PEMFC Thermal Management: Heat Rejection, Gradients And Stack Uniformity

SEP 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PEMFC Thermal Management Background and Objectives

Proton Exchange Membrane Fuel Cells (PEMFCs) have emerged as a promising clean energy technology over the past several decades, with significant advancements in efficiency, durability, and cost reduction. The thermal management of these systems represents one of the most critical aspects affecting their performance and longevity. Historically, thermal management challenges have been addressed through increasingly sophisticated approaches, evolving from simple air cooling systems to complex integrated thermal management solutions.

The evolution of PEMFC thermal management has been closely tied to the overall development of fuel cell technology. Early systems in the 1990s and early 2000s focused primarily on basic functionality, with limited attention to thermal optimization. As commercial applications expanded in the automotive, stationary power, and portable electronics sectors, the importance of effective thermal management became increasingly apparent.

Current technological trends point toward more integrated and efficient thermal management systems that can maintain optimal operating temperatures (typically 60-80°C) while minimizing parasitic power losses. The industry is moving toward solutions that address not only heat rejection but also the critical issues of temperature gradients and stack uniformity, which significantly impact cell performance and durability.

The primary objective of advanced PEMFC thermal management is to maintain uniform temperature distribution throughout the fuel cell stack while efficiently rejecting waste heat. This is particularly challenging as power densities increase and system sizes decrease, creating more concentrated heat generation patterns. Temperature gradients across cells can lead to uneven reaction rates, localized degradation, and reduced overall efficiency.

Another key goal is to develop thermal management solutions that function effectively across varying operational conditions, from cold start to full power operation, and in diverse environmental settings. This adaptability is essential for the widespread adoption of PEMFC technology in applications ranging from automotive to stationary power generation.

Additionally, thermal management systems must be designed with consideration for overall system efficiency, minimizing parasitic power consumption while maximizing heat transfer effectiveness. The integration of thermal management with other subsystems, such as water management and power electronics cooling, represents an important trend toward holistic system optimization.

The technical objectives also include developing solutions that are cost-effective, reliable, and manufacturable at scale, as these factors will ultimately determine the commercial viability of PEMFC technology in competitive energy markets. Innovations in materials, design methodologies, and manufacturing processes are all contributing to advancements in this critical area.

The evolution of PEMFC thermal management has been closely tied to the overall development of fuel cell technology. Early systems in the 1990s and early 2000s focused primarily on basic functionality, with limited attention to thermal optimization. As commercial applications expanded in the automotive, stationary power, and portable electronics sectors, the importance of effective thermal management became increasingly apparent.

Current technological trends point toward more integrated and efficient thermal management systems that can maintain optimal operating temperatures (typically 60-80°C) while minimizing parasitic power losses. The industry is moving toward solutions that address not only heat rejection but also the critical issues of temperature gradients and stack uniformity, which significantly impact cell performance and durability.

The primary objective of advanced PEMFC thermal management is to maintain uniform temperature distribution throughout the fuel cell stack while efficiently rejecting waste heat. This is particularly challenging as power densities increase and system sizes decrease, creating more concentrated heat generation patterns. Temperature gradients across cells can lead to uneven reaction rates, localized degradation, and reduced overall efficiency.

Another key goal is to develop thermal management solutions that function effectively across varying operational conditions, from cold start to full power operation, and in diverse environmental settings. This adaptability is essential for the widespread adoption of PEMFC technology in applications ranging from automotive to stationary power generation.

Additionally, thermal management systems must be designed with consideration for overall system efficiency, minimizing parasitic power consumption while maximizing heat transfer effectiveness. The integration of thermal management with other subsystems, such as water management and power electronics cooling, represents an important trend toward holistic system optimization.

The technical objectives also include developing solutions that are cost-effective, reliable, and manufacturable at scale, as these factors will ultimately determine the commercial viability of PEMFC technology in competitive energy markets. Innovations in materials, design methodologies, and manufacturing processes are all contributing to advancements in this critical area.

