PEMFC Hydrogen Quality: Contaminant Tolerance, Monitoring And Purge Logic

SEP 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PEMFC Hydrogen Quality Background and Objectives

Proton Exchange Membrane Fuel Cells (PEMFCs) have emerged as a promising clean energy technology over the past several decades, with significant advancements in efficiency, durability, and cost reduction. These electrochemical devices convert hydrogen and oxygen into electricity, with water as the only byproduct, making them environmentally attractive for various applications including transportation, stationary power generation, and portable devices.

The quality of hydrogen fuel is paramount to PEMFC performance and longevity. Even trace amounts of contaminants can severely impact cell operation through various degradation mechanisms, including catalyst poisoning, membrane degradation, and electrode flooding. As PEMFC technology transitions from laboratory settings to widespread commercial deployment, ensuring consistent hydrogen quality becomes increasingly critical.

Historical data indicates that early PEMFC systems suffered significant performance losses due to inadequate understanding of contaminant effects. The evolution of hydrogen quality standards, such as ISO 14687 and SAE J2719, reflects the growing recognition of this challenge. These standards specify maximum allowable concentrations for various impurities including carbon monoxide, sulfur compounds, ammonia, and halogenated compounds.

The primary objective of this technical research is to comprehensively investigate three interconnected aspects of PEMFC hydrogen quality management: contaminant tolerance thresholds, real-time monitoring techniques, and purge logic strategies. Understanding contaminant tolerance involves determining precise concentration limits for various impurities and their synergistic effects under different operating conditions. This knowledge is essential for establishing realistic specifications and developing mitigation strategies.

Monitoring hydrogen quality in real-time presents significant technical challenges due to the need for high sensitivity, selectivity, reliability, and cost-effectiveness. Current analytical methods often involve expensive laboratory equipment unsuitable for field deployment. Developing practical, in-situ monitoring solutions would enable proactive system responses to contamination events, potentially preventing catastrophic damage.

Purge logic strategies represent a critical operational aspect of PEMFC systems, involving the controlled removal of accumulated contaminants and water to restore performance. Optimizing these strategies requires balancing performance recovery against hydrogen wastage and system efficiency impacts. Advanced algorithms incorporating predictive capabilities could significantly enhance purge effectiveness.

The technological trajectory suggests increasing integration of artificial intelligence and machine learning approaches to optimize hydrogen quality management. These methods offer the potential to adapt to varying operating conditions and contaminant profiles, potentially extending PEMFC lifetimes while minimizing performance losses. As hydrogen infrastructure expands globally, standardized approaches to hydrogen quality management will become increasingly important for ensuring interoperability and reliability across diverse applications and geographical regions.

The quality of hydrogen fuel is paramount to PEMFC performance and longevity. Even trace amounts of contaminants can severely impact cell operation through various degradation mechanisms, including catalyst poisoning, membrane degradation, and electrode flooding. As PEMFC technology transitions from laboratory settings to widespread commercial deployment, ensuring consistent hydrogen quality becomes increasingly critical.

Historical data indicates that early PEMFC systems suffered significant performance losses due to inadequate understanding of contaminant effects. The evolution of hydrogen quality standards, such as ISO 14687 and SAE J2719, reflects the growing recognition of this challenge. These standards specify maximum allowable concentrations for various impurities including carbon monoxide, sulfur compounds, ammonia, and halogenated compounds.

The primary objective of this technical research is to comprehensively investigate three interconnected aspects of PEMFC hydrogen quality management: contaminant tolerance thresholds, real-time monitoring techniques, and purge logic strategies. Understanding contaminant tolerance involves determining precise concentration limits for various impurities and their synergistic effects under different operating conditions. This knowledge is essential for establishing realistic specifications and developing mitigation strategies.

Monitoring hydrogen quality in real-time presents significant technical challenges due to the need for high sensitivity, selectivity, reliability, and cost-effectiveness. Current analytical methods often involve expensive laboratory equipment unsuitable for field deployment. Developing practical, in-situ monitoring solutions would enable proactive system responses to contamination events, potentially preventing catastrophic damage.

Purge logic strategies represent a critical operational aspect of PEMFC systems, involving the controlled removal of accumulated contaminants and water to restore performance. Optimizing these strategies requires balancing performance recovery against hydrogen wastage and system efficiency impacts. Advanced algorithms incorporating predictive capabilities could significantly enhance purge effectiveness.

The technological trajectory suggests increasing integration of artificial intelligence and machine learning approaches to optimize hydrogen quality management. These methods offer the potential to adapt to varying operating conditions and contaminant profiles, potentially extending PEMFC lifetimes while minimizing performance losses. As hydrogen infrastructure expands globally, standardized approaches to hydrogen quality management will become increasingly important for ensuring interoperability and reliability across diverse applications and geographical regions.

