How Polyglutamic Acid Enhances Naturally Derived Plastics Flexibility

AUG 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PGA and Bioplastics: Background and Objectives

Polyglutamic acid (PGA) and bioplastics have emerged as promising materials in the quest for sustainable alternatives to conventional plastics. PGA, a naturally occurring biopolymer, has gained significant attention due to its unique properties and potential applications in various industries. Bioplastics, derived from renewable biomass sources, represent a growing sector in the plastics industry, driven by increasing environmental concerns and the need for biodegradable materials.

The development of PGA and bioplastics can be traced back to the early 20th century, with significant advancements occurring in recent decades. PGA was first discovered in 1937 as a component of the capsular material of Bacillus anthracis. Since then, research has expanded to explore its production methods, properties, and potential applications. Bioplastics, on the other hand, have a longer history, with early attempts dating back to the 1850s. However, it wasn't until the late 20th century that bioplastics gained momentum as viable alternatives to petroleum-based plastics.

The evolution of these materials has been driven by several factors, including environmental concerns, regulatory pressures, and technological advancements. As the world grapples with plastic pollution and the depletion of fossil resources, the demand for sustainable materials has intensified. This has led to increased research and development efforts in the field of biopolymers and bioplastics.

The primary objective of incorporating PGA into bioplastics is to enhance their flexibility and overall performance. Traditional bioplastics often suffer from brittleness and limited mechanical properties, which restrict their applications. By integrating PGA into bioplastic formulations, researchers aim to overcome these limitations and create materials with improved flexibility, durability, and biodegradability.

This technological advancement aligns with broader industry goals of developing sustainable materials that can compete with conventional plastics in terms of performance and cost-effectiveness. The integration of PGA into bioplastics represents a convergence of two promising fields in materials science, potentially leading to a new generation of eco-friendly plastics with enhanced properties.

As we delve deeper into this topic, it is crucial to understand the current state of PGA and bioplastics technology, the challenges faced in their development and implementation, and the potential impact on various industries. This exploration will provide valuable insights into the future of sustainable materials and their role in addressing global environmental challenges.

The development of PGA and bioplastics can be traced back to the early 20th century, with significant advancements occurring in recent decades. PGA was first discovered in 1937 as a component of the capsular material of Bacillus anthracis. Since then, research has expanded to explore its production methods, properties, and potential applications. Bioplastics, on the other hand, have a longer history, with early attempts dating back to the 1850s. However, it wasn't until the late 20th century that bioplastics gained momentum as viable alternatives to petroleum-based plastics.

The evolution of these materials has been driven by several factors, including environmental concerns, regulatory pressures, and technological advancements. As the world grapples with plastic pollution and the depletion of fossil resources, the demand for sustainable materials has intensified. This has led to increased research and development efforts in the field of biopolymers and bioplastics.

The primary objective of incorporating PGA into bioplastics is to enhance their flexibility and overall performance. Traditional bioplastics often suffer from brittleness and limited mechanical properties, which restrict their applications. By integrating PGA into bioplastic formulations, researchers aim to overcome these limitations and create materials with improved flexibility, durability, and biodegradability.

This technological advancement aligns with broader industry goals of developing sustainable materials that can compete with conventional plastics in terms of performance and cost-effectiveness. The integration of PGA into bioplastics represents a convergence of two promising fields in materials science, potentially leading to a new generation of eco-friendly plastics with enhanced properties.

As we delve deeper into this topic, it is crucial to understand the current state of PGA and bioplastics technology, the challenges faced in their development and implementation, and the potential impact on various industries. This exploration will provide valuable insights into the future of sustainable materials and their role in addressing global environmental challenges.

Market Analysis for Flexible Bioplastics

The market for flexible bioplastics has been experiencing significant growth in recent years, driven by increasing environmental concerns and the push for sustainable alternatives to traditional petroleum-based plastics. The global bioplastics market, which includes flexible bioplastics, is projected to expand at a compound annual growth rate (CAGR) of over 15% in the coming years.

