PEMFC Qualification: AST Protocols, Inline Sensors And Acceptance Windows

SEP 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PEMFC Qualification Background and Objectives

Proton Exchange Membrane Fuel Cells (PEMFCs) have emerged as a promising clean energy technology over the past decades, with significant advancements in efficiency, durability, and cost reduction. The qualification of these fuel cells represents a critical aspect of their development and commercialization process, ensuring that they meet the required performance standards and reliability metrics before deployment in real-world applications.

The evolution of PEMFC technology has been marked by continuous improvements in materials, design, and manufacturing processes. From the early prototypes developed in the 1960s to today's commercially viable systems, the technology has undergone substantial refinement. However, the qualification methodologies have not always kept pace with these technological advancements, creating a gap in standardized testing and validation procedures.

The primary objective of PEMFC qualification is to establish robust, repeatable, and industry-accepted protocols that can accurately predict the long-term performance and durability of fuel cell systems under various operating conditions. This includes the development of Accelerated Stress Tests (ASTs) that can simulate years of operational wear in a compressed timeframe, providing valuable insights into degradation mechanisms and failure modes.

Current qualification practices often vary significantly across different organizations and regions, leading to inconsistencies in reported performance metrics and making direct comparisons challenging. The lack of standardized qualification procedures has been identified as a significant barrier to wider PEMFC adoption, particularly in critical applications such as automotive and stationary power generation.

The integration of inline sensors represents another crucial aspect of modern PEMFC qualification, enabling real-time monitoring of key parameters such as temperature distribution, humidity levels, reactant flow rates, and electrochemical activity. These sensors provide valuable data for both qualification testing and operational control, allowing for more precise characterization of fuel cell behavior under various conditions.

Defining appropriate acceptance windows—the range of values within which a parameter must fall for the fuel cell to be considered qualified—presents another significant challenge. These windows must be stringent enough to ensure quality and reliability while being realistic enough to accommodate manufacturing variations and operational fluctuations.

This technical research aims to comprehensively examine the current state of PEMFC qualification, with a particular focus on AST protocols, inline sensing technologies, and acceptance criteria. By analyzing existing methodologies, identifying gaps, and proposing standardized approaches, this research seeks to contribute to the establishment of more effective and universally accepted qualification procedures for PEMFCs, ultimately accelerating their commercial deployment and market penetration.

The evolution of PEMFC technology has been marked by continuous improvements in materials, design, and manufacturing processes. From the early prototypes developed in the 1960s to today's commercially viable systems, the technology has undergone substantial refinement. However, the qualification methodologies have not always kept pace with these technological advancements, creating a gap in standardized testing and validation procedures.

The primary objective of PEMFC qualification is to establish robust, repeatable, and industry-accepted protocols that can accurately predict the long-term performance and durability of fuel cell systems under various operating conditions. This includes the development of Accelerated Stress Tests (ASTs) that can simulate years of operational wear in a compressed timeframe, providing valuable insights into degradation mechanisms and failure modes.

Current qualification practices often vary significantly across different organizations and regions, leading to inconsistencies in reported performance metrics and making direct comparisons challenging. The lack of standardized qualification procedures has been identified as a significant barrier to wider PEMFC adoption, particularly in critical applications such as automotive and stationary power generation.

The integration of inline sensors represents another crucial aspect of modern PEMFC qualification, enabling real-time monitoring of key parameters such as temperature distribution, humidity levels, reactant flow rates, and electrochemical activity. These sensors provide valuable data for both qualification testing and operational control, allowing for more precise characterization of fuel cell behavior under various conditions.

Defining appropriate acceptance windows—the range of values within which a parameter must fall for the fuel cell to be considered qualified—presents another significant challenge. These windows must be stringent enough to ensure quality and reliability while being realistic enough to accommodate manufacturing variations and operational fluctuations.

This technical research aims to comprehensively examine the current state of PEMFC qualification, with a particular focus on AST protocols, inline sensing technologies, and acceptance criteria. By analyzing existing methodologies, identifying gaps, and proposing standardized approaches, this research seeks to contribute to the establishment of more effective and universally accepted qualification procedures for PEMFCs, ultimately accelerating their commercial deployment and market penetration.

