PEMFC Membrane Thinning: Chemical Degradation, Mechanical Fatigue And Lifetime Mapping

SEP 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PEMFC Membrane Evolution and Research Objectives

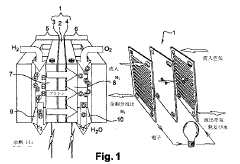

Proton Exchange Membrane Fuel Cells (PEMFCs) have evolved significantly since their inception in the early 1960s at General Electric. Initially developed for NASA's Gemini space program, these fuel cells have undergone substantial transformations in terms of materials, design, and performance characteristics. The evolution of PEMFC membranes represents a critical aspect of this technological progression, with Nafion (developed by DuPont) emerging as the industry standard due to its superior proton conductivity and chemical stability.

The historical trajectory of PEMFC membrane development reveals a consistent focus on enhancing durability while reducing thickness. Early membranes exceeded 175 μm in thickness, whereas contemporary high-performance membranes have been reduced to 10-25 μm. This thinning trend has enabled significant improvements in power density and efficiency but has simultaneously introduced new challenges related to mechanical integrity and chemical stability.

Membrane thinning, while beneficial for performance metrics, creates a complex interplay between chemical degradation mechanisms and mechanical stress factors. Chemical degradation primarily occurs through radical attack, particularly from hydroxyl and hydroperoxyl radicals generated during fuel cell operation. These radicals attack the polymer backbone and side chains, leading to membrane decomposition and thinning over time.

Mechanical fatigue represents another critical degradation pathway, resulting from hygrothermal cycling during operational and shutdown periods. The repeated swelling and contraction of the membrane creates mechanical stress that can lead to pinhole formation, cracking, and eventual failure. The intersection of these chemical and mechanical degradation mechanisms presents a multifaceted challenge that requires comprehensive understanding.

Current research objectives in the field focus on developing a holistic understanding of membrane degradation mechanisms and their interdependencies. Specifically, researchers aim to establish quantitative relationships between operational conditions, degradation rates, and membrane lifetime. This includes mapping the relative contributions of chemical and mechanical factors across different operating regimes and developing accelerated testing protocols that accurately predict real-world performance.

Another key research objective involves creating predictive models that can estimate membrane lifetime based on operational parameters and material properties. These models seek to incorporate both chemical degradation kinetics and mechanical stress analysis to provide a comprehensive framework for lifetime prediction. The ultimate goal is to develop design guidelines for next-generation membranes that optimize the balance between performance and durability.

Advanced characterization techniques, including in-situ and operando methods, represent a critical research focus area for monitoring membrane degradation in real-time. These techniques aim to provide deeper insights into degradation mechanisms under actual operating conditions, enabling more effective mitigation strategies and material innovations.

The historical trajectory of PEMFC membrane development reveals a consistent focus on enhancing durability while reducing thickness. Early membranes exceeded 175 μm in thickness, whereas contemporary high-performance membranes have been reduced to 10-25 μm. This thinning trend has enabled significant improvements in power density and efficiency but has simultaneously introduced new challenges related to mechanical integrity and chemical stability.

Membrane thinning, while beneficial for performance metrics, creates a complex interplay between chemical degradation mechanisms and mechanical stress factors. Chemical degradation primarily occurs through radical attack, particularly from hydroxyl and hydroperoxyl radicals generated during fuel cell operation. These radicals attack the polymer backbone and side chains, leading to membrane decomposition and thinning over time.

Mechanical fatigue represents another critical degradation pathway, resulting from hygrothermal cycling during operational and shutdown periods. The repeated swelling and contraction of the membrane creates mechanical stress that can lead to pinhole formation, cracking, and eventual failure. The intersection of these chemical and mechanical degradation mechanisms presents a multifaceted challenge that requires comprehensive understanding.

Current research objectives in the field focus on developing a holistic understanding of membrane degradation mechanisms and their interdependencies. Specifically, researchers aim to establish quantitative relationships between operational conditions, degradation rates, and membrane lifetime. This includes mapping the relative contributions of chemical and mechanical factors across different operating regimes and developing accelerated testing protocols that accurately predict real-world performance.

