PEMFC Stack Compression: Seal Integrity, Contact Resistance And Deformation

SEP 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PEMFC Stack Compression Background and Objectives

Proton Exchange Membrane Fuel Cells (PEMFCs) have emerged as a promising clean energy technology since their development in the early 1960s. The evolution of PEMFC technology has been marked by significant improvements in materials, design, and manufacturing processes, with stack compression representing a critical aspect of this development. Stack compression directly impacts the performance, durability, and efficiency of fuel cell systems through its influence on seal integrity, electrical contact resistance, and component deformation.

The historical trajectory of PEMFC stack compression research began with rudimentary mechanical designs and has progressed toward sophisticated engineering solutions that balance multiple competing requirements. Early designs often employed excessive compression forces to ensure proper sealing and electrical contact, but this approach frequently resulted in mechanical damage to delicate components such as membrane electrode assemblies (MEAs) and gas diffusion layers (GDLs).

Current technological trends in PEMFC stack compression focus on optimizing the distribution of compression forces across the active area while maintaining adequate sealing at the periphery. This optimization aims to minimize contact resistance without causing excessive deformation of porous transport layers that could impede reactant gas flow and water management.

The primary technical objectives in this field include developing compression systems that provide uniform pressure distribution across the entire active area, maintain consistent compression throughout thermal and humidity cycling, and achieve long-term stability without relaxation or creep of components. Additionally, there is a growing emphasis on designing compression solutions that facilitate mass production and assembly automation to reduce manufacturing costs.

Another critical objective is to establish standardized testing methodologies and performance metrics for evaluating compression effects on fuel cell performance. This standardization would enable more effective comparison between different compression approaches and accelerate the identification of optimal solutions.

The advancement of computational modeling techniques has become increasingly important in this field, with objectives centered on developing accurate predictive models that can simulate the complex interplay between compression, material deformation, and electrochemical performance. These models aim to reduce the need for extensive experimental testing and enable rapid design iteration.

As PEMFC technology moves toward widespread commercial deployment in automotive, stationary, and portable applications, the objectives of compression research have expanded to include considerations of system integration, volume constraints, and cost reduction while maintaining performance and durability requirements across diverse operating conditions and duty cycles.

The historical trajectory of PEMFC stack compression research began with rudimentary mechanical designs and has progressed toward sophisticated engineering solutions that balance multiple competing requirements. Early designs often employed excessive compression forces to ensure proper sealing and electrical contact, but this approach frequently resulted in mechanical damage to delicate components such as membrane electrode assemblies (MEAs) and gas diffusion layers (GDLs).

Current technological trends in PEMFC stack compression focus on optimizing the distribution of compression forces across the active area while maintaining adequate sealing at the periphery. This optimization aims to minimize contact resistance without causing excessive deformation of porous transport layers that could impede reactant gas flow and water management.

The primary technical objectives in this field include developing compression systems that provide uniform pressure distribution across the entire active area, maintain consistent compression throughout thermal and humidity cycling, and achieve long-term stability without relaxation or creep of components. Additionally, there is a growing emphasis on designing compression solutions that facilitate mass production and assembly automation to reduce manufacturing costs.

Another critical objective is to establish standardized testing methodologies and performance metrics for evaluating compression effects on fuel cell performance. This standardization would enable more effective comparison between different compression approaches and accelerate the identification of optimal solutions.

The advancement of computational modeling techniques has become increasingly important in this field, with objectives centered on developing accurate predictive models that can simulate the complex interplay between compression, material deformation, and electrochemical performance. These models aim to reduce the need for extensive experimental testing and enable rapid design iteration.

As PEMFC technology moves toward widespread commercial deployment in automotive, stationary, and portable applications, the objectives of compression research have expanded to include considerations of system integration, volume constraints, and cost reduction while maintaining performance and durability requirements across diverse operating conditions and duty cycles.

Market Analysis for PEMFC Stack Technology

The global market for Proton Exchange Membrane Fuel Cell (PEMFC) stack technology has witnessed significant growth in recent years, driven primarily by increasing demand for clean energy solutions and the push towards decarbonization across various sectors. The market size for PEMFC technology was valued at approximately $4.5 billion in 2022, with projections indicating a compound annual growth rate (CAGR) of 21.4% through 2030, potentially reaching $20.7 billion by the end of the decade.