Market Demand Analysis for Advanced PEMFC Cooling Solutions

The global market for advanced PEMFC (Proton Exchange Membrane Fuel Cell) cooling solutions is experiencing significant growth driven by the increasing adoption of fuel cell technology across multiple sectors. The automotive industry represents the largest market segment, with major manufacturers investing heavily in fuel cell electric vehicles (FCEVs) as a complementary zero-emission solution to battery electric vehicles. This sector's demand for thermal management solutions is projected to grow at a compound annual rate exceeding 25% through 2030.

Commercial vehicle applications, particularly in heavy-duty trucks and buses, present another substantial market opportunity. These applications require robust thermal management systems capable of handling higher power outputs and longer operational cycles. The stationary power generation sector, including backup power systems and distributed energy resources, also contributes significantly to market demand, particularly in regions with unreliable grid infrastructure.

Market research indicates that end-users are increasingly prioritizing thermal management solutions that address three critical performance parameters: heat rejection efficiency, temperature gradient control, and stack uniformity. Heat rejection efficiency directly impacts system power density and overall efficiency, with customers demanding solutions that can maintain optimal operating temperatures (typically 60-80°C) while minimizing parasitic power losses.

Temperature gradient management has emerged as a crucial requirement as stack sizes increase. Uneven temperature distribution can lead to localized membrane degradation, reducing stack lifetime by up to 40% according to durability studies. This has created strong demand for cooling solutions that can maintain temperature differentials below 5°C across the entire stack.

Stack uniformity concerns have intensified as manufacturers push for higher power densities and longer operational lifetimes. The market increasingly values solutions that ensure consistent cooling across all cells, preventing hotspots that accelerate degradation. This is particularly important in transportation applications where dynamic load profiles create challenging thermal conditions.

Regional analysis reveals varying market dynamics. Asia-Pacific, led by China, Japan, and South Korea, represents the fastest-growing market for PEMFC cooling solutions, supported by strong government incentives and industrial policies promoting hydrogen technologies. North America and Europe follow closely, with particular strength in commercial vehicle and stationary power applications.

The market structure is evolving from primarily custom-engineered solutions toward more standardized offerings, reflecting the industry's maturation. This transition is creating opportunities for specialized thermal management component suppliers to develop optimized products for specific PEMFC applications, potentially reducing system costs while improving performance.

Commercial vehicle applications, particularly in heavy-duty trucks and buses, present another substantial market opportunity. These applications require robust thermal management systems capable of handling higher power outputs and longer operational cycles. The stationary power generation sector, including backup power systems and distributed energy resources, also contributes significantly to market demand, particularly in regions with unreliable grid infrastructure.

Market research indicates that end-users are increasingly prioritizing thermal management solutions that address three critical performance parameters: heat rejection efficiency, temperature gradient control, and stack uniformity. Heat rejection efficiency directly impacts system power density and overall efficiency, with customers demanding solutions that can maintain optimal operating temperatures (typically 60-80°C) while minimizing parasitic power losses.

Temperature gradient management has emerged as a crucial requirement as stack sizes increase. Uneven temperature distribution can lead to localized membrane degradation, reducing stack lifetime by up to 40% according to durability studies. This has created strong demand for cooling solutions that can maintain temperature differentials below 5°C across the entire stack.

Stack uniformity concerns have intensified as manufacturers push for higher power densities and longer operational lifetimes. The market increasingly values solutions that ensure consistent cooling across all cells, preventing hotspots that accelerate degradation. This is particularly important in transportation applications where dynamic load profiles create challenging thermal conditions.

Regional analysis reveals varying market dynamics. Asia-Pacific, led by China, Japan, and South Korea, represents the fastest-growing market for PEMFC cooling solutions, supported by strong government incentives and industrial policies promoting hydrogen technologies. North America and Europe follow closely, with particular strength in commercial vehicle and stationary power applications.

The market structure is evolving from primarily custom-engineered solutions toward more standardized offerings, reflecting the industry's maturation. This transition is creating opportunities for specialized thermal management component suppliers to develop optimized products for specific PEMFC applications, potentially reducing system costs while improving performance.

