Powder Metallurgy Copper–Graphite Bearings: Impregnation, Permeability And Life

SEP 16, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Copper-Graphite Bearing Technology Evolution and Objectives

Copper-graphite bearings represent a significant advancement in tribological systems, with their development tracing back to the early 20th century. These self-lubricating components emerged as a solution to the limitations of traditional bearing materials in high-temperature and high-load applications where conventional lubrication methods proved inadequate. The evolution of copper-graphite bearing technology has been driven by increasing demands in automotive, aerospace, and industrial machinery sectors for components that can withstand extreme operating conditions while maintaining reliability.

The fundamental concept behind copper-graphite bearings leverages the complementary properties of both materials: copper provides structural integrity and excellent thermal conductivity, while graphite offers inherent lubricity and chemical stability. This synergistic combination has evolved through several technological generations, from simple copper-graphite mixtures to sophisticated engineered composites with precisely controlled microstructures.

A pivotal advancement in this field came with the development of powder metallurgy techniques in the mid-20th century, which enabled more precise control over material composition and porosity. This manufacturing approach allowed for the creation of bearings with optimized graphite distribution and interconnected pore networks, essential for oil impregnation and retention capabilities.

The impregnation process itself has undergone significant refinement, transitioning from basic oil soaking methods to vacuum-assisted techniques that ensure complete pore saturation. This evolution has directly addressed one of the key performance parameters of these bearings: their ability to maintain adequate lubrication over extended operational periods.

Current technological objectives in copper-graphite bearing development focus on several critical areas: enhancing permeability characteristics to improve lubricant retention and distribution; optimizing the copper-graphite ratio for specific application requirements; developing more effective impregnation agents that can withstand increasingly demanding operating environments; and extending service life through improved resistance to wear, fatigue, and corrosion.

The trajectory of copper-graphite bearing technology is now moving toward nano-engineered structures, with research exploring the incorporation of carbon nanotubes, graphene, and other advanced materials to further enhance performance characteristics. Additionally, computational modeling and simulation tools are increasingly being employed to predict bearing behavior under various operating conditions, allowing for more targeted development efforts.

The ultimate technological goal remains the creation of copper-graphite bearings with predictable, consistent performance characteristics that can operate reliably in extreme conditions while requiring minimal maintenance. This objective drives ongoing research into improved manufacturing processes, novel material combinations, and enhanced impregnation techniques to extend bearing life and reliability.

The fundamental concept behind copper-graphite bearings leverages the complementary properties of both materials: copper provides structural integrity and excellent thermal conductivity, while graphite offers inherent lubricity and chemical stability. This synergistic combination has evolved through several technological generations, from simple copper-graphite mixtures to sophisticated engineered composites with precisely controlled microstructures.

A pivotal advancement in this field came with the development of powder metallurgy techniques in the mid-20th century, which enabled more precise control over material composition and porosity. This manufacturing approach allowed for the creation of bearings with optimized graphite distribution and interconnected pore networks, essential for oil impregnation and retention capabilities.

The impregnation process itself has undergone significant refinement, transitioning from basic oil soaking methods to vacuum-assisted techniques that ensure complete pore saturation. This evolution has directly addressed one of the key performance parameters of these bearings: their ability to maintain adequate lubrication over extended operational periods.

Current technological objectives in copper-graphite bearing development focus on several critical areas: enhancing permeability characteristics to improve lubricant retention and distribution; optimizing the copper-graphite ratio for specific application requirements; developing more effective impregnation agents that can withstand increasingly demanding operating environments; and extending service life through improved resistance to wear, fatigue, and corrosion.

The trajectory of copper-graphite bearing technology is now moving toward nano-engineered structures, with research exploring the incorporation of carbon nanotubes, graphene, and other advanced materials to further enhance performance characteristics. Additionally, computational modeling and simulation tools are increasingly being employed to predict bearing behavior under various operating conditions, allowing for more targeted development efforts.

The ultimate technological goal remains the creation of copper-graphite bearings with predictable, consistent performance characteristics that can operate reliably in extreme conditions while requiring minimal maintenance. This objective drives ongoing research into improved manufacturing processes, novel material combinations, and enhanced impregnation techniques to extend bearing life and reliability.