Transportation remains the dominant application segment, accounting for over 45% of the market share. This is largely attributed to the automotive industry's shift towards hydrogen fuel cell vehicles (FCVs) as a viable alternative to battery electric vehicles, particularly for heavy-duty and long-range applications. Major automotive manufacturers including Toyota, Hyundai, and Honda have made substantial investments in PEMFC technology for their vehicle lineups.

The stationary power generation sector represents the second-largest market segment, with growing adoption in backup power systems, distributed generation, and combined heat and power (CHP) applications. This segment is expected to grow at a CAGR of 23.2% through 2030, driven by increasing grid instability concerns and the need for reliable power sources.

Regionally, Asia Pacific dominates the PEMFC stack technology market, accounting for approximately 42% of global revenue. Japan, South Korea, and China lead this regional market due to favorable government policies, substantial R&D investments, and aggressive deployment targets for hydrogen infrastructure. North America and Europe follow closely, with both regions implementing supportive regulatory frameworks and incentive programs to accelerate PEMFC adoption.

Key market drivers include declining production costs, with the cost per kilowatt of PEMFC systems decreasing by approximately 60% over the past decade. Technological advancements in stack compression techniques that address seal integrity, contact resistance, and deformation issues have contributed significantly to this cost reduction while simultaneously improving performance and durability metrics.

Market challenges persist, including the need for further cost reductions to achieve price parity with conventional technologies, limited hydrogen infrastructure, and technical hurdles related to stack compression optimization. The balance between adequate compression for electrical conductivity and preventing excessive mechanical stress remains a critical engineering challenge that directly impacts market growth potential.

Industry analysts forecast that breakthroughs in stack compression technology could reduce PEMFC system costs by an additional 25-30% by 2025, potentially accelerating market adoption across multiple sectors and strengthening the competitive position of PEMFC technology in the broader clean energy landscape.

Transportation remains the dominant application segment, accounting for over 45% of the market share. This is largely attributed to the automotive industry's shift towards hydrogen fuel cell vehicles (FCVs) as a viable alternative to battery electric vehicles, particularly for heavy-duty and long-range applications. Major automotive manufacturers including Toyota, Hyundai, and Honda have made substantial investments in PEMFC technology for their vehicle lineups.

The stationary power generation sector represents the second-largest market segment, with growing adoption in backup power systems, distributed generation, and combined heat and power (CHP) applications. This segment is expected to grow at a CAGR of 23.2% through 2030, driven by increasing grid instability concerns and the need for reliable power sources.

Regionally, Asia Pacific dominates the PEMFC stack technology market, accounting for approximately 42% of global revenue. Japan, South Korea, and China lead this regional market due to favorable government policies, substantial R&D investments, and aggressive deployment targets for hydrogen infrastructure. North America and Europe follow closely, with both regions implementing supportive regulatory frameworks and incentive programs to accelerate PEMFC adoption.

Key market drivers include declining production costs, with the cost per kilowatt of PEMFC systems decreasing by approximately 60% over the past decade. Technological advancements in stack compression techniques that address seal integrity, contact resistance, and deformation issues have contributed significantly to this cost reduction while simultaneously improving performance and durability metrics.

Market challenges persist, including the need for further cost reductions to achieve price parity with conventional technologies, limited hydrogen infrastructure, and technical hurdles related to stack compression optimization. The balance between adequate compression for electrical conductivity and preventing excessive mechanical stress remains a critical engineering challenge that directly impacts market growth potential.

Industry analysts forecast that breakthroughs in stack compression technology could reduce PEMFC system costs by an additional 25-30% by 2025, potentially accelerating market adoption across multiple sectors and strengthening the competitive position of PEMFC technology in the broader clean energy landscape.

Technical Challenges in Stack Compression Systems

Stack compression systems in PEMFC (Proton Exchange Membrane Fuel Cell) technology face several critical technical challenges that significantly impact overall performance and durability. The primary challenge lies in achieving optimal compression pressure distribution across the entire active area of the cell stack. Uneven compression leads to localized stress concentrations, resulting in mechanical deformation of bipolar plates and membrane electrode assemblies (MEAs), which can cause premature component failure and reduced stack lifetime.