Another key research objective involves creating predictive models that can estimate membrane lifetime based on operational parameters and material properties. These models seek to incorporate both chemical degradation kinetics and mechanical stress analysis to provide a comprehensive framework for lifetime prediction. The ultimate goal is to develop design guidelines for next-generation membranes that optimize the balance between performance and durability.

Advanced characterization techniques, including in-situ and operando methods, represent a critical research focus area for monitoring membrane degradation in real-time. These techniques aim to provide deeper insights into degradation mechanisms under actual operating conditions, enabling more effective mitigation strategies and material innovations.

Market Analysis for Durable PEMFC Technologies

The global market for durable PEMFC (Proton Exchange Membrane Fuel Cell) technologies is experiencing significant growth, driven by increasing demand for clean energy solutions across automotive, stationary power, and portable applications. Current market valuations indicate the PEMFC market reached approximately 4.5 billion USD in 2022, with projections suggesting a compound annual growth rate of 21.7% through 2030, potentially reaching 26.8 billion USD.

Durability remains a critical market differentiator, with membrane thinning issues representing one of the primary barriers to widespread commercial adoption. End-users across sectors consistently rank longevity as a top purchasing consideration, with automotive applications demanding 5,000-8,000 hours of operation (equivalent to 150,000-240,000 miles) and stationary applications requiring 40,000-60,000 hours (5-7 years of continuous operation).

Regional market analysis reveals Asia-Pacific as the fastest-growing market segment, with Japan, South Korea, and China making substantial investments in hydrogen infrastructure and fuel cell manufacturing capabilities. North America and Europe maintain strong positions through established research networks and policy support mechanisms, including substantial subsidies for hydrogen technologies.

Customer segmentation shows distinct requirements across application domains. The automotive sector prioritizes rapid start-up capability and freeze-thaw cycle resistance alongside membrane durability. Stationary power applications emphasize continuous operation under varying load conditions, while portable and backup power systems require reliable performance after extended storage periods.

Market barriers specifically related to membrane durability include cost premiums for enhanced materials, with high-performance membranes commanding 30-45% price increases over standard options. This creates a complex value proposition where initial acquisition costs must be balanced against lifetime operational benefits.

Competitive analysis reveals a market bifurcation between established players focusing on incremental improvements to existing membrane technologies and emerging companies pursuing radical innovations in material science. Patent activity in membrane durability has increased by 37% over the past five years, indicating intensifying R&D focus on addressing degradation mechanisms.

Customer willingness-to-pay assessments demonstrate that commercial fleet operators are increasingly receptive to premium pricing for demonstrably durable fuel cell systems, recognizing the total cost of ownership benefits. This trend is particularly pronounced in material handling applications, where operational downtime carries significant financial penalties.

Durability remains a critical market differentiator, with membrane thinning issues representing one of the primary barriers to widespread commercial adoption. End-users across sectors consistently rank longevity as a top purchasing consideration, with automotive applications demanding 5,000-8,000 hours of operation (equivalent to 150,000-240,000 miles) and stationary applications requiring 40,000-60,000 hours (5-7 years of continuous operation).

Regional market analysis reveals Asia-Pacific as the fastest-growing market segment, with Japan, South Korea, and China making substantial investments in hydrogen infrastructure and fuel cell manufacturing capabilities. North America and Europe maintain strong positions through established research networks and policy support mechanisms, including substantial subsidies for hydrogen technologies.

Customer segmentation shows distinct requirements across application domains. The automotive sector prioritizes rapid start-up capability and freeze-thaw cycle resistance alongside membrane durability. Stationary power applications emphasize continuous operation under varying load conditions, while portable and backup power systems require reliable performance after extended storage periods.

Market barriers specifically related to membrane durability include cost premiums for enhanced materials, with high-performance membranes commanding 30-45% price increases over standard options. This creates a complex value proposition where initial acquisition costs must be balanced against lifetime operational benefits.

Competitive analysis reveals a market bifurcation between established players focusing on incremental improvements to existing membrane technologies and emerging companies pursuing radical innovations in material science. Patent activity in membrane durability has increased by 37% over the past five years, indicating intensifying R&D focus on addressing degradation mechanisms.

Customer willingness-to-pay assessments demonstrate that commercial fleet operators are increasingly receptive to premium pricing for demonstrably durable fuel cell systems, recognizing the total cost of ownership benefits. This trend is particularly pronounced in material handling applications, where operational downtime carries significant financial penalties.

