How Powder Metallurgy Achieves Corrosion Targets With Residual Porosity?

SEP 16, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Powder Metallurgy Corrosion Resistance Evolution

The evolution of corrosion resistance in powder metallurgy (PM) components represents a significant technological advancement in materials science. Initially, PM parts were primarily used in non-critical applications due to inherent porosity issues that compromised corrosion performance. The 1970s marked the beginning of systematic research into improving corrosion resistance, with early efforts focusing on density optimization and basic alloying techniques.

By the 1980s, researchers developed the first generation of corrosion-resistant PM stainless steels, though these still exhibited significantly lower corrosion resistance compared to wrought counterparts. The introduction of hot isostatic pressing (HIP) during this period represented a breakthrough, allowing for substantial reduction in residual porosity.

The 1990s witnessed the emergence of advanced infiltration techniques, where lower melting point metals were used to fill pores in the sintered matrix. Simultaneously, surface treatments such as steam treatment for iron-based PM parts began gaining traction, forming magnetite layers that provided enhanced corrosion protection.

A paradigm shift occurred in the early 2000s with the development of specialized PM stainless steel grades specifically engineered for corrosion resistance rather than adapting wrought compositions. These formulations accounted for the unique sintering environment and residual porosity challenges inherent to PM processes.

The 2010s brought significant advancements in post-processing technologies, including polymer impregnation methods that effectively sealed surface porosity while maintaining dimensional precision. Innovations in sintering atmospheres and temperature profiles further enhanced densification without compromising economic viability.

Recent developments have focused on nanoscale additives that promote passive film formation even in the presence of residual porosity. These additives work by creating localized galvanic effects that enhance the stability of protective oxide layers. Additionally, researchers have developed specialized corrosion inhibitors that can be incorporated directly into the powder mix, providing long-term protection from within the material matrix.

The latest frontier involves computational modeling of pore networks to predict and optimize corrosion behavior. These models account for pore size distribution, connectivity, and surface chemistry to design PM components with optimized corrosion resistance despite unavoidable porosity. This approach has enabled engineers to strategically accept certain levels of porosity while still meeting stringent corrosion requirements.

Today's state-of-the-art PM components can achieve corrosion resistance approaching 85-95% of wrought equivalents, representing remarkable progress from the early days when PM parts were considered unsuitable for corrosive environments.

By the 1980s, researchers developed the first generation of corrosion-resistant PM stainless steels, though these still exhibited significantly lower corrosion resistance compared to wrought counterparts. The introduction of hot isostatic pressing (HIP) during this period represented a breakthrough, allowing for substantial reduction in residual porosity.

The 1990s witnessed the emergence of advanced infiltration techniques, where lower melting point metals were used to fill pores in the sintered matrix. Simultaneously, surface treatments such as steam treatment for iron-based PM parts began gaining traction, forming magnetite layers that provided enhanced corrosion protection.

A paradigm shift occurred in the early 2000s with the development of specialized PM stainless steel grades specifically engineered for corrosion resistance rather than adapting wrought compositions. These formulations accounted for the unique sintering environment and residual porosity challenges inherent to PM processes.

The 2010s brought significant advancements in post-processing technologies, including polymer impregnation methods that effectively sealed surface porosity while maintaining dimensional precision. Innovations in sintering atmospheres and temperature profiles further enhanced densification without compromising economic viability.

Recent developments have focused on nanoscale additives that promote passive film formation even in the presence of residual porosity. These additives work by creating localized galvanic effects that enhance the stability of protective oxide layers. Additionally, researchers have developed specialized corrosion inhibitors that can be incorporated directly into the powder mix, providing long-term protection from within the material matrix.

The latest frontier involves computational modeling of pore networks to predict and optimize corrosion behavior. These models account for pore size distribution, connectivity, and surface chemistry to design PM components with optimized corrosion resistance despite unavoidable porosity. This approach has enabled engineers to strategically accept certain levels of porosity while still meeting stringent corrosion requirements.

Today's state-of-the-art PM components can achieve corrosion resistance approaching 85-95% of wrought equivalents, representing remarkable progress from the early days when PM parts were considered unsuitable for corrosive environments.