Seal integrity represents another major challenge, as maintaining gas-tight seals under varying operating conditions is essential for preventing reactant crossover and ensuring safety. Current sealing materials, typically elastomers or gaskets, experience stress relaxation over time, leading to compression loss and potential leakage paths. This issue is exacerbated by thermal cycling during operation, which causes differential thermal expansion between stack components and further compromises seal integrity.

Contact resistance management presents significant technical difficulties, particularly at the interfaces between gas diffusion layers (GDLs) and bipolar plates. Insufficient compression increases electrical resistance, while excessive compression can damage porous transport layers and restrict reactant flow. The inherent trade-off between electrical conductivity and mass transport creates a narrow operational window for optimal compression.

Material selection for compression systems introduces additional complexities. Compression hardware must maintain consistent force while withstanding corrosive environments and high temperatures. Traditional metal springs and hydraulic systems suffer from stress relaxation and fluid leakage respectively, while newer technologies like Belleville washers and pneumatic systems present their own integration challenges.

Monitoring and control of compression during operation remains technically challenging. Real-time measurement of compression force distribution is difficult to implement without introducing additional components that may compromise stack integrity. Most current systems rely on initial assembly compression without capability for dynamic adjustment during operation, leading to suboptimal performance as components age and deform.

Manufacturing variability compounds these challenges, as component thickness tolerances directly impact compression distribution. Even minor variations in GDL, MEA, or gasket thickness can create significant pressure differentials across the active area. Advanced manufacturing techniques and quality control processes are required to minimize these variations and ensure consistent compression.

Seal integrity represents another major challenge, as maintaining gas-tight seals under varying operating conditions is essential for preventing reactant crossover and ensuring safety. Current sealing materials, typically elastomers or gaskets, experience stress relaxation over time, leading to compression loss and potential leakage paths. This issue is exacerbated by thermal cycling during operation, which causes differential thermal expansion between stack components and further compromises seal integrity.

Contact resistance management presents significant technical difficulties, particularly at the interfaces between gas diffusion layers (GDLs) and bipolar plates. Insufficient compression increases electrical resistance, while excessive compression can damage porous transport layers and restrict reactant flow. The inherent trade-off between electrical conductivity and mass transport creates a narrow operational window for optimal compression.

Material selection for compression systems introduces additional complexities. Compression hardware must maintain consistent force while withstanding corrosive environments and high temperatures. Traditional metal springs and hydraulic systems suffer from stress relaxation and fluid leakage respectively, while newer technologies like Belleville washers and pneumatic systems present their own integration challenges.

Monitoring and control of compression during operation remains technically challenging. Real-time measurement of compression force distribution is difficult to implement without introducing additional components that may compromise stack integrity. Most current systems rely on initial assembly compression without capability for dynamic adjustment during operation, leading to suboptimal performance as components age and deform.

Manufacturing variability compounds these challenges, as component thickness tolerances directly impact compression distribution. Even minor variations in GDL, MEA, or gasket thickness can create significant pressure differentials across the active area. Advanced manufacturing techniques and quality control processes are required to minimize these variations and ensure consistent compression.

Current Compression Solutions and Methodologies

01 Stack compression techniques for PEMFC

Various compression techniques are employed in PEMFC stacks to ensure optimal contact between components. These include mechanical compression systems, spring-loaded mechanisms, and hydraulic compression methods. Proper compression is critical for reducing contact resistance between bipolar plates and membrane electrode assemblies, which directly impacts the overall performance and efficiency of the fuel cell stack. Controlled compression also helps prevent over-compression that could lead to membrane damage or deformation of other stack components.- Stack compression techniques for PEMFC: Various compression techniques are employed in PEMFC stacks to ensure optimal contact between components. These include mechanical compression systems, spring-loaded mechanisms, and hydraulic compression methods. Proper compression is critical for reducing contact resistance between bipolar plates and membrane electrode assemblies, which directly impacts the fuel cell's electrical performance and efficiency. Controlled compression also helps prevent over-compression that could damage delicate components.