Market Analysis for Powder Metallurgy Bearings

The global powder metallurgy bearings market has demonstrated robust growth over the past decade, with a current market valuation estimated at $2.3 billion in 2023. This segment represents approximately 18% of the overall bearings market, with copper-graphite bearings constituting a significant portion due to their superior performance characteristics in specific applications. The compound annual growth rate (CAGR) for powder metallurgy bearings is projected at 5.7% through 2028, outpacing traditional bearing technologies.

Regional analysis reveals that Asia-Pacific dominates the market with approximately 45% share, followed by Europe (27%) and North America (21%). China, in particular, has emerged as both the largest producer and consumer of powder metallurgy copper-graphite bearings, driven by its expansive manufacturing base and growing automotive sector. Japan and Germany maintain leadership in high-precision applications requiring advanced bearing technologies.

The automotive industry remains the primary end-user, accounting for 38% of powder metallurgy bearing consumption. These components are extensively used in transmission systems, engine components, and steering mechanisms where their self-lubricating properties provide significant advantages. The industrial machinery sector follows at 24%, with applications in pumps, compressors, and material handling equipment.

Consumer demand is increasingly driven by performance requirements rather than purely cost considerations. End-users are willing to pay premium prices for bearings that offer extended service life, reduced maintenance needs, and improved energy efficiency. This trend has particularly benefited copper-graphite bearings, which demonstrate superior performance in high-temperature and high-load applications compared to traditional alternatives.

Market research indicates that approximately 62% of procurement decisions for industrial bearings now include total cost of ownership calculations rather than focusing solely on initial purchase price. This shift has strengthened the value proposition of powder metallurgy copper-graphite bearings, which typically offer longer service intervals and reduced downtime despite higher upfront costs.

The aftermarket segment represents approximately 30% of total market revenue, with replacement cycles varying significantly across applications. In automotive applications, the average replacement cycle is 5-7 years, while industrial applications may see cycles of 3-10 years depending on operating conditions and maintenance practices.

Market forecasts suggest that demand for specialized copper-graphite bearings with enhanced impregnation techniques will grow at 7.2% annually through 2028, outpacing the broader category. This growth is primarily driven by increasing requirements for bearings capable of operating in extreme conditions, including high temperatures, corrosive environments, and applications requiring electrical conductivity.

Regional analysis reveals that Asia-Pacific dominates the market with approximately 45% share, followed by Europe (27%) and North America (21%). China, in particular, has emerged as both the largest producer and consumer of powder metallurgy copper-graphite bearings, driven by its expansive manufacturing base and growing automotive sector. Japan and Germany maintain leadership in high-precision applications requiring advanced bearing technologies.

The automotive industry remains the primary end-user, accounting for 38% of powder metallurgy bearing consumption. These components are extensively used in transmission systems, engine components, and steering mechanisms where their self-lubricating properties provide significant advantages. The industrial machinery sector follows at 24%, with applications in pumps, compressors, and material handling equipment.

Consumer demand is increasingly driven by performance requirements rather than purely cost considerations. End-users are willing to pay premium prices for bearings that offer extended service life, reduced maintenance needs, and improved energy efficiency. This trend has particularly benefited copper-graphite bearings, which demonstrate superior performance in high-temperature and high-load applications compared to traditional alternatives.

Market research indicates that approximately 62% of procurement decisions for industrial bearings now include total cost of ownership calculations rather than focusing solely on initial purchase price. This shift has strengthened the value proposition of powder metallurgy copper-graphite bearings, which typically offer longer service intervals and reduced downtime despite higher upfront costs.

The aftermarket segment represents approximately 30% of total market revenue, with replacement cycles varying significantly across applications. In automotive applications, the average replacement cycle is 5-7 years, while industrial applications may see cycles of 3-10 years depending on operating conditions and maintenance practices.

Market forecasts suggest that demand for specialized copper-graphite bearings with enhanced impregnation techniques will grow at 7.2% annually through 2028, outpacing the broader category. This growth is primarily driven by increasing requirements for bearings capable of operating in extreme conditions, including high temperatures, corrosive environments, and applications requiring electrical conductivity.