Market Demand for Porous Corrosion-Resistant PM Components

The global market for corrosion-resistant powder metallurgy (PM) components with controlled porosity has been experiencing significant growth, driven primarily by industries requiring specialized materials that balance corrosion resistance with functional porosity. The automotive sector represents the largest market segment, with increasing demand for components such as bearings, filters, and structural parts that can withstand corrosive environments while maintaining specific porosity levels for weight reduction, fluid flow, or acoustic properties.

Aerospace and defense industries have emerged as high-value markets for these specialized materials, where the combination of weight reduction and corrosion resistance translates directly into operational efficiency and extended service life. Market analysis indicates that these sectors are willing to pay premium prices for PM components that deliver consistent performance in challenging environments.

The medical device industry presents another significant growth area, with demand for biocompatible, corrosion-resistant porous materials used in implants and surgical instruments. The controlled porosity allows for tissue ingrowth in implants while maintaining structural integrity in corrosive bodily fluids. This segment is expected to grow substantially as populations age globally and healthcare spending increases.

Industrial equipment manufacturers constitute a stable market base, requiring components that can withstand harsh chemical environments while maintaining specific functional characteristics enabled by controlled porosity. Applications include filtration systems, fluid control components, and specialized bearings for chemical processing equipment.

Regional market analysis reveals that North America and Europe currently lead in consumption of high-performance PM components with corrosion resistance, though Asia-Pacific markets are showing the fastest growth rates. This growth is attributed to rapid industrialization, increasing automotive production, and expanding healthcare infrastructure in countries like China and India.

Customer requirements are increasingly focused on performance predictability, with end-users demanding comprehensive corrosion performance data across various environmental conditions. This trend is driving manufacturers to develop more sophisticated testing protocols and performance guarantees for their porous PM products.

Price sensitivity varies significantly across application segments. While automotive applications remain highly cost-conscious, aerospace and medical applications demonstrate greater willingness to absorb premium pricing for materials with proven performance characteristics and regulatory compliance. This market stratification is creating opportunities for manufacturers to develop tiered product offerings with varying performance-to-cost ratios.

The overall market trajectory indicates sustained growth potential, with particular opportunities in developing specialized solutions for emerging applications in renewable energy systems, marine equipment, and advanced electronics cooling systems, where the combination of corrosion resistance and functional porosity delivers unique performance advantages.

Aerospace and defense industries have emerged as high-value markets for these specialized materials, where the combination of weight reduction and corrosion resistance translates directly into operational efficiency and extended service life. Market analysis indicates that these sectors are willing to pay premium prices for PM components that deliver consistent performance in challenging environments.

The medical device industry presents another significant growth area, with demand for biocompatible, corrosion-resistant porous materials used in implants and surgical instruments. The controlled porosity allows for tissue ingrowth in implants while maintaining structural integrity in corrosive bodily fluids. This segment is expected to grow substantially as populations age globally and healthcare spending increases.

Industrial equipment manufacturers constitute a stable market base, requiring components that can withstand harsh chemical environments while maintaining specific functional characteristics enabled by controlled porosity. Applications include filtration systems, fluid control components, and specialized bearings for chemical processing equipment.

Regional market analysis reveals that North America and Europe currently lead in consumption of high-performance PM components with corrosion resistance, though Asia-Pacific markets are showing the fastest growth rates. This growth is attributed to rapid industrialization, increasing automotive production, and expanding healthcare infrastructure in countries like China and India.

Customer requirements are increasingly focused on performance predictability, with end-users demanding comprehensive corrosion performance data across various environmental conditions. This trend is driving manufacturers to develop more sophisticated testing protocols and performance guarantees for their porous PM products.

Price sensitivity varies significantly across application segments. While automotive applications remain highly cost-conscious, aerospace and medical applications demonstrate greater willingness to absorb premium pricing for materials with proven performance characteristics and regulatory compliance. This market stratification is creating opportunities for manufacturers to develop tiered product offerings with varying performance-to-cost ratios.

The overall market trajectory indicates sustained growth potential, with particular opportunities in developing specialized solutions for emerging applications in renewable energy systems, marine equipment, and advanced electronics cooling systems, where the combination of corrosion resistance and functional porosity delivers unique performance advantages.