Market Analysis for PEMFC Testing Solutions

The global market for Proton Exchange Membrane Fuel Cell (PEMFC) testing solutions is experiencing robust growth, driven by increasing adoption of hydrogen fuel cell technology across automotive, stationary power, and portable applications. Current market valuation stands at approximately 1.2 billion USD, with projections indicating a compound annual growth rate of 15-18% through 2030, significantly outpacing many traditional energy technology sectors.

Demand for sophisticated PEMFC testing equipment is primarily concentrated in regions with strong hydrogen strategies, including Japan, Germany, South Korea, China, and the United States. These markets collectively represent over 75% of global demand, with China showing the fastest growth trajectory due to aggressive government support for hydrogen infrastructure development.

The Accelerated Stress Testing (AST) protocols segment represents the largest market share within PEMFC testing solutions, accounting for roughly 40% of the total market value. This dominance reflects the critical importance of durability validation in fuel cell development and the industry's focus on extending operational lifetimes to meet commercial viability thresholds.

Inline sensor technologies for real-time monitoring constitute the fastest-growing segment, with a projected CAGR of 22% over the next five years. This growth is fueled by increasing demands for more precise performance data during operation and the trend toward predictive maintenance capabilities in fuel cell systems.

Customer segmentation reveals three primary market groups: research institutions (30%), fuel cell manufacturers (45%), and end-product integrators (25%). Research institutions typically prioritize flexibility and comprehensive data collection capabilities, while manufacturers focus on throughput and standardization. End-product integrators, particularly in the automotive sector, emphasize testing solutions that can simulate real-world operating conditions.

Price sensitivity varies significantly across these segments, with research institutions often having access to grant funding for high-end equipment, while commercial manufacturers are increasingly seeking cost-effective solutions that can be deployed at scale. This has created a bifurcated market with premium and value-oriented product tiers emerging.

The competitive landscape features both established analytical instrument manufacturers expanding into fuel cell testing and specialized players focused exclusively on PEMFC testing solutions. Recent market consolidation through mergers and acquisitions suggests the industry is entering a maturation phase, with integrated testing platforms that combine AST protocols, inline sensing, and automated acceptance criteria evaluation becoming the new standard.

Demand for sophisticated PEMFC testing equipment is primarily concentrated in regions with strong hydrogen strategies, including Japan, Germany, South Korea, China, and the United States. These markets collectively represent over 75% of global demand, with China showing the fastest growth trajectory due to aggressive government support for hydrogen infrastructure development.

The Accelerated Stress Testing (AST) protocols segment represents the largest market share within PEMFC testing solutions, accounting for roughly 40% of the total market value. This dominance reflects the critical importance of durability validation in fuel cell development and the industry's focus on extending operational lifetimes to meet commercial viability thresholds.

Inline sensor technologies for real-time monitoring constitute the fastest-growing segment, with a projected CAGR of 22% over the next five years. This growth is fueled by increasing demands for more precise performance data during operation and the trend toward predictive maintenance capabilities in fuel cell systems.

Customer segmentation reveals three primary market groups: research institutions (30%), fuel cell manufacturers (45%), and end-product integrators (25%). Research institutions typically prioritize flexibility and comprehensive data collection capabilities, while manufacturers focus on throughput and standardization. End-product integrators, particularly in the automotive sector, emphasize testing solutions that can simulate real-world operating conditions.

Price sensitivity varies significantly across these segments, with research institutions often having access to grant funding for high-end equipment, while commercial manufacturers are increasingly seeking cost-effective solutions that can be deployed at scale. This has created a bifurcated market with premium and value-oriented product tiers emerging.

The competitive landscape features both established analytical instrument manufacturers expanding into fuel cell testing and specialized players focused exclusively on PEMFC testing solutions. Recent market consolidation through mergers and acquisitions suggests the industry is entering a maturation phase, with integrated testing platforms that combine AST protocols, inline sensing, and automated acceptance criteria evaluation becoming the new standard.