Market Analysis for High-Purity Hydrogen

The global market for high-purity hydrogen is experiencing significant growth, primarily driven by the expanding adoption of Proton Exchange Membrane Fuel Cells (PEMFCs) across various sectors. The automotive industry represents the largest market segment, with major manufacturers investing heavily in hydrogen fuel cell vehicles as part of their zero-emission strategies. This sector is projected to grow at a compound annual growth rate of over 25% through 2030, particularly in regions with established hydrogen infrastructure.

Industrial applications constitute the second-largest market segment, where high-purity hydrogen is essential for semiconductor manufacturing, glass production, and metallurgical processes. The electronics industry specifically demands hydrogen with purity levels exceeding 99.9999% to prevent contamination during chip fabrication processes.

The stationary power generation sector is emerging as a rapidly growing market for high-purity hydrogen, with increasing deployment of fuel cell systems for backup power in data centers, hospitals, and telecommunications infrastructure. This segment values hydrogen quality particularly highly due to the critical nature of these applications and the high cost of system downtime caused by contaminant-related failures.

Geographically, Asia Pacific dominates the market share, led by Japan, South Korea, and China, where government initiatives strongly support hydrogen economy development. Europe follows closely, with Germany, France, and the UK implementing ambitious hydrogen strategies focused on decarbonization goals. North America shows steady growth, primarily in California and the northeastern states where hydrogen infrastructure is more developed.

Price sensitivity varies significantly by application. While industrial users typically prioritize consistent supply and quality over minor price differences, automotive applications remain highly price-sensitive as manufacturers work to achieve cost parity with conventional vehicles. Current high-purity hydrogen prices range from $10-15 per kilogram at retail stations, with production costs between $4-8 per kilogram depending on the production method and scale.

Market barriers include insufficient hydrogen infrastructure, high purification costs, and complex quality monitoring requirements. The lack of standardized contaminant detection systems specifically designed for on-board vehicle applications represents a significant market gap. Companies developing cost-effective, real-time monitoring solutions for critical contaminants like carbon monoxide, sulfur compounds, and ammonia are positioned to capture substantial market share.

The regulatory landscape is evolving rapidly, with ISO 14687 and SAE J2719 standards establishing increasingly stringent purity requirements for automotive applications. These standards are driving innovation in purification technologies and creating market opportunities for specialized filtration and monitoring systems.

Industrial applications constitute the second-largest market segment, where high-purity hydrogen is essential for semiconductor manufacturing, glass production, and metallurgical processes. The electronics industry specifically demands hydrogen with purity levels exceeding 99.9999% to prevent contamination during chip fabrication processes.

The stationary power generation sector is emerging as a rapidly growing market for high-purity hydrogen, with increasing deployment of fuel cell systems for backup power in data centers, hospitals, and telecommunications infrastructure. This segment values hydrogen quality particularly highly due to the critical nature of these applications and the high cost of system downtime caused by contaminant-related failures.

Geographically, Asia Pacific dominates the market share, led by Japan, South Korea, and China, where government initiatives strongly support hydrogen economy development. Europe follows closely, with Germany, France, and the UK implementing ambitious hydrogen strategies focused on decarbonization goals. North America shows steady growth, primarily in California and the northeastern states where hydrogen infrastructure is more developed.

Price sensitivity varies significantly by application. While industrial users typically prioritize consistent supply and quality over minor price differences, automotive applications remain highly price-sensitive as manufacturers work to achieve cost parity with conventional vehicles. Current high-purity hydrogen prices range from $10-15 per kilogram at retail stations, with production costs between $4-8 per kilogram depending on the production method and scale.

Market barriers include insufficient hydrogen infrastructure, high purification costs, and complex quality monitoring requirements. The lack of standardized contaminant detection systems specifically designed for on-board vehicle applications represents a significant market gap. Companies developing cost-effective, real-time monitoring solutions for critical contaminants like carbon monoxide, sulfur compounds, and ammonia are positioned to capture substantial market share.

The regulatory landscape is evolving rapidly, with ISO 14687 and SAE J2719 standards establishing increasingly stringent purity requirements for automotive applications. These standards are driving innovation in purification technologies and creating market opportunities for specialized filtration and monitoring systems.

Current Challenges in Hydrogen Contaminant Management

Despite significant advancements in PEMFC technology, hydrogen contaminant management remains a critical challenge that impedes widespread adoption and optimal performance of fuel cell systems. Current hydrogen quality standards such as ISO 14687 and SAE J2719 establish strict limits for contaminants, yet meeting these requirements consistently in real-world applications presents substantial difficulties.