Flexible bioplastics, enhanced by innovations such as the incorporation of polyglutamic acid, are finding applications across various industries. The packaging sector remains the largest consumer of flexible bioplastics, accounting for a substantial portion of the market share. This is primarily due to the growing demand for eco-friendly packaging solutions in food and beverage, personal care, and household products.

The automotive industry is also emerging as a significant market for flexible bioplastics. Manufacturers are increasingly adopting these materials for interior components, contributing to weight reduction and improved fuel efficiency. Additionally, the textile and agriculture sectors are showing promising growth potential for flexible bioplastics applications.

Consumer awareness and preference for sustainable products are key drivers of market growth. A survey conducted by a leading market research firm revealed that over 60% of consumers are willing to pay a premium for products made from biodegradable materials. This trend is particularly strong among younger demographics, indicating a long-term shift in consumer behavior.

Regionally, Europe leads the flexible bioplastics market, followed by North America and Asia-Pacific. European countries have implemented stringent regulations on single-use plastics, which has accelerated the adoption of bioplastic alternatives. The Asia-Pacific region is expected to witness the fastest growth, driven by increasing industrialization, rising environmental awareness, and supportive government policies in countries like China and India.

However, the market faces challenges such as higher production costs compared to conventional plastics and limitations in performance characteristics. The integration of polyglutamic acid and similar bio-based additives aims to address these performance issues, particularly in terms of flexibility and durability. As research and development efforts continue to improve the properties and reduce costs, the market for flexible bioplastics is expected to expand further.

The competitive landscape of the flexible bioplastics market is characterized by a mix of established chemical companies and innovative startups. Major players are investing heavily in research and development to enhance product properties and expand their product portfolios. Collaborations between material scientists, biotechnology firms, and end-user industries are becoming increasingly common, fostering innovation in the sector.

Flexible bioplastics, enhanced by innovations such as the incorporation of polyglutamic acid, are finding applications across various industries. The packaging sector remains the largest consumer of flexible bioplastics, accounting for a substantial portion of the market share. This is primarily due to the growing demand for eco-friendly packaging solutions in food and beverage, personal care, and household products.

The automotive industry is also emerging as a significant market for flexible bioplastics. Manufacturers are increasingly adopting these materials for interior components, contributing to weight reduction and improved fuel efficiency. Additionally, the textile and agriculture sectors are showing promising growth potential for flexible bioplastics applications.

Consumer awareness and preference for sustainable products are key drivers of market growth. A survey conducted by a leading market research firm revealed that over 60% of consumers are willing to pay a premium for products made from biodegradable materials. This trend is particularly strong among younger demographics, indicating a long-term shift in consumer behavior.

Regionally, Europe leads the flexible bioplastics market, followed by North America and Asia-Pacific. European countries have implemented stringent regulations on single-use plastics, which has accelerated the adoption of bioplastic alternatives. The Asia-Pacific region is expected to witness the fastest growth, driven by increasing industrialization, rising environmental awareness, and supportive government policies in countries like China and India.

However, the market faces challenges such as higher production costs compared to conventional plastics and limitations in performance characteristics. The integration of polyglutamic acid and similar bio-based additives aims to address these performance issues, particularly in terms of flexibility and durability. As research and development efforts continue to improve the properties and reduce costs, the market for flexible bioplastics is expected to expand further.

The competitive landscape of the flexible bioplastics market is characterized by a mix of established chemical companies and innovative startups. Major players are investing heavily in research and development to enhance product properties and expand their product portfolios. Collaborations between material scientists, biotechnology firms, and end-user industries are becoming increasingly common, fostering innovation in the sector.