Current AST Protocols and Technical Challenges

Accelerated Stress Testing (AST) protocols for Proton Exchange Membrane Fuel Cells (PEMFCs) have evolved significantly over the past decade, with several standardized methodologies now established by organizations such as the U.S. Department of Energy (DOE), European Commission's Fuel Cells and Hydrogen Joint Undertaking (FCH JU), and the Japanese New Energy and Industrial Technology Development Organization (NEDO). These protocols aim to simulate real-world degradation mechanisms within compressed timeframes, enabling faster qualification and validation of fuel cell components and systems.

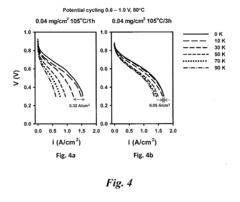

Current AST protocols primarily focus on four critical degradation areas: catalyst layer degradation, membrane degradation, support corrosion, and bipolar plate degradation. The DOE's protocols typically involve potential cycling between 0.6V and 0.95V for catalyst durability assessment, while membrane durability tests often incorporate relative humidity cycling under open circuit voltage conditions. These standardized approaches have become industry benchmarks but present several technical challenges.

A significant challenge with existing AST protocols is the lack of correlation between accelerated testing and real-world operational degradation. Studies indicate that degradation mechanisms triggered during AST may differ from those occurring during actual field operation, particularly regarding spatial distribution of degradation within the cell. This discrepancy complicates the extrapolation of AST results to predict real-world performance and lifetime.

Another critical limitation is the absence of universally accepted protocols for system-level testing. While component-level ASTs are well-established, comprehensive protocols that address the complex interactions between components under system-level operation remain underdeveloped. This gap is particularly problematic for automotive applications where system integration effects significantly impact overall durability.

The sensitivity of current protocols to testing conditions presents additional challenges. Minor variations in temperature control, gas humidification, or flow distribution can lead to substantial differences in test outcomes, compromising reproducibility across different testing facilities. This variability undermines confidence in qualification results and complicates cross-comparison between different fuel cell technologies.

Current inline sensing capabilities also present limitations for effective AST implementation. While voltage monitoring is standard, more advanced diagnostic tools such as spatially resolved current density measurement, localized impedance spectroscopy, and real-time gas analysis remain primarily research tools rather than integrated components of standardized testing protocols. This instrumentation gap limits the mechanistic insights that can be derived from AST procedures.

The definition of appropriate acceptance windows represents another significant challenge. Current industry standards often specify arbitrary performance thresholds (e.g., <10% voltage degradation after 30,000 cycles) without sufficient statistical validation or clear correlation to end-of-life criteria in actual applications. This approach can lead to either overly conservative or insufficiently rigorous qualification standards.

Current AST protocols primarily focus on four critical degradation areas: catalyst layer degradation, membrane degradation, support corrosion, and bipolar plate degradation. The DOE's protocols typically involve potential cycling between 0.6V and 0.95V for catalyst durability assessment, while membrane durability tests often incorporate relative humidity cycling under open circuit voltage conditions. These standardized approaches have become industry benchmarks but present several technical challenges.

A significant challenge with existing AST protocols is the lack of correlation between accelerated testing and real-world operational degradation. Studies indicate that degradation mechanisms triggered during AST may differ from those occurring during actual field operation, particularly regarding spatial distribution of degradation within the cell. This discrepancy complicates the extrapolation of AST results to predict real-world performance and lifetime.

Another critical limitation is the absence of universally accepted protocols for system-level testing. While component-level ASTs are well-established, comprehensive protocols that address the complex interactions between components under system-level operation remain underdeveloped. This gap is particularly problematic for automotive applications where system integration effects significantly impact overall durability.

The sensitivity of current protocols to testing conditions presents additional challenges. Minor variations in temperature control, gas humidification, or flow distribution can lead to substantial differences in test outcomes, compromising reproducibility across different testing facilities. This variability undermines confidence in qualification results and complicates cross-comparison between different fuel cell technologies.