Technical Challenges of Porosity-Corrosion Balance

The inherent contradiction between porosity and corrosion resistance represents one of the most significant technical challenges in powder metallurgy (PM). While porosity is an inevitable characteristic of PM components, it simultaneously creates vulnerability to corrosive environments. This fundamental conflict stems from the nature of the PM process itself, where complete densification is rarely achieved without secondary operations.

Residual porosity in PM parts creates multiple corrosion initiation sites, as these pores form an interconnected network that allows corrosive media to penetrate deep into the material structure. This phenomenon accelerates corrosion rates compared to wrought counterparts of identical composition. Studies have shown that even small amounts of interconnected porosity (as low as 5%) can reduce corrosion resistance by up to 40% in certain environments.

The geometry and distribution of pores further complicate corrosion behavior. Irregular, angular pores with high surface area-to-volume ratios create stress concentration points that become preferential sites for corrosion initiation. Additionally, the heterogeneous microstructure resulting from varying densification rates across complex PM parts leads to galvanic coupling between regions of different densities, accelerating localized corrosion.

Chemical composition control presents another significant challenge. Impurities introduced during powder production or handling can segregate at pore surfaces, creating localized electrochemical cells. Carbon content, particularly critical in ferrous PM parts, must be precisely controlled as it affects both mechanical properties and corrosion behavior. Excess carbon can lead to carbide precipitation at grain boundaries, creating susceptible paths for intergranular corrosion.

Surface treatments and coatings, while effective for solid materials, face unique challenges when applied to porous substrates. Infiltration depth, uniformity, and adhesion become problematic as treatments must penetrate the interconnected pore network. Conventional electroplating processes often result in uneven coverage, leaving untreated areas vulnerable to corrosive attack.

The testing and qualification of PM parts for corrosion resistance introduces additional complexities. Standard corrosion testing protocols designed for wrought materials often fail to accurately predict the performance of PM components in service conditions. The time-dependent nature of corrosion in porous structures, where corrosion products can temporarily seal pores before breaking down, creates misleading short-term test results.

Balancing manufacturing economics with corrosion performance adds another dimension to this challenge. Higher densification processes like hot isostatic pressing (HIP) can significantly reduce porosity but at substantially increased production costs, making them economically viable only for high-value applications where corrosion failure consequences are severe.

Residual porosity in PM parts creates multiple corrosion initiation sites, as these pores form an interconnected network that allows corrosive media to penetrate deep into the material structure. This phenomenon accelerates corrosion rates compared to wrought counterparts of identical composition. Studies have shown that even small amounts of interconnected porosity (as low as 5%) can reduce corrosion resistance by up to 40% in certain environments.

The geometry and distribution of pores further complicate corrosion behavior. Irregular, angular pores with high surface area-to-volume ratios create stress concentration points that become preferential sites for corrosion initiation. Additionally, the heterogeneous microstructure resulting from varying densification rates across complex PM parts leads to galvanic coupling between regions of different densities, accelerating localized corrosion.

Chemical composition control presents another significant challenge. Impurities introduced during powder production or handling can segregate at pore surfaces, creating localized electrochemical cells. Carbon content, particularly critical in ferrous PM parts, must be precisely controlled as it affects both mechanical properties and corrosion behavior. Excess carbon can lead to carbide precipitation at grain boundaries, creating susceptible paths for intergranular corrosion.

Surface treatments and coatings, while effective for solid materials, face unique challenges when applied to porous substrates. Infiltration depth, uniformity, and adhesion become problematic as treatments must penetrate the interconnected pore network. Conventional electroplating processes often result in uneven coverage, leaving untreated areas vulnerable to corrosive attack.

The testing and qualification of PM parts for corrosion resistance introduces additional complexities. Standard corrosion testing protocols designed for wrought materials often fail to accurately predict the performance of PM components in service conditions. The time-dependent nature of corrosion in porous structures, where corrosion products can temporarily seal pores before breaking down, creates misleading short-term test results.

Balancing manufacturing economics with corrosion performance adds another dimension to this challenge. Higher densification processes like hot isostatic pressing (HIP) can significantly reduce porosity but at substantially increased production costs, making them economically viable only for high-value applications where corrosion failure consequences are severe.