Current Challenges in Bioplastic Flexibility

The flexibility of bioplastics remains a significant challenge in the development of sustainable alternatives to conventional plastics. While bioplastics offer numerous environmental benefits, their inherent rigidity often limits their applicability in various industries. This issue stems from the molecular structure of naturally derived polymers, which typically form strong intermolecular bonds, resulting in stiff and brittle materials.

One of the primary challenges is achieving a balance between flexibility and mechanical strength. Many bioplastics, such as those derived from polylactic acid (PLA) or starch, exhibit high tensile strength but poor elongation at break. This characteristic makes them unsuitable for applications requiring elasticity or impact resistance, such as packaging materials or flexible consumer goods.

Another significant hurdle is the moisture sensitivity of many bioplastics. Natural polymers often have hydrophilic properties, leading to water absorption and subsequent changes in mechanical properties. This sensitivity can result in dimensional instability, reduced strength, and accelerated degradation, limiting the use of bioplastics in humid environments or applications involving contact with liquids.

Temperature sensitivity poses an additional challenge. Many bioplastics have a narrow processing window and low heat deflection temperatures, restricting their use in high-temperature applications or during certain manufacturing processes. This limitation narrows the range of potential applications and complicates the integration of bioplastics into existing production lines.

The cost-effectiveness of producing flexible bioplastics is also a significant concern. Current methods to enhance flexibility, such as the addition of plasticizers or the development of complex copolymer systems, often increase production costs. This economic barrier hinders widespread adoption, particularly in price-sensitive markets where conventional plastics remain more cost-competitive.

Furthermore, maintaining biodegradability while improving flexibility presents a complex challenge. Many additives or modifications that enhance flexibility can compromise the material's ability to biodegrade, potentially negating one of the key environmental benefits of bioplastics.

Addressing these challenges requires innovative approaches in polymer science and materials engineering. The exploration of novel bio-based additives, such as polyglutamic acid, offers promising avenues for enhancing the flexibility of naturally derived plastics while maintaining their environmental benefits. However, significant research and development efforts are still needed to overcome these hurdles and create bioplastics that can truly compete with conventional plastics across a wide range of applications.

One of the primary challenges is achieving a balance between flexibility and mechanical strength. Many bioplastics, such as those derived from polylactic acid (PLA) or starch, exhibit high tensile strength but poor elongation at break. This characteristic makes them unsuitable for applications requiring elasticity or impact resistance, such as packaging materials or flexible consumer goods.

Another significant hurdle is the moisture sensitivity of many bioplastics. Natural polymers often have hydrophilic properties, leading to water absorption and subsequent changes in mechanical properties. This sensitivity can result in dimensional instability, reduced strength, and accelerated degradation, limiting the use of bioplastics in humid environments or applications involving contact with liquids.

Temperature sensitivity poses an additional challenge. Many bioplastics have a narrow processing window and low heat deflection temperatures, restricting their use in high-temperature applications or during certain manufacturing processes. This limitation narrows the range of potential applications and complicates the integration of bioplastics into existing production lines.

The cost-effectiveness of producing flexible bioplastics is also a significant concern. Current methods to enhance flexibility, such as the addition of plasticizers or the development of complex copolymer systems, often increase production costs. This economic barrier hinders widespread adoption, particularly in price-sensitive markets where conventional plastics remain more cost-competitive.

Furthermore, maintaining biodegradability while improving flexibility presents a complex challenge. Many additives or modifications that enhance flexibility can compromise the material's ability to biodegrade, potentially negating one of the key environmental benefits of bioplastics.

Addressing these challenges requires innovative approaches in polymer science and materials engineering. The exploration of novel bio-based additives, such as polyglutamic acid, offers promising avenues for enhancing the flexibility of naturally derived plastics while maintaining their environmental benefits. However, significant research and development efforts are still needed to overcome these hurdles and create bioplastics that can truly compete with conventional plastics across a wide range of applications.

