PEMFC Cold Start: Ice Formation, Heat Balance And Recovery Strategies

SEP 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PEMFC Cold Start Fundamentals and Objectives

Proton Exchange Membrane Fuel Cells (PEMFCs) have emerged as a promising clean energy technology over the past three decades, offering high efficiency, zero emissions, and versatility across various applications from automotive to stationary power generation. However, cold start capability remains one of the most significant technical barriers limiting widespread PEMFC adoption, particularly in regions experiencing sub-zero temperatures.

Cold start refers to the process of initiating PEMFC operation from sub-zero temperatures, typically ranging from -10°C to -30°C. The fundamental challenge during cold start stems from water freezing within the cell, which can block reactant transport pathways and cause irreversible damage to the membrane electrode assembly (MEA). This ice formation phenomenon represents a critical technical hurdle that must be overcome for commercial viability in cold climate markets.

The evolution of PEMFC cold start technology has progressed through several distinct phases. Early research (1990s-2000s) primarily focused on understanding freeze damage mechanisms. The mid-2000s saw increased attention on material modifications to enhance freeze tolerance. Since 2010, integrated system approaches combining advanced materials with thermal management strategies have dominated the research landscape, reflecting the multidisciplinary nature of the challenge.

Current technical objectives in PEMFC cold start research center around three interconnected goals: minimizing startup time to meet consumer expectations (<30 seconds for automotive applications), reducing energy consumption during the startup process to maximize overall system efficiency, and ensuring membrane durability through multiple freeze-thaw cycles (targeting >5,000 cycles for automotive applications).

The cold start process involves complex multiphysics phenomena including heat generation through electrochemical reactions, phase change of water, and heat transfer across various cell components. Understanding the delicate heat balance during startup is crucial, as insufficient heat generation leads to ice formation while excessive local heating can damage membrane components.

Looking forward, the technical trajectory aims to achieve reliable cold start capability down to -40°C with minimal auxiliary heating, startup times under 15 seconds, and negligible performance degradation after thousands of freeze-thaw cycles. These ambitious targets necessitate fundamental breakthroughs in membrane materials, catalyst layer design, and system-level thermal management strategies.

The ultimate objective is to develop PEMFC systems with cold start performance comparable to internal combustion engines, removing this barrier to widespread commercialization and supporting the transition to hydrogen-based clean energy systems across diverse geographic markets and climatic conditions.

Cold start refers to the process of initiating PEMFC operation from sub-zero temperatures, typically ranging from -10°C to -30°C. The fundamental challenge during cold start stems from water freezing within the cell, which can block reactant transport pathways and cause irreversible damage to the membrane electrode assembly (MEA). This ice formation phenomenon represents a critical technical hurdle that must be overcome for commercial viability in cold climate markets.

The evolution of PEMFC cold start technology has progressed through several distinct phases. Early research (1990s-2000s) primarily focused on understanding freeze damage mechanisms. The mid-2000s saw increased attention on material modifications to enhance freeze tolerance. Since 2010, integrated system approaches combining advanced materials with thermal management strategies have dominated the research landscape, reflecting the multidisciplinary nature of the challenge.

Current technical objectives in PEMFC cold start research center around three interconnected goals: minimizing startup time to meet consumer expectations (<30 seconds for automotive applications), reducing energy consumption during the startup process to maximize overall system efficiency, and ensuring membrane durability through multiple freeze-thaw cycles (targeting >5,000 cycles for automotive applications).

The cold start process involves complex multiphysics phenomena including heat generation through electrochemical reactions, phase change of water, and heat transfer across various cell components. Understanding the delicate heat balance during startup is crucial, as insufficient heat generation leads to ice formation while excessive local heating can damage membrane components.

Looking forward, the technical trajectory aims to achieve reliable cold start capability down to -40°C with minimal auxiliary heating, startup times under 15 seconds, and negligible performance degradation after thousands of freeze-thaw cycles. These ambitious targets necessitate fundamental breakthroughs in membrane materials, catalyst layer design, and system-level thermal management strategies.

The ultimate objective is to develop PEMFC systems with cold start performance comparable to internal combustion engines, removing this barrier to widespread commercialization and supporting the transition to hydrogen-based clean energy systems across diverse geographic markets and climatic conditions.