One primary challenge is the development of cost-effective, real-time monitoring systems for hydrogen purity. Existing analytical techniques like gas chromatography and mass spectrometry offer high accuracy but are prohibitively expensive and impractical for on-board vehicle applications. Miniaturized sensors capable of detecting multiple contaminants at parts-per-billion levels remain elusive despite significant research efforts.

The variability in hydrogen production pathways further complicates contaminant management. Hydrogen derived from steam methane reforming, electrolysis, and biomass gasification each introduces different contaminant profiles, necessitating tailored purification strategies. This heterogeneity makes standardized approaches to contaminant management difficult to implement across the hydrogen infrastructure.

Catalyst poisoning represents another significant challenge, particularly from sulfur compounds, carbon monoxide, and ammonia. These contaminants can irreversibly damage platinum catalysts even at extremely low concentrations. Current mitigation strategies often involve oversized and expensive purification systems to ensure adequate protection, adding considerable cost to fuel cell systems.

Purge logic optimization presents technical difficulties in balancing effective contaminant removal with hydrogen conservation. Excessive purging wastes valuable fuel, while insufficient purging allows contaminant accumulation. Developing adaptive algorithms that respond to actual contamination levels rather than following fixed purge schedules requires sophisticated sensing capabilities not yet commercially viable.

The lack of comprehensive data on long-term effects of trace contaminants hampers the development of accurate tolerance thresholds. Most studies focus on short-term exposure, leaving significant knowledge gaps regarding cumulative damage from prolonged exposure to sub-threshold contaminant levels.

Infrastructure challenges compound these technical issues. The hydrogen supply chain involves multiple handling steps, each introducing potential contamination sources. Maintaining purity from production through compression, storage, transportation, and dispensing requires rigorous quality control protocols that are difficult to implement consistently across diverse geographical locations and operational environments.

One primary challenge is the development of cost-effective, real-time monitoring systems for hydrogen purity. Existing analytical techniques like gas chromatography and mass spectrometry offer high accuracy but are prohibitively expensive and impractical for on-board vehicle applications. Miniaturized sensors capable of detecting multiple contaminants at parts-per-billion levels remain elusive despite significant research efforts.

The variability in hydrogen production pathways further complicates contaminant management. Hydrogen derived from steam methane reforming, electrolysis, and biomass gasification each introduces different contaminant profiles, necessitating tailored purification strategies. This heterogeneity makes standardized approaches to contaminant management difficult to implement across the hydrogen infrastructure.

Catalyst poisoning represents another significant challenge, particularly from sulfur compounds, carbon monoxide, and ammonia. These contaminants can irreversibly damage platinum catalysts even at extremely low concentrations. Current mitigation strategies often involve oversized and expensive purification systems to ensure adequate protection, adding considerable cost to fuel cell systems.

Purge logic optimization presents technical difficulties in balancing effective contaminant removal with hydrogen conservation. Excessive purging wastes valuable fuel, while insufficient purging allows contaminant accumulation. Developing adaptive algorithms that respond to actual contamination levels rather than following fixed purge schedules requires sophisticated sensing capabilities not yet commercially viable.

The lack of comprehensive data on long-term effects of trace contaminants hampers the development of accurate tolerance thresholds. Most studies focus on short-term exposure, leaving significant knowledge gaps regarding cumulative damage from prolonged exposure to sub-threshold contaminant levels.

Infrastructure challenges compound these technical issues. The hydrogen supply chain involves multiple handling steps, each introducing potential contamination sources. Maintaining purity from production through compression, storage, transportation, and dispensing requires rigorous quality control protocols that are difficult to implement consistently across diverse geographical locations and operational environments.

Current Contaminant Monitoring and Purge Solutions

01 Contaminant detection and monitoring systems

Various systems and methods for detecting and monitoring contaminants in PEMFCs have been developed. These include sensors that can detect specific contaminants like carbon monoxide, sulfur compounds, and ammonia that may poison the fuel cell catalyst. Advanced monitoring techniques utilize electrochemical impedance spectroscopy and voltage pattern recognition to identify contamination events before significant performance degradation occurs. Real-time monitoring allows for immediate response to contamination, helping maintain fuel cell efficiency and longevity.- Contaminant detection and monitoring systems: Various systems and methods for detecting and monitoring contaminants in PEMFCs have been developed. These include sensors that can detect impurities in fuel streams, real-time monitoring systems that track contaminant levels, and diagnostic tools that can identify the presence of specific contaminants affecting fuel cell performance. These monitoring systems help in early detection of contamination issues, allowing for timely intervention to prevent performance degradation.