- Seal integrity and leakage prevention: Seal integrity is crucial for preventing gas leakage in PEMFC stacks. Various sealing materials and designs are utilized, including gaskets, O-rings, and integrated sealing solutions. Advanced sealing technologies incorporate elastomeric compounds with specific hardness and compression set characteristics to maintain seal integrity under thermal cycling and mechanical stress. Some designs feature self-healing or self-adjusting seals that respond to changes in operating conditions to maintain consistent sealing pressure throughout the stack's operational life.

- Contact resistance optimization: Minimizing contact resistance between stack components is essential for PEMFC efficiency. This is achieved through surface treatments of bipolar plates, application of conductive coatings, and optimization of interface materials. Contact resistance is particularly critical at the interface between gas diffusion layers and bipolar plates. Techniques such as micropatterned surfaces, conductive pastes, and controlled surface roughness help ensure uniform electrical contact across the active area, reducing hotspots and improving overall stack performance.

- Deformation analysis and prevention: Component deformation in PEMFC stacks can lead to performance degradation and failure. Methods for analyzing and preventing deformation include finite element analysis, stress distribution modeling, and material selection for dimensional stability. Reinforced membrane designs, optimized flow field patterns, and graduated compression systems help distribute mechanical stress evenly across components. Some approaches incorporate real-time monitoring of deformation during operation to adjust compression dynamically and prevent permanent component damage.

- Compression measurement and control systems: Advanced systems for measuring and controlling compression in PEMFC stacks ensure optimal performance throughout operation. These include pressure-sensitive films, embedded sensors, and automated compression control mechanisms. Real-time monitoring allows for dynamic adjustment of compression forces in response to changing operating conditions, thermal expansion, and component aging. Some systems incorporate machine learning algorithms to predict optimal compression settings based on operating parameters and historical performance data.

02 Seal integrity and leakage prevention

Maintaining seal integrity in PEMFC stacks is essential to prevent reactant gas leakage and ensure operational efficiency. Various sealing materials and designs are utilized, including gaskets, O-rings, and integrated sealing solutions. Advanced sealing technologies incorporate elastomeric compounds with specific compression properties that maintain their integrity under thermal cycling and mechanical stress. Proper seal design must balance compression forces to prevent both under-compression (leading to leaks) and over-compression (causing seal damage or deformation of adjacent components).Expand Specific Solutions03 Contact resistance optimization

Minimizing contact resistance between PEMFC stack components is crucial for maximizing electrical efficiency and power output. This is achieved through surface treatments of bipolar plates, application of conductive coatings, and optimization of compression forces. Contact resistance is particularly important at the interface between gas diffusion layers and bipolar plates. Techniques for measuring and monitoring contact resistance during assembly and operation help ensure optimal stack performance throughout the fuel cell lifetime.Expand Specific Solutions04 Component deformation analysis and prevention

Deformation of PEMFC components under compression can significantly impact performance and durability. Advanced modeling techniques and experimental methods are used to analyze stress distribution and resulting deformation in membranes, gas diffusion layers, and bipolar plates. Strategies to mitigate harmful deformation include optimized component designs, reinforced materials, and controlled compression distribution systems. Uniform compression across the active area helps prevent localized deformation that could lead to performance degradation or premature failure.Expand Specific Solutions05 Monitoring and control systems for stack compression

Real-time monitoring and control systems for PEMFC stack compression ensure optimal performance throughout operation. These systems incorporate pressure sensors, displacement transducers, and advanced algorithms to maintain ideal compression levels despite thermal expansion, material relaxation, and other dynamic factors. Adaptive compression control systems can adjust compression forces in response to changing operating conditions, extending stack lifetime and maintaining consistent performance. Some designs include self-adjusting mechanisms that compensate for component settling or relaxation over time.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The PEMFC stack compression technology market is currently in a growth phase, with increasing focus on optimizing seal integrity, contact resistance, and deformation challenges. The market is expanding as fuel cell adoption accelerates across automotive, stationary power, and industrial applications. Leading players include established automotive giants like Robert Bosch, Honda Motor, and Mercedes-Benz Group, who are investing heavily in fuel cell technology. Specialized sealing solution providers such as Trelleborg Sealing Solutions, ElringKlinger, and EagleBurgmann bring critical expertise in managing compression issues. Research institutions like Korea Advanced Institute of Science & Technology and Guangzhou University are advancing fundamental understanding, while materials companies including Shin-Etsu Chemical and W.L. Gore contribute innovative materials solutions. The technology is approaching commercial maturity but still requires optimization for cost reduction and durability improvement.