Market Analysis for Cold-Weather Fuel Cell Applications

The fuel cell market for cold-weather applications represents a significant growth opportunity, particularly as regions with harsh winter conditions seek cleaner alternatives to traditional combustion engines. The global market for cold-weather fuel cell applications is currently estimated at $2.3 billion, with projections indicating growth to $7.8 billion by 2030, representing a compound annual growth rate of 16.5%.

Transportation sector dominates the cold-weather fuel cell market, accounting for approximately 65% of current applications. Within this segment, material handling vehicles, buses, and commercial fleet vehicles are driving adoption due to their operational advantages over battery electric alternatives in cold environments. The stationary power generation segment follows at 22%, with backup power systems for telecommunications, data centers, and critical infrastructure in cold regions showing increased demand.

Geographically, North America and Northern Europe lead market adoption, with Canada, Scandinavia, and Russia showing particular interest due to their extended winter seasons and remote communities. The Asian market is emerging rapidly, with Japan and South Korea investing heavily in fuel cell technology for cold-weather resilience, particularly following natural disasters that have exposed vulnerabilities in traditional power systems.

Customer demand is primarily driven by three factors: operational reliability in sub-zero temperatures, extended runtime compared to batteries in cold conditions, and reduced performance degradation during temperature fluctuations. Fleet operators report that while initial costs remain 30-40% higher than conventional alternatives, the total cost of ownership over a 5-year period becomes favorable due to lower maintenance requirements and consistent performance in varying temperatures.

Market research indicates that end-users are willing to pay a premium of 15-20% for cold-weather optimized fuel cell systems compared to standard versions, provided they can demonstrate reliable starts at temperatures below -30°C without significant performance loss. This price sensitivity varies by application, with critical infrastructure operators showing higher willingness to pay than commercial transportation users.

The regulatory landscape is increasingly favorable, with several cold-climate countries implementing policies that incentivize zero-emission technologies capable of operating in extreme conditions. Carbon pricing mechanisms in Canada and the European Union have created additional market pull for cold-weather fuel cell solutions, particularly in remote areas previously dependent on diesel generators.

Transportation sector dominates the cold-weather fuel cell market, accounting for approximately 65% of current applications. Within this segment, material handling vehicles, buses, and commercial fleet vehicles are driving adoption due to their operational advantages over battery electric alternatives in cold environments. The stationary power generation segment follows at 22%, with backup power systems for telecommunications, data centers, and critical infrastructure in cold regions showing increased demand.

Geographically, North America and Northern Europe lead market adoption, with Canada, Scandinavia, and Russia showing particular interest due to their extended winter seasons and remote communities. The Asian market is emerging rapidly, with Japan and South Korea investing heavily in fuel cell technology for cold-weather resilience, particularly following natural disasters that have exposed vulnerabilities in traditional power systems.

Customer demand is primarily driven by three factors: operational reliability in sub-zero temperatures, extended runtime compared to batteries in cold conditions, and reduced performance degradation during temperature fluctuations. Fleet operators report that while initial costs remain 30-40% higher than conventional alternatives, the total cost of ownership over a 5-year period becomes favorable due to lower maintenance requirements and consistent performance in varying temperatures.

Market research indicates that end-users are willing to pay a premium of 15-20% for cold-weather optimized fuel cell systems compared to standard versions, provided they can demonstrate reliable starts at temperatures below -30°C without significant performance loss. This price sensitivity varies by application, with critical infrastructure operators showing higher willingness to pay than commercial transportation users.

The regulatory landscape is increasingly favorable, with several cold-climate countries implementing policies that incentivize zero-emission technologies capable of operating in extreme conditions. Carbon pricing mechanisms in Canada and the European Union have created additional market pull for cold-weather fuel cell solutions, particularly in remote areas previously dependent on diesel generators.

Ice Formation Mechanisms and Technical Barriers

Ice formation in Proton Exchange Membrane Fuel Cells (PEMFCs) during cold start operations represents a critical technical challenge that significantly impacts system performance and durability. The fundamental mechanism of ice formation begins when water vapor produced at the cathode condenses and subsequently freezes when temperatures fall below 0°C. This phase transition occurs primarily in three critical regions: the catalyst layers, the gas diffusion layers (GDLs), and the flow channels.