Global PEMFC Membrane Degradation Challenges

Proton Exchange Membrane Fuel Cells (PEMFCs) face significant degradation challenges globally, with membrane thinning representing one of the most critical failure modes affecting performance and durability. The membrane, typically composed of perfluorosulfonic acid polymers like Nafion, serves as both an electrolyte and a barrier between reactants, making its integrity essential for fuel cell operation.

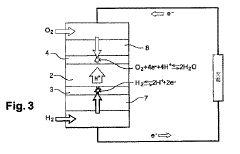

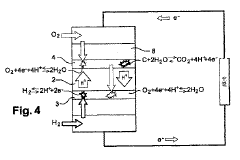

Chemical degradation of PEMFC membranes occurs primarily through radical attack mechanisms. Hydrogen peroxide (H₂O₂) formed during operation decomposes into highly reactive hydroxyl (•OH) and hydroperoxyl (•OOH) radicals that attack polymer end groups and side chains. This process is particularly accelerated by metal ion contamination, which catalyzes radical formation through Fenton reactions.

Mechanical fatigue constitutes another major degradation pathway globally observed in PEMFC systems. Membranes undergo significant dimensional changes during hydration/dehydration cycles and freeze/thaw events. These stresses induce mechanical failures including pinhole formation, cracking, and delamination from electrode layers. The repeated swelling and contraction during operational cycling creates cumulative damage that eventually leads to catastrophic failure.

Regional variations in degradation patterns present additional challenges. In cold-climate regions like Northern Europe, Canada, and parts of China, freeze/thaw damage predominates. Conversely, in hot, humid environments such as Southeast Asia, chemical degradation accelerates due to increased reaction kinetics at higher temperatures.

Manufacturing inconsistencies across global supply chains further complicate membrane durability. Variations in membrane thickness uniformity, reinforcement quality, and chemical stabilization techniques lead to significant performance disparities between nominally identical fuel cell systems deployed in different regions.

Automotive applications face particularly severe degradation challenges due to dynamic load cycling, frequent start-stop operations, and exposure to contaminants. Stationary power applications, while experiencing more stable operating conditions, still suffer from long-term chemical degradation that limits system lifetime to typically under 40,000 hours—well below the 80,000+ hours desired for commercial viability.

Recent global research has identified correlations between operating conditions and degradation rates, enabling the development of lifetime mapping methodologies. These approaches combine accelerated stress testing with mathematical modeling to predict membrane failure under various usage scenarios, though significant gaps remain in accounting for real-world variability and combined stress factors.

Chemical degradation of PEMFC membranes occurs primarily through radical attack mechanisms. Hydrogen peroxide (H₂O₂) formed during operation decomposes into highly reactive hydroxyl (•OH) and hydroperoxyl (•OOH) radicals that attack polymer end groups and side chains. This process is particularly accelerated by metal ion contamination, which catalyzes radical formation through Fenton reactions.

Mechanical fatigue constitutes another major degradation pathway globally observed in PEMFC systems. Membranes undergo significant dimensional changes during hydration/dehydration cycles and freeze/thaw events. These stresses induce mechanical failures including pinhole formation, cracking, and delamination from electrode layers. The repeated swelling and contraction during operational cycling creates cumulative damage that eventually leads to catastrophic failure.

Regional variations in degradation patterns present additional challenges. In cold-climate regions like Northern Europe, Canada, and parts of China, freeze/thaw damage predominates. Conversely, in hot, humid environments such as Southeast Asia, chemical degradation accelerates due to increased reaction kinetics at higher temperatures.

Manufacturing inconsistencies across global supply chains further complicate membrane durability. Variations in membrane thickness uniformity, reinforcement quality, and chemical stabilization techniques lead to significant performance disparities between nominally identical fuel cell systems deployed in different regions.

Automotive applications face particularly severe degradation challenges due to dynamic load cycling, frequent start-stop operations, and exposure to contaminants. Stationary power applications, while experiencing more stable operating conditions, still suffer from long-term chemical degradation that limits system lifetime to typically under 40,000 hours—well below the 80,000+ hours desired for commercial viability.

