Influence of Polyglutamic Acid in Cascade Biotransformations

AUG 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Polyglutamic Acid in Biotransformations: Background and Objectives

Polyglutamic acid (PGA) has emerged as a significant player in the field of biotransformations, particularly in cascade reactions. This naturally occurring biopolymer, composed of glutamic acid units, has garnered increasing attention due to its unique properties and potential applications in various industrial and biomedical sectors.

The development of PGA-based biotransformations can be traced back to the early 2000s when researchers began exploring its potential as a biodegradable and biocompatible material. Initially, the focus was primarily on its use in drug delivery systems and tissue engineering. However, as the understanding of PGA's chemical and physical properties deepened, its potential in enzymatic reactions became apparent.

The evolution of PGA in biotransformations has been driven by the growing demand for sustainable and efficient catalytic processes in the chemical and pharmaceutical industries. As traditional chemical synthesis methods face challenges related to environmental concerns and process efficiency, biotransformations offer a promising alternative. PGA's role in this field has been particularly noteworthy due to its ability to enhance enzyme stability and activity in multi-step reactions.

Recent years have witnessed a surge in research focusing on the influence of PGA in cascade biotransformations. These multi-step enzymatic reactions, which mimic natural metabolic pathways, have gained prominence for their potential to synthesize complex molecules with high selectivity and yield. The integration of PGA into these systems has shown remarkable improvements in reaction efficiency and product yield.

The primary objective of current research in this area is to fully elucidate the mechanisms by which PGA influences cascade biotransformations. This includes understanding its interactions with enzymes, substrates, and intermediates in multi-step reactions. Researchers aim to optimize PGA's performance as a support material for immobilized enzymes and as a stabilizing agent in solution-phase reactions.

Another critical goal is to expand the application scope of PGA in biotransformations. This involves exploring its potential in new reaction types, particularly those involving challenging substrates or conditions. The development of novel PGA-based materials with enhanced properties for specific biotransformation applications is also a key focus area.

Furthermore, there is a growing emphasis on scaling up PGA-assisted cascade biotransformations for industrial applications. This necessitates addressing challenges related to process engineering, cost-effectiveness, and product purification. The ultimate aim is to establish PGA as a versatile and indispensable tool in the biotechnology industry, capable of facilitating complex chemical transformations with high efficiency and sustainability.

The development of PGA-based biotransformations can be traced back to the early 2000s when researchers began exploring its potential as a biodegradable and biocompatible material. Initially, the focus was primarily on its use in drug delivery systems and tissue engineering. However, as the understanding of PGA's chemical and physical properties deepened, its potential in enzymatic reactions became apparent.

The evolution of PGA in biotransformations has been driven by the growing demand for sustainable and efficient catalytic processes in the chemical and pharmaceutical industries. As traditional chemical synthesis methods face challenges related to environmental concerns and process efficiency, biotransformations offer a promising alternative. PGA's role in this field has been particularly noteworthy due to its ability to enhance enzyme stability and activity in multi-step reactions.

Recent years have witnessed a surge in research focusing on the influence of PGA in cascade biotransformations. These multi-step enzymatic reactions, which mimic natural metabolic pathways, have gained prominence for their potential to synthesize complex molecules with high selectivity and yield. The integration of PGA into these systems has shown remarkable improvements in reaction efficiency and product yield.

The primary objective of current research in this area is to fully elucidate the mechanisms by which PGA influences cascade biotransformations. This includes understanding its interactions with enzymes, substrates, and intermediates in multi-step reactions. Researchers aim to optimize PGA's performance as a support material for immobilized enzymes and as a stabilizing agent in solution-phase reactions.

Another critical goal is to expand the application scope of PGA in biotransformations. This involves exploring its potential in new reaction types, particularly those involving challenging substrates or conditions. The development of novel PGA-based materials with enhanced properties for specific biotransformation applications is also a key focus area.

Furthermore, there is a growing emphasis on scaling up PGA-assisted cascade biotransformations for industrial applications. This necessitates addressing challenges related to process engineering, cost-effectiveness, and product purification. The ultimate aim is to establish PGA as a versatile and indispensable tool in the biotechnology industry, capable of facilitating complex chemical transformations with high efficiency and sustainability.

Market Analysis for Cascade Biotransformation Products

The market for cascade biotransformation products is experiencing significant growth, driven by increasing demand for sustainable and eco-friendly production processes across various industries. Cascade biotransformations, which involve multiple enzymatic reactions in a single process, offer numerous advantages over traditional chemical synthesis methods, including higher efficiency, reduced waste generation, and improved product purity.