Current Approaches to PM Corrosion Mitigation

01 Alloying elements for corrosion resistance

Specific alloying elements can be incorporated into powder metallurgy compositions to enhance corrosion resistance. Elements such as chromium, nickel, molybdenum, and silicon form protective oxide layers on the surface of the material, preventing further corrosion. The careful selection and proportion of these elements in the powder mixture can significantly improve the corrosion resistance of the final sintered product while maintaining other desirable mechanical properties.- Alloying elements for corrosion resistance: Specific alloying elements can be incorporated into powder metallurgy compositions to enhance corrosion resistance. Elements such as chromium, nickel, molybdenum, and silicon form protective oxide layers on the surface of the material, preventing further corrosion. The proper selection and proportion of these alloying elements can significantly improve the corrosion resistance of powder metallurgy parts while maintaining other desirable mechanical properties.

- Surface treatment and coating techniques: Various surface treatment and coating methods can be applied to powder metallurgy components to enhance their corrosion resistance. These include passivation treatments, electroplating, physical vapor deposition, chemical vapor deposition, and the application of organic or inorganic coatings. These treatments create a protective barrier between the base material and the corrosive environment, significantly extending the service life of powder metallurgy parts exposed to harsh conditions.

- Densification and porosity control: The corrosion resistance of powder metallurgy components can be improved by increasing their density and reducing porosity. Higher densification reduces the surface area exposed to corrosive media and limits the penetration of corrosive agents into the material. Techniques such as hot isostatic pressing, spark plasma sintering, and optimized compaction and sintering parameters can achieve near-full density in powder metallurgy parts, significantly enhancing their corrosion resistance properties.

- Composite and multi-phase materials: Developing composite and multi-phase materials through powder metallurgy processes can enhance corrosion resistance. By combining different materials with complementary properties, such as metal matrix composites reinforced with ceramic particles or the creation of specific intermetallic phases, the overall corrosion resistance can be improved. These composite structures can provide both mechanical strength and superior corrosion resistance by creating beneficial microstructures that inhibit corrosion mechanisms.

- Specialized sintering atmospheres and processes: The sintering atmosphere and process parameters significantly impact the corrosion resistance of powder metallurgy products. Controlled sintering in specific atmospheres such as hydrogen, nitrogen, or vacuum can reduce oxide formation and improve the material's inherent corrosion resistance. Advanced sintering techniques like microwave sintering, pulse electric current sintering, and controlled cooling rates can create optimized microstructures with enhanced corrosion resistance properties while maintaining dimensional accuracy and mechanical performance.

02 Surface treatment and coating techniques

Various surface treatment methods can be applied to powder metallurgy parts to enhance their corrosion resistance. These include passivation treatments, conversion coatings, and the application of protective layers such as polymers or metals. Techniques like physical vapor deposition, chemical vapor deposition, and electroplating can be used to apply corrosion-resistant coatings to powder metallurgy components, extending their service life in corrosive environments.Expand Specific Solutions03 Density control and porosity reduction

Controlling the density and reducing porosity in powder metallurgy products is crucial for improving corrosion resistance. Higher density parts with minimal interconnected porosity provide fewer pathways for corrosive media to penetrate the material. Advanced compaction techniques, optimized sintering parameters, and post-sintering operations like hot isostatic pressing can be employed to achieve near-full density, thereby significantly enhancing the corrosion resistance of powder metallurgy components.Expand Specific Solutions04 Corrosion-resistant powder compositions

Specialized powder compositions have been developed specifically for applications requiring high corrosion resistance. These include stainless steel powders, nickel-based superalloys, and titanium alloy powders. The particle size distribution, morphology, and purity of these powders are carefully controlled to ensure optimal sintering behavior and final properties. Some compositions also incorporate corrosion inhibitors or sacrificial particles that preferentially corrode to protect the bulk material.Expand Specific Solutions05 Processing parameters optimization

Optimizing processing parameters during powder metallurgy production significantly impacts the corrosion resistance of the final parts. Factors such as sintering temperature, time, atmosphere, cooling rate, and post-sintering heat treatments all affect the microstructure and phase composition of the material, which in turn influence its corrosion behavior. Controlled cooling rates and specific heat treatment protocols can promote the formation of corrosion-resistant phases and minimize susceptibility to intergranular corrosion.Expand Specific Solutions