Robert Bosch GmbH

Technical Solution: Bosch has developed an advanced compression system for PEMFC stacks that utilizes dynamic pressure regulation technology. Their solution incorporates pressure-sensitive sensors integrated within the stack assembly to continuously monitor compression forces during operation. The system automatically adjusts compression through electromechanical actuators based on real-time feedback, maintaining optimal contact pressure despite thermal cycling and material relaxation. Bosch's approach includes specialized edge sealing designs that prevent reactant leakage while accommodating dimensional changes during operation. Their compression plates feature optimized flow field designs that distribute pressure evenly across the active area, reducing localized stress concentrations that can damage membrane electrode assemblies (MEAs). The company has also developed proprietary gasket materials specifically engineered to maintain seal integrity under varying temperature and humidity conditions typical in automotive PEMFC applications.

Strengths: Superior dynamic pressure regulation that adapts to changing operating conditions; integrated sensor technology provides real-time monitoring capabilities; automotive-grade reliability suitable for demanding transportation applications. Weaknesses: Higher system complexity increases cost; requires additional control systems and power for actuators; potential reliability concerns with long-term operation of mechanical components.

Weichai Power

Technical Solution: Weichai Power has pioneered a comprehensive PEMFC stack compression solution focused on commercial vehicle applications. Their technology employs a hybrid compression system combining rigid end plates with internal elastic elements strategically positioned to maintain optimal contact pressure across the entire active area. The company's approach features specially designed compression plates manufactured using precision CNC machining that ensure parallelism within 0.02mm across large-format stacks. Weichai has developed a proprietary clamping mechanism that compensates for material creep and thermal expansion during operation while maintaining consistent compression force. Their sealing solution incorporates multi-layer gasket technology with reinforced edge regions to prevent gas leakage under high-pressure hydrogen operation. The company has also implemented advanced computational modeling to optimize compression distribution, reducing contact resistance while preventing excessive deformation of bipolar plates and MEAs. This technology has been successfully deployed in their commercial fuel cell systems for heavy-duty trucks and buses.

Strengths: Optimized for heavy-duty applications with proven durability in commercial vehicles; excellent pressure distribution across large-format stacks; robust design suitable for high vibration environments. Weaknesses: System is relatively heavy compared to competitors; limited flexibility for different stack sizes requires significant redesign for new applications; higher manufacturing costs due to precision machining requirements.

Key Patents and Research on Seal Integrity

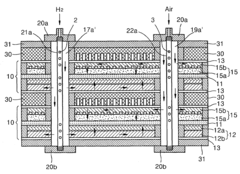

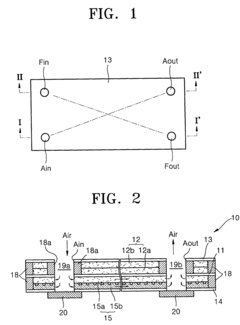

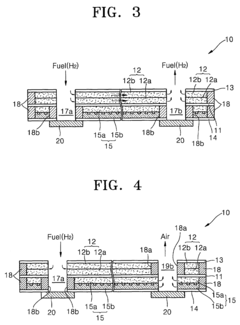

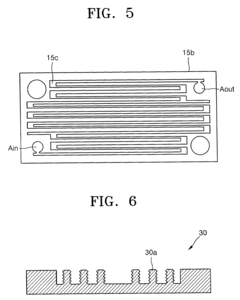

Proton exchange membrane fuel cell stack

PatentInactiveUS7335436B2

Innovation

- A PEMFC stack design featuring catalyzed membranes with parallel and orthogonal flow fields, bipolar plates, and external sealing layers to facilitate easy assembly and disassembly, along with conductive cooling members for improved heat dissipation and fuel conversion efficiency.