The pharmaceutical industry represents a major market segment for cascade biotransformation products, particularly in the synthesis of complex drug molecules and intermediates. The ability to perform multiple reactions in a single step allows for streamlined production processes and reduced manufacturing costs. Additionally, the food and beverage industry is increasingly adopting cascade biotransformations for the production of natural flavors, colors, and nutritional supplements.

In the context of polyglutamic acid (PGA) influence on cascade biotransformations, the market potential is particularly promising. PGA, a biodegradable and biocompatible polymer, has shown remarkable capabilities in enhancing enzyme stability and activity in multi-step biotransformations. This has opened up new possibilities for the development of more efficient and cost-effective biocatalytic processes.

The global market for enzyme-based cascade biotransformation products is projected to grow steadily over the next five years. Key factors driving this growth include increasing environmental regulations, rising consumer demand for natural and sustainable products, and advancements in enzyme engineering and immobilization technologies.

Geographically, North America and Europe currently dominate the market for cascade biotransformation products, owing to their well-established biotechnology sectors and stringent environmental regulations. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, fueled by rapid industrialization, increasing investments in biotechnology research, and growing awareness of sustainable production methods.

Key market players in the cascade biotransformation sector include major enzyme manufacturers, biotechnology companies, and pharmaceutical firms. These companies are actively investing in research and development to expand their product portfolios and improve process efficiencies. Collaborations between academic institutions and industry partners are also playing a crucial role in driving innovation and market growth.

Despite the positive outlook, challenges such as high initial investment costs, complexity in process scale-up, and regulatory hurdles remain. However, ongoing technological advancements and increasing focus on sustainable manufacturing practices are expected to address these challenges and further propel market growth in the coming years.

The pharmaceutical industry represents a major market segment for cascade biotransformation products, particularly in the synthesis of complex drug molecules and intermediates. The ability to perform multiple reactions in a single step allows for streamlined production processes and reduced manufacturing costs. Additionally, the food and beverage industry is increasingly adopting cascade biotransformations for the production of natural flavors, colors, and nutritional supplements.

In the context of polyglutamic acid (PGA) influence on cascade biotransformations, the market potential is particularly promising. PGA, a biodegradable and biocompatible polymer, has shown remarkable capabilities in enhancing enzyme stability and activity in multi-step biotransformations. This has opened up new possibilities for the development of more efficient and cost-effective biocatalytic processes.

The global market for enzyme-based cascade biotransformation products is projected to grow steadily over the next five years. Key factors driving this growth include increasing environmental regulations, rising consumer demand for natural and sustainable products, and advancements in enzyme engineering and immobilization technologies.

Geographically, North America and Europe currently dominate the market for cascade biotransformation products, owing to their well-established biotechnology sectors and stringent environmental regulations. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, fueled by rapid industrialization, increasing investments in biotechnology research, and growing awareness of sustainable production methods.

Key market players in the cascade biotransformation sector include major enzyme manufacturers, biotechnology companies, and pharmaceutical firms. These companies are actively investing in research and development to expand their product portfolios and improve process efficiencies. Collaborations between academic institutions and industry partners are also playing a crucial role in driving innovation and market growth.

Despite the positive outlook, challenges such as high initial investment costs, complexity in process scale-up, and regulatory hurdles remain. However, ongoing technological advancements and increasing focus on sustainable manufacturing practices are expected to address these challenges and further propel market growth in the coming years.

Current State and Challenges in Polyglutamic Acid Applications

Polyglutamic acid (PGA) has emerged as a versatile biopolymer with significant potential in various industrial and biomedical applications. The current state of PGA applications is characterized by a growing interest in its use as a key component in cascade biotransformations. This innovative approach leverages PGA's unique properties to enhance the efficiency and sustainability of multi-step enzymatic processes.

In the field of biocatalysis, PGA has shown promising results as an immobilization matrix for enzymes. Its high water retention capacity and biocompatibility provide an ideal microenvironment for enzymatic reactions. Recent studies have demonstrated that PGA-based enzyme immobilization can significantly improve the stability and reusability of biocatalysts in cascade reactions, leading to increased overall process efficiency.