Leading Companies in Corrosion-Resistant PM Industry

The powder metallurgy market is currently in a growth phase, with increasing applications in automotive, aerospace, and medical industries despite challenges related to residual porosity and corrosion resistance. The global market is projected to reach approximately $35-40 billion by 2027, driven by demand for lightweight, complex-shaped components. Technologically, companies are at varying maturity levels: established leaders like Höganäs AB and Hoeganaes Corp. have developed advanced corrosion-resistant powder formulations, while research institutions including University of Liverpool, Central South University, and Fraunhofer-Gesellschaft are pioneering innovative surface treatments and impregnation techniques. Medical device manufacturers such as Smith + Nephew and Biomet Manufacturing are specifically focusing on biocompatible powder metallurgy solutions that balance porosity requirements with corrosion resistance for implantable devices.

Höganäs AB

Technical Solution: Höganäs AB has developed advanced powder metallurgy solutions to address corrosion challenges despite residual porosity. Their proprietary technology involves a multi-stage approach combining specialized alloy compositions with optimized processing parameters. The company utilizes high-density compaction techniques achieving 95-98% theoretical density, significantly reducing interconnected porosity. Their corrosion-resistant powder systems incorporate chromium, nickel, and molybdenum in precise ratios, creating passive oxide layers that protect internal pore structures. Höganäs has pioneered infiltration technologies where lower-melting-point metals or polymers fill residual pores, creating effective barriers against corrosive media. Their diffusion-alloyed powders enable the formation of more homogeneous microstructures with improved corrosion resistance compared to admixed systems. Additionally, Höganäs has developed specialized sintering atmospheres and post-sintering treatments that promote pore rounding and isolation, minimizing corrosion pathways while maintaining the beneficial properties of controlled porosity.

Strengths: Industry-leading density achievement with standard pressing equipment; proprietary alloy compositions specifically designed for corrosion resistance; comprehensive approach addressing both material composition and processing parameters. Weaknesses: Higher production costs compared to conventional PM processes; some solutions require additional processing steps; performance may still be inferior to wrought materials in extremely aggressive environments.

Hoeganaes Corp.

Technical Solution: Hoeganaes Corporation has developed the ANCORSHIELD™ technology platform specifically addressing corrosion challenges in powder metallurgy components with residual porosity. Their approach combines specialized pre-alloyed powders with tailored surface treatments to create corrosion-resistant parts without sacrificing the economic benefits of conventional PM processing. The technology utilizes strategic additions of chromium, copper, and phosphorus to enhance corrosion resistance while maintaining compressibility. Their process involves optimized sintering protocols that promote the formation of isolated rather than interconnected pores, significantly reducing corrosion pathways. Hoeganaes has also pioneered vapor phase inhibitor treatments that penetrate and protect internal pore networks. Their ANCOR® stainless steel powder grades achieve corrosion resistance comparable to wrought 304L and 316L while maintaining the dimensional precision of PM. Additionally, they've developed specialized post-sintering impregnation techniques using environmentally-friendly sealants that effectively block corrosive media from accessing internal pores without compromising part tolerances.

Strengths: Maintains good compressibility despite alloying additions for corrosion resistance; compatible with existing PM equipment and processing parameters; offers scalable solutions from moderate to high corrosion resistance applications. Weaknesses: Some treatments add processing steps and cost; highest performance grades require more expensive alloying elements; complete elimination of corrosion susceptibility remains challenging in highly porous components.

Key Patents in Porous PM Corrosion Protection

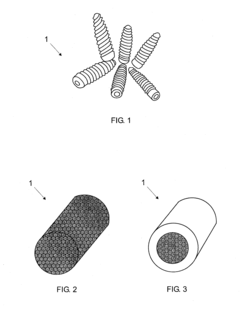

Manufacturing process of a porous component and a porous component

PatentInactiveUS20150266094A1

Innovation

- The use of refined porous materials produced through powder injection molding, which allows for controlled porosity and flow restriction by sintering at lower temperatures, creating a dual-porosity component with a dense outer layer and high open porosity inner layer, enabling precise control of gas flow without additional machining steps.