Current Thermal Management Challenges in PEMFC Stacks

Proton Exchange Membrane Fuel Cells (PEMFCs) face significant thermal management challenges that directly impact their performance, durability, and commercial viability. The primary challenge stems from the inherent inefficiency of the electrochemical reactions, which generate substantial waste heat during operation. Approximately 50% of the energy input is converted to heat rather than electrical power, necessitating effective heat rejection systems to maintain optimal operating temperatures.

Temperature uniformity across the stack represents a critical challenge in PEMFC thermal management. Current systems struggle to maintain consistent temperatures throughout the cell active areas, resulting in localized hot spots that accelerate membrane degradation and catalyst sintering. These thermal gradients are particularly problematic in larger stacks designed for automotive and stationary applications, where heat distribution becomes increasingly uneven as stack size increases.

The operating temperature window for PEMFCs presents another significant constraint. These systems typically operate between 60-80°C, requiring precise temperature control to maintain membrane hydration while preventing overheating. This narrow operational range complicates thermal management strategies, especially during transient operations such as startup, shutdown, and rapid load changes that characterize real-world applications.

Heat rejection mechanisms in current PEMFC systems rely predominantly on liquid cooling circuits that add considerable weight, volume, and complexity to the overall system. These cooling subsystems can account for up to 30% of the total system weight and volume in automotive applications, directly impacting vehicle range and packaging constraints. The balance between effective cooling and system compactness remains unresolved in many commercial designs.

Interface thermal resistance between bipolar plates and cooling channels creates additional challenges for heat transfer efficiency. Current materials and manufacturing techniques often result in suboptimal thermal contact, creating bottlenecks in the heat rejection pathway. This issue is exacerbated by the need for electrically insulating yet thermally conductive interfaces in stack design.

Cold-start capability represents another significant thermal management challenge, particularly for automotive applications in cold climates. Water freezing within the membrane and gas channels can cause mechanical damage and prevent system startup. Current solutions involving heating elements add further complexity and parasitic power demands to the system.

The integration of thermal management with water management systems presents compounding challenges, as the two are inherently linked through evaporation, condensation, and membrane hydration dynamics. Balancing these interdependent systems while minimizing parasitic power consumption continues to challenge PEMFC designers and engineers across all application domains.

Temperature uniformity across the stack represents a critical challenge in PEMFC thermal management. Current systems struggle to maintain consistent temperatures throughout the cell active areas, resulting in localized hot spots that accelerate membrane degradation and catalyst sintering. These thermal gradients are particularly problematic in larger stacks designed for automotive and stationary applications, where heat distribution becomes increasingly uneven as stack size increases.

The operating temperature window for PEMFCs presents another significant constraint. These systems typically operate between 60-80°C, requiring precise temperature control to maintain membrane hydration while preventing overheating. This narrow operational range complicates thermal management strategies, especially during transient operations such as startup, shutdown, and rapid load changes that characterize real-world applications.

Heat rejection mechanisms in current PEMFC systems rely predominantly on liquid cooling circuits that add considerable weight, volume, and complexity to the overall system. These cooling subsystems can account for up to 30% of the total system weight and volume in automotive applications, directly impacting vehicle range and packaging constraints. The balance between effective cooling and system compactness remains unresolved in many commercial designs.

Interface thermal resistance between bipolar plates and cooling channels creates additional challenges for heat transfer efficiency. Current materials and manufacturing techniques often result in suboptimal thermal contact, creating bottlenecks in the heat rejection pathway. This issue is exacerbated by the need for electrically insulating yet thermally conductive interfaces in stack design.

Cold-start capability represents another significant thermal management challenge, particularly for automotive applications in cold climates. Water freezing within the membrane and gas channels can cause mechanical damage and prevent system startup. Current solutions involving heating elements add further complexity and parasitic power demands to the system.

The integration of thermal management with water management systems presents compounding challenges, as the two are inherently linked through evaporation, condensation, and membrane hydration dynamics. Balancing these interdependent systems while minimizing parasitic power consumption continues to challenge PEMFC designers and engineers across all application domains.