Recent global research has identified correlations between operating conditions and degradation rates, enabling the development of lifetime mapping methodologies. These approaches combine accelerated stress testing with mathematical modeling to predict membrane failure under various usage scenarios, though significant gaps remain in accounting for real-world variability and combined stress factors.

Current Approaches to Mitigate Chemical and Mechanical Degradation

01 Membrane degradation mechanisms in PEMFCs

Proton exchange membrane fuel cells (PEMFCs) experience membrane thinning due to various degradation mechanisms. These include chemical degradation from radical attacks, mechanical stress during operation cycles, and thermal degradation at elevated temperatures. Understanding these mechanisms is crucial for developing more durable membranes and extending PEMFC lifetimes. Research focuses on identifying the primary causes of membrane thinning to develop mitigation strategies.- Membrane degradation mechanisms in PEMFCs: Membrane thinning in Proton Exchange Membrane Fuel Cells (PEMFCs) occurs through various degradation mechanisms including chemical attack by free radicals, mechanical stress during operation cycles, and thermal degradation. These mechanisms lead to progressive membrane thickness reduction, compromising the cell's performance and durability. Understanding these fundamental degradation pathways is essential for developing mitigation strategies and improving membrane longevity.

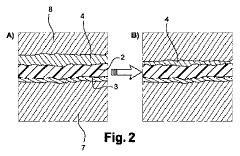

- Reinforced membrane structures to prevent thinning: Reinforced membrane structures incorporate supporting materials such as porous substrates, fiber networks, or nanocomposites to enhance mechanical stability and reduce membrane thinning. These reinforcement techniques distribute mechanical stress more evenly across the membrane, preventing localized thinning and extending operational lifetime. The reinforced membranes maintain dimensional stability during hydration-dehydration cycles while preserving proton conductivity essential for fuel cell performance.

- Diagnostic methods for membrane thinning detection: Advanced diagnostic techniques have been developed to detect and monitor membrane thinning in operational PEMFCs. These methods include electrochemical impedance spectroscopy, gas crossover measurements, voltage decay analysis, and in-situ thickness monitoring. Early detection of membrane thinning allows for timely intervention before catastrophic failure occurs. These diagnostic approaches enable real-time assessment of membrane health and can be integrated into fuel cell control systems for predictive maintenance.

- Chemical stabilization additives to reduce membrane degradation: Chemical stabilization additives are incorporated into PEMFC membranes to mitigate thinning by neutralizing free radicals and reducing chemical degradation. These additives include antioxidants, radical scavengers, metal ion decomposers, and stabilizing compounds that protect the polymer backbone. The strategic incorporation of these stabilizers significantly extends membrane lifetime by preventing the chain scission reactions that lead to membrane thinning, particularly under accelerated stress conditions.

- Operating condition optimization to minimize membrane thinning: Optimizing operating conditions is crucial for minimizing membrane thinning in PEMFCs. This includes controlling humidity levels, temperature gradients, pressure differentials, and load cycling patterns. Proper water management prevents dehydration-induced stress while temperature control limits thermal degradation. Advanced control strategies that adapt operating parameters based on real-time membrane condition assessments can significantly reduce thinning rates and extend fuel cell lifetime without requiring membrane material modifications.

02 Reinforced membrane structures to prevent thinning

Reinforced membrane structures incorporate supporting materials to enhance mechanical stability and reduce membrane thinning. These structures typically use porous support layers, fiber reinforcements, or composite materials that maintain proton conductivity while improving mechanical durability. The reinforcement helps distribute mechanical stress more evenly across the membrane, reducing localized thinning and preventing premature failure during operational cycling.Expand Specific Solutions03 Diagnostic methods for membrane thinning detection

Advanced diagnostic techniques have been developed to detect and monitor membrane thinning in PEMFCs. These include electrochemical impedance spectroscopy, gas crossover measurements, and in-situ thickness monitoring systems. Early detection of membrane thinning allows for preventive maintenance and helps researchers understand degradation patterns under various operating conditions, ultimately leading to improved membrane designs and operational protocols.Expand Specific Solutions04 Chemical stabilization additives to reduce membrane degradation

Chemical additives are incorporated into proton exchange membranes to enhance their resistance to degradation and thinning. These include radical scavengers, antioxidants, and metal ion decomposers that neutralize harmful species responsible for membrane chemical degradation. The additives work by intercepting hydroxyl and peroxy radicals before they can attack the polymer backbone, significantly extending membrane lifetime under operational conditions.Expand Specific Solutions05 Operating condition optimization to minimize membrane thinning