Current Challenges in Copper-Graphite Bearing Manufacturing

The manufacturing of copper-graphite bearings through powder metallurgy faces several significant technical challenges that impact product quality, performance, and production efficiency. One of the primary difficulties lies in achieving uniform graphite distribution throughout the copper matrix. Inconsistent distribution creates performance variability, with some bearing sections experiencing premature wear while others maintain integrity, leading to unpredictable service life and potential catastrophic failures in critical applications.

Impregnation processes present another substantial hurdle. Current methods struggle to achieve complete penetration of lubricants into the porous structure, particularly in bearings with complex geometries or varying wall thicknesses. The incomplete impregnation results in dry spots that become failure initiation points during operation, significantly reducing bearing longevity and reliability.

Permeability control represents a delicate balancing act in manufacturing. Insufficient permeability prevents adequate lubricant retention, while excessive permeability compromises structural integrity. Manufacturers lack precise, real-time measurement techniques to monitor and adjust permeability during production, resulting in high rejection rates and inconsistent product quality.

The sintering process introduces additional complexities, as temperature and atmosphere control must be precisely maintained to prevent graphite oxidation while ensuring proper copper particle bonding. Even minor deviations in sintering parameters can dramatically alter the bearing's mechanical properties and porosity characteristics, affecting both impregnation capability and operational performance.

Material selection challenges persist as manufacturers seek optimal copper-graphite ratios for specific applications. Higher graphite content improves lubricity but reduces mechanical strength and thermal conductivity. This trade-off becomes particularly problematic in high-load or high-temperature applications where both properties are essential.

Quality control methods remain inadequate for detecting internal defects without destructive testing. Non-destructive evaluation techniques currently available lack the sensitivity to identify micro-cracks, impregnation voids, or density variations that may lead to premature bearing failure.

Environmental and regulatory pressures further complicate manufacturing processes. Traditional impregnation oils and additives face increasing restrictions due to environmental concerns, forcing manufacturers to develop new, compliant formulations without compromising bearing performance or production economics.

Impregnation processes present another substantial hurdle. Current methods struggle to achieve complete penetration of lubricants into the porous structure, particularly in bearings with complex geometries or varying wall thicknesses. The incomplete impregnation results in dry spots that become failure initiation points during operation, significantly reducing bearing longevity and reliability.

Permeability control represents a delicate balancing act in manufacturing. Insufficient permeability prevents adequate lubricant retention, while excessive permeability compromises structural integrity. Manufacturers lack precise, real-time measurement techniques to monitor and adjust permeability during production, resulting in high rejection rates and inconsistent product quality.

The sintering process introduces additional complexities, as temperature and atmosphere control must be precisely maintained to prevent graphite oxidation while ensuring proper copper particle bonding. Even minor deviations in sintering parameters can dramatically alter the bearing's mechanical properties and porosity characteristics, affecting both impregnation capability and operational performance.

Material selection challenges persist as manufacturers seek optimal copper-graphite ratios for specific applications. Higher graphite content improves lubricity but reduces mechanical strength and thermal conductivity. This trade-off becomes particularly problematic in high-load or high-temperature applications where both properties are essential.

Quality control methods remain inadequate for detecting internal defects without destructive testing. Non-destructive evaluation techniques currently available lack the sensitivity to identify micro-cracks, impregnation voids, or density variations that may lead to premature bearing failure.

Environmental and regulatory pressures further complicate manufacturing processes. Traditional impregnation oils and additives face increasing restrictions due to environmental concerns, forcing manufacturers to develop new, compliant formulations without compromising bearing performance or production economics.

Impregnation Methods and Permeability Enhancement Solutions

01 Impregnation methods for copper-graphite bearings

Various impregnation methods are used to enhance the properties of copper-graphite bearings. These methods include vacuum impregnation, pressure impregnation, and combined vacuum-pressure techniques to ensure complete penetration of lubricants or other materials into the porous structure. The impregnation process typically involves heating the bearing to a specific temperature, applying vacuum to remove air from pores, and then introducing the impregnating material. These methods significantly improve the bearing's performance characteristics and service life.- Impregnation methods for copper-graphite bearings: Various impregnation methods can be used to enhance the properties of copper-graphite bearings. These methods include vacuum impregnation, pressure impregnation, and combined vacuum-pressure techniques to ensure complete penetration of lubricants or other materials into the porous structure. The impregnation process typically involves heating the bearing to a specific temperature, applying vacuum to remove air from the pores, and then introducing the impregnating material. This process significantly improves the bearing's performance characteristics and service life.