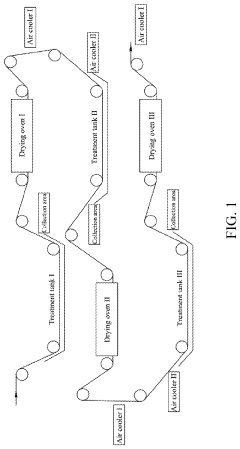

Preparation process for composite membrane for fuel cell

PatentPendingUS20240039024A1

Innovation

- A multi-stage impregnation process for composite membranes using tetrafluoroethylene microporous membranes, involving pre-treatment with alkaline solvents and ultraviolet irradiation, followed by sequential impregnation with perfluorosulfonic acid resin solutions and sulfonated polyetheretherketone, with water-retaining agents and free radical quenchers to ensure uniform resin distribution and enhanced mechanical and electrochemical performance.

Material Science Advancements for PEMFC Components

Recent advancements in material science have significantly contributed to overcoming challenges in PEMFC stack compression, particularly addressing seal integrity, contact resistance, and deformation issues. Novel composite materials with enhanced mechanical properties have been developed specifically for bipolar plates, allowing for more uniform compression distribution across the stack while maintaining electrical conductivity.

Elastomeric materials with improved chemical resistance have revolutionized sealing technologies in PEMFCs. These materials demonstrate exceptional durability under the harsh operating conditions of fuel cells, including exposure to acidic environments and temperature fluctuations. Silicone-based compounds reinforced with nanomaterials have shown particular promise, exhibiting minimal stress relaxation over extended operational periods while maintaining gas impermeability.

For gas diffusion layers (GDLs), carbon-based materials with optimized porosity and compressibility characteristics have been engineered to balance mechanical stability with mass transport properties. These advanced GDLs maintain effective electrical contact under compression while minimizing deformation that could impede reactant flow channels.

Membrane electrode assembly (MEA) components have benefited from reinforced polymer membranes that resist mechanical degradation under compression. These reinforced membranes incorporate supportive networks that distribute compressive forces more evenly, reducing the risk of pinhole formation and subsequent gas crossover failures that compromise cell performance.

Interface materials between stack components have seen significant innovation through the development of electrically conductive interface pastes and coatings. These materials effectively reduce contact resistance while accommodating microscale surface irregularities that would otherwise create uneven compression profiles across the active area.

Computational material science has enabled precise modeling of material behavior under various compression scenarios, allowing for virtual testing of new material formulations before physical prototyping. This approach has accelerated the development cycle for compression-optimized components while reducing experimental costs.

Nanomaterial incorporation into traditional PEMFC components has yielded composite structures with unprecedented combinations of flexibility and strength. Carbon nanotubes and graphene-enhanced polymers demonstrate superior resistance to compression-induced deformation while maintaining essential functional properties such as gas impermeability for seals and electrical conductivity for bipolar plates.

Elastomeric materials with improved chemical resistance have revolutionized sealing technologies in PEMFCs. These materials demonstrate exceptional durability under the harsh operating conditions of fuel cells, including exposure to acidic environments and temperature fluctuations. Silicone-based compounds reinforced with nanomaterials have shown particular promise, exhibiting minimal stress relaxation over extended operational periods while maintaining gas impermeability.

For gas diffusion layers (GDLs), carbon-based materials with optimized porosity and compressibility characteristics have been engineered to balance mechanical stability with mass transport properties. These advanced GDLs maintain effective electrical contact under compression while minimizing deformation that could impede reactant flow channels.

Membrane electrode assembly (MEA) components have benefited from reinforced polymer membranes that resist mechanical degradation under compression. These reinforced membranes incorporate supportive networks that distribute compressive forces more evenly, reducing the risk of pinhole formation and subsequent gas crossover failures that compromise cell performance.

Interface materials between stack components have seen significant innovation through the development of electrically conductive interface pastes and coatings. These materials effectively reduce contact resistance while accommodating microscale surface irregularities that would otherwise create uneven compression profiles across the active area.

Computational material science has enabled precise modeling of material behavior under various compression scenarios, allowing for virtual testing of new material formulations before physical prototyping. This approach has accelerated the development cycle for compression-optimized components while reducing experimental costs.