Existing PGA-Based Flexibility Solutions

01 Molecular structure and flexibility of polyglutamic acid

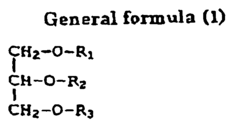

Polyglutamic acid exhibits flexibility due to its unique molecular structure. The polymer chain consists of repeating glutamic acid units connected by peptide bonds, allowing for rotational freedom around these bonds. This structural characteristic contributes to the overall flexibility of the molecule, which can be influenced by factors such as pH, temperature, and ionic strength of the surrounding environment.- Molecular structure and flexibility of polyglutamic acid: Polyglutamic acid exhibits flexibility due to its unique molecular structure. The polymer chain can adopt various conformations, allowing it to adapt to different environments and interact with other molecules. This flexibility contributes to its versatility in various applications, including drug delivery systems and biomaterials.

- Modification techniques to enhance polyglutamic acid flexibility: Various modification techniques can be employed to enhance the flexibility of polyglutamic acid. These may include chemical modifications, such as crosslinking or grafting with other polymers, as well as physical modifications like blending with other materials. These modifications can tailor the flexibility of polyglutamic acid for specific applications.

- Applications utilizing polyglutamic acid flexibility: The flexibility of polyglutamic acid is exploited in numerous applications across various fields. In cosmetics, it can be used as a film-forming agent or moisturizer. In biomedical applications, its flexibility allows for the development of scaffolds for tissue engineering or controlled release systems for drug delivery. The food industry also utilizes its flexible properties in texture modification and encapsulation.

- Influence of environmental factors on polyglutamic acid flexibility: The flexibility of polyglutamic acid can be influenced by various environmental factors such as pH, temperature, and ionic strength. These factors can affect the polymer's conformation and interactions, thereby altering its flexibility. Understanding these influences is crucial for optimizing the performance of polyglutamic acid in different applications and environments.

- Characterization methods for polyglutamic acid flexibility: Various analytical techniques are employed to characterize the flexibility of polyglutamic acid. These may include spectroscopic methods, rheological measurements, and microscopy techniques. Such characterization is essential for understanding the polymer's behavior, optimizing its properties, and ensuring its suitability for specific applications.

02 Applications of polyglutamic acid in cosmetics and personal care

The flexibility of polyglutamic acid makes it suitable for various cosmetic and personal care applications. It can form thin, flexible films on the skin, providing moisturizing and protective properties. Its ability to retain water and form hydrogels contributes to its effectiveness in skincare formulations, hair care products, and other personal care items.Expand Specific Solutions03 Polyglutamic acid in drug delivery systems

The flexible nature of polyglutamic acid makes it an excellent candidate for drug delivery systems. Its ability to form nanoparticles, micelles, and other structures allows for the encapsulation and controlled release of various therapeutic agents. The flexibility of the polymer chain can be tailored to optimize drug loading, release kinetics, and targeting efficiency.Expand Specific Solutions04 Modification of polyglutamic acid to enhance flexibility

Various chemical modifications can be applied to polyglutamic acid to enhance its flexibility and tailor its properties for specific applications. These modifications may include grafting with other polymers, crosslinking, or introducing specific functional groups. Such modifications can alter the polymer's conformation, hydrophobicity, and interactions with other molecules, thereby influencing its overall flexibility and performance in different environments.Expand Specific Solutions05 Characterization and measurement of polyglutamic acid flexibility

Various analytical techniques are employed to characterize and measure the flexibility of polyglutamic acid. These may include rheological measurements, dynamic light scattering, atomic force microscopy, and molecular dynamics simulations. Understanding the flexibility characteristics of polyglutamic acid is crucial for optimizing its performance in different applications and predicting its behavior under various conditions.Expand Specific Solutions

Key Players in PGA and Bioplastics Industry

The development of polyglutamic acid to enhance naturally derived plastics flexibility is in an emerging stage, with growing market potential due to increasing demand for sustainable materials. The technology is still evolving, with varying levels of maturity across different companies. Key players like Beijing University of Chemical Technology and Northern Technologies International Corp. are at the forefront of research and development, while established chemical giants such as China Petroleum & Chemical Corp. and LG Chem Ltd. are leveraging their resources to advance the technology. Smaller specialized firms like Zymochem, Inc. are also contributing innovative solutions. The competitive landscape is diverse, with academic institutions, multinational corporations, and startups all vying to capitalize on this promising eco-friendly material enhancement technology.