The pharmaceutical industry has also recognized the potential of PGA in drug delivery systems. Current applications focus on utilizing PGA's biodegradability and non-toxicity to develop controlled-release formulations. However, the integration of PGA-based drug delivery systems into complex cascade biotransformations remains a challenging frontier, with ongoing research aimed at optimizing drug release kinetics in multi-step enzymatic processes.

Despite these advancements, several challenges persist in the widespread adoption of PGA in cascade biotransformations. One significant hurdle is the scalability of PGA production. While fermentation processes using Bacillus subtilis have been established, the cost-effective large-scale production of high-molecular-weight PGA remains a challenge. This limitation impacts the economic viability of PGA-based solutions in industrial-scale biotransformations.

Another critical challenge lies in the fine-tuning of PGA properties for specific cascade reactions. The molecular weight, degree of crosslinking, and surface modifications of PGA significantly influence its performance in different biotransformation steps. Developing standardized methods for tailoring PGA characteristics to suit diverse enzymatic cascades is an ongoing area of research and development.

The integration of PGA into existing biotransformation processes also presents technical challenges. Optimizing reaction conditions to accommodate PGA-based systems while maintaining the efficiency of each step in the cascade requires extensive experimentation and process engineering. This integration complexity often results in increased development timelines and costs, potentially limiting the adoption of PGA-based solutions in established industrial processes.

Furthermore, the long-term stability of PGA in complex reaction environments remains a concern. While PGA exhibits excellent biocompatibility, its susceptibility to degradation under certain conditions can affect the consistency and reproducibility of cascade biotransformations. Addressing this challenge requires the development of stabilization strategies and protective formulations to enhance PGA's resilience in diverse reaction media.

In the field of biocatalysis, PGA has shown promising results as an immobilization matrix for enzymes. Its high water retention capacity and biocompatibility provide an ideal microenvironment for enzymatic reactions. Recent studies have demonstrated that PGA-based enzyme immobilization can significantly improve the stability and reusability of biocatalysts in cascade reactions, leading to increased overall process efficiency.

The pharmaceutical industry has also recognized the potential of PGA in drug delivery systems. Current applications focus on utilizing PGA's biodegradability and non-toxicity to develop controlled-release formulations. However, the integration of PGA-based drug delivery systems into complex cascade biotransformations remains a challenging frontier, with ongoing research aimed at optimizing drug release kinetics in multi-step enzymatic processes.

Despite these advancements, several challenges persist in the widespread adoption of PGA in cascade biotransformations. One significant hurdle is the scalability of PGA production. While fermentation processes using Bacillus subtilis have been established, the cost-effective large-scale production of high-molecular-weight PGA remains a challenge. This limitation impacts the economic viability of PGA-based solutions in industrial-scale biotransformations.

Another critical challenge lies in the fine-tuning of PGA properties for specific cascade reactions. The molecular weight, degree of crosslinking, and surface modifications of PGA significantly influence its performance in different biotransformation steps. Developing standardized methods for tailoring PGA characteristics to suit diverse enzymatic cascades is an ongoing area of research and development.

The integration of PGA into existing biotransformation processes also presents technical challenges. Optimizing reaction conditions to accommodate PGA-based systems while maintaining the efficiency of each step in the cascade requires extensive experimentation and process engineering. This integration complexity often results in increased development timelines and costs, potentially limiting the adoption of PGA-based solutions in established industrial processes.

Furthermore, the long-term stability of PGA in complex reaction environments remains a concern. While PGA exhibits excellent biocompatibility, its susceptibility to degradation under certain conditions can affect the consistency and reproducibility of cascade biotransformations. Addressing this challenge requires the development of stabilization strategies and protective formulations to enhance PGA's resilience in diverse reaction media.

Existing Solutions for Enhancing Cascade Biotransformations

01 Production methods of polyglutamic acid

Various methods for producing polyglutamic acid are described, including fermentation techniques using microorganisms, enzymatic synthesis, and chemical synthesis. These methods aim to optimize yield, purity, and molecular weight of the resulting polyglutamic acid.- Production methods of polyglutamic acid: Various methods for producing polyglutamic acid are described, including fermentation techniques using microorganisms, enzymatic synthesis, and chemical synthesis. These methods aim to optimize yield, purity, and molecular weight of the resulting polyglutamic acid.

- Applications in cosmetics and personal care: Polyglutamic acid is utilized in cosmetic and personal care products due to its moisturizing, film-forming, and anti-aging properties. It is incorporated into formulations such as creams, lotions, and masks to improve skin hydration and texture.