Existing Heat Rejection and Gradient Control Methods

01 Cooling systems for heat rejection in PEMFC stacks

Various cooling systems are employed in proton exchange membrane fuel cells to manage heat rejection and maintain optimal operating temperatures. These systems include liquid cooling channels, heat exchangers, and cooling plates integrated within the stack architecture. Effective cooling systems help prevent overheating, extend fuel cell lifespan, and maintain consistent performance by removing excess heat generated during electrochemical reactions.- Cooling systems for thermal management in PEMFC stacks: Various cooling systems are employed to manage heat rejection in proton exchange membrane fuel cells. These include liquid cooling channels, heat exchangers, and cooling plates integrated within the stack architecture. Effective cooling systems help maintain optimal operating temperatures, prevent thermal gradients, and ensure uniform temperature distribution across the stack, which is crucial for consistent performance and longevity of the fuel cell.

- Flow field design for uniform temperature distribution: The design of flow fields within fuel cell stacks significantly impacts thermal uniformity. Optimized flow field patterns help distribute reactant gases evenly while facilitating uniform heat removal. Serpentine, parallel, interdigitated, and hybrid flow field designs can be implemented to minimize temperature gradients across the active area of the membrane electrode assembly, thereby improving overall stack performance and preventing localized hotspots that could degrade membrane integrity.

- Thermal interface materials and heat spreaders: Specialized thermal interface materials and heat spreaders are used to enhance heat transfer from the fuel cell stack to cooling systems. These materials, which may include graphite sheets, metal foams, or composite materials with high thermal conductivity, help reduce contact resistance between components and promote more uniform heat distribution. By efficiently conducting heat away from generation sites, these materials minimize thermal gradients and improve stack temperature uniformity.

- Temperature monitoring and control systems: Advanced temperature monitoring and control systems are implemented to maintain thermal uniformity in PEMFC stacks. These systems utilize temperature sensors strategically placed throughout the stack to provide real-time data on thermal conditions. Feedback control algorithms adjust cooling parameters, reactant flow rates, and load distribution to minimize temperature variations. Some systems incorporate predictive models to anticipate thermal behavior and proactively manage potential gradient formation.

- Stack design optimization for thermal uniformity: Innovative stack design approaches focus on achieving thermal uniformity through structural modifications. These include optimized bipolar plate designs with integrated cooling features, graduated compression systems that maintain uniform contact pressure despite thermal expansion, and strategic placement of cooling cells within the stack. Some designs incorporate phase change materials or variable thermal resistance elements to passively regulate temperature distribution and mitigate the formation of thermal gradients during operation.

02 Thermal gradient management for stack uniformity

Managing thermal gradients across PEMFC stacks is crucial for maintaining uniform performance and preventing localized hotspots that can damage membrane electrode assemblies. Techniques include strategic coolant flow distribution, thermal interface materials, and temperature monitoring systems. Uniform temperature distribution ensures consistent reaction rates throughout the stack, prevents membrane degradation, and optimizes overall system efficiency by avoiding areas of excessive heat buildup.Expand Specific Solutions03 Advanced materials for thermal management

Specialized materials are being developed to enhance thermal conductivity and heat distribution within PEMFC stacks. These include thermally conductive bipolar plates, advanced heat transfer fluids, and composite materials with tailored thermal properties. These materials facilitate more efficient heat rejection while maintaining electrical conductivity and chemical stability in the fuel cell environment, contributing to improved stack uniformity and performance.Expand Specific Solutions04 Flow field designs for uniform temperature distribution

Innovative flow field designs in bipolar plates help achieve uniform temperature distribution across the active area of PEMFCs. These designs optimize reactant distribution while simultaneously facilitating heat removal through strategic channel configurations, interdigitated patterns, and multi-pass arrangements. Well-designed flow fields prevent localized heating, ensure consistent reactant delivery, and contribute to overall stack uniformity by balancing electrochemical reactions across the membrane surface.Expand Specific Solutions05 Control systems for thermal management