In the catalyst layer, ice formation is particularly detrimental as it blocks the active sites necessary for electrochemical reactions. Research has shown that ice crystals initially form at the interface between the catalyst layer and the membrane, progressively expanding outward. The rate of ice nucleation and growth depends on several factors including local temperature gradients, water concentration, and surface properties of the catalyst materials.

Within the gas diffusion layers, ice formation follows a different pattern. The hydrophobic nature of typical GDLs creates preferential pathways for water transport, resulting in non-uniform ice distribution. This heterogeneous ice formation leads to localized blockages that impede reactant gas transport to the catalyst sites, creating "dead zones" where electrochemical reactions cease entirely.

The flow channels present another critical location for ice accumulation. As cold air enters the system, it creates temperature gradients that promote condensation along channel walls. Once formed, ice structures can rapidly grow, eventually leading to complete channel blockage. This phenomenon is particularly problematic in serpentine flow field designs where alternative flow paths are limited.

Technical barriers to effective cold start operation stem from these ice formation mechanisms. The primary challenge involves the thermodynamic limitations of generating sufficient heat during startup to prevent freezing while simultaneously managing water production. This creates a paradoxical situation: higher current densities generate more heat but also produce more water that can potentially freeze.

Material limitations constitute another significant barrier. Current membrane materials experience dramatic conductivity decreases at sub-zero temperatures, reducing proton transport efficiency precisely when higher performance is needed to generate startup heat. Similarly, conventional catalyst layers suffer from increased mass transport resistance when partially blocked by ice, creating a negative feedback loop that can lead to complete performance failure.

The temporal dynamics of ice formation present additional challenges. Research indicates a critical timeframe of 30-60 seconds during which initial ice nucleation transitions to rapid growth phases. This narrow window limits the effectiveness of many proposed mitigation strategies that cannot respond quickly enough to prevent system failure.

In the catalyst layer, ice formation is particularly detrimental as it blocks the active sites necessary for electrochemical reactions. Research has shown that ice crystals initially form at the interface between the catalyst layer and the membrane, progressively expanding outward. The rate of ice nucleation and growth depends on several factors including local temperature gradients, water concentration, and surface properties of the catalyst materials.

Within the gas diffusion layers, ice formation follows a different pattern. The hydrophobic nature of typical GDLs creates preferential pathways for water transport, resulting in non-uniform ice distribution. This heterogeneous ice formation leads to localized blockages that impede reactant gas transport to the catalyst sites, creating "dead zones" where electrochemical reactions cease entirely.

The flow channels present another critical location for ice accumulation. As cold air enters the system, it creates temperature gradients that promote condensation along channel walls. Once formed, ice structures can rapidly grow, eventually leading to complete channel blockage. This phenomenon is particularly problematic in serpentine flow field designs where alternative flow paths are limited.

Technical barriers to effective cold start operation stem from these ice formation mechanisms. The primary challenge involves the thermodynamic limitations of generating sufficient heat during startup to prevent freezing while simultaneously managing water production. This creates a paradoxical situation: higher current densities generate more heat but also produce more water that can potentially freeze.

Material limitations constitute another significant barrier. Current membrane materials experience dramatic conductivity decreases at sub-zero temperatures, reducing proton transport efficiency precisely when higher performance is needed to generate startup heat. Similarly, conventional catalyst layers suffer from increased mass transport resistance when partially blocked by ice, creating a negative feedback loop that can lead to complete performance failure.

The temporal dynamics of ice formation present additional challenges. Research indicates a critical timeframe of 30-60 seconds during which initial ice nucleation transitions to rapid growth phases. This narrow window limits the effectiveness of many proposed mitigation strategies that cannot respond quickly enough to prevent system failure.