- Medical and pharmaceutical applications: Polyglutamic acid finds applications in the medical and pharmaceutical fields, including drug delivery systems, tissue engineering scaffolds, and wound healing materials. Its biocompatibility and biodegradability make it suitable for various biomedical applications.

- Agricultural and environmental uses: Polyglutamic acid is employed in agriculture as a soil conditioner, fertilizer additive, and plant growth promoter. It also has applications in environmental remediation, such as heavy metal removal from contaminated water and soil.

- Modifications and derivatives of polyglutamic acid: Research focuses on developing modified forms and derivatives of polyglutamic acid to enhance its properties and expand its applications. This includes chemical modifications, copolymerization, and the creation of composite materials incorporating polyglutamic acid.

02 Applications in cosmetics and personal care

Polyglutamic acid is utilized in cosmetic and personal care products due to its moisturizing, anti-aging, and skin-conditioning properties. It can be incorporated into formulations such as creams, lotions, and serums to improve skin hydration and texture.Expand Specific Solutions03 Medical and pharmaceutical applications

Polyglutamic acid has various medical and pharmaceutical applications, including drug delivery systems, tissue engineering scaffolds, and wound healing materials. Its biocompatibility and biodegradability make it suitable for use in medical devices and drug formulations.Expand Specific Solutions04 Agricultural and environmental uses

Polyglutamic acid finds applications in agriculture and environmental protection, such as soil conditioners, plant growth promoters, and water treatment agents. It can improve soil structure, enhance nutrient uptake by plants, and aid in the removal of pollutants from water.Expand Specific Solutions05 Modifications and derivatives of polyglutamic acid

Various modifications and derivatives of polyglutamic acid are developed to enhance its properties or create new functionalities. These include chemical modifications, copolymerization with other monomers, and the creation of composite materials incorporating polyglutamic acid.Expand Specific Solutions

Key Players in Polyglutamic Acid and Biotransformation Industries

The influence of polyglutamic acid in cascade biotransformations represents an emerging field in biotechnology, currently in its early development stage. The market size is relatively small but growing, driven by increasing interest in sustainable and efficient bioprocesses. The technology's maturity is still evolving, with key players like Jiangnan University, University of Bristol, and BASF Plant Science LLC leading research efforts. Companies such as Suntory Holdings Ltd. and DuPont de Nemours, Inc. are exploring industrial applications, while research institutions like CSIR and Huazhong Agricultural University contribute to fundamental understanding. As the technology advances, it is expected to find applications in various sectors, including pharmaceuticals, food production, and industrial biotechnology, potentially reshaping these industries' landscape.

Jiangnan University

Technical Solution: Jiangnan University has developed innovative approaches for utilizing polyglutamic acid (PGA) in cascade biotransformations. Their research focuses on enhancing the efficiency and stability of multi-enzyme systems by incorporating PGA as a scaffold. They have demonstrated that PGA can effectively immobilize multiple enzymes, creating a microenvironment that promotes synergistic interactions between the catalysts[1]. This approach has shown significant improvements in reaction rates and product yields, particularly in the production of high-value chemicals and pharmaceuticals[2]. The university has also explored the use of PGA-based hydrogels as a matrix for enzyme encapsulation, which provides protection against harsh reaction conditions and enables easy recovery and reuse of the biocatalysts[3].

Strengths: Improved enzyme stability and reusability, enhanced reaction efficiency, and potential for industrial scale-up. Weaknesses: Possible diffusion limitations in highly crosslinked PGA matrices and potential challenges in optimizing the PGA structure for diverse enzyme systems.

University of Bristol

Technical Solution: The University of Bristol has made significant strides in understanding the influence of polyglutamic acid (PGA) in cascade biotransformations. Their research team has developed a novel approach using PGA as a molecular chaperone to enhance the stability and activity of enzymes in multi-step reactions[1]. By carefully engineering the PGA structure, they have created a protective microenvironment that shields enzymes from denaturation and aggregation, particularly in organic solvents and at elevated temperatures[2]. The university's work has also focused on the development of PGA-based nanoreactors, which allow for the compartmentalization of cascade reactions, mimicking the efficiency of natural cellular processes[3]. These nanoreactors have shown promise in improving the overall yield and selectivity of complex biotransformations, especially in the synthesis of fine chemicals and pharmaceutical intermediates[4].