- Permeability enhancement techniques: Permeability is a critical factor affecting the performance of copper-graphite bearings. Various techniques can be employed to enhance permeability, including controlled porosity during powder compaction, specific sintering parameters, and post-sintering treatments. The particle size distribution of copper and graphite powders also plays a significant role in determining the final permeability of the bearing. Higher permeability allows for better lubricant retention and distribution, which directly impacts the bearing's operational efficiency and longevity.

- Composition optimization for extended bearing life: The composition of copper-graphite bearings can be optimized to extend their service life. This includes adjusting the copper-to-graphite ratio, incorporating additional elements such as tin, lead, or zinc, and adding specific reinforcement materials. The graphite content typically ranges from 5% to 30% by weight, with higher graphite content providing better self-lubrication properties but potentially reducing strength. Advanced compositions may include nano-additives or surface treatments to further enhance wear resistance and reduce friction, resulting in significantly longer bearing life under various operating conditions.

- Manufacturing processes affecting bearing properties: The manufacturing processes used in powder metallurgy significantly affect the final properties of copper-graphite bearings. These processes include powder preparation (blending, mixing), compaction techniques (uniaxial, isostatic), sintering parameters (temperature, time, atmosphere), and post-sintering operations (sizing, machining). Each step must be carefully controlled to achieve the desired density, strength, and tribological properties. Advanced manufacturing techniques such as hot isostatic pressing or spark plasma sintering can produce bearings with superior performance characteristics, including enhanced density, improved mechanical properties, and more uniform microstructure.

- Lubrication systems and their impact on bearing performance: The lubrication system used with copper-graphite bearings significantly impacts their performance and longevity. While these bearings offer self-lubricating properties due to the graphite content, additional lubrication can further enhance their performance. Oil-impregnated bearings can operate for extended periods without external lubrication, while grease-lubricated systems may provide better protection under heavy loads. The selection of appropriate lubricants based on operating conditions (temperature, load, speed) is crucial for maximizing bearing life. Advanced lubrication systems may incorporate solid lubricants or special additives to improve extreme pressure performance and reduce wear under boundary lubrication conditions.

02 Permeability enhancement techniques

Permeability is a critical factor affecting the performance of copper-graphite bearings. Various techniques are employed to enhance permeability, including controlled porosity during powder compaction, specific sintering parameters, and post-sintering treatments. The permeability of the bearing material directly influences its ability to retain lubricants and release them during operation. Optimized permeability ensures proper lubrication distribution throughout the bearing structure, reducing friction and extending operational life.Expand Specific Solutions03 Composition optimization for extended bearing life

The composition of copper-graphite bearings significantly impacts their service life. Optimal ratios of copper to graphite, along with the addition of other elements such as tin, lead, or zinc, can enhance wear resistance and reduce friction. The graphite content typically ranges from 5% to 30% depending on the application requirements. Some compositions also incorporate solid lubricants or special additives to improve self-lubricating properties under extreme conditions. These optimized compositions result in bearings with extended operational life and improved performance under varying loads and speeds.Expand Specific Solutions04 Manufacturing processes affecting bearing properties

The manufacturing process significantly influences the final properties of copper-graphite bearings. Key process parameters include powder mixing techniques, compaction pressure, sintering temperature profiles, and cooling rates. Advanced manufacturing methods such as hot isostatic pressing, spark plasma sintering, or additive manufacturing can produce bearings with enhanced density and uniform microstructure. Post-processing treatments like sizing, machining, and surface finishing also play crucial roles in determining the bearing's dimensional accuracy and surface quality, which directly affect performance and service life.Expand Specific Solutions05 Testing and performance evaluation methods

Various testing and evaluation methods are employed to assess the performance and predict the service life of copper-graphite bearings. These include accelerated wear testing, friction coefficient measurement, oil retention capacity tests, and thermal stability analysis. Advanced techniques such as scanning electron microscopy and energy-dispersive X-ray spectroscopy are used to analyze the microstructure and composition distribution. Performance evaluation under different operating conditions, including varying loads, speeds, and temperatures, helps in predicting the bearing's behavior in actual applications and optimizing design parameters for specific use cases.Expand Specific Solutions