- Purge strategies and control logic: Advanced purge strategies and control logic have been developed to remove contaminants from PEMFCs. These include algorithms that determine optimal purging timing and duration based on operating conditions, adaptive purge control systems that respond to detected contaminant levels, and sequential purging techniques for different cell components. Effective purge logic helps maintain fuel cell performance by removing accumulated contaminants while minimizing hydrogen waste and system downtime.

- Contaminant-tolerant membrane and catalyst designs: Innovations in membrane and catalyst materials have improved PEMFC tolerance to various contaminants. These include modified membrane structures that resist poisoning, catalyst compositions with enhanced resistance to specific contaminants, and protective coatings that prevent contaminant adsorption. These designs help maintain fuel cell performance even when exposed to certain levels of impurities in fuel or air streams, extending operational lifetime in real-world conditions.

- Filtration and contaminant removal systems: Various filtration and contaminant removal systems have been developed for PEMFCs. These include advanced filter materials that can selectively remove specific contaminants, multi-stage purification systems for both fuel and air streams, and regenerable adsorbents that can be reactivated during operation. These systems help prevent contaminants from reaching sensitive fuel cell components, thereby maintaining performance and extending service life.

- Diagnostic and recovery methods for contaminated cells: Methods for diagnosing contamination issues and recovering performance in affected PEMFCs have been developed. These include electrochemical techniques to identify specific contaminants, voltage recovery protocols that can reverse certain poisoning effects, and regeneration procedures that can restore catalyst activity. These methods help extend fuel cell lifetime by providing means to recover performance after contamination events rather than requiring component replacement.

02 Purge strategies and control logic

Purge strategies involve algorithms and control logic to remove accumulated contaminants from fuel cell systems. These strategies typically monitor cell voltage, current density, and pressure drops to determine optimal purging timing. Adaptive purge logic can adjust purge duration and frequency based on operating conditions and contamination levels. Some systems implement predictive purging before critical thresholds are reached, while others use event-triggered purging when contamination is detected. Effective purge strategies balance contaminant removal with minimizing hydrogen waste and system disruption.Expand Specific Solutions03 Contaminant-tolerant catalyst and membrane materials

Research has focused on developing catalyst and membrane materials with enhanced tolerance to common contaminants. These include platinum alloy catalysts that show improved resistance to carbon monoxide poisoning and modified membrane materials that reduce absorption of contaminants. Some approaches incorporate sacrificial materials that preferentially bind with contaminants before they reach active catalyst sites. Other innovations include self-healing membranes that can recover from contamination effects and protective coatings that prevent contaminant adsorption while maintaining proton conductivity.Expand Specific Solutions04 Filtration and pre-treatment systems

Filtration and pre-treatment systems are designed to remove contaminants before they enter the fuel cell stack. These systems may include multi-stage filters targeting specific contaminants in both the hydrogen fuel stream and air intake. Advanced filtration technologies incorporate selective adsorbents, catalytic converters, and molecular sieves to trap or convert harmful compounds. Some systems feature regenerable filters that can be periodically cleaned or reactivated, while others implement bypass mechanisms during high load conditions to maintain system efficiency while managing contaminant exposure.Expand Specific Solutions05 Recovery and regeneration techniques

Various techniques have been developed to recover fuel cell performance after contamination events. These include voltage cycling, where the cell potential is temporarily increased to oxidize and remove adsorbed contaminants from catalyst surfaces. Other approaches involve controlled exposure to oxygen or air to oxidize contaminants, temperature cycling to promote desorption, and specialized flushing procedures using clean hydrogen. Some systems implement automated recovery protocols that detect performance degradation and initiate appropriate regeneration sequences based on the suspected contaminant type and severity of poisoning.Expand Specific Solutions

Key Industry Players in Hydrogen Quality Control

The PEMFC hydrogen quality market is currently in a growth phase, characterized by increasing adoption of fuel cell technologies across automotive and stationary power sectors. The global market is expanding rapidly, driven by clean energy initiatives and hydrogen economy investments. Technologically, the field shows varying maturity levels, with established players like Toyota Motor Corp., Hyundai Motor Co., and Honda Motor Co. leading with advanced contaminant tolerance solutions, while newer entrants such as Sunrise Power and Intelligent Energy are developing innovative monitoring systems. Companies including Air Liquide, Shell, and Praxair Technology are focusing on hydrogen purification technologies, while automotive manufacturers like GM and Mercedes-Benz are integrating sophisticated purge logic systems into their fuel cell vehicles to optimize performance and longevity.