Strengths: Enhanced enzyme stability in harsh conditions, improved reaction compartmentalization, and potential for mimicking cellular efficiency. Weaknesses: Complexity in designing and optimizing PGA structures for specific enzyme systems, and potential scalability challenges for industrial applications.

Core Innovations in Polyglutamic Acid-Mediated Biotransformations

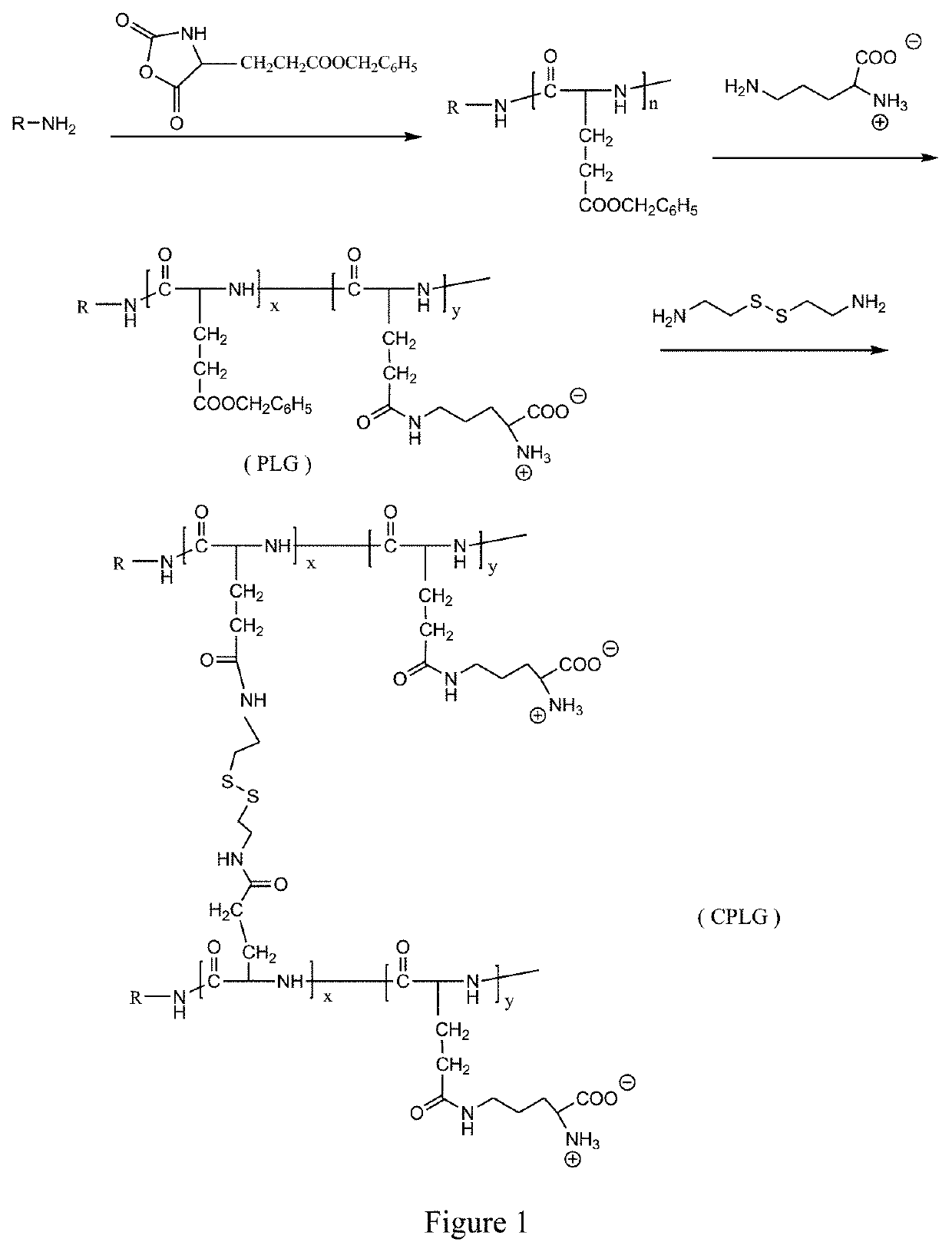

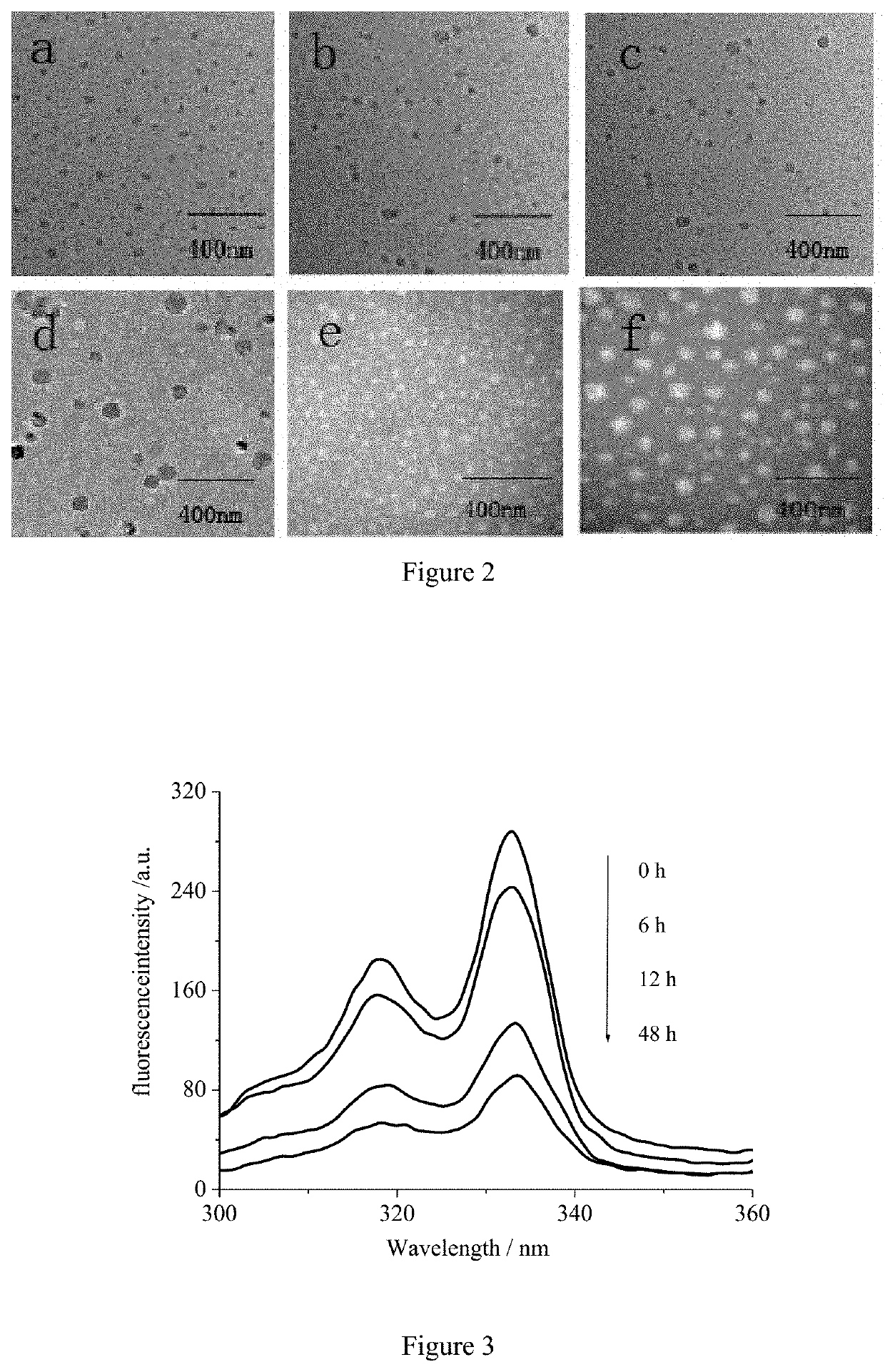

A method of preparing pH/reduction responsive polyamino acid zwitterionic nanoparticles

PatentActiveUS20200281865A1

Innovation

- A method involving ring-opening polymerization of polyglutamic acid, introduction of L-lysine to form zwitterionic ions, and cross-linking with cysteamine to create pH/reduction responsive polyamino acid zwitterionic nanoparticles, which are biocompatible and controllable in size and reaction efficiency, allowing for targeted drug release at tumor sites.

Maize nucleotide sequence coding for a protein with transglutaminase activity and use thereof

PatentInactiveUS20100092606A1

Innovation

- Identification of DNA sequences with TGase activity from corn, which encode proteins capable of catalyzing covalent links between proteins, and the use of these DNA sequences to create expression vectors for producing recombinant proteins with TGase activity in plant cells, enabling their application in food processing and transgenic plant development.