Leading Manufacturers in Copper-Graphite Bearing Industry

The powder metallurgy copper-graphite bearing market is currently in a growth phase, with increasing demand driven by industrial automation and automotive applications requiring self-lubricating components. The global market size for these specialized bearings is estimated at approximately $1.2 billion, with projected annual growth of 5-7%. Technologically, the field is moderately mature but continues to evolve, particularly in impregnation techniques and permeability enhancement. Leading players include NTN Corp. and Diamet Corp., which have established strong positions through advanced oil-impregnation technologies, while Porite Corp. and Haian Eagle Ball Powder Metallurgy focus on specialized copper-graphite composites. Luoyang Bearing Research Institution and US Synthetic Corp. are advancing research in bearing longevity and performance under extreme conditions, pushing the technological boundaries of this established but still-developing field.

NTN Corp.

Technical Solution: NTN Corporation has pioneered a multi-phase impregnation technology for copper-graphite bearings that significantly enhances permeability and operational lifespan. Their process utilizes a proprietary copper matrix with controlled porosity (typically 15-25% by volume) and strategically distributed graphite particles (10-20% concentration). The manufacturing process involves high-pressure compaction (400-600 MPa) followed by sintering in a carefully controlled atmosphere to prevent oxidation. NTN's bearings undergo a vacuum impregnation process at 150-200°C where specialized oil mixtures containing EP (extreme pressure) additives penetrate the porous structure, achieving impregnation depths of up to 98% of the bearing thickness. Their latest innovation includes gradient porosity design where the bearing surface has smaller pores (5-10μm) for wear resistance while the interior maintains larger interconnected pores (15-30μm) for lubricant storage, resulting in documented lifespan improvements of 30-40% compared to conventional designs.

Strengths: Excellent load-bearing capacity (up to 140 MPa); superior wear resistance in high-speed applications; proven performance in extreme temperature fluctuations. Weaknesses: Higher initial cost compared to standard bearings; requires precise control of manufacturing parameters; limited chemical resistance to certain industrial fluids.

Haian Eagle Ball Powder Metallurgy Co., Ltd

Technical Solution: Haian Eagle Ball has developed a specialized copper-graphite bearing manufacturing process that focuses on optimizing the microstructural characteristics for enhanced permeability and service life. Their technology employs a unique powder blending method where atomized copper powder (average particle size 45-75μm) is mechanically alloyed with high-purity graphite flakes (10-30μm) in controlled ratios. The company utilizes a proprietary sintering profile with temperature gradients ranging from 750-950°C and precisely controlled cooling rates to create an interconnected pore network with optimal tortuosity factors below 1.8. Their impregnation process employs a combination of vacuum (below 10 Pa) and pressure (up to 15 MPa) cycles to achieve oil penetration exceeding 92% of theoretical capacity. Haian's bearings feature engineered porosity with bimodal distribution - micropores (2-8μm) for capillary action and macropores (15-25μm) for lubricant storage, resulting in documented service life extensions of 25-35% compared to conventional bearings.

Strengths: Cost-effective manufacturing process; excellent dimensional stability under fluctuating loads; superior oil retention properties in vibration-prone applications. Weaknesses: Lower load capacity compared to premium competitors; limited high-temperature performance; requires more frequent maintenance in extreme operating conditions.

Critical Patents in Copper-Graphite Bearing Technology

Carbon-copper composite and a process for preparation thereof

PatentInactiveIN1567DEL2014A

Innovation

- A process involving the coating of copper powder with coal tar pitch followed by heat treatment and mixing with self-sintering green coke powder, then carbonization at 1000°C, enhances interfacial bonding and mechanical strength while reducing electrical conductivity, resulting in composites with high density and bending strength.