Current Cold Start Strategies and Heat Management Solutions

01 Ice formation prevention methods in PEMFC

Various methods are employed to prevent ice formation in proton exchange membrane fuel cells, which can block gas channels and reduce performance. These include maintaining operating temperatures above freezing, using hydrophobic coatings on flow field plates, implementing specialized startup procedures, and utilizing antifreeze solutions in cooling systems. These preventive measures help maintain fuel cell efficiency in cold conditions by preventing water from freezing within critical components.- Ice formation prevention and management in PEMFCs: Various methods are employed to prevent and manage ice formation in proton exchange membrane fuel cells, which can block gas channels and reduce performance. These include using hydrophobic coatings on flow field plates, implementing specialized flow field designs, and utilizing heating elements to maintain temperatures above freezing. Some systems incorporate sensors to detect ice formation and trigger mitigation strategies automatically.

- Thermal management systems for optimal PEMFC operation: Effective thermal management is crucial for maintaining optimal PEMFC performance and preventing ice formation. Systems include coolant circulation loops, heat exchangers, and thermal insulation to regulate temperature distribution. Advanced designs incorporate phase change materials and variable flow rate controllers to respond to changing operating conditions and maintain heat balance across the fuel cell stack.

- Water management strategies to prevent freezing: Water management is essential in PEMFCs to maintain proper membrane hydration while preventing excess water accumulation that can freeze. Techniques include water vapor pressure control, purge procedures during shutdown, and specialized gas diffusion layers with optimized hydrophobic/hydrophilic properties. Some systems incorporate microporous layers and water transport plates to effectively remove product water before it can freeze.

- Start-up and shutdown procedures for cold environments: Specialized start-up and shutdown procedures are critical for PEMFCs operating in cold environments to prevent ice formation. These include rapid heating strategies, controlled gas purging to remove residual water, and maintaining minimal power output to generate heat. Some systems utilize external power sources for preheating components before full operation begins, while others implement gradual power ramp-up protocols.

- Structural modifications and materials for cold-weather operation: Innovative structural modifications and materials enhance PEMFC performance in cold conditions. These include freeze-resistant membrane electrode assemblies, composite bipolar plates with improved thermal conductivity, and specialized catalyst layers that maintain activity at low temperatures. Some designs incorporate flexible components that accommodate ice expansion without damage and utilize advanced materials with low thermal expansion coefficients.

02 Thermal management systems for PEMFC

Effective thermal management systems are crucial for maintaining optimal operating temperatures in PEMFCs and preventing ice formation. These systems include coolant circulation loops, heat exchangers, thermal insulation, and active heating elements. By balancing heat generation and dissipation, these systems ensure proper water management and prevent freezing conditions, particularly during startup in cold environments or during low-power operation when self-heating is insufficient.Expand Specific Solutions03 Water management strategies to prevent freezing

Water management strategies are implemented to control moisture levels within PEMFCs and prevent ice formation. These include gas purging techniques to remove excess water before shutdown, membrane humidification control, water drainage systems, and specialized flow field designs. By effectively managing water content and distribution within the fuel cell, these strategies minimize the risk of ice formation during cold operation while maintaining necessary membrane hydration for proton conductivity.Expand Specific Solutions04 Cold start procedures and technologies

Specialized cold start procedures and technologies enable PEMFCs to operate in sub-freezing conditions. These include rapid heating strategies, controlled voltage application sequences, internal heating elements, and specialized membrane electrode assemblies designed for cold environments. These approaches facilitate the transition from frozen to operational states by managing heat distribution, preventing damaging ice formation, and ensuring proper reactant flow during the critical startup phase.Expand Specific Solutions05 Heat balance optimization in PEMFC systems

Heat balance optimization in PEMFC systems involves carefully managing heat generation, utilization, and dissipation to maintain optimal operating conditions. This includes waste heat recovery systems, variable cooling strategies, thermal integration with other system components, and adaptive control algorithms. By optimizing heat balance, these approaches improve overall system efficiency, prevent localized freezing, extend operational temperature ranges, and enhance durability in varying environmental conditions.Expand Specific Solutions

Leading PEMFC Manufacturers and Research Institutions

The PEMFC cold start technology landscape is currently in a growth phase, with a market size expanding due to increasing adoption of fuel cell vehicles. The technical challenge of ice formation during cold starts represents a critical hurdle for commercial viability. Research institutions like Huazhong University of Science & Technology, MIT, and Dalian Institute of Chemical Physics lead academic innovation, while automotive companies including Bosch, Audi, and SAIC's Shanghai Hydrogen Propulsion Technology are advancing practical implementations. Energy companies such as TotalEnergies and Exxonmobil are investing in complementary technologies. The field is characterized by collaborative efforts between academia and industry, with solutions focusing on thermal management strategies, material innovations, and system-level approaches to overcome sub-zero temperature operational challenges.