Advanced control systems monitor and regulate temperature distribution in PEMFC stacks to maintain thermal uniformity. These systems employ temperature sensors, predictive algorithms, and adaptive cooling strategies to respond to changing load conditions and environmental factors. Intelligent thermal management controls help prevent thermal cycling damage, optimize system efficiency, and ensure consistent performance across various operating conditions by dynamically adjusting cooling parameters based on real-time temperature data.Expand Specific Solutions

Key Industry Players in PEMFC Thermal Solutions

PEMFC thermal management technology is currently in a growth phase, with increasing market adoption driven by the expanding hydrogen economy. The global market for fuel cell thermal management systems is projected to reach significant scale as automotive and stationary power applications grow. Technologically, the field shows varying maturity levels across different thermal management approaches. Leading academic institutions like Huazhong University of Science & Technology, Zhejiang University, and Tianjin University are advancing fundamental research, while commercial players including Siemens AG, Modine Manufacturing, and Sunrise Power are developing practical solutions. Applied Materials and ASML contribute enabling technologies for manufacturing precision components. The competitive landscape features collaboration between academic institutions and industrial partners to address heat rejection challenges and thermal gradient control for improved stack uniformity.

Modine Manufacturing Co.

Technical Solution: Modine Manufacturing has leveraged its extensive heat exchanger expertise to develop a dedicated PEMFC thermal management system that addresses the critical challenges of heat rejection and temperature uniformity. Their solution centers around a patented parallel flow design that ensures consistent coolant distribution across all cells within the stack. The system incorporates specially designed cooling plates with optimized flow channels that balance pressure drop with heat transfer efficiency[7]. Modine's approach includes a unique manifold design that minimizes flow maldistribution, a common cause of temperature gradients in fuel cell stacks. Their thermal management system features advanced materials with tailored thermal conductivity properties that help maintain uniform temperature profiles even during dynamic operating conditions[8]. The company has also developed specialized coatings for cooling channels that prevent corrosion while enhancing heat transfer characteristics. Modine's solution includes integrated freeze protection features that enable reliable cold-weather operation without compromising system efficiency. Their thermal management technology has been successfully implemented in both automotive and stationary PEMFC applications, demonstrating consistent performance and durability across various power ranges.

Strengths: Exceptional thermal uniformity across large stacks, proven durability in field applications, and optimized balance between performance and manufacturability. Weaknesses: Relatively higher weight compared to some competing solutions, and limited flexibility for retrofitting into existing stack designs.

Sunrise Power Co., Ltd.

Technical Solution: Sunrise Power has developed an advanced thermal management system for PEMFC stacks that utilizes a combination of liquid cooling plates and phase-change materials. Their system incorporates microchannels within bipolar plates that allow for efficient heat removal while maintaining uniform temperature distribution across the stack. The company has implemented a dual-loop cooling architecture where a primary loop manages the stack temperature directly, while a secondary loop handles heat rejection to the environment[1]. Their proprietary coolant formulation provides enhanced heat transfer capabilities while remaining electrically non-conductive to prevent shunt currents. Sunrise Power's thermal management solution also features adaptive control algorithms that adjust coolant flow rates based on real-time temperature monitoring, effectively addressing temperature gradients during dynamic load changes[3]. The system has been successfully deployed in commercial fuel cell vehicles, demonstrating reliable performance across various operating conditions.

Strengths: Superior temperature uniformity across stack (±3°C variation), integrated sensors for real-time monitoring, and compatibility with automotive requirements. Weaknesses: Higher system complexity increases manufacturing costs, and the specialized coolant requires periodic maintenance and replacement.

Critical Technologies for Stack Temperature Uniformity

Thermal management method for fuel cell

PatentWO2023216150A1

Innovation

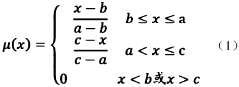

- The exit fuzzy controller and the inlet fuzzy controller are used, combined with the particle swarm-genetic hybrid algorithm to optimize the membership function of the fuzzy controller. The stack inlet and outlet temperature error and error change rate are used as inputs to optimize the cooling water flow and fan speed to increase the temperature. Control accuracy and stability.