Toyota Motor Corp.

Technical Solution: Toyota has pioneered a comprehensive hydrogen quality management system for their PEMFC vehicles that addresses contaminant tolerance through multiple innovative approaches. Their system employs a three-tier protection strategy: preventive filtration, real-time monitoring, and adaptive purge control. The filtration system uses proprietary composite materials with selective adsorption properties for different contaminants, particularly targeting CO, sulfur compounds, and ammonia. Toyota's monitoring technology integrates voltage pattern recognition algorithms with cell voltage monitoring to detect specific contaminant signatures before significant performance degradation occurs. Their purge logic incorporates predictive modeling that accounts for driving patterns, environmental conditions, and historical contamination data to optimize purge timing and duration. The system features a self-learning capability that continuously refines purge strategies based on actual performance data, improving hydrogen utilization efficiency over the vehicle's lifetime while maintaining strict performance standards.

Strengths: Highly integrated with Toyota's overall fuel cell system management; excellent balance between contaminant tolerance and system efficiency; proven reliability in commercial vehicles. Weaknesses: Proprietary system components increase replacement costs; system optimization requires significant data collection during initial operation periods.

GM Global Technology Operations LLC

Technical Solution: GM has developed an advanced contamination management system for PEMFC that integrates real-time monitoring with adaptive purge logic. Their solution employs electrochemical impedance spectroscopy (EIS) to detect minute changes in fuel cell performance indicative of contaminant presence. The system features a multi-stage filtration approach with specialized adsorbent materials that target specific impurities like CO, H2S, and NH3. GM's proprietary algorithm analyzes performance degradation patterns to distinguish between different contaminant types and triggers targeted purge cycles accordingly. The system incorporates machine learning capabilities that adapt purge frequency and duration based on operational history and detected contamination levels, optimizing both hydrogen utilization and stack longevity. Their approach includes a predictive maintenance component that estimates remaining filter capacity and schedules replacements before performance degradation occurs.

Strengths: Comprehensive integration with vehicle systems allows for optimized purge timing based on driving conditions; advanced diagnostics capability distinguishes between different contaminant types. Weaknesses: System complexity increases cost and requires sophisticated control systems; purge cycles still result in some hydrogen wastage despite optimization efforts.

Critical Patents in Hydrogen Purity Sensing Technology

Polymers for proton exchange membranes, proton exchange membranes, and their fabrication methods

PatentInactiveEP1828271A1

Innovation

- Development of polymers with a main chain and branch chain structure, where the branch chain contains a sulfo-alkyl radical connected to a benzene ring, fabricated using a sulfo-alkylation process, resulting in proton exchange membranes that are chemically, hydrolytically, dimensionally, and thermally stable, and pliant.