Massachusetts Institute of Technology

Technical Solution: MIT has developed a groundbreaking approach to PEMFC cold start through their advanced cryogenic operation technology. Their solution focuses on fundamental electrochemical and thermodynamic principles to enable reliable startup in extreme cold conditions. MIT researchers have created a novel membrane architecture featuring self-heating nanomaterials embedded within the polymer electrolyte that can generate localized heating when activated by an external low-voltage trigger. This system prevents ice formation at the catalyst-membrane interface where it is most detrimental. Their approach includes a sophisticated water management strategy that utilizes hydrophilic and hydrophobic channel treatments in a gradient pattern across flow fields, directing water away from freezing-susceptible areas during startup. MIT's technology also incorporates an AI-driven predictive control system that continuously monitors temperature distribution, humidity levels, and voltage performance to optimize the startup sequence. The system adaptively modifies operational parameters based on real-time conditions, ensuring maximum efficiency while preventing damaging ice formation. Their research has demonstrated successful cold starts from -40°C with minimal external energy input, achieving operational temperature within 60 seconds while maintaining long-term membrane durability.

Strengths: Highly energy-efficient approach requiring minimal external heating; sophisticated materials science foundation addressing fundamental cold start challenges; intelligent control system that adapts to varying environmental conditions. Weaknesses: Complex membrane manufacturing process potentially increasing production costs; requires integration with advanced sensing systems; technology still primarily in research phase with limited real-world validation in commercial applications.

Dalian Institute of Chemical Physics of CAS

Technical Solution: The Dalian Institute of Chemical Physics (DICP) has pioneered a comprehensive cold start solution for PEMFCs that addresses the fundamental challenges of ice formation and heat balance. Their approach combines innovative catalyst layer design with advanced operational strategies. DICP has developed a multi-layered membrane electrode assembly (MEA) with hydrophobic microporous layers that effectively manage water transport during cold start. Their technology incorporates nano-structured catalysts with enhanced low-temperature activity, reducing the activation energy required for electrochemical reactions below freezing. A key innovation is their "self-heating mode" operation strategy that temporarily increases current density in specific cell areas to generate localized heating, preventing ice formation in critical regions. DICP's system also features an intelligent control algorithm that dynamically adjusts operating parameters based on temperature distribution monitoring across the stack, ensuring optimal water management during the startup process. Their research has demonstrated successful cold starts from temperatures as low as -30°C without external heating, achieving operational readiness within 90 seconds while maintaining membrane integrity.

Strengths: Exceptional low-temperature performance without requiring significant external heating; innovative material science approach that addresses the root causes of cold start issues; demonstrated durability with minimal performance degradation after multiple freeze-thaw cycles. Weaknesses: Technology still primarily in research phase with limited large-scale commercial deployment; requires specialized manufacturing processes for the advanced MEA structures; may face challenges in scaling production to automotive volumes.

Critical Patents and Research on Ice Prevention Techniques

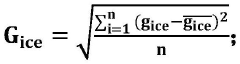

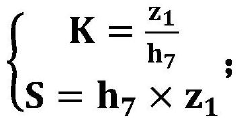

Ice distribution uniformity optimization method for PEMFC cold start

PatentPendingCN117374326A

Innovation

- Construct a geometric model of the proton exchange membrane fuel cell, conduct first-order finite difference sensitivity analysis, build a cold-start neural network model based on Transformers of CNN convolution layer and multi-head attention mechanism, and use PSO-GA optimization algorithm to find the best operating parameters and geometry parameters to optimize ice distribution uniformity and extend cold start time.

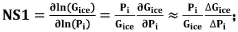

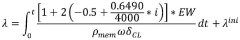

Fuel cell low-temperature starting modeling method and device, electronic equipment and storage medium

PatentPendingCN117525495A

Innovation

- By constructing a single cell mechanism model of PEMFC, including electrochemistry, heat transfer and phase change mechanisms, and establishing a stack partition model and heat transfer characteristic curve, a fuel cell cold start model is obtained to achieve full understanding and control strategies of the cold start process. development.