Current inline sensing capabilities also present limitations for effective AST implementation. While voltage monitoring is standard, more advanced diagnostic tools such as spatially resolved current density measurement, localized impedance spectroscopy, and real-time gas analysis remain primarily research tools rather than integrated components of standardized testing protocols. This instrumentation gap limits the mechanistic insights that can be derived from AST procedures.

The definition of appropriate acceptance windows represents another significant challenge. Current industry standards often specify arbitrary performance thresholds (e.g., <10% voltage degradation after 30,000 cycles) without sufficient statistical validation or clear correlation to end-of-life criteria in actual applications. This approach can lead to either overly conservative or insufficiently rigorous qualification standards.

State-of-the-Art AST Protocol Implementation

01 Performance and durability testing parameters

PEMFC qualification involves rigorous performance and durability testing to ensure reliable operation. Key parameters include power density, voltage stability, current density, and lifetime testing under various operating conditions. These tests evaluate the fuel cell's ability to maintain performance over time and under stress conditions such as load cycling, start-stop cycles, and extended operation periods.- Performance and durability testing parameters: PEMFC qualification involves rigorous performance and durability testing to ensure reliable operation. Key parameters include power density, voltage stability, and lifetime under various operating conditions. Testing protocols typically measure cell performance degradation over time through accelerated stress tests that simulate real-world conditions. These tests evaluate the fuel cell's ability to maintain consistent power output and efficiency throughout its operational life.

- Membrane electrode assembly (MEA) qualification metrics: The membrane electrode assembly is a critical component requiring specific qualification parameters. Testing focuses on proton conductivity, gas permeability, mechanical strength, and chemical stability of the membrane. Electrode qualification includes catalyst activity, electrochemical surface area, and uniform distribution assessment. MEA testing also evaluates interface properties between layers and resistance to delamination under thermal and humidity cycling conditions.

- Environmental and operational condition parameters: PEMFC qualification requires testing under various environmental and operational conditions. Parameters include temperature range tolerance (typically -40°C to 120°C), humidity cycling resistance, freeze/thaw cycle durability, and altitude performance. Operational qualification involves testing response to load cycling, start-stop cycles, and idle conditions. These parameters ensure the fuel cell can function reliably across expected deployment environments and usage patterns.

- System integration and balance of plant qualification: System-level qualification parameters evaluate how the PEMFC integrates with auxiliary components. Testing includes thermal management efficiency, water management capabilities, gas supply system performance, and control system responsiveness. Parameters measure system startup time, load following capability, and efficiency across the operational range. These tests ensure the complete fuel cell system functions as a cohesive unit with all components working harmoniously under various conditions.

- Safety and regulatory compliance parameters: Safety qualification parameters ensure PEMFCs meet regulatory standards and operate safely. Testing includes hydrogen leak detection, electrical isolation integrity, pressure vessel compliance, and emergency shutdown functionality. Parameters also cover electromagnetic compatibility, vibration resistance, and shock tolerance. These tests verify the fuel cell's ability to operate safely under normal conditions and respond appropriately to fault scenarios, protecting both equipment and users.

02 Membrane electrode assembly (MEA) qualification metrics

The membrane electrode assembly is a critical component requiring specific qualification parameters. These include proton conductivity, gas permeability, mechanical strength, chemical stability, and electrode catalyst activity. Testing protocols evaluate membrane thickness uniformity, ion exchange capacity, water uptake characteristics, and resistance to chemical degradation under operating conditions to ensure optimal performance and longevity.Expand Specific Solutions03 Thermal management and operating temperature parameters

Thermal qualification parameters are essential for PEMFC reliability. These include temperature distribution uniformity, thermal cycling resistance, cooling system efficiency, and heat rejection capacity. Tests evaluate the fuel cell's performance across operating temperature ranges, thermal gradient management, freeze-start capability, and thermal stability under various load conditions to ensure consistent operation in different environments.Expand Specific Solutions04 Water and humidity management qualification

Water management is critical for PEMFC operation, requiring specific qualification parameters. These include membrane hydration levels, water balance monitoring, condensation control, and humidity tolerance ranges. Testing protocols evaluate the fuel cell's performance under varying humidity conditions, water removal efficiency, flooding resistance, and membrane dehydration prevention to ensure optimal proton conductivity and gas diffusion.Expand Specific Solutions05 Stack assembly and system integration parameters