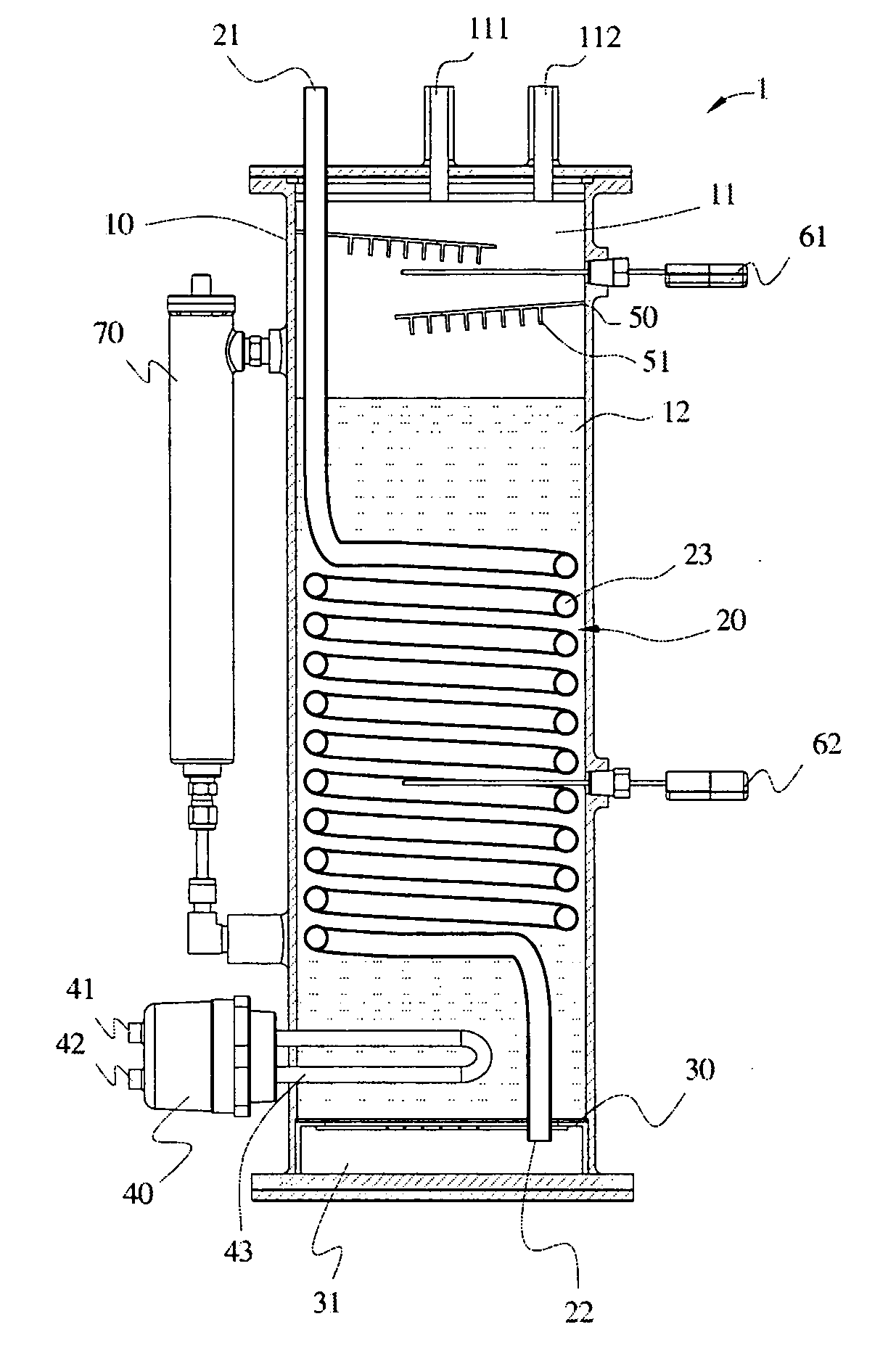

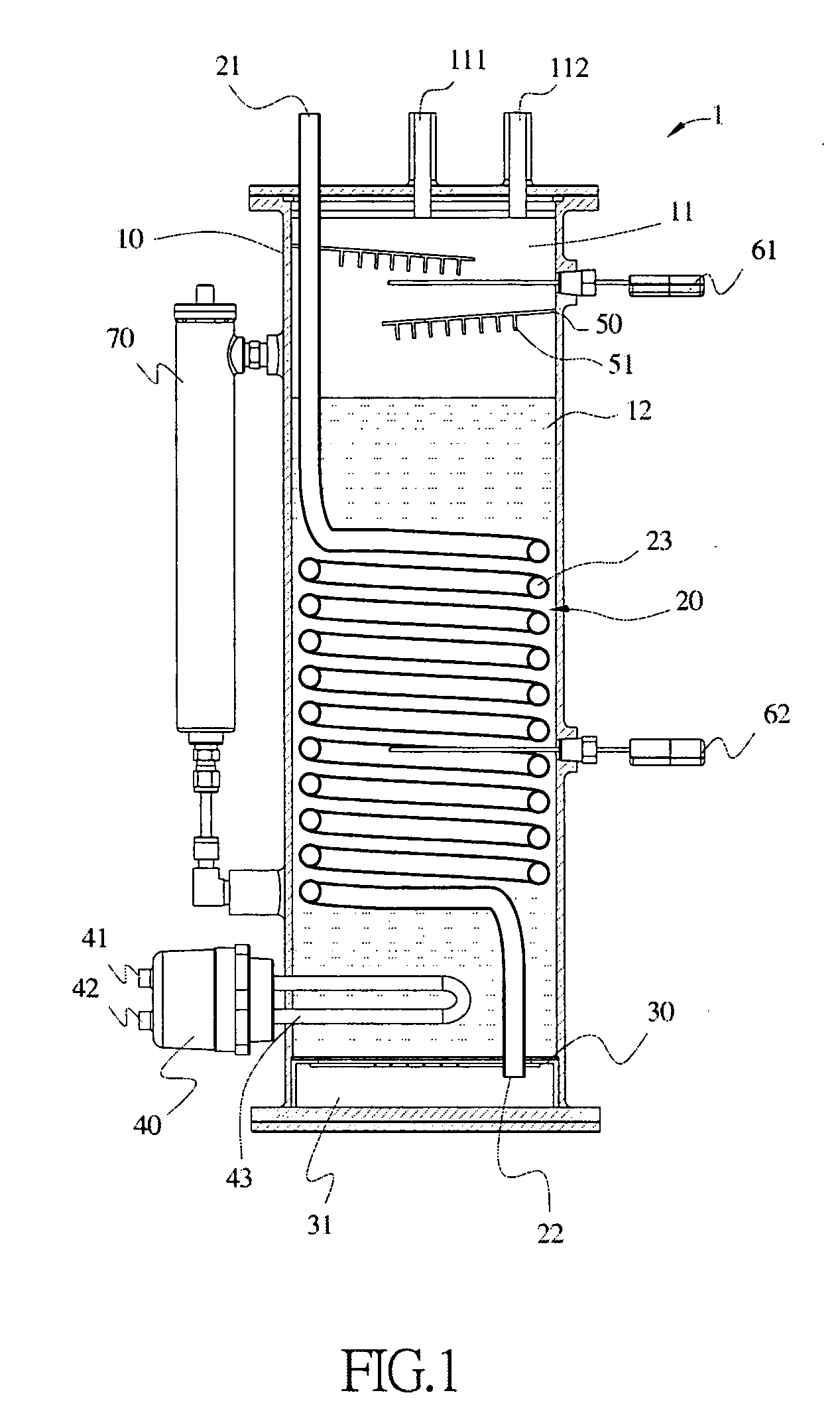

External gas humidifier for fuel cell

PatentActiveUS20070257384A1

Innovation

- An external gas humidifier with a barrel, preheating serpentine, gas disperser, and baffle plates is designed to utilize recycled high-temperature waste heat to efficiently heat and humidify reactant gases, increasing moisture content and preventing flooding by enhancing contact area and retention time with humidifying liquid.

Regulatory Standards for Hydrogen Fuel Quality

The regulatory landscape for hydrogen fuel quality has evolved significantly over the past decade, with several international standards bodies establishing comprehensive frameworks to ensure PEMFC (Proton Exchange Membrane Fuel Cell) safety and performance. The most prominent standard is ISO 14687, which specifies hydrogen fuel quality requirements for various applications, including automotive PEMFCs. This standard defines maximum allowable concentrations for critical contaminants such as carbon monoxide (CO), sulfur compounds, ammonia, and halogenated compounds that can poison fuel cell catalysts.

In the United States, SAE J2719 provides similar specifications tailored to the American market, while in Europe, EN 17124 establishes regional requirements. These standards are continuously updated to reflect advancements in fuel cell technology and improved understanding of contaminant effects. The latest revisions have generally trended toward stricter limits on impurities as fuel cell systems become more sophisticated and sensitive.

Regulatory compliance verification methods are equally important components of these standards. ISO 21087 outlines analytical methods for hydrogen fuel quality assurance, detailing procedures for sampling, handling, and testing hydrogen to verify compliance with purity specifications. These methods include gas chromatography, mass spectrometry, and specialized techniques for detecting trace contaminants at parts-per-billion levels.