Optimizing operating conditions plays a crucial role in minimizing membrane thinning in PEMFCs. This includes controlling humidity levels, temperature gradients, and pressure differentials across the membrane. Proper start-up and shutdown procedures are also essential to prevent accelerated degradation. Research shows that maintaining appropriate hydration levels and avoiding rapid temperature fluctuations can significantly reduce mechanical stress on the membrane and extend its operational lifetime.Expand Specific Solutions

Leading PEMFC Membrane Manufacturers and Research Institutions

The PEMFC membrane thinning technology landscape is currently in a growth phase, with increasing market adoption driven by the automotive and energy sectors. The global market size for PEMFC technology is expanding rapidly, projected to reach significant scale as hydrogen energy solutions gain traction. From a technical maturity perspective, the field shows varied development levels across key players. Research institutions like CEA, Tongji University, and Wuhan University of Technology are advancing fundamental degradation mechanisms, while commercial entities including Air Liquide, Hyundai Motor, and W.L. Gore & Associates are focusing on practical applications and durability improvements. Companies such as Sunrise Power and LG Chem are developing proprietary membrane technologies, while automotive manufacturers like Toyota and GM are integrating these advances into commercial fuel cell vehicles, creating a competitive ecosystem balancing academic research with industrial implementation.

Commissariat à l´énergie atomique et aux énergies Alternatives

Technical Solution: CEA has developed advanced multi-scale characterization techniques for PEMFC membrane degradation analysis, combining in-situ and ex-situ methodologies. Their approach integrates electrochemical impedance spectroscopy with microscopic imaging to track chemical degradation pathways in real-time. They've pioneered a novel accelerated stress testing protocol that correlates mechanical fatigue with chemical degradation mechanisms, particularly focusing on radical-induced membrane thinning. CEA's research has established quantitative relationships between operational conditions (humidity cycling, load cycling) and membrane degradation rates, enabling predictive lifetime mapping models. Their technology incorporates fluoride release rate monitoring as a key indicator of membrane chemical stability, while simultaneously measuring mechanical property changes through specialized tensile testing of aged membranes.

Strengths: Comprehensive multi-scale characterization capabilities allow for detailed degradation mechanism understanding. Their predictive lifetime mapping models enable accurate durability forecasting for different operational profiles. Weakness: Their approach requires sophisticated analytical equipment, limiting widespread industrial implementation, and their models may need further validation across diverse real-world operating conditions.

Air Liquide SA

Technical Solution: Air Liquide has developed a comprehensive approach to PEMFC membrane degradation focusing on gas purity and operational strategies. Their technology includes specialized gas purification systems that minimize contaminants known to accelerate membrane chemical degradation, particularly focusing on removal of trace impurities that catalyze radical formation. They've engineered advanced humidification control systems that precisely manage water content within the membrane to reduce mechanical stress during operational cycling. Air Liquide's approach incorporates real-time monitoring of membrane health through proprietary diagnostic algorithms that analyze electrochemical signatures to detect early signs of membrane thinning. Their research has established correlations between specific operational parameters (start-stop cycles, idle conditions) and membrane degradation rates, enabling the development of optimized operational protocols that extend membrane lifetime. Additionally, they've developed membrane regeneration techniques that can partially restore performance of degraded membranes through controlled treatment processes.

Strengths: Their holistic approach addresses both operational conditions and gas quality factors affecting membrane durability. The real-time monitoring capabilities allow for preventative maintenance before catastrophic failure occurs. Weakness: Their solutions are heavily dependent on peripheral systems rather than addressing fundamental membrane material limitations, and implementation requires significant modification to existing fuel cell systems.

Critical Patents and Literature on Membrane Lifetime Extension

Devices and methods for limiting aging of fuel cells with proton exchange membranes

PatentInactiveJP2011512012A

Innovation

- Introducing a compound, such as carbon monoxide (CO) or carbon dioxide (CO2), at the anode to react with oxygen and prevent its crossover, thereby reducing cathode carbon corrosion and limiting the decomposition of proton-conducting electrolytes by acting as an oxygen trap.