Environmental Impact and Sustainability Considerations

The environmental impact of Proton Exchange Membrane Fuel Cell (PEMFC) thermal management systems represents a critical consideration in the broader sustainability context of hydrogen fuel cell technologies. While PEMFCs are often promoted as clean energy solutions due to their zero-emission operation, the environmental footprint of their thermal management systems requires careful assessment across the entire lifecycle.

Current thermal management approaches for PEMFCs typically involve liquid cooling systems utilizing water-glycol mixtures or specialized heat transfer fluids. These coolants may contain additives that pose environmental risks if leaked or improperly disposed of. Additionally, the manufacturing processes for heat exchangers, cooling plates, and thermal interface materials often involve energy-intensive production methods and potentially toxic materials, contributing to the overall environmental burden.

The energy efficiency of thermal management systems directly impacts the sustainability profile of PEMFC technology. Parasitic power losses from cooling pumps, fans, and control systems can reduce the net efficiency of fuel cell systems by 2-8%, depending on design and operating conditions. More efficient thermal management approaches that minimize these parasitic losses would significantly improve the overall environmental performance of PEMFC systems.

Water consumption represents another environmental consideration, particularly for thermal management systems that rely on evaporative cooling or require regular fluid replacement. In regions facing water scarcity, this aspect becomes increasingly important. Advanced closed-loop cooling systems with minimal water requirements offer more sustainable alternatives, though they may present greater technical complexity.

End-of-life considerations for thermal management components also merit attention. The recyclability of materials used in cooling plates, heat exchangers, and thermal interface materials varies considerably. Aluminum components typically offer good recyclability, while composite materials or specialized coatings may complicate recycling processes. Design approaches that facilitate disassembly and material separation can substantially improve end-of-life environmental performance.

From a lifecycle perspective, the environmental benefits of improved thermal management extend beyond operational efficiency. More uniform temperature distribution within PEMFC stacks can significantly extend operational lifetimes, reducing the frequency of replacement and associated material consumption. Research indicates that effective thermal management strategies can potentially extend PEMFC stack lifetimes by 30-50%, representing a substantial sustainability improvement through reduced material throughput and manufacturing energy requirements.

Current thermal management approaches for PEMFCs typically involve liquid cooling systems utilizing water-glycol mixtures or specialized heat transfer fluids. These coolants may contain additives that pose environmental risks if leaked or improperly disposed of. Additionally, the manufacturing processes for heat exchangers, cooling plates, and thermal interface materials often involve energy-intensive production methods and potentially toxic materials, contributing to the overall environmental burden.

The energy efficiency of thermal management systems directly impacts the sustainability profile of PEMFC technology. Parasitic power losses from cooling pumps, fans, and control systems can reduce the net efficiency of fuel cell systems by 2-8%, depending on design and operating conditions. More efficient thermal management approaches that minimize these parasitic losses would significantly improve the overall environmental performance of PEMFC systems.

Water consumption represents another environmental consideration, particularly for thermal management systems that rely on evaporative cooling or require regular fluid replacement. In regions facing water scarcity, this aspect becomes increasingly important. Advanced closed-loop cooling systems with minimal water requirements offer more sustainable alternatives, though they may present greater technical complexity.

End-of-life considerations for thermal management components also merit attention. The recyclability of materials used in cooling plates, heat exchangers, and thermal interface materials varies considerably. Aluminum components typically offer good recyclability, while composite materials or specialized coatings may complicate recycling processes. Design approaches that facilitate disassembly and material separation can substantially improve end-of-life environmental performance.

From a lifecycle perspective, the environmental benefits of improved thermal management extend beyond operational efficiency. More uniform temperature distribution within PEMFC stacks can significantly extend operational lifetimes, reducing the frequency of replacement and associated material consumption. Research indicates that effective thermal management strategies can potentially extend PEMFC stack lifetimes by 30-50%, representing a substantial sustainability improvement through reduced material throughput and manufacturing energy requirements.

System Integration and Performance Optimization Strategies

Effective system integration and performance optimization are critical for maximizing PEMFC efficiency while maintaining proper thermal management. The holistic approach to PEMFC system design requires careful consideration of component interactions and their collective impact on thermal behavior.