Nanomaterial incorporation into traditional PEMFC components has yielded composite structures with unprecedented combinations of flexibility and strength. Carbon nanotubes and graphene-enhanced polymers demonstrate superior resistance to compression-induced deformation while maintaining essential functional properties such as gas impermeability for seals and electrical conductivity for bipolar plates.

Durability and Lifetime Assessment Methods

Durability assessment of PEMFC stack compression systems requires comprehensive methodologies to evaluate long-term performance under various operational conditions. Accelerated stress testing (AST) protocols have been developed specifically for compression components, subjecting seals and bipolar plates to thermal cycling, humidity fluctuations, and mechanical load variations that simulate years of operation within weeks or months. These protocols typically involve 5,000-10,000 cycles of temperature variations between -40°C and 90°C to evaluate seal integrity degradation over time.

In-situ monitoring techniques have advanced significantly, allowing real-time assessment of compression-related parameters during stack operation. Distributed pressure-sensitive films and embedded force sensors provide spatial resolution of compression distribution, while electrical impedance spectroscopy (EIS) measurements track changes in contact resistance as compression elements degrade. These methods enable early detection of compression-related failure modes before catastrophic stack failure occurs.

Ex-situ characterization methods complement operational testing by focusing on material property changes. Stress relaxation testing of gaskets and seals under constant deformation reveals their time-dependent behavior, typically showing 15-30% reduction in sealing force after 5,000 hours at operating temperature. Compression set measurements quantify the permanent deformation of elastomeric components, with values exceeding 70% generally indicating end-of-life conditions for most sealing materials.

Computational lifetime prediction models have emerged as valuable tools for durability assessment. Finite element analysis incorporating viscoelastic material models can predict long-term compression behavior based on short-term test data. These models typically employ time-temperature superposition principles to extrapolate material performance beyond practical test durations, though validation against real-world data remains challenging.

Standardized test procedures from organizations like the US Department of Energy and the International Electrotechnical Commission provide benchmarks for durability assessment. Current targets specify that compression systems should maintain performance with less than 10% degradation in seal integrity and contact resistance over 5,000-8,000 hours of operation under dynamic conditions, though automotive applications increasingly demand 20,000+ hour lifetimes.

Post-mortem analysis techniques complete the durability assessment toolkit, offering insights into failure mechanisms after testing. Surface profilometry, scanning electron microscopy, and chemical composition analysis reveal degradation patterns in compression components, while mechanical property testing of aged materials quantifies the extent of property changes that occurred during operation.

In-situ monitoring techniques have advanced significantly, allowing real-time assessment of compression-related parameters during stack operation. Distributed pressure-sensitive films and embedded force sensors provide spatial resolution of compression distribution, while electrical impedance spectroscopy (EIS) measurements track changes in contact resistance as compression elements degrade. These methods enable early detection of compression-related failure modes before catastrophic stack failure occurs.

Ex-situ characterization methods complement operational testing by focusing on material property changes. Stress relaxation testing of gaskets and seals under constant deformation reveals their time-dependent behavior, typically showing 15-30% reduction in sealing force after 5,000 hours at operating temperature. Compression set measurements quantify the permanent deformation of elastomeric components, with values exceeding 70% generally indicating end-of-life conditions for most sealing materials.

Computational lifetime prediction models have emerged as valuable tools for durability assessment. Finite element analysis incorporating viscoelastic material models can predict long-term compression behavior based on short-term test data. These models typically employ time-temperature superposition principles to extrapolate material performance beyond practical test durations, though validation against real-world data remains challenging.

Standardized test procedures from organizations like the US Department of Energy and the International Electrotechnical Commission provide benchmarks for durability assessment. Current targets specify that compression systems should maintain performance with less than 10% degradation in seal integrity and contact resistance over 5,000-8,000 hours of operation under dynamic conditions, though automotive applications increasingly demand 20,000+ hour lifetimes.

Post-mortem analysis techniques complete the durability assessment toolkit, offering insights into failure mechanisms after testing. Surface profilometry, scanning electron microscopy, and chemical composition analysis reveal degradation patterns in compression components, while mechanical property testing of aged materials quantifies the extent of property changes that occurred during operation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!