Method for increasing the lifespan of a fuel cell with a proton exchange membrane

PatentInactiveEP2805371A1

Innovation

- A method involving a three-phase process: a first phase with pure hydrogen to initiate carbon degradation, a second phase with a controlled exposure to sulfur-based impurities like hydrogen sulfide to poison the catalytic electrode, and a third phase of regeneration at reduced hydrogen flow to oxidize and eliminate the impurities, thereby reducing oxygen reduction and carbon corrosion.

Accelerated Testing Protocols for Lifetime Prediction

Accelerated testing protocols are essential for evaluating PEMFC membrane durability without waiting for natural end-of-life occurrences. These protocols deliberately stress the membrane under controlled but intensified conditions to induce accelerated degradation mechanisms that mirror real-world failure modes. The U.S. Department of Energy has established standardized protocols including chemical stability tests with open circuit voltage (OCV) hold tests at elevated temperatures (90-95°C) and low relative humidity (30%) conditions.

Mechanical durability protocols typically employ relative humidity (RH) cycling between dry (0-20% RH) and saturated (80-100% RH) conditions at elevated temperatures. These cycles induce repetitive swelling and contraction of the membrane, simulating the mechanical stresses experienced during operational duty cycles. The standard protocol often involves 3-5 minute cycles between humidity extremes for thousands of iterations.

Combined chemical-mechanical protocols have emerged as more representative of real-world conditions. These protocols alternate between OCV hold periods and RH cycling, creating synergistic degradation effects that better predict actual field failures. The DOE's suggested protocol includes 1000-hour tests with simultaneous chemical and mechanical stressors.

Electrochemical accelerated stress tests (ASTs) apply potential cycling between 0.6V and OCV conditions, often with square or triangular wave patterns. These tests specifically target catalyst-membrane interface degradation and radical formation mechanisms. The frequency typically ranges from 1-5 minutes per cycle for 500-1000 hours of total test duration.

Advanced diagnostic techniques are integrated into these protocols to monitor degradation in real-time. Fluoride release rate (FRR) measurements serve as a key indicator of chemical degradation, while hydrogen crossover measurements track membrane thinning progression. Electrochemical impedance spectroscopy (EIS) provides insights into resistance changes and degradation mechanisms during testing.

Correlation factors between accelerated and real-world degradation have been established through extensive validation studies. These factors typically range from 10-50x acceleration rates depending on the specific protocol and membrane chemistry. Recent advances in machine learning approaches have improved the accuracy of lifetime predictions by incorporating multivariate analysis of degradation indicators collected during accelerated testing.

Mechanical durability protocols typically employ relative humidity (RH) cycling between dry (0-20% RH) and saturated (80-100% RH) conditions at elevated temperatures. These cycles induce repetitive swelling and contraction of the membrane, simulating the mechanical stresses experienced during operational duty cycles. The standard protocol often involves 3-5 minute cycles between humidity extremes for thousands of iterations.

Combined chemical-mechanical protocols have emerged as more representative of real-world conditions. These protocols alternate between OCV hold periods and RH cycling, creating synergistic degradation effects that better predict actual field failures. The DOE's suggested protocol includes 1000-hour tests with simultaneous chemical and mechanical stressors.

Electrochemical accelerated stress tests (ASTs) apply potential cycling between 0.6V and OCV conditions, often with square or triangular wave patterns. These tests specifically target catalyst-membrane interface degradation and radical formation mechanisms. The frequency typically ranges from 1-5 minutes per cycle for 500-1000 hours of total test duration.

Advanced diagnostic techniques are integrated into these protocols to monitor degradation in real-time. Fluoride release rate (FRR) measurements serve as a key indicator of chemical degradation, while hydrogen crossover measurements track membrane thinning progression. Electrochemical impedance spectroscopy (EIS) provides insights into resistance changes and degradation mechanisms during testing.

Correlation factors between accelerated and real-world degradation have been established through extensive validation studies. These factors typically range from 10-50x acceleration rates depending on the specific protocol and membrane chemistry. Recent advances in machine learning approaches have improved the accuracy of lifetime predictions by incorporating multivariate analysis of degradation indicators collected during accelerated testing.