System-level qualification parameters evaluate the complete PEMFC stack and its integration. These include uniform compression, sealing integrity, gas distribution uniformity, electrical connection quality, and balance-of-plant compatibility. Testing protocols assess stack uniformity, cell-to-cell voltage variation, pressure drop characteristics, manifold design efficiency, and overall system integration to ensure reliable operation in the intended application.Expand Specific Solutions

Leading PEMFC Testing Equipment Manufacturers

The PEMFC qualification market is currently in a growth phase, with increasing adoption across automotive, stationary power, and portable applications. The global market size for fuel cell testing equipment is projected to expand significantly as hydrogen economies develop worldwide. Technologically, the sector is transitioning from early maturity to standardization, with companies focusing on developing robust accelerated stress test (AST) protocols and inline monitoring solutions. Huawei Technologies and ZTE are leveraging their telecommunications expertise to develop advanced sensor networks for PEMFC systems, while State Grid Corporation of China is exploring grid integration capabilities. Academic institutions like Huazhong University of Science & Technology and Harbin Institute of Technology are contributing fundamental research, while specialized players such as Synaptics and Analog Devices are advancing sensor technologies critical for real-time PEMFC monitoring and qualification.

State Grid Corp. of China

Technical Solution: State Grid Corporation of China has developed comprehensive PEMFC qualification protocols focused on stationary power applications, particularly for grid support and backup power systems. Their AST methodology emphasizes long-duration steady-state operation interspersed with rapid load-following cycles to simulate grid-support scenarios. The corporation has implemented a distributed sensor network that combines conventional electrochemical measurements with thermal imaging and gas composition analysis at both inlet and outlet streams. Their acceptance criteria establish performance windows based on power density, efficiency, and degradation rate thresholds specific to different grid-support applications. State Grid has integrated these qualification protocols into their broader distributed energy resource certification framework, enabling standardized assessment of PEMFC systems for grid integration across various scales from kilowatt to megawatt installations.

Strengths: Extensive experience with grid integration requirements provides practical acceptance criteria; comprehensive testing infrastructure enables thorough qualification across multiple parameters. Weaknesses: Focus on stationary applications may limit applicability to transportation or portable PEMFC systems; conservative grid requirements may impose unnecessarily stringent qualification standards for some applications.

Huazhong University of Science & Technology

Technical Solution: Huazhong University of Science & Technology has developed advanced PEMFC qualification methodologies focusing on fundamental degradation mechanisms. Their AST protocols incorporate multi-stress factor acceleration, combining potential cycling, temperature cycling, and relative humidity cycling in a statistically designed experimental framework. Their sensor technology integrates distributed temperature sensing with segmented current density measurement, enabling spatial resolution of degradation phenomena within operating cells. The university has established performance-based acceptance windows derived from statistical analysis of degradation data across multiple cell designs, with particular emphasis on identifying early indicators of membrane and catalyst degradation. Their approach incorporates machine learning algorithms to correlate specific degradation signatures with failure modes, enabling predictive quality assessment during manufacturing and operation.

Strengths: Strong fundamental research approach provides deep understanding of degradation mechanisms; advanced data analytics enable predictive quality assessment. Weaknesses: Academic focus may present challenges in scaling to industrial applications; complex multi-parameter testing requires sophisticated equipment and expertise.

Key Innovations in Inline Sensor Technologies

Method for calculating optimal working pressure of proton exchange membrane fuel cell

PatentPendingCN118656967A

Innovation

- By establishing the battery voltage and current density polarization curves, using the interpolation method to convert into a three-dimensional curve, combined with the particle swarm optimization algorithm, the system efficiency is calculated and the working pressure is optimized to obtain the optimal working pressure under different current densities.

Rejuvenation of automotive fuel cells

PatentInactiveUS20150303497A1

Innovation

- A rejuvenation process involving dehydration of the fuel cell followed by exposure to a dry gas at elevated temperatures to mitigate current density deterioration, effectively reversing performance loss and maintaining high performance levels.