Beijing University of Chemical Technology

Technical Solution: Beijing University of Chemical Technology has developed a novel approach to enhance the flexibility of naturally derived plastics using polyglutamic acid (PGA). Their research focuses on incorporating PGA into bioplastic formulations, particularly those based on polylactic acid (PLA). The team has successfully demonstrated that the addition of PGA can significantly improve the elongation at break and impact strength of PLA-based materials[1]. Their method involves a two-step process: first, they synthesize PGA through microbial fermentation, and then they blend it with PLA using a reactive extrusion technique. This process creates a more flexible and durable bioplastic that maintains its biodegradability[2].

Strengths: Improved flexibility and impact resistance of bioplastics, maintains biodegradability. Weaknesses: Potential increase in production costs, may affect other mechanical properties.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed a proprietary technology for incorporating polyglutamic acid (PGA) into their bioplastic formulations. Their approach involves grafting PGA onto the backbone of naturally derived plastics, such as polyhydroxyalkanoates (PHAs). This grafting process creates a comb-like structure that enhances the intermolecular interactions within the plastic matrix, resulting in improved flexibility and toughness[3]. Sinopec's method also includes the use of a compatibilizer to ensure better dispersion of PGA within the bioplastic. The company has reported a 30% increase in elongation at break and a 25% improvement in impact strength for their PGA-enhanced bioplastics compared to conventional formulations[4].

Strengths: Significant improvements in flexibility and toughness, scalable production process. Weaknesses: May require additional processing steps, potential increase in material costs.

Core Innovations in PGA-Enhanced Bioplastics

Eco-friendly plastic, eco-friendly plastic fiber, and PGA ion complex

PatentWO2024085131A1

Innovation

- Incorporating a poly-γ-glutamic acid (PGA) ion complex into synthetic polymer compounds that are difficult to decompose by microorganisms, which accelerates microbial decomposition and imparts antibacterial properties, using PGA in the form of a filler or ion complex with polyvalent metal ions to enhance heat resistance and degradability.

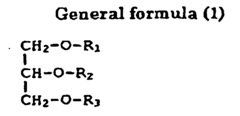

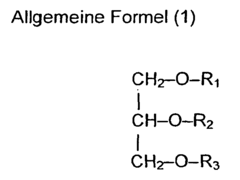

Aliphatic polyester composition and flexible products

PatentInactiveEP1270659B1

Innovation

- A composition of polylactic acid blended with polyglycerol acetic ester and a specific acetic and fatty acid ester of glycerol, which provides flexibility and suitable physical characteristics for molding into films, sheets, and bags, using a specific acetylization ratio and combination of esters to enhance compatibility and performance.

Environmental Impact Assessment

The incorporation of polyglutamic acid (PGA) into naturally derived plastics presents a promising avenue for enhancing flexibility while maintaining environmental sustainability. This assessment examines the potential environmental impacts of using PGA as a plasticizer in bioplastics.

PGA is a biodegradable polymer produced through microbial fermentation, primarily using Bacillus subtilis. Its production process is generally considered environmentally friendly, as it utilizes renewable resources and generates minimal waste. The use of PGA in naturally derived plastics could potentially reduce the overall environmental footprint of plastic products.