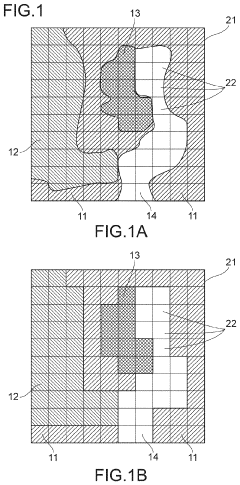

Iron-copper-based oil-impregnated sintered bearing and method for manufacturing same

PatentActiveUS20190345980A1

Innovation

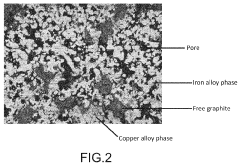

- The bearing composition includes 10-55% Cu, 0.5-7% Sn, 0-4% Zn, 0-0.6% P, and 0.5-4.5% C, with a free graphite area ratio of 5-35% and a copper phase area ratio of at least 30% in the metal matrix, sintered at 820-940°C to control hardness and prevent aggressive reaction, enhancing wear resistance and cost performance.

Tribological Performance Assessment Methodologies

The assessment of tribological performance for powder metallurgy copper-graphite bearings requires systematic methodologies to evaluate their friction, wear, and lubrication characteristics under various operating conditions. These methodologies are essential for predicting bearing life and optimizing their performance in practical applications.

Standard tribological testing for copper-graphite bearings typically involves pin-on-disc, block-on-ring, and thrust washer tests. These configurations simulate different loading conditions and sliding interfaces that bearings encounter in service. For copper-graphite bearings specifically, testing protocols must account for the unique properties resulting from the impregnation process and graphite content distribution.

Permeability testing represents a critical assessment methodology for impregnated copper-graphite bearings. This involves measuring the rate at which lubricant penetrates through the porous structure, typically using standardized methods such as the Gurley permeability test or mercury intrusion porosimetry. The permeability coefficient directly correlates with the bearing's ability to maintain a lubricant film during operation.

Microstructural analysis complements performance testing by examining the bearing's physical characteristics. Techniques including scanning electron microscopy (SEM) and energy-dispersive X-ray spectroscopy (EDX) allow for evaluation of graphite distribution, pore connectivity, and impregnant penetration depth. These factors significantly influence tribological behavior and bearing longevity.

Life prediction methodologies for copper-graphite bearings incorporate accelerated aging tests under elevated temperatures and loads. The PV (pressure × velocity) limit testing is particularly important, as it determines the maximum operating conditions before thermal failure occurs. Modern approaches increasingly utilize computational models that integrate wear rate data with operating parameters to predict service life more accurately.

Real-time monitoring techniques have emerged as valuable assessment tools, employing acoustic emission sensors and vibration analysis to detect early signs of bearing degradation. These methods provide insights into the progressive wear mechanisms and can identify the transition from normal to boundary lubrication conditions, which is critical for impregnated bearings.

Industry standards such as ASTM B438 and ISO 4379 provide standardized frameworks for evaluating copper-graphite bearing performance. These standards ensure consistency in testing procedures and enable meaningful comparisons between different bearing compositions and manufacturing processes. Compliance with these standards is essential for quality assurance and product specification.

Standard tribological testing for copper-graphite bearings typically involves pin-on-disc, block-on-ring, and thrust washer tests. These configurations simulate different loading conditions and sliding interfaces that bearings encounter in service. For copper-graphite bearings specifically, testing protocols must account for the unique properties resulting from the impregnation process and graphite content distribution.

Permeability testing represents a critical assessment methodology for impregnated copper-graphite bearings. This involves measuring the rate at which lubricant penetrates through the porous structure, typically using standardized methods such as the Gurley permeability test or mercury intrusion porosimetry. The permeability coefficient directly correlates with the bearing's ability to maintain a lubricant film during operation.

Microstructural analysis complements performance testing by examining the bearing's physical characteristics. Techniques including scanning electron microscopy (SEM) and energy-dispersive X-ray spectroscopy (EDX) allow for evaluation of graphite distribution, pore connectivity, and impregnant penetration depth. These factors significantly influence tribological behavior and bearing longevity.

Life prediction methodologies for copper-graphite bearings incorporate accelerated aging tests under elevated temperatures and loads. The PV (pressure × velocity) limit testing is particularly important, as it determines the maximum operating conditions before thermal failure occurs. Modern approaches increasingly utilize computational models that integrate wear rate data with operating parameters to predict service life more accurately.

Real-time monitoring techniques have emerged as valuable assessment tools, employing acoustic emission sensors and vibration analysis to detect early signs of bearing degradation. These methods provide insights into the progressive wear mechanisms and can identify the transition from normal to boundary lubrication conditions, which is critical for impregnated bearings.