High corrosion resistant powder for powder metallurgy

PatentInactiveJP1993005154A

Innovation

- A highly corrosion-resistant powder is obtained by blending aluminum powder with predetermined alloy powders, forming a protective Al2O3 film or layer during sintering, thereby suppressing rust formation and preventing Cr volatilization.

Sustainability Aspects of PM Corrosion Solutions

The sustainability implications of powder metallurgy (PM) corrosion solutions represent a critical dimension in evaluating their long-term viability and environmental impact. PM processes inherently offer several sustainability advantages compared to traditional manufacturing methods, particularly in addressing corrosion challenges while managing residual porosity.

Energy consumption in PM manufacturing is significantly lower than in conventional metallurgical processes, with estimates suggesting 30-50% energy savings. This reduction stems from lower processing temperatures and elimination of extensive machining operations, directly contributing to reduced carbon footprints across the production lifecycle.

Material utilization efficiency stands as another cornerstone of PM sustainability. The process achieves near-net shape production with material utilization rates exceeding 95% in many applications, dramatically reducing waste compared to subtractive manufacturing techniques. When addressing corrosion concerns, this efficiency extends to more precise application of corrosion-resistant elements and treatments.

The recyclability of PM components presents both challenges and opportunities in sustainability contexts. While residual porosity can sometimes harbor corrosion accelerants, it also creates pathways for more effective recycling processes. Advanced PM materials designed for corrosion resistance typically incorporate elements that remain recoverable at end-of-life, supporting circular economy principles.

Environmental impact assessments of PM corrosion solutions reveal reduced requirements for hazardous surface treatments and coatings. Traditional corrosion prevention often relies on environmentally problematic processes like chromating or cadmium plating, whereas PM's ability to incorporate corrosion resistance directly into the material matrix minimizes these concerns.

Life-cycle analysis (LCA) studies demonstrate that PM components with engineered corrosion resistance typically outperform conventional alternatives when considering total environmental impact. The extended service life achieved through controlled porosity and strategic alloying translates to fewer replacement parts and reduced maintenance requirements over product lifespans.

Water conservation represents another significant sustainability advantage, as PM processes generally require substantially less water than conventional metallurgical operations. This becomes increasingly important as water scarcity concerns grow globally, positioning PM as a more responsible manufacturing approach in water-stressed regions.

Looking forward, emerging research in biodegradable PM materials offers promising sustainability pathways, particularly for temporary applications where controlled corrosion is actually desirable. These innovations could revolutionize medical implants and environmental remediation technologies, where material dissolution at predetermined rates serves functional purposes.

Energy consumption in PM manufacturing is significantly lower than in conventional metallurgical processes, with estimates suggesting 30-50% energy savings. This reduction stems from lower processing temperatures and elimination of extensive machining operations, directly contributing to reduced carbon footprints across the production lifecycle.

Material utilization efficiency stands as another cornerstone of PM sustainability. The process achieves near-net shape production with material utilization rates exceeding 95% in many applications, dramatically reducing waste compared to subtractive manufacturing techniques. When addressing corrosion concerns, this efficiency extends to more precise application of corrosion-resistant elements and treatments.

The recyclability of PM components presents both challenges and opportunities in sustainability contexts. While residual porosity can sometimes harbor corrosion accelerants, it also creates pathways for more effective recycling processes. Advanced PM materials designed for corrosion resistance typically incorporate elements that remain recoverable at end-of-life, supporting circular economy principles.

Environmental impact assessments of PM corrosion solutions reveal reduced requirements for hazardous surface treatments and coatings. Traditional corrosion prevention often relies on environmentally problematic processes like chromating or cadmium plating, whereas PM's ability to incorporate corrosion resistance directly into the material matrix minimizes these concerns.

Life-cycle analysis (LCA) studies demonstrate that PM components with engineered corrosion resistance typically outperform conventional alternatives when considering total environmental impact. The extended service life achieved through controlled porosity and strategic alloying translates to fewer replacement parts and reduced maintenance requirements over product lifespans.