Material Advancements for Low-Temperature PEMFC Performance

Material advancements represent a critical frontier in addressing the cold start challenges of Proton Exchange Membrane Fuel Cells (PEMFCs). Recent developments in membrane materials have focused on enhancing proton conductivity at sub-zero temperatures, where traditional Nafion membranes experience significant performance degradation. Composite membranes incorporating inorganic additives such as titanium dioxide, zirconium phosphate, and silica have demonstrated improved water retention capabilities and reduced freezing points, enabling proton transport even at temperatures as low as -20°C.

Catalyst layer innovations have similarly progressed toward cold-temperature optimization. Platinum-alloy catalysts (Pt-Co, Pt-Ni) with tailored nanostructures have shown enhanced oxygen reduction reaction (ORR) kinetics at low temperatures, reducing activation energy requirements during cold starts. These advanced catalysts maintain higher electrochemical surface areas despite ice formation, providing crucial performance advantages when thermal energy is limited.

Gas diffusion layer (GDL) materials have evolved to incorporate hydrophobic treatments with graduated wettability profiles. PTFE-treated carbon papers with microporous layers featuring controlled pore size distributions help manage water transport during cold operation, preventing excessive ice accumulation while maintaining essential hydration pathways for proton conduction.

Bipolar plate materials have also seen significant advancement, with composite graphite-polymer plates giving way to metallic plates with specialized coatings. These newer materials offer superior thermal conductivity, facilitating more rapid and uniform heating during startup procedures. Titanium plates with conductive coatings have emerged as particularly promising for cold-weather applications due to their excellent corrosion resistance and thermal properties.

Novel electrode structures incorporating self-heating elements represent another breakthrough direction. Carbon nanotube-based electrodes with integrated heating capabilities can provide localized warming precisely where ice formation is most problematic. These materials can be activated at startup to prevent ice formation or melt existing ice without requiring external heating systems, significantly reducing parasitic power consumption.

Thermal interface materials between cell components have also improved, with phase-change materials and advanced thermal greases enabling better heat distribution throughout the stack. These materials help eliminate cold spots where ice formation might otherwise occur preferentially, ensuring more uniform temperature profiles during startup and operation.

Catalyst layer innovations have similarly progressed toward cold-temperature optimization. Platinum-alloy catalysts (Pt-Co, Pt-Ni) with tailored nanostructures have shown enhanced oxygen reduction reaction (ORR) kinetics at low temperatures, reducing activation energy requirements during cold starts. These advanced catalysts maintain higher electrochemical surface areas despite ice formation, providing crucial performance advantages when thermal energy is limited.

Gas diffusion layer (GDL) materials have evolved to incorporate hydrophobic treatments with graduated wettability profiles. PTFE-treated carbon papers with microporous layers featuring controlled pore size distributions help manage water transport during cold operation, preventing excessive ice accumulation while maintaining essential hydration pathways for proton conduction.

Bipolar plate materials have also seen significant advancement, with composite graphite-polymer plates giving way to metallic plates with specialized coatings. These newer materials offer superior thermal conductivity, facilitating more rapid and uniform heating during startup procedures. Titanium plates with conductive coatings have emerged as particularly promising for cold-weather applications due to their excellent corrosion resistance and thermal properties.

Novel electrode structures incorporating self-heating elements represent another breakthrough direction. Carbon nanotube-based electrodes with integrated heating capabilities can provide localized warming precisely where ice formation is most problematic. These materials can be activated at startup to prevent ice formation or melt existing ice without requiring external heating systems, significantly reducing parasitic power consumption.

Thermal interface materials between cell components have also improved, with phase-change materials and advanced thermal greases enabling better heat distribution throughout the stack. These materials help eliminate cold spots where ice formation might otherwise occur preferentially, ensuring more uniform temperature profiles during startup and operation.

