be approved for production vehicles.

Quantitative Risk Assessment (QRA) techniques have gained prominence for stationary PEMFC installations, particularly in urban or sensitive environments. These methodologies employ probabilistic models to calculate the likelihood and consequences of various failure scenarios, often utilizing specialized software tools like PHAST or SAFETI to model hydrogen dispersion and potential explosion effects.

Event Tree Analysis (ETA) and Fault Tree Analysis (FTA) are complementary methodologies that examine the progression of initiating events and the combination of failures leading to hazardous outcomes. These techniques have proven particularly valuable for analyzing complex PEMFC system interactions and establishing safety integrity levels (SILs) in accordance with IEC 61508 for functional safety.

For stationary applications, the IEC 62282 standard series provides specific risk assessment frameworks tailored to fuel cell installations. These methodologies incorporate unique considerations for indoor air quality, ventilation requirements, and integration with building safety systems. Similarly, automotive applications follow specialized risk assessment protocols outlined in standards like SAE J2578 and ISO 23273.

Modern PEMFC risk assessment increasingly incorporates digital twins and real-time monitoring systems that enable dynamic risk evaluation throughout the operational lifecycle. These advanced methodologies allow for continuous safety verification rather than relying solely on initial design-phase assessments, representing a significant evolution in ensuring PEMFC systems maintain compliance with evolving safety standards.

The HAZOP (Hazard and Operability Study) methodology has emerged as a cornerstone approach for PEMFC risk assessment. This process-based technique systematically examines each component and operational parameter of the fuel cell system to identify potential deviations and their consequences. For automotive applications, HAZOP studies particularly focus on crash scenarios, thermal management failures, and hydrogen leakage during refueling operations.

Failure Mode and Effects Analysis (FMEA) represents another critical methodology widely adopted by automotive manufacturers integrating PEMFC technology. This bottom-up approach evaluates individual component failures and their system-wide impacts, assigning Risk Priority Numbers (RPNs) based on severity, occurrence probability, and detection difficulty. The automotive industry typically requires RPNs below specific thresholds before PEMFC systems can be approved for production vehicles.

Quantitative Risk Assessment (QRA) techniques have gained prominence for stationary PEMFC installations, particularly in urban or sensitive environments. These methodologies employ probabilistic models to calculate the likelihood and consequences of various failure scenarios, often utilizing specialized software tools like PHAST or SAFETI to model hydrogen dispersion and potential explosion effects.

Event Tree Analysis (ETA) and Fault Tree Analysis (FTA) are complementary methodologies that examine the progression of initiating events and the combination of failures leading to hazardous outcomes. These techniques have proven particularly valuable for analyzing complex PEMFC system interactions and establishing safety integrity levels (SILs) in accordance with IEC 61508 for functional safety.

For stationary applications, the IEC 62282 standard series provides specific risk assessment frameworks tailored to fuel cell installations. These methodologies incorporate unique considerations for indoor air quality, ventilation requirements, and integration with building safety systems. Similarly, automotive applications follow specialized risk assessment protocols outlined in standards like SAE J2578 and ISO 23273.

Modern PEMFC risk assessment increasingly incorporates digital twins and real-time monitoring systems that enable dynamic risk evaluation throughout the operational lifecycle. These advanced methodologies allow for continuous safety verification rather than relying solely on initial design-phase assessments, representing a significant evolution in ensuring PEMFC systems maintain compliance with evolving safety standards.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!