The economic implications of these standards are significant for hydrogen infrastructure development. Higher purity requirements necessitate more sophisticated purification technologies at production facilities and distribution points, potentially increasing the cost of hydrogen as a fuel. However, these costs must be balanced against the benefits of extended fuel cell lifetimes and improved system reliability.

Regional variations in regulatory approaches present challenges for global hydrogen mobility deployment. While efforts toward international harmonization are ongoing through organizations like the International Partnership for Hydrogen and Fuel Cells in the Economy (IPHE), differences remain in implementation timelines and specific contaminant limits across jurisdictions.

Emerging regulatory considerations include the development of standards for hydrogen produced from diverse sources, including electrolysis, biomass gasification, and industrial byproducts. These new pathways introduce unique contaminant profiles that may require tailored regulatory approaches. Additionally, regulatory bodies are beginning to address real-time monitoring requirements and establishing protocols for hydrogen quality verification throughout the supply chain.

In the United States, SAE J2719 provides similar specifications tailored to the American market, while in Europe, EN 17124 establishes regional requirements. These standards are continuously updated to reflect advancements in fuel cell technology and improved understanding of contaminant effects. The latest revisions have generally trended toward stricter limits on impurities as fuel cell systems become more sophisticated and sensitive.

Regulatory compliance verification methods are equally important components of these standards. ISO 21087 outlines analytical methods for hydrogen fuel quality assurance, detailing procedures for sampling, handling, and testing hydrogen to verify compliance with purity specifications. These methods include gas chromatography, mass spectrometry, and specialized techniques for detecting trace contaminants at parts-per-billion levels.