Environmental Impact of Polyglutamic Acid in Biotransformations

The environmental impact of polyglutamic acid (PGA) in biotransformations is a crucial aspect to consider when evaluating the sustainability and eco-friendliness of cascade biotransformation processes. PGA, a biodegradable and non-toxic biopolymer, offers several environmental benefits when used in biotransformations.

One of the primary advantages of PGA in biotransformations is its ability to reduce the use of harmful organic solvents. Traditional chemical processes often rely on environmentally damaging solvents, which can lead to air and water pollution. By incorporating PGA into cascade biotransformations, the need for these solvents can be significantly reduced or eliminated, resulting in cleaner and more sustainable production methods.

PGA also contributes to waste reduction in biotransformation processes. As a biodegradable polymer, PGA can be easily broken down by microorganisms in the environment, leaving behind no persistent pollutants. This characteristic makes it an excellent choice for large-scale industrial applications, where waste management is a critical concern.

Furthermore, the use of PGA in biotransformations can lead to improved energy efficiency. PGA-based systems often operate under milder conditions compared to traditional chemical processes, requiring less energy input. This reduction in energy consumption translates to lower greenhouse gas emissions and a smaller carbon footprint for the overall biotransformation process.

The water-soluble nature of PGA also presents environmental benefits in biotransformations. It allows for easier separation and purification of products, reducing the need for extensive downstream processing. This efficiency in product recovery not only saves resources but also minimizes the generation of secondary waste streams.

In terms of resource conservation, PGA offers advantages as it can be produced from renewable resources. The production of PGA through microbial fermentation utilizes sustainable feedstocks, contributing to the circular economy and reducing dependence on fossil-based materials.

Additionally, the use of PGA in biotransformations can enhance the stability and reusability of enzymes. This increased enzyme longevity reduces the frequency of enzyme replacement, leading to less waste generation and more efficient use of biocatalysts.

However, it is important to note that the environmental impact of PGA in biotransformations is not without challenges. The production of PGA itself requires resources and energy, and the overall life cycle assessment of PGA-based processes must be carefully evaluated to ensure a net positive environmental impact.

In conclusion, the incorporation of PGA in cascade biotransformations offers significant potential for improving the environmental sustainability of industrial processes. Its biodegradability, ability to reduce solvent use, and contribution to energy efficiency make it a promising component in the development of greener biotechnologies. As research in this field progresses, further optimization of PGA-based systems is expected to enhance their environmental benefits and broaden their applications in sustainable industrial practices.

One of the primary advantages of PGA in biotransformations is its ability to reduce the use of harmful organic solvents. Traditional chemical processes often rely on environmentally damaging solvents, which can lead to air and water pollution. By incorporating PGA into cascade biotransformations, the need for these solvents can be significantly reduced or eliminated, resulting in cleaner and more sustainable production methods.

PGA also contributes to waste reduction in biotransformation processes. As a biodegradable polymer, PGA can be easily broken down by microorganisms in the environment, leaving behind no persistent pollutants. This characteristic makes it an excellent choice for large-scale industrial applications, where waste management is a critical concern.

Furthermore, the use of PGA in biotransformations can lead to improved energy efficiency. PGA-based systems often operate under milder conditions compared to traditional chemical processes, requiring less energy input. This reduction in energy consumption translates to lower greenhouse gas emissions and a smaller carbon footprint for the overall biotransformation process.

The water-soluble nature of PGA also presents environmental benefits in biotransformations. It allows for easier separation and purification of products, reducing the need for extensive downstream processing. This efficiency in product recovery not only saves resources but also minimizes the generation of secondary waste streams.

In terms of resource conservation, PGA offers advantages as it can be produced from renewable resources. The production of PGA through microbial fermentation utilizes sustainable feedstocks, contributing to the circular economy and reducing dependence on fossil-based materials.

Additionally, the use of PGA in biotransformations can enhance the stability and reusability of enzymes. This increased enzyme longevity reduces the frequency of enzyme replacement, leading to less waste generation and more efficient use of biocatalysts.

However, it is important to note that the environmental impact of PGA in biotransformations is not without challenges. The production of PGA itself requires resources and energy, and the overall life cycle assessment of PGA-based processes must be carefully evaluated to ensure a net positive environmental impact.