Environmental Impact and Sustainability Considerations

The environmental impact of Proton Exchange Membrane Fuel Cells (PEMFCs) is intrinsically linked to membrane degradation processes. As membranes thin through chemical degradation and mechanical fatigue, their operational lifetime decreases, necessitating more frequent replacement. This accelerated replacement cycle significantly increases the environmental footprint of PEMFC systems through increased resource consumption and waste generation.

Material sustainability represents a critical consideration in PEMFC technology. Current perfluorosulfonic acid (PFSA) membranes, while effective, contain fluorinated compounds that present end-of-life disposal challenges due to their persistence in the environment. The chemical degradation byproducts, particularly fluoride emissions, may contribute to environmental contamination if not properly managed. Research into biodegradable or recyclable membrane alternatives could substantially improve the sustainability profile of these systems.

Energy efficiency implications of membrane thinning warrant careful examination. As membranes degrade, increased gas crossover reduces fuel cell efficiency, resulting in higher hydrogen consumption for equivalent power output. This efficiency loss translates directly to increased upstream environmental impacts from hydrogen production, particularly when hydrogen is derived from fossil fuel sources rather than renewable pathways.

Life cycle assessment (LCA) studies indicate that extending membrane lifetime through improved resistance to chemical degradation and mechanical fatigue could reduce overall environmental impact by 15-30%, depending on application scenarios. The manufacturing phase of PEMFC membranes is energy-intensive, with significant embedded carbon footprint that can only be justified through extended operational lifetimes.

Water management aspects of membrane degradation also present environmental considerations. As membranes thin and their properties change, water balance within the fuel cell becomes more difficult to maintain, potentially increasing water consumption in certain applications. In water-scarce regions, this additional demand could exacerbate resource pressures.

Circular economy approaches to PEMFC technology are emerging as potential solutions to sustainability challenges. These include membrane recycling technologies, recovery of catalyst materials, and design-for-disassembly strategies that facilitate component reuse. Advanced lifetime mapping techniques contribute to sustainability by enabling predictive maintenance rather than scheduled replacement, optimizing resource utilization throughout the system lifecycle.

Regulatory frameworks increasingly recognize the importance of sustainable fuel cell technologies. Several jurisdictions have implemented or are developing end-of-life management requirements for fuel cell components, including membranes. These regulations may drive innovation toward more environmentally benign materials and degradation-resistant designs that align technological advancement with sustainability objectives.

Material sustainability represents a critical consideration in PEMFC technology. Current perfluorosulfonic acid (PFSA) membranes, while effective, contain fluorinated compounds that present end-of-life disposal challenges due to their persistence in the environment. The chemical degradation byproducts, particularly fluoride emissions, may contribute to environmental contamination if not properly managed. Research into biodegradable or recyclable membrane alternatives could substantially improve the sustainability profile of these systems.

Energy efficiency implications of membrane thinning warrant careful examination. As membranes degrade, increased gas crossover reduces fuel cell efficiency, resulting in higher hydrogen consumption for equivalent power output. This efficiency loss translates directly to increased upstream environmental impacts from hydrogen production, particularly when hydrogen is derived from fossil fuel sources rather than renewable pathways.

Life cycle assessment (LCA) studies indicate that extending membrane lifetime through improved resistance to chemical degradation and mechanical fatigue could reduce overall environmental impact by 15-30%, depending on application scenarios. The manufacturing phase of PEMFC membranes is energy-intensive, with significant embedded carbon footprint that can only be justified through extended operational lifetimes.

Water management aspects of membrane degradation also present environmental considerations. As membranes thin and their properties change, water balance within the fuel cell becomes more difficult to maintain, potentially increasing water consumption in certain applications. In water-scarce regions, this additional demand could exacerbate resource pressures.

Circular economy approaches to PEMFC technology are emerging as potential solutions to sustainability challenges. These include membrane recycling technologies, recovery of catalyst materials, and design-for-disassembly strategies that facilitate component reuse. Advanced lifetime mapping techniques contribute to sustainability by enabling predictive maintenance rather than scheduled replacement, optimizing resource utilization throughout the system lifecycle.

Regulatory frameworks increasingly recognize the importance of sustainable fuel cell technologies. Several jurisdictions have implemented or are developing end-of-life management requirements for fuel cell components, including membranes. These regulations may drive innovation toward more environmentally benign materials and degradation-resistant designs that align technological advancement with sustainability objectives.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!