Regulatory Framework for Fuel Cell Testing

The regulatory landscape for fuel cell testing, particularly for Proton Exchange Membrane Fuel Cells (PEMFCs), has evolved significantly in response to the growing adoption of hydrogen technologies. International standards organizations have established comprehensive frameworks to ensure consistency, reliability, and safety in fuel cell qualification processes. The International Organization for Standardization (ISO) has developed the ISO 14687 standard, which specifies hydrogen fuel quality requirements for PEMFCs, while IEC 62282 provides standards for fuel cell technologies including testing methodologies.

In the United States, the Department of Energy (DOE) has established technical targets and testing protocols for fuel cell durability and performance. These include specific Accelerated Stress Test (AST) protocols designed to simulate long-term operational conditions within compressed timeframes. The DOE's Fuel Cell Technologies Office regularly updates these protocols to reflect technological advancements and emerging industry needs.

The European Union has implemented regulations through the Joint Research Centre (JRC) and the Fuel Cells and Hydrogen Joint Undertaking (FCH JU), which provide harmonized testing procedures across member states. These frameworks incorporate specific requirements for inline sensor implementation and define acceptance windows for various performance parameters. The EU's approach emphasizes the integration of fuel cell testing within broader hydrogen strategy frameworks, particularly focusing on green hydrogen production and utilization.

Japanese regulatory bodies, including NEDO (New Energy and Industrial Technology Development Organization), have pioneered some of the most stringent qualification standards for automotive fuel cell applications. Their frameworks specifically address durability requirements under various operational conditions and have significantly influenced global standards development.

Regulatory compliance for PEMFC qualification necessitates adherence to specific AST protocols that evaluate membrane degradation, catalyst stability, and overall system durability. These protocols typically require continuous monitoring through inline sensors measuring parameters such as cell voltage, current density, temperature distribution, and reactant utilization. The acceptance windows for these parameters vary based on application domains (automotive, stationary, portable) and are increasingly being standardized across international markets.

Recent regulatory developments have focused on harmonizing testing methodologies to facilitate global market access for fuel cell technologies. This includes the development of mutual recognition agreements between major regulatory bodies and the establishment of international certification schemes that reduce redundant testing requirements while maintaining rigorous quality standards.

In the United States, the Department of Energy (DOE) has established technical targets and testing protocols for fuel cell durability and performance. These include specific Accelerated Stress Test (AST) protocols designed to simulate long-term operational conditions within compressed timeframes. The DOE's Fuel Cell Technologies Office regularly updates these protocols to reflect technological advancements and emerging industry needs.

The European Union has implemented regulations through the Joint Research Centre (JRC) and the Fuel Cells and Hydrogen Joint Undertaking (FCH JU), which provide harmonized testing procedures across member states. These frameworks incorporate specific requirements for inline sensor implementation and define acceptance windows for various performance parameters. The EU's approach emphasizes the integration of fuel cell testing within broader hydrogen strategy frameworks, particularly focusing on green hydrogen production and utilization.

Japanese regulatory bodies, including NEDO (New Energy and Industrial Technology Development Organization), have pioneered some of the most stringent qualification standards for automotive fuel cell applications. Their frameworks specifically address durability requirements under various operational conditions and have significantly influenced global standards development.

Regulatory compliance for PEMFC qualification necessitates adherence to specific AST protocols that evaluate membrane degradation, catalyst stability, and overall system durability. These protocols typically require continuous monitoring through inline sensors measuring parameters such as cell voltage, current density, temperature distribution, and reactant utilization. The acceptance windows for these parameters vary based on application domains (automotive, stationary, portable) and are increasingly being standardized across international markets.

Recent regulatory developments have focused on harmonizing testing methodologies to facilitate global market access for fuel cell technologies. This includes the development of mutual recognition agreements between major regulatory bodies and the establishment of international certification schemes that reduce redundant testing requirements while maintaining rigorous quality standards.