The economic implications of these standards are significant for hydrogen infrastructure development. Higher purity requirements necessitate more sophisticated purification technologies at production facilities and distribution points, potentially increasing the cost of hydrogen as a fuel. However, these costs must be balanced against the benefits of extended fuel cell lifetimes and improved system reliability.

Regional variations in regulatory approaches present challenges for global hydrogen mobility deployment. While efforts toward international harmonization are ongoing through organizations like the International Partnership for Hydrogen and Fuel Cells in the Economy (IPHE), differences remain in implementation timelines and specific contaminant limits across jurisdictions.

Emerging regulatory considerations include the development of standards for hydrogen produced from diverse sources, including electrolysis, biomass gasification, and industrial byproducts. These new pathways introduce unique contaminant profiles that may require tailored regulatory approaches. Additionally, regulatory bodies are beginning to address real-time monitoring requirements and establishing protocols for hydrogen quality verification throughout the supply chain.

Economic Impact of Hydrogen Quality on PEMFC Lifecycle

The economic implications of hydrogen quality on Proton Exchange Membrane Fuel Cell (PEMFC) lifecycle costs are substantial and multifaceted. Analysis indicates that contaminants in hydrogen fuel directly correlate with accelerated degradation rates of critical PEMFC components, particularly catalyst layers and membrane assemblies. This degradation translates to shortened operational lifespans, with studies showing that exposure to just 1 ppm of certain sulfur compounds can reduce cell performance by up to 50% within 500 operating hours.

From a capital expenditure perspective, the initial investment in higher-quality hydrogen purification systems represents a significant cost factor. Industrial-grade hydrogen purification systems capable of achieving automotive-grade purity (99.999%) typically add 15-25% to hydrogen production infrastructure costs. However, this front-loaded investment demonstrates favorable returns when evaluated against total ownership costs.

Operational expenditures reveal an even more compelling economic case for stringent hydrogen quality standards. Maintenance intervals for fuel cell systems operating with high-purity hydrogen can be extended by 30-40% compared to those using lower-quality fuel. This extension directly reduces service costs and minimizes revenue-impacting downtime, particularly critical for commercial applications such as fleet vehicles or stationary power systems.

The relationship between contaminant monitoring capabilities and economic performance presents another significant dimension. Real-time monitoring systems, while adding approximately 5-8% to system costs, enable predictive maintenance protocols that can reduce unplanned downtime by up to 60%. These systems also optimize purge cycles, reducing hydrogen wastage by 10-15% compared to fixed-interval purging strategies.

Insurance and warranty considerations further amplify the economic impact of hydrogen quality. Manufacturers offering extended warranties on PEMFC systems typically mandate specific hydrogen purity levels, with non-compliance potentially voiding coverage for costly repairs. This creates a direct financial incentive for maintaining hydrogen quality throughout the supply chain.

Long-term market analysis suggests that standardization of hydrogen quality metrics could reduce lifecycle costs by 18-22% across the PEMFC ecosystem by 2030. This reduction stems from economies of scale in purification technology, reduced certification complexity, and improved interoperability between hydrogen production and consumption systems.

From a capital expenditure perspective, the initial investment in higher-quality hydrogen purification systems represents a significant cost factor. Industrial-grade hydrogen purification systems capable of achieving automotive-grade purity (99.999%) typically add 15-25% to hydrogen production infrastructure costs. However, this front-loaded investment demonstrates favorable returns when evaluated against total ownership costs.

Operational expenditures reveal an even more compelling economic case for stringent hydrogen quality standards. Maintenance intervals for fuel cell systems operating with high-purity hydrogen can be extended by 30-40% compared to those using lower-quality fuel. This extension directly reduces service costs and minimizes revenue-impacting downtime, particularly critical for commercial applications such as fleet vehicles or stationary power systems.

The relationship between contaminant monitoring capabilities and economic performance presents another significant dimension. Real-time monitoring systems, while adding approximately 5-8% to system costs, enable predictive maintenance protocols that can reduce unplanned downtime by up to 60%. These systems also optimize purge cycles, reducing hydrogen wastage by 10-15% compared to fixed-interval purging strategies.

Insurance and warranty considerations further amplify the economic impact of hydrogen quality. Manufacturers offering extended warranties on PEMFC systems typically mandate specific hydrogen purity levels, with non-compliance potentially voiding coverage for costly repairs. This creates a direct financial incentive for maintaining hydrogen quality throughout the supply chain.

Long-term market analysis suggests that standardization of hydrogen quality metrics could reduce lifecycle costs by 18-22% across the PEMFC ecosystem by 2030. This reduction stems from economies of scale in purification technology, reduced certification complexity, and improved interoperability between hydrogen production and consumption systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!