Water conservation represents another significant sustainability advantage, as PM processes generally require substantially less water than conventional metallurgical operations. This becomes increasingly important as water scarcity concerns grow globally, positioning PM as a more responsible manufacturing approach in water-stressed regions.

Looking forward, emerging research in biodegradable PM materials offers promising sustainability pathways, particularly for temporary applications where controlled corrosion is actually desirable. These innovations could revolutionize medical implants and environmental remediation technologies, where material dissolution at predetermined rates serves functional purposes.

Testing Standards and Quality Control Methods

Quality control in powder metallurgy processes with residual porosity presents unique challenges for ensuring corrosion resistance. The industry has developed comprehensive testing standards that specifically address the correlation between porosity levels and corrosion performance. ASTM B925 serves as the primary standard for evaluating corrosion resistance in powder metallurgy components, providing detailed procedures for salt spray testing that account for the inherent porosity of these materials.

ISO 4490 and MPIF Standard 42 offer complementary methodologies for characterizing porosity distribution and interconnectivity, critical factors affecting corrosion behavior. These standards establish threshold values for acceptable porosity levels based on specific application requirements and environmental exposure conditions.

Electrochemical testing protocols, including potentiodynamic polarization and electrochemical impedance spectroscopy (EIS), have been adapted specifically for porous PM materials. These techniques allow for quantitative assessment of corrosion rates and mechanisms while accounting for the complex surface area created by residual pores.

Non-destructive testing methods have evolved to address the unique challenges of PM components. Advanced imaging techniques such as X-ray computed tomography (CT) enable three-dimensional visualization of pore networks and their potential pathways for corrosive media. This allows manufacturers to predict corrosion behavior before components enter service.

Statistical process control (SPC) methodologies tailored for PM manufacturing track key parameters including compaction pressure, sintering temperature profiles, and density variations. These parameters directly influence final porosity characteristics and subsequent corrosion performance. Implementation of SPC has demonstrated significant improvements in achieving consistent corrosion resistance across production batches.

Accelerated corrosion testing protocols have been standardized to simulate years of environmental exposure within compressed timeframes. These include cyclic corrosion testing (CCT) per ASTM G85, which alternates between salt spray exposure and controlled humidity/temperature conditions to replicate real-world service environments more accurately than traditional constant exposure tests.

Quality control documentation systems for PM components with corrosion requirements typically include material traceability, processing parameters, porosity measurements, and corrosion test results. This comprehensive documentation enables root cause analysis when performance deviations occur and facilitates continuous improvement in manufacturing processes to optimize the balance between necessary porosity and corrosion resistance.

ISO 4490 and MPIF Standard 42 offer complementary methodologies for characterizing porosity distribution and interconnectivity, critical factors affecting corrosion behavior. These standards establish threshold values for acceptable porosity levels based on specific application requirements and environmental exposure conditions.

Electrochemical testing protocols, including potentiodynamic polarization and electrochemical impedance spectroscopy (EIS), have been adapted specifically for porous PM materials. These techniques allow for quantitative assessment of corrosion rates and mechanisms while accounting for the complex surface area created by residual pores.

Non-destructive testing methods have evolved to address the unique challenges of PM components. Advanced imaging techniques such as X-ray computed tomography (CT) enable three-dimensional visualization of pore networks and their potential pathways for corrosive media. This allows manufacturers to predict corrosion behavior before components enter service.

Statistical process control (SPC) methodologies tailored for PM manufacturing track key parameters including compaction pressure, sintering temperature profiles, and density variations. These parameters directly influence final porosity characteristics and subsequent corrosion performance. Implementation of SPC has demonstrated significant improvements in achieving consistent corrosion resistance across production batches.

Accelerated corrosion testing protocols have been standardized to simulate years of environmental exposure within compressed timeframes. These include cyclic corrosion testing (CCT) per ASTM G85, which alternates between salt spray exposure and controlled humidity/temperature conditions to replicate real-world service environments more accurately than traditional constant exposure tests.

Quality control documentation systems for PM components with corrosion requirements typically include material traceability, processing parameters, porosity measurements, and corrosion test results. This comprehensive documentation enables root cause analysis when performance deviations occur and facilitates continuous improvement in manufacturing processes to optimize the balance between necessary porosity and corrosion resistance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!