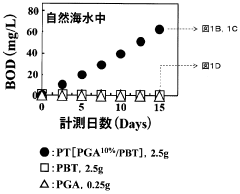

One of the primary environmental benefits of PGA-enhanced bioplastics is their improved biodegradability. PGA's hydrophilic nature accelerates the breakdown of plastic materials in various environmental conditions, potentially reducing the persistence of plastic waste in ecosystems. This characteristic could significantly mitigate the long-term environmental impacts associated with conventional plastics.

The enhanced flexibility imparted by PGA may also contribute to reduced material usage in certain applications. More flexible bioplastics could allow for thinner packaging materials, potentially decreasing the overall volume of plastic waste generated. Additionally, the improved mechanical properties might extend the lifespan of some products, further reducing waste.

However, the environmental impact of PGA production must be carefully considered. While the fermentation process is generally eco-friendly, scaling up production could lead to increased energy consumption and potential land use changes for raw material cultivation. It is crucial to ensure that the environmental benefits of PGA-enhanced bioplastics outweigh the impacts of their production.

Water usage in PGA production and the potential for eutrophication from nutrient-rich effluents should also be evaluated. Implementing closed-loop systems and efficient water treatment processes could help mitigate these concerns. Furthermore, the end-of-life management of PGA-enhanced bioplastics requires careful consideration to ensure proper composting or recycling infrastructure is in place.

The use of PGA in naturally derived plastics may also have indirect environmental benefits. By improving the performance of bioplastics, PGA could accelerate the transition away from petroleum-based plastics, potentially reducing greenhouse gas emissions and fossil fuel dependence in the plastics industry.

In conclusion, while the incorporation of PGA into naturally derived plastics shows promise for enhancing environmental sustainability, a comprehensive life cycle assessment is necessary to fully quantify its environmental impacts and benefits. Ongoing research and development should focus on optimizing PGA production processes and ensuring the overall sustainability of PGA-enhanced bioplastics throughout their lifecycle.

PGA is a biodegradable polymer produced through microbial fermentation, primarily using Bacillus subtilis. Its production process is generally considered environmentally friendly, as it utilizes renewable resources and generates minimal waste. The use of PGA in naturally derived plastics could potentially reduce the overall environmental footprint of plastic products.

One of the primary environmental benefits of PGA-enhanced bioplastics is their improved biodegradability. PGA's hydrophilic nature accelerates the breakdown of plastic materials in various environmental conditions, potentially reducing the persistence of plastic waste in ecosystems. This characteristic could significantly mitigate the long-term environmental impacts associated with conventional plastics.

The enhanced flexibility imparted by PGA may also contribute to reduced material usage in certain applications. More flexible bioplastics could allow for thinner packaging materials, potentially decreasing the overall volume of plastic waste generated. Additionally, the improved mechanical properties might extend the lifespan of some products, further reducing waste.

However, the environmental impact of PGA production must be carefully considered. While the fermentation process is generally eco-friendly, scaling up production could lead to increased energy consumption and potential land use changes for raw material cultivation. It is crucial to ensure that the environmental benefits of PGA-enhanced bioplastics outweigh the impacts of their production.

Water usage in PGA production and the potential for eutrophication from nutrient-rich effluents should also be evaluated. Implementing closed-loop systems and efficient water treatment processes could help mitigate these concerns. Furthermore, the end-of-life management of PGA-enhanced bioplastics requires careful consideration to ensure proper composting or recycling infrastructure is in place.

The use of PGA in naturally derived plastics may also have indirect environmental benefits. By improving the performance of bioplastics, PGA could accelerate the transition away from petroleum-based plastics, potentially reducing greenhouse gas emissions and fossil fuel dependence in the plastics industry.

In conclusion, while the incorporation of PGA into naturally derived plastics shows promise for enhancing environmental sustainability, a comprehensive life cycle assessment is necessary to fully quantify its environmental impacts and benefits. Ongoing research and development should focus on optimizing PGA production processes and ensuring the overall sustainability of PGA-enhanced bioplastics throughout their lifecycle.