Industry standards such as ASTM B438 and ISO 4379 provide standardized frameworks for evaluating copper-graphite bearing performance. These standards ensure consistency in testing procedures and enable meaningful comparisons between different bearing compositions and manufacturing processes. Compliance with these standards is essential for quality assurance and product specification.

Environmental Impact and Sustainability Considerations

The production and lifecycle of powder metallurgy copper-graphite bearings present significant environmental and sustainability considerations that warrant careful examination. The manufacturing process involves energy-intensive steps including powder production, compaction, sintering, and impregnation, all of which contribute to considerable carbon emissions and resource consumption. Traditional manufacturing methods typically require high temperatures exceeding 800°C during sintering, resulting in substantial energy usage and associated greenhouse gas emissions.

Material extraction represents another critical environmental concern. Copper mining generates significant ecological disruption through habitat destruction, soil erosion, and potential water contamination from acid mine drainage. Additionally, the extraction of graphite, particularly natural graphite, involves extensive land disturbance and potential release of particulate matter that can affect air quality in surrounding communities.

The impregnation process for these bearings often utilizes petroleum-based oils or synthetic lubricants, many of which contain environmentally persistent compounds. When these bearings reach end-of-life, these impregnated substances may leach into soil or water systems if not properly managed, creating potential ecological hazards and contamination issues.

Recent advancements in sustainable manufacturing approaches offer promising alternatives. Bio-based impregnation oils derived from renewable resources can reduce dependence on petroleum products while maintaining comparable performance characteristics. Additionally, closed-loop manufacturing systems that capture and reuse process materials are increasingly being implemented to minimize waste generation and resource consumption.

The recyclability of copper-graphite bearings presents both opportunities and challenges. While copper possesses excellent recyclability with minimal quality degradation through multiple cycles, the composite nature of these bearings complicates recovery processes. The presence of impregnation oils and the intimate mixing of copper and graphite necessitate specialized separation techniques to achieve effective material recovery.

Life cycle assessment studies indicate that extending bearing service life through improved design and material selection offers significant sustainability benefits. Bearings with enhanced permeability characteristics and optimized graphite distribution demonstrate superior lubrication retention, potentially doubling operational lifespans and thereby reducing replacement frequency and associated environmental impacts.

Regulatory frameworks increasingly emphasize producer responsibility for product lifecycle management, including end-of-life considerations. Manufacturers are now developing take-back programs and exploring design-for-disassembly approaches that facilitate more effective material recovery and reduce landfill disposal of these components.

Material extraction represents another critical environmental concern. Copper mining generates significant ecological disruption through habitat destruction, soil erosion, and potential water contamination from acid mine drainage. Additionally, the extraction of graphite, particularly natural graphite, involves extensive land disturbance and potential release of particulate matter that can affect air quality in surrounding communities.

The impregnation process for these bearings often utilizes petroleum-based oils or synthetic lubricants, many of which contain environmentally persistent compounds. When these bearings reach end-of-life, these impregnated substances may leach into soil or water systems if not properly managed, creating potential ecological hazards and contamination issues.

Recent advancements in sustainable manufacturing approaches offer promising alternatives. Bio-based impregnation oils derived from renewable resources can reduce dependence on petroleum products while maintaining comparable performance characteristics. Additionally, closed-loop manufacturing systems that capture and reuse process materials are increasingly being implemented to minimize waste generation and resource consumption.

The recyclability of copper-graphite bearings presents both opportunities and challenges. While copper possesses excellent recyclability with minimal quality degradation through multiple cycles, the composite nature of these bearings complicates recovery processes. The presence of impregnation oils and the intimate mixing of copper and graphite necessitate specialized separation techniques to achieve effective material recovery.

Life cycle assessment studies indicate that extending bearing service life through improved design and material selection offers significant sustainability benefits. Bearings with enhanced permeability characteristics and optimized graphite distribution demonstrate superior lubrication retention, potentially doubling operational lifespans and thereby reducing replacement frequency and associated environmental impacts.

Regulatory frameworks increasingly emphasize producer responsibility for product lifecycle management, including end-of-life considerations. Manufacturers are now developing take-back programs and exploring design-for-disassembly approaches that facilitate more effective material recovery and reduce landfill disposal of these components.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!