In conclusion, the incorporation of PGA in cascade biotransformations offers significant potential for improving the environmental sustainability of industrial processes. Its biodegradability, ability to reduce solvent use, and contribution to energy efficiency make it a promising component in the development of greener biotechnologies. As research in this field progresses, further optimization of PGA-based systems is expected to enhance their environmental benefits and broaden their applications in sustainable industrial practices.

Scale-up Strategies for Polyglutamic Acid-Based Biotransformations

Scaling up polyglutamic acid-based biotransformations presents unique challenges and opportunities in the realm of industrial biotechnology. As these processes move from laboratory scale to industrial production, several key strategies must be considered to ensure efficiency, consistency, and economic viability.

One primary consideration is the optimization of bioreactor design. For polyglutamic acid (PGA) production, fed-batch fermentation has shown promising results. This approach allows for better control of nutrient supply and metabolite accumulation, which is crucial for maintaining high productivity. Implementing advanced monitoring systems, such as real-time sensors for pH, dissolved oxygen, and substrate concentration, can significantly enhance process control and product quality.

The choice of microorganism strain is another critical factor. Strains that exhibit high PGA productivity and stability under industrial conditions are essential. Genetic engineering techniques can be employed to develop robust strains capable of withstanding the stresses associated with large-scale fermentation, such as shear forces and fluctuations in temperature or pH.

Downstream processing represents a significant challenge in scaling up PGA-based biotransformations. Developing efficient separation and purification methods is crucial for maintaining product quality and reducing costs. Membrane filtration technologies, such as ultrafiltration and diafiltration, have shown promise in separating PGA from fermentation broths. Additionally, chromatographic techniques can be optimized for large-scale purification.

Addressing the issue of substrate availability and cost is vital for successful scale-up. PGA production typically requires glutamic acid as a primary substrate. Exploring alternative, cost-effective sources of glutamic acid, such as agricultural by-products or engineered strains capable of utilizing cheaper carbon sources, can significantly improve the economic feasibility of large-scale production.

Process integration and continuous manufacturing strategies can further enhance the efficiency of PGA-based biotransformations. Implementing continuous fermentation systems, coupled with in-situ product recovery, can lead to higher productivity and reduced downtime. This approach also allows for better space utilization and potentially lower capital costs.

Lastly, the development of scalable analytical methods is crucial for maintaining product quality and consistency. High-throughput techniques for monitoring PGA molecular weight distribution, purity, and functional properties must be adapted for industrial-scale operations. This ensures that the scaled-up process consistently produces PGA that meets the required specifications for various applications, from food additives to biomedical materials.

One primary consideration is the optimization of bioreactor design. For polyglutamic acid (PGA) production, fed-batch fermentation has shown promising results. This approach allows for better control of nutrient supply and metabolite accumulation, which is crucial for maintaining high productivity. Implementing advanced monitoring systems, such as real-time sensors for pH, dissolved oxygen, and substrate concentration, can significantly enhance process control and product quality.

The choice of microorganism strain is another critical factor. Strains that exhibit high PGA productivity and stability under industrial conditions are essential. Genetic engineering techniques can be employed to develop robust strains capable of withstanding the stresses associated with large-scale fermentation, such as shear forces and fluctuations in temperature or pH.

Downstream processing represents a significant challenge in scaling up PGA-based biotransformations. Developing efficient separation and purification methods is crucial for maintaining product quality and reducing costs. Membrane filtration technologies, such as ultrafiltration and diafiltration, have shown promise in separating PGA from fermentation broths. Additionally, chromatographic techniques can be optimized for large-scale purification.

Addressing the issue of substrate availability and cost is vital for successful scale-up. PGA production typically requires glutamic acid as a primary substrate. Exploring alternative, cost-effective sources of glutamic acid, such as agricultural by-products or engineered strains capable of utilizing cheaper carbon sources, can significantly improve the economic feasibility of large-scale production.

Process integration and continuous manufacturing strategies can further enhance the efficiency of PGA-based biotransformations. Implementing continuous fermentation systems, coupled with in-situ product recovery, can lead to higher productivity and reduced downtime. This approach also allows for better space utilization and potentially lower capital costs.

Lastly, the development of scalable analytical methods is crucial for maintaining product quality and consistency. High-throughput techniques for monitoring PGA molecular weight distribution, purity, and functional properties must be adapted for industrial-scale operations. This ensures that the scaled-up process consistently produces PGA that meets the required specifications for various applications, from food additives to biomedical materials.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!