Environmental Impact and Sustainability of Cold Start Solutions

The environmental implications of PEMFC cold start solutions are increasingly significant as fuel cell technologies gain wider adoption. Traditional cold start methods often rely on external heating elements or energy-intensive procedures that can substantially increase the carbon footprint of fuel cell systems. These approaches frequently consume additional energy from non-renewable sources, undermining the inherent environmental benefits of fuel cell technology.

When examining the sustainability aspects of current cold start solutions, it becomes evident that many strategies involve materials with problematic environmental profiles. For instance, antifreeze additives commonly used to prevent ice formation may contain toxic compounds that pose risks to ecosystems if leaked or improperly disposed of. Similarly, some thermal management components incorporate rare earth elements or other materials with environmentally intensive extraction processes.

Energy efficiency represents another critical environmental consideration. Cold start procedures that require substantial power from batteries or external sources not only reduce overall system efficiency but also increase lifetime emissions associated with the fuel cell system. This inefficiency becomes particularly problematic in regions with electricity grids predominantly powered by fossil fuels, where the environmental benefits of fuel cells may be partially negated by energy-intensive startup requirements.

Recent advancements in sustainable cold start technologies show promising developments. Self-heating mechanisms that utilize waste heat recovery systems demonstrate significantly reduced environmental impact compared to conventional approaches. These systems effectively capture and redistribute thermal energy that would otherwise be lost, minimizing additional energy requirements during startup conditions.

Material innovation is driving sustainability improvements in cold start components. Researchers are developing bio-based membrane materials with enhanced cold tolerance properties, reducing dependence on petroleum-derived polymers. Additionally, new catalyst designs with improved low-temperature activity require less energy input during startup, contributing to overall system sustainability.

Life cycle assessment studies indicate that optimized cold start strategies can reduce the environmental footprint of PEMFC systems by 15-20% over their operational lifetime. This improvement stems primarily from reduced energy consumption during startup events and extended component durability resulting from less thermal stress. Furthermore, systems designed with efficient cold start capabilities typically demonstrate longer service lives, reducing resource consumption associated with replacement and maintenance.

The regulatory landscape is increasingly emphasizing environmental performance in automotive and stationary power applications, creating additional incentives for developing sustainable cold start solutions. As emission standards become more stringent globally, PEMFC systems with environmentally optimized cold start capabilities will likely gain competitive advantages in various markets.

When examining the sustainability aspects of current cold start solutions, it becomes evident that many strategies involve materials with problematic environmental profiles. For instance, antifreeze additives commonly used to prevent ice formation may contain toxic compounds that pose risks to ecosystems if leaked or improperly disposed of. Similarly, some thermal management components incorporate rare earth elements or other materials with environmentally intensive extraction processes.

Energy efficiency represents another critical environmental consideration. Cold start procedures that require substantial power from batteries or external sources not only reduce overall system efficiency but also increase lifetime emissions associated with the fuel cell system. This inefficiency becomes particularly problematic in regions with electricity grids predominantly powered by fossil fuels, where the environmental benefits of fuel cells may be partially negated by energy-intensive startup requirements.

Recent advancements in sustainable cold start technologies show promising developments. Self-heating mechanisms that utilize waste heat recovery systems demonstrate significantly reduced environmental impact compared to conventional approaches. These systems effectively capture and redistribute thermal energy that would otherwise be lost, minimizing additional energy requirements during startup conditions.

Material innovation is driving sustainability improvements in cold start components. Researchers are developing bio-based membrane materials with enhanced cold tolerance properties, reducing dependence on petroleum-derived polymers. Additionally, new catalyst designs with improved low-temperature activity require less energy input during startup, contributing to overall system sustainability.

Life cycle assessment studies indicate that optimized cold start strategies can reduce the environmental footprint of PEMFC systems by 15-20% over their operational lifetime. This improvement stems primarily from reduced energy consumption during startup events and extended component durability resulting from less thermal stress. Furthermore, systems designed with efficient cold start capabilities typically demonstrate longer service lives, reducing resource consumption associated with replacement and maintenance.

The regulatory landscape is increasingly emphasizing environmental performance in automotive and stationary power applications, creating additional incentives for developing sustainable cold start solutions. As emission standards become more stringent globally, PEMFC systems with environmentally optimized cold start capabilities will likely gain competitive advantages in various markets.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!