Integration of thermal management subsystems with other PEMFC components demands strategic placement of sensors, cooling channels, and heat exchangers. Advanced control algorithms that dynamically adjust cooling parameters based on real-time operating conditions have shown significant improvements in stack temperature uniformity. Studies indicate that model predictive control (MPC) strategies can reduce temperature gradients by up to 40% compared to conventional PID controllers.

Computational fluid dynamics (CFD) coupled with electrochemical modeling has emerged as an essential tool for system-level optimization. These simulation approaches enable engineers to predict thermal hotspots and flow distribution issues before physical prototyping, reducing development cycles by approximately 30-40%. Recent advances in machine learning algorithms have further enhanced these models by incorporating operational data to improve prediction accuracy.

Balance of plant (BOP) components significantly influence thermal management performance. Optimized integration of humidifiers, air compressors, and hydrogen recirculation systems can reduce parasitic power consumption while maintaining proper thermal conditions. Research shows that up to 15% improvement in system efficiency can be achieved through careful BOP integration and sizing relative to stack thermal requirements.

Thermal-electrical-mechanical co-optimization represents the frontier of PEMFC system design. This approach considers the interdependencies between thermal gradients, electrical performance, and mechanical stress. Advanced optimization algorithms utilizing multi-physics simulations have demonstrated the ability to extend stack lifetime by up to 20% while maintaining high power density through optimized thermal management strategies.

Modular system architectures with standardized thermal interfaces are gaining traction in commercial applications. These designs facilitate easier maintenance and component upgrades while ensuring consistent thermal performance. The automotive industry has particularly benefited from this approach, with several manufacturers reporting improved thermal uniformity and reduced integration costs through modular designs.

Cost-performance optimization remains a significant challenge, particularly for commercial applications. Thermal management systems typically represent 15-25% of total PEMFC system costs. Advanced materials and manufacturing techniques, such as additive manufacturing for complex cooling channels, offer promising pathways to reduce costs while maintaining or improving thermal performance metrics.

Integration of thermal management subsystems with other PEMFC components demands strategic placement of sensors, cooling channels, and heat exchangers. Advanced control algorithms that dynamically adjust cooling parameters based on real-time operating conditions have shown significant improvements in stack temperature uniformity. Studies indicate that model predictive control (MPC) strategies can reduce temperature gradients by up to 40% compared to conventional PID controllers.

Computational fluid dynamics (CFD) coupled with electrochemical modeling has emerged as an essential tool for system-level optimization. These simulation approaches enable engineers to predict thermal hotspots and flow distribution issues before physical prototyping, reducing development cycles by approximately 30-40%. Recent advances in machine learning algorithms have further enhanced these models by incorporating operational data to improve prediction accuracy.

Balance of plant (BOP) components significantly influence thermal management performance. Optimized integration of humidifiers, air compressors, and hydrogen recirculation systems can reduce parasitic power consumption while maintaining proper thermal conditions. Research shows that up to 15% improvement in system efficiency can be achieved through careful BOP integration and sizing relative to stack thermal requirements.

Thermal-electrical-mechanical co-optimization represents the frontier of PEMFC system design. This approach considers the interdependencies between thermal gradients, electrical performance, and mechanical stress. Advanced optimization algorithms utilizing multi-physics simulations have demonstrated the ability to extend stack lifetime by up to 20% while maintaining high power density through optimized thermal management strategies.

Modular system architectures with standardized thermal interfaces are gaining traction in commercial applications. These designs facilitate easier maintenance and component upgrades while ensuring consistent thermal performance. The automotive industry has particularly benefited from this approach, with several manufacturers reporting improved thermal uniformity and reduced integration costs through modular designs.

Cost-performance optimization remains a significant challenge, particularly for commercial applications. Thermal management systems typically represent 15-25% of total PEMFC system costs. Advanced materials and manufacturing techniques, such as additive manufacturing for complex cooling channels, offer promising pathways to reduce costs while maintaining or improving thermal performance metrics.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!