Cost-Benefit Analysis of Advanced Testing Methods

The implementation of advanced testing methodologies for Proton Exchange Membrane Fuel Cells (PEMFCs) requires significant investment in equipment, expertise, and time. This analysis examines the economic implications of adopting sophisticated Accelerated Stress Tests (ASTs), inline sensors, and comprehensive acceptance criteria compared to traditional testing approaches.

Initial capital expenditure for advanced testing systems represents a substantial front-end cost. High-precision inline sensors for real-time monitoring of critical parameters such as membrane humidity, gas crossover, and electrochemical surface area can range from $50,000 to $250,000 depending on sophistication and integration capabilities. Additionally, specialized equipment for conducting standardized AST protocols may require investments of $100,000-500,000 per testing station.

Despite these considerable upfront costs, the long-term economic benefits present a compelling case for implementation. Advanced testing methodologies significantly reduce the time required for qualification, with AST protocols compressing years of operational degradation into weeks or months of testing. This acceleration factor translates to approximately 60-80% reduction in time-to-market for new PEMFC technologies, representing substantial competitive advantage and earlier revenue generation.

Operational cost savings emerge through multiple channels. Precise inline sensors enable early detection of failure modes, reducing waste from producing defective units. Data indicates that advanced testing can decrease scrap rates by 30-45% compared to conventional methods. Furthermore, comprehensive acceptance windows established through statistical analysis of performance data allow for more accurate prediction of field reliability, reducing warranty claims by an estimated 25-35%.

The enhanced data quality from advanced testing methods delivers additional value through improved design iteration. Engineers can identify specific degradation mechanisms with greater precision, enabling targeted improvements rather than broad redesigns. This focused approach reduces development cycles by approximately 40%, with corresponding reductions in engineering labor costs.

Risk mitigation represents perhaps the most significant though least quantifiable benefit. Early identification of potential failure modes through comprehensive AST protocols substantially reduces the likelihood of costly field recalls or reputation damage. Industry case studies suggest that advanced qualification testing can reduce major quality incidents by up to 70%, protecting both financial resources and market position.

When evaluating return on investment, most manufacturers implementing comprehensive PEMFC testing programs report breakeven periods of 18-36 months, with accelerating returns as testing expertise and data accumulation create additional efficiency improvements and competitive advantages in subsequent product generations.

Initial capital expenditure for advanced testing systems represents a substantial front-end cost. High-precision inline sensors for real-time monitoring of critical parameters such as membrane humidity, gas crossover, and electrochemical surface area can range from $50,000 to $250,000 depending on sophistication and integration capabilities. Additionally, specialized equipment for conducting standardized AST protocols may require investments of $100,000-500,000 per testing station.

Despite these considerable upfront costs, the long-term economic benefits present a compelling case for implementation. Advanced testing methodologies significantly reduce the time required for qualification, with AST protocols compressing years of operational degradation into weeks or months of testing. This acceleration factor translates to approximately 60-80% reduction in time-to-market for new PEMFC technologies, representing substantial competitive advantage and earlier revenue generation.

Operational cost savings emerge through multiple channels. Precise inline sensors enable early detection of failure modes, reducing waste from producing defective units. Data indicates that advanced testing can decrease scrap rates by 30-45% compared to conventional methods. Furthermore, comprehensive acceptance windows established through statistical analysis of performance data allow for more accurate prediction of field reliability, reducing warranty claims by an estimated 25-35%.

The enhanced data quality from advanced testing methods delivers additional value through improved design iteration. Engineers can identify specific degradation mechanisms with greater precision, enabling targeted improvements rather than broad redesigns. This focused approach reduces development cycles by approximately 40%, with corresponding reductions in engineering labor costs.

Risk mitigation represents perhaps the most significant though least quantifiable benefit. Early identification of potential failure modes through comprehensive AST protocols substantially reduces the likelihood of costly field recalls or reputation damage. Industry case studies suggest that advanced qualification testing can reduce major quality incidents by up to 70%, protecting both financial resources and market position.

When evaluating return on investment, most manufacturers implementing comprehensive PEMFC testing programs report breakeven periods of 18-36 months, with accelerating returns as testing expertise and data accumulation create additional efficiency improvements and competitive advantages in subsequent product generations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!