Scalability and Cost Analysis

The scalability and cost analysis of incorporating polyglutamic acid (PGA) into naturally derived plastics is crucial for determining its commercial viability. PGA production can be scaled up through fermentation processes using various bacterial strains, with Bacillus subtilis and Bacillus licheniformis being the most common. The scalability of PGA production is promising, as these bacteria can be cultivated in large bioreactors, allowing for industrial-scale production.

However, the current cost of PGA production remains a significant challenge. The fermentation process requires specific growth conditions and nutrients, which can be expensive to maintain at scale. Additionally, the downstream processing and purification of PGA add to the overall production costs. As of now, the price of PGA is considerably higher than conventional plasticizers used in the industry, which could limit its widespread adoption in naturally derived plastics.

To address these cost concerns, research is ongoing to optimize fermentation conditions and develop more efficient bacterial strains. Some studies have explored the use of agricultural waste products as low-cost substrates for PGA production, which could significantly reduce raw material costs. Furthermore, advancements in bioprocess engineering and separation technologies are expected to improve PGA yield and reduce purification costs in the coming years.

The integration of PGA into naturally derived plastics production processes presents another scalability challenge. Existing plastic manufacturing equipment may require modifications to accommodate PGA incorporation effectively. This could involve additional capital investments for manufacturers looking to adopt PGA-enhanced naturally derived plastics.

From a market perspective, the scalability of PGA-enhanced naturally derived plastics will depend on consumer demand and regulatory incentives. As environmental concerns grow, there is an increasing market pull for sustainable and biodegradable plastic alternatives. This trend could drive investments in scaling up PGA production and integration technologies.

Cost-wise, while the initial production costs of PGA-enhanced naturally derived plastics may be higher than conventional plastics, economies of scale and technological improvements are expected to narrow this gap over time. Moreover, the potential for extended product lifecycles and reduced environmental impact could offset higher upfront costs in certain applications, particularly in industries prioritizing sustainability.

In conclusion, while there are current challenges in scalability and cost, ongoing research and development efforts, coupled with growing market demand for sustainable materials, suggest a positive outlook for the large-scale adoption of PGA-enhanced naturally derived plastics in the future.

However, the current cost of PGA production remains a significant challenge. The fermentation process requires specific growth conditions and nutrients, which can be expensive to maintain at scale. Additionally, the downstream processing and purification of PGA add to the overall production costs. As of now, the price of PGA is considerably higher than conventional plasticizers used in the industry, which could limit its widespread adoption in naturally derived plastics.

To address these cost concerns, research is ongoing to optimize fermentation conditions and develop more efficient bacterial strains. Some studies have explored the use of agricultural waste products as low-cost substrates for PGA production, which could significantly reduce raw material costs. Furthermore, advancements in bioprocess engineering and separation technologies are expected to improve PGA yield and reduce purification costs in the coming years.

The integration of PGA into naturally derived plastics production processes presents another scalability challenge. Existing plastic manufacturing equipment may require modifications to accommodate PGA incorporation effectively. This could involve additional capital investments for manufacturers looking to adopt PGA-enhanced naturally derived plastics.

From a market perspective, the scalability of PGA-enhanced naturally derived plastics will depend on consumer demand and regulatory incentives. As environmental concerns grow, there is an increasing market pull for sustainable and biodegradable plastic alternatives. This trend could drive investments in scaling up PGA production and integration technologies.

Cost-wise, while the initial production costs of PGA-enhanced naturally derived plastics may be higher than conventional plastics, economies of scale and technological improvements are expected to narrow this gap over time. Moreover, the potential for extended product lifecycles and reduced environmental impact could offset higher upfront costs in certain applications, particularly in industries prioritizing sustainability.

In conclusion, while there are current challenges in scalability and cost, ongoing research and development efforts, coupled with growing market demand for sustainable materials, suggest a positive outlook for the large-scale adoption of PGA-enhanced naturally derived plastics in the future.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!